Continuous mining on:

[Wikipedia]

[Google]

[Amazon]

Room and pillar or pillar and stall is a variant of breast

Room and pillar mines are developed on a grid basis except where geological features such as faults require the regular pattern to be modified. The size of the pillars is determined by calculation. The load-bearing capacity of the material above and below the material being mined and the capacity of the mined material determines the pillar size.

Random mine layout makes ventilation planning difficult, and if the pillars are too small, there is the risk of pillar failure. In coal mines, pillar failures are known as squeezes because the roof squeezes down, crushing the pillars. Once one pillar fails, the weight on the adjacent pillars increases, and the result is a chain reaction of pillar failures. Once started, such chain reactions can be extremely difficult to stop, even if they spread slowly. To prevent this from happening, the mine is divided up into areas or panels. Pillars known as barrier pillars separate the panels. The barrier pillars are significantly larger than the "panel" pillars and are sized to allow them to support a significant part of the panel and prevent progressive collapse of the mine in the event of failure of the panel pillars.

Room and pillar mines are developed on a grid basis except where geological features such as faults require the regular pattern to be modified. The size of the pillars is determined by calculation. The load-bearing capacity of the material above and below the material being mined and the capacity of the mined material determines the pillar size.

Random mine layout makes ventilation planning difficult, and if the pillars are too small, there is the risk of pillar failure. In coal mines, pillar failures are known as squeezes because the roof squeezes down, crushing the pillars. Once one pillar fails, the weight on the adjacent pillars increases, and the result is a chain reaction of pillar failures. Once started, such chain reactions can be extremely difficult to stop, even if they spread slowly. To prevent this from happening, the mine is divided up into areas or panels. Pillars known as barrier pillars separate the panels. The barrier pillars are significantly larger than the "panel" pillars and are sized to allow them to support a significant part of the panel and prevent progressive collapse of the mine in the event of failure of the panel pillars.

Room and pillar mining is one of the oldest mining methods. Early room and pillar mines were developed more or less at random, with pillar sizes determined empirically and headings driven in whichever direction was convenient.

Room and pillar mining was in use throughout Europe as early as the 13th century, and the United States since the late 18th century. It is still in use throughout the US, but has slowed or stopped entirely in parts of Europe.

Coal mining in the United States has nearly always operated with a room and pillar layout, although originally operated with significantly more manpower.

Room and pillar mining of gypsum was used in Iowa beginning in 1892, and was phased out of use in 1927 due to low recovery and development of technologies that made

Room and pillar mining is one of the oldest mining methods. Early room and pillar mines were developed more or less at random, with pillar sizes determined empirically and headings driven in whichever direction was convenient.

Room and pillar mining was in use throughout Europe as early as the 13th century, and the United States since the late 18th century. It is still in use throughout the US, but has slowed or stopped entirely in parts of Europe.

Coal mining in the United States has nearly always operated with a room and pillar layout, although originally operated with significantly more manpower.

Room and pillar mining of gypsum was used in Iowa beginning in 1892, and was phased out of use in 1927 due to low recovery and development of technologies that made

stoping

Stoping is the process of extracting the desired ore or other mineral from an underground mine, leaving behind an open space known as a stope. Stoping is used when the country rock is sufficiently strong not to collapse into the stope, althou ...

. It is a mining

Mining is the Resource extraction, extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agriculture, agricultural processes, or feasib ...

system in which the mined material is extracted across a horizontal plane, creating horizontal arrays of rooms and pillars. To do this, "rooms" of ore

Ore is natural rock or sediment that contains one or more valuable minerals, typically including metals, concentrated above background levels, and that is economically viable to mine and process. The grade of ore refers to the concentration ...

are dug out while "pillars" of untouched material are left to support the roof – overburden

In mining, overburden (also called waste or spoil) is the material that lies above an area that lends itself to economical exploitation, such as the rock, soil, and ecosystem that lies above a coal seam or ore body. Overburden is distinct from tai ...

. Calculating the size, shape, and position of pillars is a complicated procedure, and an area of active research. The technique is usually used for relatively flat-lying deposits, such as those that follow a particular stratum

In geology and related fields, a stratum (: strata) is a layer of rock or sediment characterized by certain lithologic properties or attributes that distinguish it from adjacent layers from which it is separated by visible surfaces known as ...

. Room and pillar mining can be advantageous because it reduces the risk of surface subsidence

Subsidence is a general term for downward vertical movement of the Earth's surface, which can be caused by both natural processes and human activities. Subsidence involves little or no horizontal movement, which distinguishes it from slope mov ...

compared to other underground mining techniques. It is also advantageous because it can be mechanized, and is relatively simple. However, because significant portions of ore may have to be left behind, recovery and profits can be low. Room and pillar mining was one of the earliest methods used, although with significantly more manpower.

The room and pillar system is used in mining coal

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other Chemical element, elements, chiefly hydrogen, sulfur, oxygen, and nitrogen.

Coal i ...

, gypsum

Gypsum is a soft sulfate mineral composed of calcium sulfate Hydrate, dihydrate, with the chemical formula . It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk ...

, iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

, limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

, and uranium

Uranium is a chemical element; it has chemical symbol, symbol U and atomic number 92. It is a silvery-grey metal in the actinide series of the periodic table. A uranium atom has 92 protons and 92 electrons, of which 6 are valence electrons. Ura ...

Paul, Michael, et al. "Mine flooding and water management at underground uranium mines two decades after decommissioning." ''Proc. IMWA Conference''. 2013. ores, particularly when found as manto or blanket deposits, stone

In geology, rock (or stone) is any naturally occurring solid mass or aggregate of minerals or mineraloid matter. It is categorized by the minerals included, its Chemical compound, chemical composition, and the way in which it is formed. Rocks ...

and aggregates, talc

Talc, or talcum, is a clay mineral composed of hydrated magnesium silicate, with the chemical formula . Talc in powdered form, often combined with corn starch, is used as baby powder. This mineral is used as a thickening agent and lubricant ...

, soda ash

Sodium carbonate (also known as washing soda, soda ash, sal soda, and soda crystals) is the inorganic compound with the formula and its various hydrates. All forms are white, odourless, water-soluble salts that yield alkaline solutions in water ...

, and potash

Potash ( ) includes various mined and manufactured salts that contain potassium in water- soluble form.

. It has been used worldwide from the Czech Republic to Canada, to China to the US.

Process

Stage 1—exploration and development

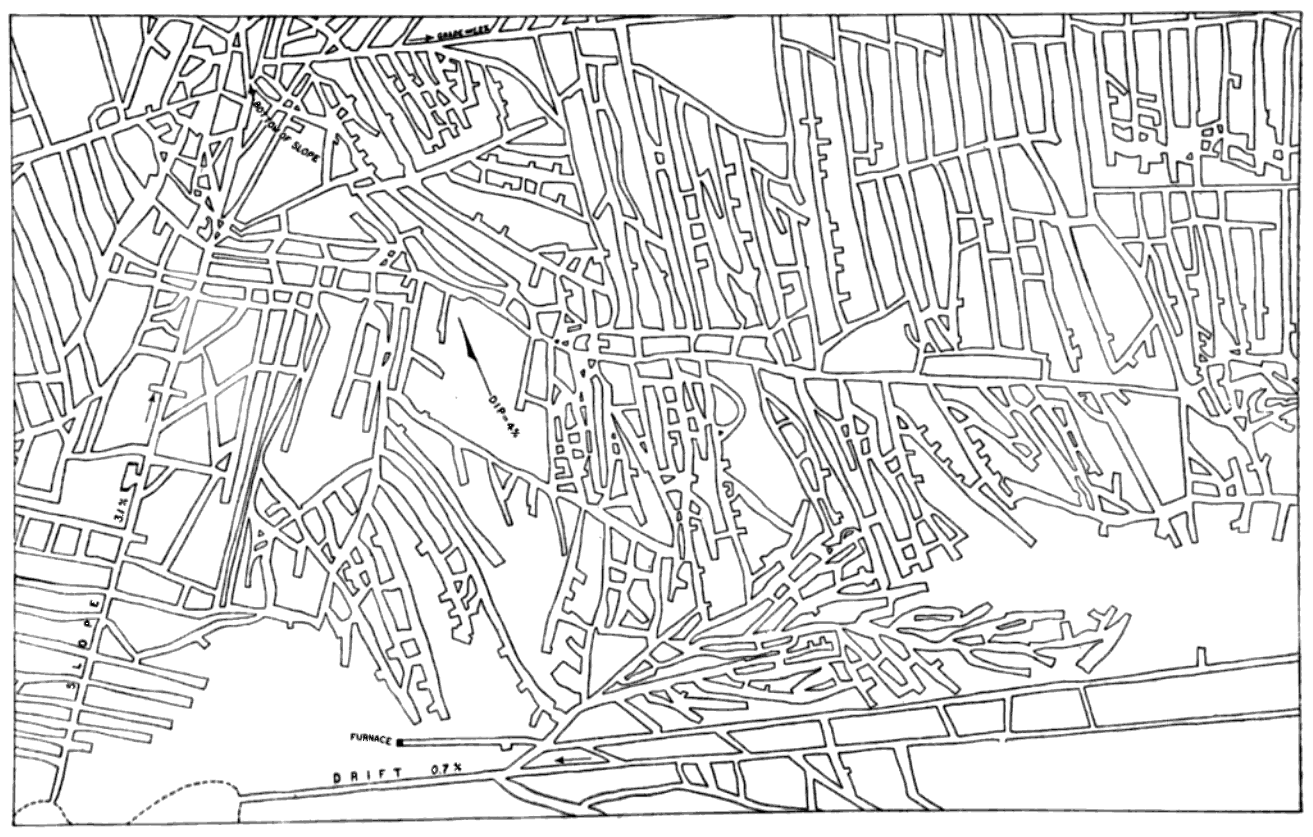

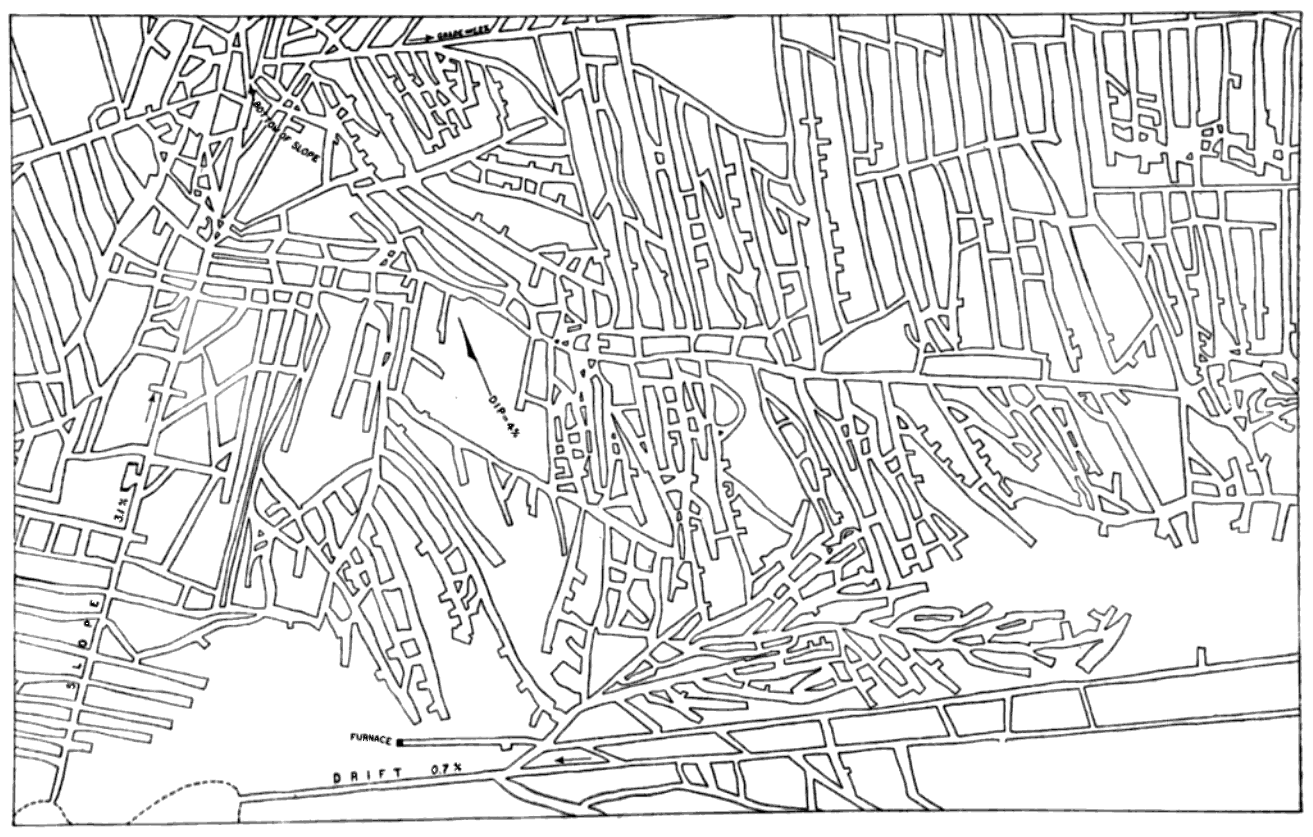

Planning for the development of room and pillar mines operates in much the same way as other mining methods, and begins with establishing ownership of the mine. Following this, the geology of the mine must be analysed, as this will determine factors like the lifespan of the mine, the production requirements, and the cost to develop and maintain. Next, mine layout should be determined, as factors like ventilation, electrical power, and haulage of the ore must be considered in cost analysis. Due to the non-homogeneous nature of mineral deposits typically mined by room and pillar, mine layout must be mapped very carefully. It is desirable to keep the size and shape of rooms and pillars consistent, but some mines strayed from this formula due to lack of planning and deposit characteristics. Mine layout includes the size of rooms and pillars in the mines, but also includes factors like the number and type of entries, roof height, ventilation, and cut sequence.Mine layout

Room and pillar mines are developed on a grid basis except where geological features such as faults require the regular pattern to be modified. The size of the pillars is determined by calculation. The load-bearing capacity of the material above and below the material being mined and the capacity of the mined material determines the pillar size.

Random mine layout makes ventilation planning difficult, and if the pillars are too small, there is the risk of pillar failure. In coal mines, pillar failures are known as squeezes because the roof squeezes down, crushing the pillars. Once one pillar fails, the weight on the adjacent pillars increases, and the result is a chain reaction of pillar failures. Once started, such chain reactions can be extremely difficult to stop, even if they spread slowly. To prevent this from happening, the mine is divided up into areas or panels. Pillars known as barrier pillars separate the panels. The barrier pillars are significantly larger than the "panel" pillars and are sized to allow them to support a significant part of the panel and prevent progressive collapse of the mine in the event of failure of the panel pillars.

Room and pillar mines are developed on a grid basis except where geological features such as faults require the regular pattern to be modified. The size of the pillars is determined by calculation. The load-bearing capacity of the material above and below the material being mined and the capacity of the mined material determines the pillar size.

Random mine layout makes ventilation planning difficult, and if the pillars are too small, there is the risk of pillar failure. In coal mines, pillar failures are known as squeezes because the roof squeezes down, crushing the pillars. Once one pillar fails, the weight on the adjacent pillars increases, and the result is a chain reaction of pillar failures. Once started, such chain reactions can be extremely difficult to stop, even if they spread slowly. To prevent this from happening, the mine is divided up into areas or panels. Pillars known as barrier pillars separate the panels. The barrier pillars are significantly larger than the "panel" pillars and are sized to allow them to support a significant part of the panel and prevent progressive collapse of the mine in the event of failure of the panel pillars.

Stage 2—mining

Traditionally, the act of mining consists of three steps. First, the deposit is "undercut", where a slot is cut as deep as possible along the bottom of a section of ore. This undercut allows for a manageable pile of rock in later stages. The second step is the drilling and blasting of the section. This creates a pile of ore that is loaded and hauled out of the mine—the final step of the mining process. More modern room and pillar mines use a more "continuous" method, that uses machinery to simultaneously grind off rock and move it to the surface. Other processes, such asbackfill

This page is a glossary of archaeology, the study of the human past from material remains.

A

B

C

D

E

F

...

, where discarded tailings

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material ...

are unloaded into mined-out areas, can be used, but are not required. Retreat mining (below) is an example of a process like this.

Retreat mining

Retreat mining

Retreat mining is the removal of pillars in the underground mining

Mining is the Resource extraction, extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that ca ...

is often the final stage of room and pillar mining. Once a deposit has been exhausted using this method, the pillars that were left behind initially are removed, or "pulled", retreating back towards the mine's entrance. After the pillars are removed, the roof (or back) is allowed to collapse behind the mining area. Pillar removal must occur in a very precise order to reduce the risks to workers, owing to the high stresses placed on the remaining pillars by the abutment stresses of the caving ground.

Retreat mining is a particularly dangerous form of mining. According to the Mine Safety and Health Administration

The Mine Safety and Health Administration (MSHA) () is a small agency of the United States Department of Labor which administers the provisions of the Federal Mine Safety and Health Act of 1977 (Mine Act) to enforce compliance with mandatory sa ...

(MSHA), pillar recovery mining has been historically responsible for 25% of American coal mining deaths caused by failures of the roof or walls, even though it represents only 10% of the coal mining industry. Retreat mining cannot be used in areas where subsidence is not acceptable, reducing profitability.

Sometimes retreat mining is not used and the underground space is repurposed as climate controlled storage or office space instead.

Stage 3—maintenance and remediation

Many room and pillar mines have been abandoned for as long as 100 years. This drastically increases the risk of subsidence unless properly maintained, however, maintenance does not often occur.History

Room and pillar mining is one of the oldest mining methods. Early room and pillar mines were developed more or less at random, with pillar sizes determined empirically and headings driven in whichever direction was convenient.

Room and pillar mining was in use throughout Europe as early as the 13th century, and the United States since the late 18th century. It is still in use throughout the US, but has slowed or stopped entirely in parts of Europe.

Coal mining in the United States has nearly always operated with a room and pillar layout, although originally operated with significantly more manpower.

Room and pillar mining of gypsum was used in Iowa beginning in 1892, and was phased out of use in 1927 due to low recovery and development of technologies that made

Room and pillar mining is one of the oldest mining methods. Early room and pillar mines were developed more or less at random, with pillar sizes determined empirically and headings driven in whichever direction was convenient.

Room and pillar mining was in use throughout Europe as early as the 13th century, and the United States since the late 18th century. It is still in use throughout the US, but has slowed or stopped entirely in parts of Europe.

Coal mining in the United States has nearly always operated with a room and pillar layout, although originally operated with significantly more manpower.

Room and pillar mining of gypsum was used in Iowa beginning in 1892, and was phased out of use in 1927 due to low recovery and development of technologies that made surface mining

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit (the overburden) are removed, in contrast to underground mining, in whic ...

more practical, safe, and cost effective. More recently, the United States Gypsum

USG Corporation, also known as United States Gypsum Corporation, is an American company which manufactures construction materials, most notably drywall and joint compound. The company is the largest distributor of wallboard in the United State ...

Sperry mine, near Mediapolis, Iowa, opened in 1961. This room-and-pillar mine, below the surface, has square pillars on a side separating rooms of the same width in a gypsum bed about thick.

Many salt mines use room and pillar layouts. The Sifto salt mine in Goderich, Ontario

Goderich ( or ) is a town in the Canadian province of Ontario and is the county seat of Huron County. The town was founded by John Galt and William "Tiger" Dunlop of the Canada Company in 1827. First laid out in 1828, the town is named after ...

, the largest in the world, was opened in 1959. It taps a salt bed thick below the surface, mostly under Lake Huron

Lake Huron ( ) is one of the five Great Lakes of North America. It is shared on the north and east by the Canadian province of Ontario and on the south and west by the U.S. state of Michigan. The name of the lake is derived from early French ex ...

. The Cargill salt mine below the surface, mostly under Lake Erie

Lake Erie ( ) is the fourth-largest lake by surface area of the five Great Lakes in North America and the eleventh-largest globally. It is the southernmost, shallowest, and smallest by volume of the Great Lakes and also has the shortest avera ...

at Cleveland, Ohio

Cleveland is a city in the U.S. state of Ohio and the county seat of Cuyahoga County, Ohio, Cuyahoga County. Located along the southern shore of Lake Erie, it is situated across the Canada–United States border, Canada–U.S. maritime border ...

is similar.

Modern use

Modern room and pillar mines can be few and far between. This is due to many factors, including the dangers to miners associated with subsidence, increasing use of other methods with more mechanization, and the decreasing cost of surface mining.Advantages

Room and pillar mining is not particularly dependent on the depth of the deposit. At particularly deep depths, room and pillar mining can be more cost effective compared to strip mining due to the fact that significantly lessoverburden

In mining, overburden (also called waste or spoil) is the material that lies above an area that lends itself to economical exploitation, such as the rock, soil, and ecosystem that lies above a coal seam or ore body. Overburden is distinct from tai ...

needs to be removed. This means that today, room and pillar mining is mostly used for high grade, but small, deep deposits.

Disadvantages

Due to a recovery rate as low as 40% in some cases, room and pillar mining cannot compete in terms of profitability with many modern, more mechanized types of mining such as longwall orsurface mining

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit (the overburden) are removed, in contrast to underground mining, in whic ...

.

Abandoned mines have a tendency to collapse. In remote areas, collapses can be dangerous to wildlife, but subsidence of abandoned mines can be hazardous to infrastructure above and nearby. Significant amount of coal is left on the pillars as roof support.

See also

*Longwall mining

Longwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically thick). The section of rock that is being mined, known as the longwall panel, is typically long, but can be up to long and wi ...

*Coal mining in the United States

Coal mining is an industry in transition in the United States. Production in 2019 was down 40% from the peak production of in 2008. Employment of 43,000 coal miners is down from a peak of 883,000 in 1923. Generation of electricity is the l ...

*Surface mining

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit (the overburden) are removed, in contrast to underground mining, in whic ...

References

Note {{DEFAULTSORT:Room And Pillar Underground mining