Charpy impact test on:

[Wikipedia]

[Google]

[Amazon]

In

materials science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries.

The intellectual origins of materials sci ...

, the Charpy impact test, also known as the Charpy V-notch test, is a standardized

Standardization (American English) or standardisation (British English) is the process of implementing and developing technical standards based on the consensus of different parties that include firms, users, interest groups, standards organiza ...

high strain rate

In mechanics and materials science, strain rate is the time derivative of strain of a material. Strain rate has dimension of inverse time and SI units of inverse second, s−1 (or its multiples).

The strain rate at some point within the mat ...

test which determines the amount of energy

Energy () is the physical quantity, quantitative physical property, property that is transferred to a physical body, body or to a physical system, recognizable in the performance of Work (thermodynamics), work and in the form of heat and l ...

absorbed by a material during fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress (mechanics), stress. The fracture of a solid usually occurs due to the development of certain displacemen ...

. Absorbed energy is a measure of the material's notch toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.

The test was pivotal in understanding the fracture problems of ships during World War II.

The test was developed around 1900 by S. B. Russell (1898, American) and Georges Charpy (1901, French). The test became known as the Charpy test in the early 1900s due to the technical contributions and standardization efforts by Charpy.

The apparatus consists of a

The apparatus consists of a

CalculatorVideo on the Charpy impact test

{{Authority control Fracture mechanics Materials testing

History

In 1896, S. B. Russell introduced the idea of ''residual fracture energy'' and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont introduced a test to measure the same phenomenon using a spring-loaded machine. In 1901, Georges Charpy proposed a standardized method improving Russell's by introducing a redesigned pendulum and notched sample, giving precise specifications.Definition

The apparatus consists of a

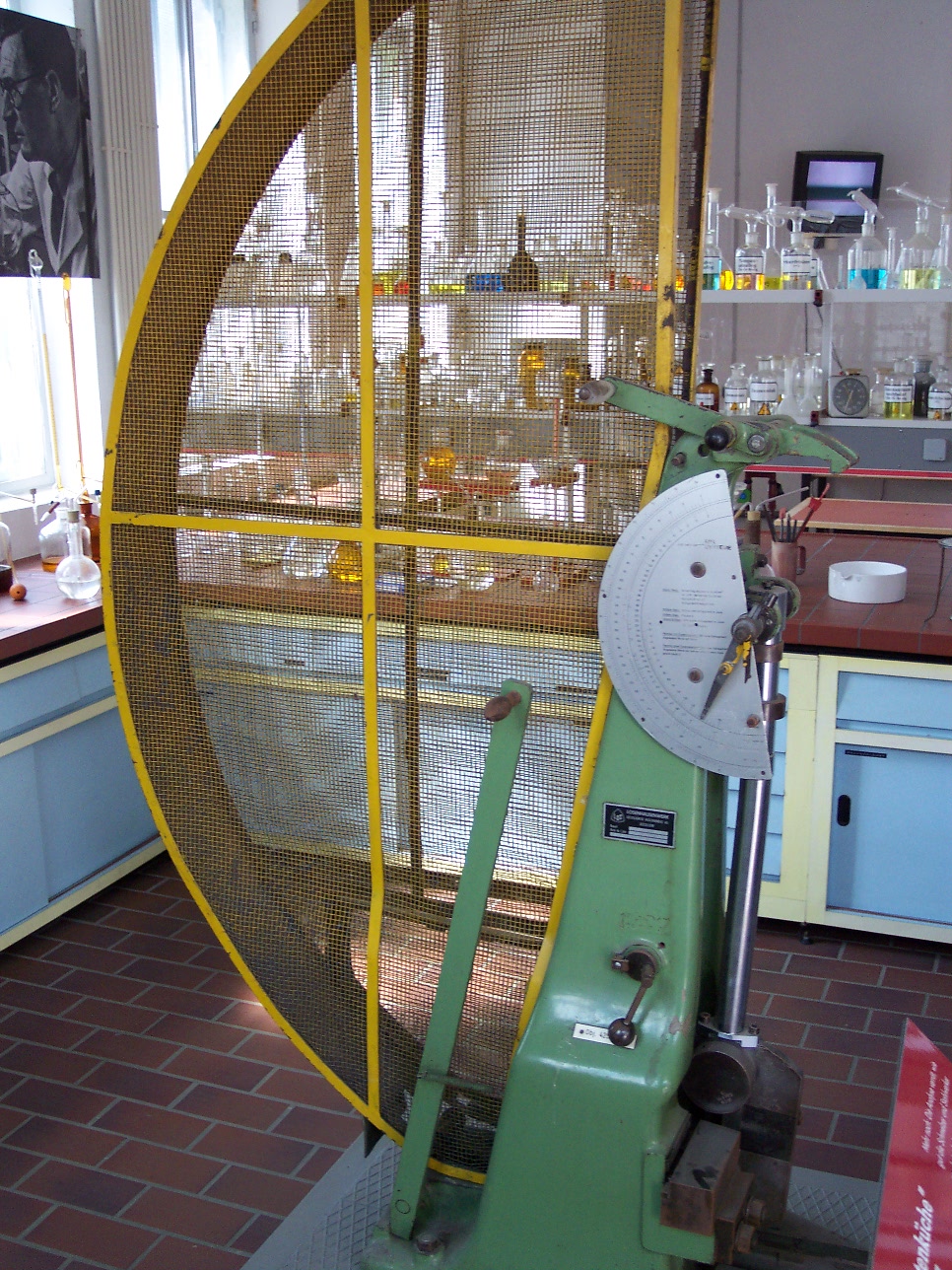

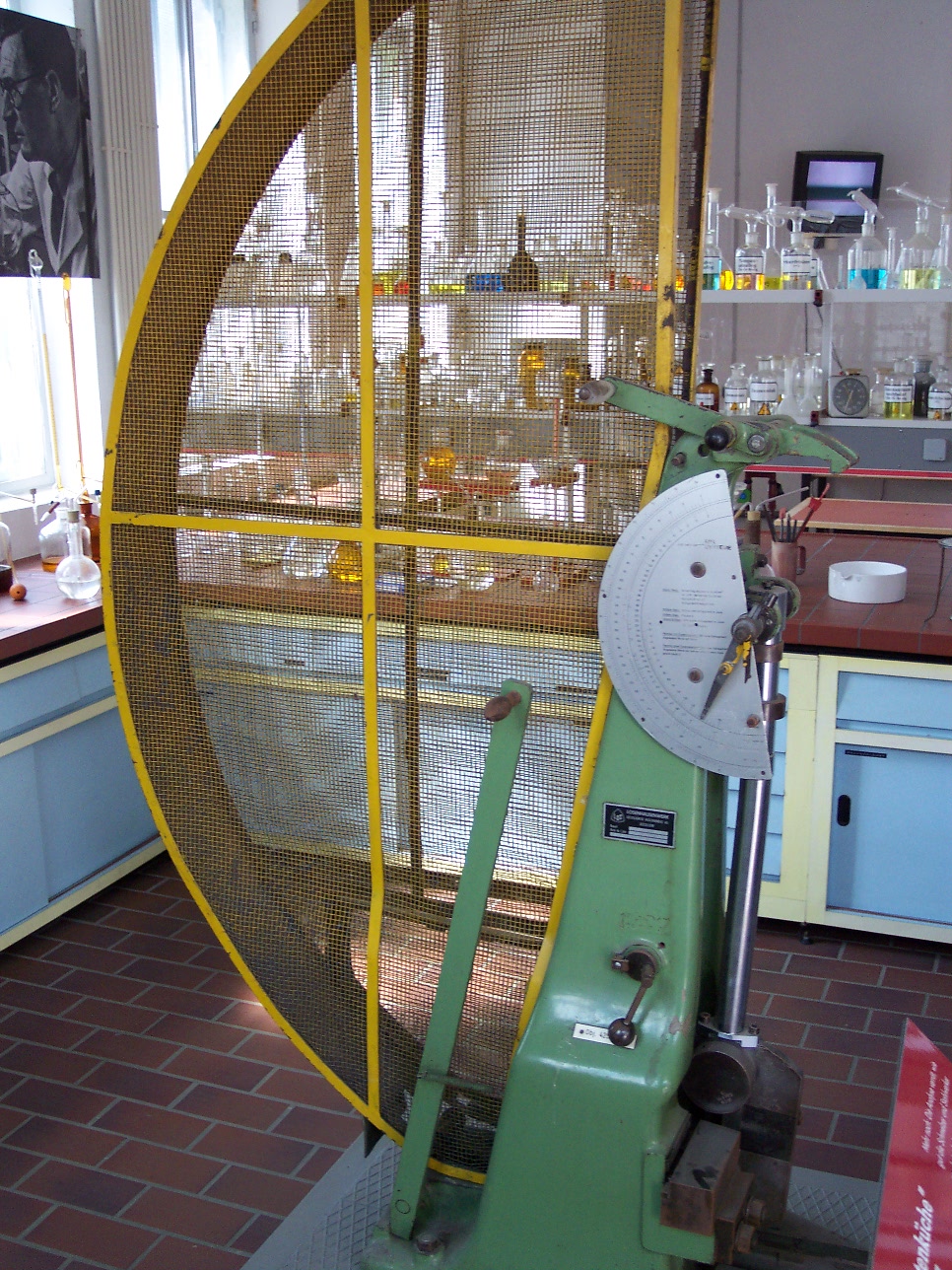

The apparatus consists of a pendulum

A pendulum is a device made of a weight suspended from a pivot so that it can swing freely. When a pendulum is displaced sideways from its resting, equilibrium position, it is subject to a restoring force due to gravity that will accelerate i ...

of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the material can be inferred by comparing the difference in the height of the hammer before and after the fracture (energy absorbed by the fracture event).

The notch in the sample affects the results of the impact test,

thus it is necessary for the notch to be of regular dimensions and geometry. The size of the sample can also affect results, since the dimensions determine whether or not the material is in plane strain

Plane most often refers to:

* Aero- or airplane, a powered, fixed-wing aircraft

* Plane (geometry), a flat, 2-dimensional surface

* Plane (mathematics), generalizations of a geometrical plane

Plane or planes may also refer to:

Biology

* Pl ...

. This difference can greatly affect the conclusions made.

The ''Standard methods for Notched Bar Impact Testing of Metallic Materials'' can be found in ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

E23,ASTM E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials ISO

The International Organization for Standardization (ISO ; ; ) is an independent, non-governmental, international standard development organization composed of representatives from the national standards organizations of member countries.

Me ...

148-1ISO 148-1 Metallic materials - Charpy pendulum impact test - Part 1: Test method or EN 10045-1 (retired and replaced with ISO 148-1),EN 10045-1 Charpy impact test on metallic materials. Test method (V- and U-notches) where all the aspects of the test and equipment used are described in detail.

Quantitative results

The quantitative result of the impact tests the energy needed to fracture a material and can be used to measure the toughness of the material. There is a connection to theyield strength

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and w ...

but it cannot be expressed by a standard formula. Also, the strain rate may be studied and analyzed for its effect on fracture.

The ductile-brittle transition temperature (DBTT) may be derived from the temperature where the energy needed to fracture the material drastically changes. However, in practice there is no sharp transition and it is difficult to obtain a precise transition temperature (it is really a transition region). An exact DBTT may be empirically derived in many ways: a specific absorbed energy, change in aspect of fracture (such as 50% of the area is cleavage), etc.

Qualitative results

The qualitative results of the impact test can be used to determine theductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

of a material.

If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with jagged edges or shear lips, then the fracture was ductile. Usually, a material does not break in just one way or the other and thus comparing the jagged to flat surface areas of the fracture will give an estimate of the percentage of ductile and brittle fracture.

Sample sizes

According toASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and s ...

A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: 10 mm × 7.5 mm × 55 mm, 10 mm × 6.7 mm × 55 mm, 10 mm × 5 mm × 55 mm, 10 mm × 3.3 mm × 55 mm, 10 mm × 2.5 mm × 55 mm. Details of specimens as per ASTM A370 (Standard Test Method and Definitions for Mechanical Testing of Steel Products).

According to EN 10045-1 (retired and replaced with ISO 148), standard specimen sizes are 10 mm × 10 mm × 55 mm. Subsize specimens are: 10 mm × 7.5 mm × 55 mm and 10 mm × 5 mm × 55 mm.

According to ISO 148, standard specimen sizes are 10 mm × 10 mm × 55 mm. Subsize specimens are: 10 mm × 7.5 mm × 55 mm, 10 mm × 5 mm × 55 mm and 10 mm × 2.5 mm × 55 mm.

According to MPIF Standard 40, the standard unnotched specimen size is 10 mm (±0.125 mm) x 10 mm (±0.125 mm) x 55 mm (±2.5 mm).

Impact test results on low- and high-strength materials

The impact energy of low-strength metals that do not show a change of fracture mode with temperature, is usually high and insensitive to temperature. For these reasons, impact tests are not widely used for assessing the fracture-resistance of low-strength materials whose fracture modes remain unchanged with temperature. Impact tests typically show a ductile-brittle transition for high-strength materials that do exhibit change in fracture mode with temperature such asbody-centered cubic

In crystallography, the cubic (or isometric) crystal system is a crystal system where the Crystal structure#Unit cell, unit cell is in the shape of a cube. This is one of the most common and simplest shapes found in crystals and minerals.

There ...

(BCC) transition metals. Impact tests on natural materials (can be considered as low-strength), such as wood, are used to study the material toughness and are subjected to a number of issues that include the interaction between the pendulum and a specimen as well as higher modes of vibration and multiple contacts between pendulum tup and the specimen.

Generally, high-strength materials have low impact energies which attest to the fact that fractures easily initiate and propagate in high-strength materials. The impact energies of high-strength materials other than steels or BCC transition metals are usually insensitive to temperature. High-strength BCC steels display a wider variation of impact energy than high-strength metal that do not have a BCC structure because steels undergo microscopic ductile-brittle transition. Regardless, the maximum impact energy of high-strength steels is still low due to their brittleness.

See also

*Izod impact strength test

The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released. The arm swings down hitting a notched sample ...

* Brittle

A material is brittle if, when subjected to stress, it fractures with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. ...

* Impact force

In mechanics, an impact is when two bodies collide. During this collision, both bodies decelerate. The deceleration causes a high force or shock, applied over a short time period. A high force, over a short duration, usually causes more dam ...

Notes

External links

Calculator

{{Authority control Fracture mechanics Materials testing