Cobalt-chrome on:

[Wikipedia]

[Google]

[Amazon]

Cobalt-chrome or cobalt-chromium (CoCr) is a

Cobalt-chrome or cobalt-chromium (CoCr) is a

Co-Cr alloy

Co-Cr alloy

Cobalt-chrome or cobalt-chromium (CoCr) is a

Cobalt-chrome or cobalt-chromium (CoCr) is a metal

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, electricity and thermal conductivity, heat relatively well. These properties are all associated wit ...

alloy

An alloy is a mixture of chemical elements of which in most cases at least one is a metal, metallic element, although it is also sometimes used for mixtures of elements; herein only metallic alloys are described. Metallic alloys often have prop ...

of cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. ...

and chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal.

Chromium ...

. Cobalt-chrome has a very high specific strength

The specific strength is a material's (or muscle's) strength (force per unit area at failure) divided by its density. It is also known as the strength-to-weight ratio or strength/weight ratio or strength-to-mass ratio. In fiber or textile applic ...

and is commonly used in gas turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas gene ...

s, dental implant

A dental implant (also known as an endosseous implant or fixture) is a prosthesis that interfaces with the bone of the jaw or skull to support a dental prosthesis such as a crown (dentistry), crown, bridge (dentistry), bridge, dentures, denture ...

s, and orthopedic implants.ARCAM ASTM F75 CoCr AlloyHistory

Co-Cr alloy was first discovered by Elwood Haynes in the early 1900s by fusing cobalt and chromium. The alloy was first discovered with many other elements such astungsten

Tungsten (also called wolfram) is a chemical element; it has symbol W and atomic number 74. It is a metal found naturally on Earth almost exclusively in compounds with other elements. It was identified as a distinct element in 1781 and first ...

and molybdenum

Molybdenum is a chemical element; it has Symbol (chemistry), symbol Mo (from Neo-Latin ''molybdaenum'') and atomic number 42. The name derived from Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals hav ...

in it. Haynes reported his alloy was capable of resisting oxidation and corrosive fumes and exhibited no visible sign of tarnish even when subjecting the alloy to boiling nitric acid. Under the name Stellite

Stellite alloys are a range of cobalt-chromium alloys designed for wear resistance. "Stellite" is also a registered trademark of Kennametal Inc. and is used in association with cobalt-chromium alloys.

History

Stellite was invented by Elwood Hay ...

, Co-Cr alloy has been used in various fields where high wear-resistance was needed including aerospace industry

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial, and military applications. Aerospace engineering consists of aeronautics and astr ...

,Ratner, B. D.; Hoffman, A. S.; Schoen, F. J.; Lemons, J. E. ''Biomaterial Science, ''2nd ed.; Academic Press, 1996. cutlery, bearings, and blades.

Co-Cr alloy started receiving more attention as its biomedical application was found. In the 20th century, the alloy was first used in medical tool manufacturing,Hyslop, D. J. S.; Abdelkader, A. M.; Cox, A.; Fray, D. J. Electrochemical Synthesis of a Biomedically Important Co-Cr Alloy. ''Acta Materialia''. 2010, ''58, ''3124-3130. and in 1960, the first Co-Cr prosthetic heart valve was implanted, which happened to last over 30 years showing its high wear-resistance. Recently, due to excellent resistant properties, biocompatibility

Biocompatibility is related to the behavior of biomaterials in various contexts. The term refers to the ability of a material to perform with an appropriate host response in a specific situation. The ambiguity of the term reflects the ongoin ...

, high melting points, and incredible strength at high temperatures, Co-Cr alloy is used for the manufacture of many artificial joints including hips and knees, dental partial bridge work, gas turbines, and many others.

Synthesis

The common Co-Cr alloy production requires the extraction of cobalt andchromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal.

Chromium ...

from cobalt oxide and chromium oxide ores. Both of the ores need to go through reduction process to obtain pure metals. Chromium usually goes through aluminothermic reduction technique, and pure cobalt can be achieved through many different ways depending on the characteristics of the specific ore. Pure metals are then fused together under vacuum either by electric arc

An electric arc (or arc discharge) is an electrical breakdown of a gas that produces a prolonged electrical discharge. The electric current, current through a normally Electrical conductance, nonconductive medium such as air produces a plasma ( ...

or by induction melting. Due to the chemical reactivity of metals at high temperature, the process requires vacuum conditions or inert atmosphere to prevent oxygen uptake by the metal. ASTM F75, a Co-Cr-Mo alloy, is produced in an inert argon atmosphere by ejecting molten metals through a small nozzle that is immediately cooled to produce a fine powder of the alloy.

However, synthesis of Co-Cr alloy through the method mentioned above is very expensive and difficult. Recently, in 2010, scientists at the University of Cambridge have produced the alloy through a novel electrochemical, solid-state reduction technique known as the FFC Cambridge Process which involves the reduction of an oxide precursor cathode in a molten chloride electrolyte.

Properties

Co-Cr alloys show high resistance to corrosion due to the spontaneous formation of a protective passive film composed of mostly Cr2O3, and minor amounts of cobalt and other metal oxides on the surface. CoCr has a melting point around . As its wide application in biomedical industry indicates, Co-Cr alloys are well known for their biocompatibility.Biocompatibility

Biocompatibility is related to the behavior of biomaterials in various contexts. The term refers to the ability of a material to perform with an appropriate host response in a specific situation. The ambiguity of the term reflects the ongoin ...

also depends on the film and how this oxidized surface interacts with physiological environment. Good mechanical properties that are similar to stainless steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromi ...

are a result of a multiphase structure and precipitation of carbides, which increase the hardness of Co-Cr alloys tremendously. The hardness of Co-Cr alloys varies ranging 550-800 MPa, and tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

varies ranging 145-270 MPa. Moreover, tensile and fatigue

Fatigue is a state of tiredness (which is not sleepiness), exhaustion or loss of energy. It is a signs and symptoms, symptom of any of various diseases; it is not a disease in itself.

Fatigue (in the medical sense) is sometimes associated wit ...

strength increases radically as they are heat-treated. However, Co-Cr alloys tend to have low ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

, which can cause component fracture. This is a concern as the alloys are commonly used in hip replacements. In order to overcome the low ductility, nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

, and/or nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

are added. These elements stabilize the γ phase, which has better mechanical properties compared to other phases of Co-Cr alloys.Lee, S.; Nomura, N.; Chiba, A. Significant Improvement in Mechanical Properties of Biomedical Co-Cr-Mo Alloys with Combination of N Addition and Cr-Enrichment. ''Materials Transactions. ''2008, ''2, ''260-264.

Common types

There are several Co-Cr alloys that are commonly produced and used in various fields. ASTM F75, ASTM F799, ASTM F1537 are Co-Cr-Mo alloys with very similar composition yet slightly different production processes, ASTM F90 is a Co-Cr-W-Ni alloy, and ASTM F562 is a Co-Ni-Cr-Mo-Ti alloy.Structure

Depending on the percent composition of cobalt or chromium and the temperature, Co-Cr alloys show different structures. The σ phase, where the alloy contains approximately 60–75% chromium, tends to be brittle and subject to afracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress (mechanics), stress. The fracture of a solid usually occurs due to the development of certain displacemen ...

. FCC crystal structure is found in the γ phase, and the γ phase shows improved strength and ductility compared to the σ phase. FCC crystal structure is commonly found in cobalt rich alloys, while chromium rich alloys tend to have BCC crystal structure. The γ phase Co-Cr alloy can be converted into the ε phase at high pressures, which shows a HCP crystal structure.

Uses

Jewelry making

Medical implants

Co-Cr alloys are most commonly used to make artificial joints including knee and hip joints due to high wear-resistance and biocompatibility. Co-Cr alloys tend to becorrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

resistant, which reduces complication with the surrounding tissues when implanted, and chemically inert that they minimize the possibility of irritation, allergic reaction

Allergies, also known as allergic diseases, are various conditions caused by hypersensitivity of the immune system to typically harmless substances in the environment. These diseases include Allergic rhinitis, hay fever, Food allergy, food al ...

, and immune response

An immune response is a physiological reaction which occurs within an organism in the context of inflammation for the purpose of defending against exogenous factors. These include a wide variety of different toxins, viruses, intra- and extracellula ...

. Co-Cr alloy has also been widely used in the manufacture of stent and other surgical implants as Co-Cr alloy demonstrates excellent biocompatibility with blood and soft tissues as well. The alloy composition used in orthopedic implants is described in industry standard ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

-F75: mainly cobalt, with 27 to 30% chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal.

Chromium ...

, 5 to 7% molybdenum

Molybdenum is a chemical element; it has Symbol (chemistry), symbol Mo (from Neo-Latin ''molybdaenum'') and atomic number 42. The name derived from Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals hav ...

, and upper limits on other important elements such as less than 1% each of manganese

Manganese is a chemical element; it has Symbol (chemistry), symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese was first isolated in the 1770s. It is a transition m ...

and silicon

Silicon is a chemical element; it has symbol Si and atomic number 14. It is a hard, brittle crystalline solid with a blue-grey metallic lustre, and is a tetravalent metalloid (sometimes considered a non-metal) and semiconductor. It is a membe ...

, less than 0.75% iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

, less than 0.5% nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

, and very small amounts of carbon

Carbon () is a chemical element; it has chemical symbol, symbol C and atomic number 6. It is nonmetallic and tetravalence, tetravalent—meaning that its atoms are able to form up to four covalent bonds due to its valence shell exhibiting 4 ...

, nitrogen

Nitrogen is a chemical element; it has Symbol (chemistry), symbol N and atomic number 7. Nitrogen is a Nonmetal (chemistry), nonmetal and the lightest member of pnictogen, group 15 of the periodic table, often called the Pnictogen, pnictogens. ...

, tungsten

Tungsten (also called wolfram) is a chemical element; it has symbol W and atomic number 74. It is a metal found naturally on Earth almost exclusively in compounds with other elements. It was identified as a distinct element in 1781 and first ...

, phosphorus

Phosphorus is a chemical element; it has Chemical symbol, symbol P and atomic number 15. All elemental forms of phosphorus are highly Reactivity (chemistry), reactive and are therefore never found in nature. They can nevertheless be prepared ar ...

, sulfur

Sulfur ( American spelling and the preferred IUPAC name) or sulphur ( Commonwealth spelling) is a chemical element; it has symbol S and atomic number 16. It is abundant, multivalent and nonmetallic. Under normal conditions, sulfur atoms ...

, boron

Boron is a chemical element; it has symbol B and atomic number 5. In its crystalline form it is a brittle, dark, lustrous metalloid; in its amorphous form it is a brown powder. As the lightest element of the boron group it has three ...

, etc.

Besides cobalt-chromium-molybdenum (CoCrMo), cobalt-nickel-chromium-molybdenum (CoNiCrMo) is also used for implants. The possible toxicity of released Ni ions from CoNiCr alloys and also their limited frictional properties are a matter of concern in using these alloys as articulating components. Thus, CoCrMo is usually the dominant alloy for total joint arthroplasty

Arthroplasty (literally " e-orming of joint") is an orthopedic surgical procedure where the articular surface of a musculoskeletal joint is replaced, remodeled, or realigned by osteotomy or some other procedure. It is an elective procedure that ...

.

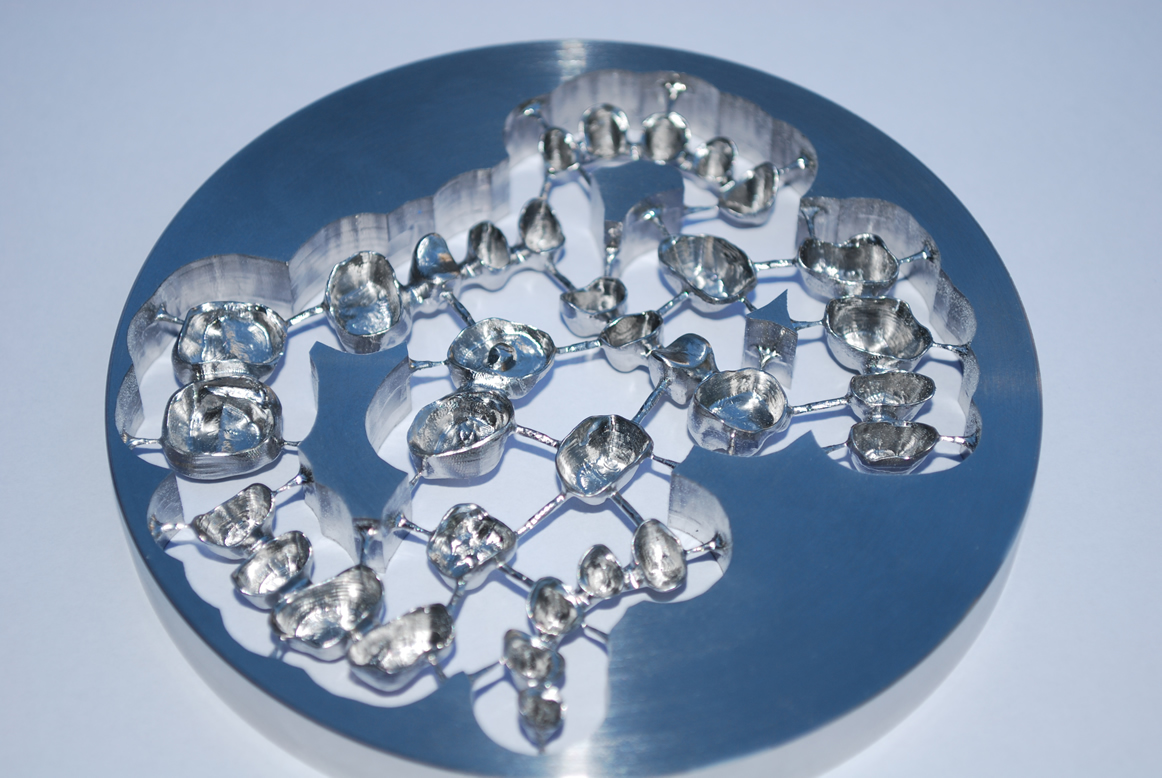

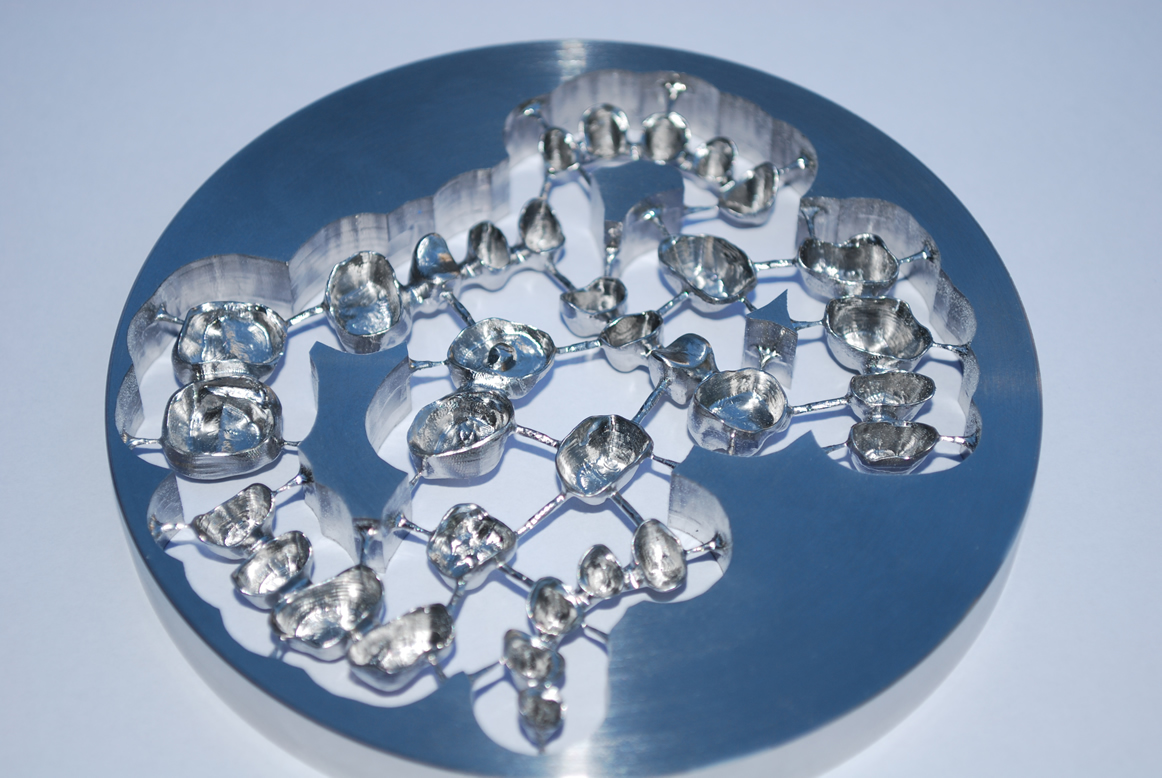

Dental prosthetics

Co-Cr alloy

Co-Cr alloy dentures

Dentures (also known as false teeth) are prosthetic devices constructed to replace missing teeth, supported by the surrounding soft and hard tissues of the oral cavity. Conventional dentures are removable ( removable partial denture or comp ...

and cast partial dentures have been commonly manufactured since 1929 due to lower cost and lower density compared to gold alloys; however, Co-Cr alloys tend to exhibit a higher modulus of elasticity

An elastic modulus (also known as modulus of elasticity (MOE)) is a quantity that describes an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it.

Definition

The elastic modu ...

and cyclic fatigue resistance, which are significant factors for dental prosthesis. The alloy is a commonly used as a metal framework for dental partials. A well known brand for this purpose is Vitallium.

Industry

Due to mechanical properties such as high resistance to corrosion and wear, Co-Cr alloys (e.g.,Stellite

Stellite alloys are a range of cobalt-chromium alloys designed for wear resistance. "Stellite" is also a registered trademark of Kennametal Inc. and is used in association with cobalt-chromium alloys.

History

Stellite was invented by Elwood Hay ...

s) are used in making wind turbines, engine components, and many other industrial/mechanical components where high wear resistance is needed.

Co-Cr alloy is also very commonly used in fashion industry to make jewellery, especially wedding bands.

Hazards

Metals released from Co-Cr alloy tools and prosthetics may cause allergic reactions and skineczema

Dermatitis is a term used for different types of skin inflammation, typically characterized by itchiness, redness and a rash. In cases of short duration, there may be small blisters, while in long-term cases the skin may become thickened ...

.Kettelarij, J. A.; Liden, C.; Axen, E.; Julander, A. Cobalt, Nickel, and Chromium Release

from Dental Tools and Alloys. ''Contact Dermititis. ''2014, ''70, ''3-10. Prosthetics or any medical equipment with high nickel mass percentage Co-Cr alloy should be avoided due to low biocompatibility, as nickel

Nickel is a chemical element; it has symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive, but large pieces are slo ...

is the most common metal sensitizer in the human body.

See also

* Alacrite * HastelloyReferences

{{Reflist, colwidth=35em Biomaterials Chromium alloys Cobalt alloys