C-glass on:

[Wikipedia]

[Google]

[Amazon]

Fiberglass (

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal

Fiberglass is versatile because it is lightweight, strong, weather-resistant, and can have a variety of surface textures.

During World War II, fiberglass was developed as a replacement for the molded plywood used in aircraft

Fiberglass is versatile because it is lightweight, strong, weather-resistant, and can have a variety of surface textures.

During World War II, fiberglass was developed as a replacement for the molded plywood used in aircraft

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys,

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys,

White Paper, Topic: "Clean Air in the Manufacture of Glass Fibre Reinforced Plastic (GRP) Parts"

GRP Technique & Service The general population can get exposed to fibreglass from insulation and building materials or from fibers in the air near manufacturing facilities or when they are near building fires or implosions. The

American English

American English, sometimes called United States English or U.S. English, is the set of variety (linguistics), varieties of the English language native to the United States. English is the Languages of the United States, most widely spoken lang ...

) or fibreglass (Commonwealth English

The use of the English language in current and former Member states of the Commonwealth of Nations, countries of Commonwealth of Nations, the Commonwealth was largely inherited from British Empire, British colonisation, with some exceptions. Eng ...

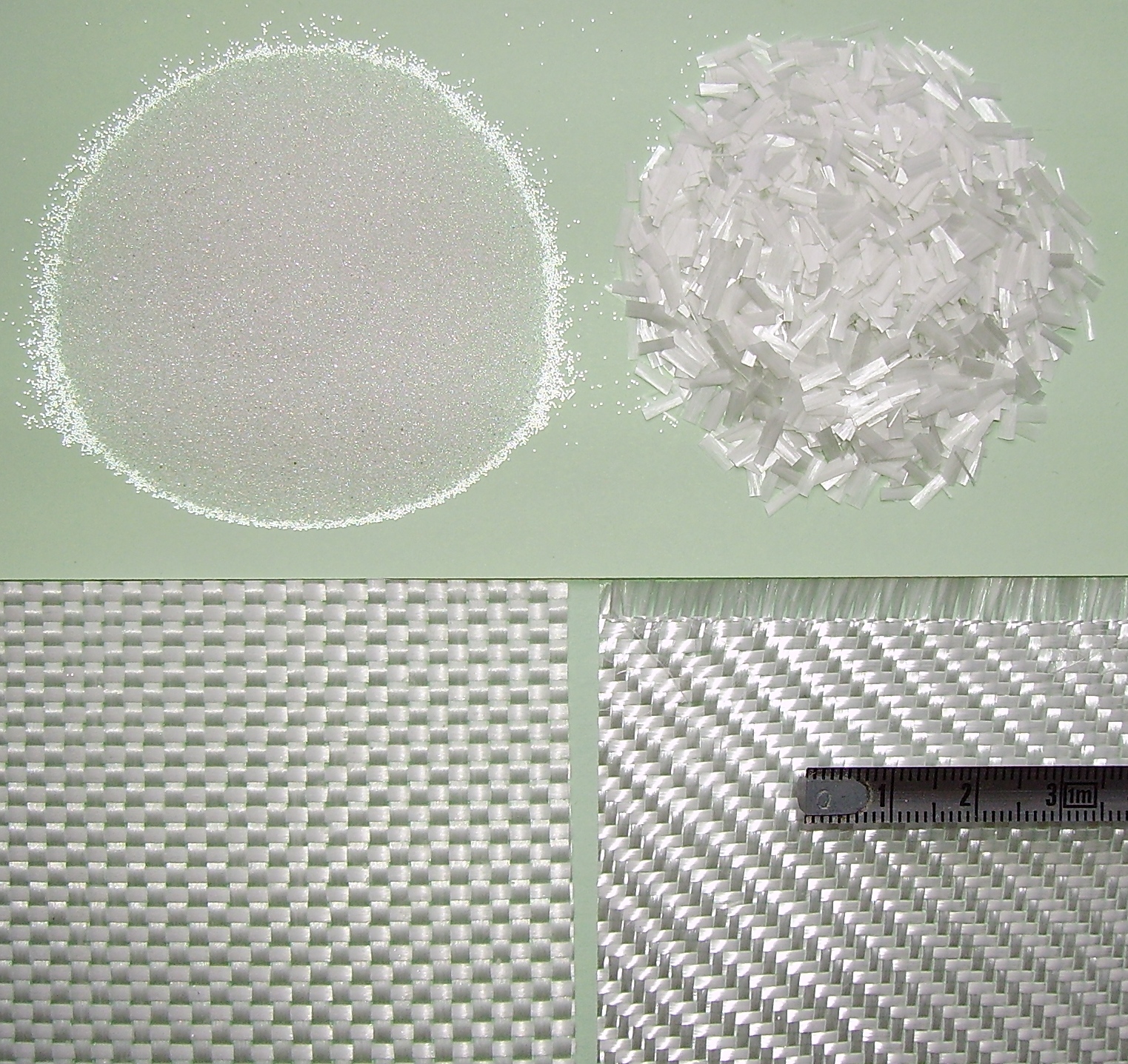

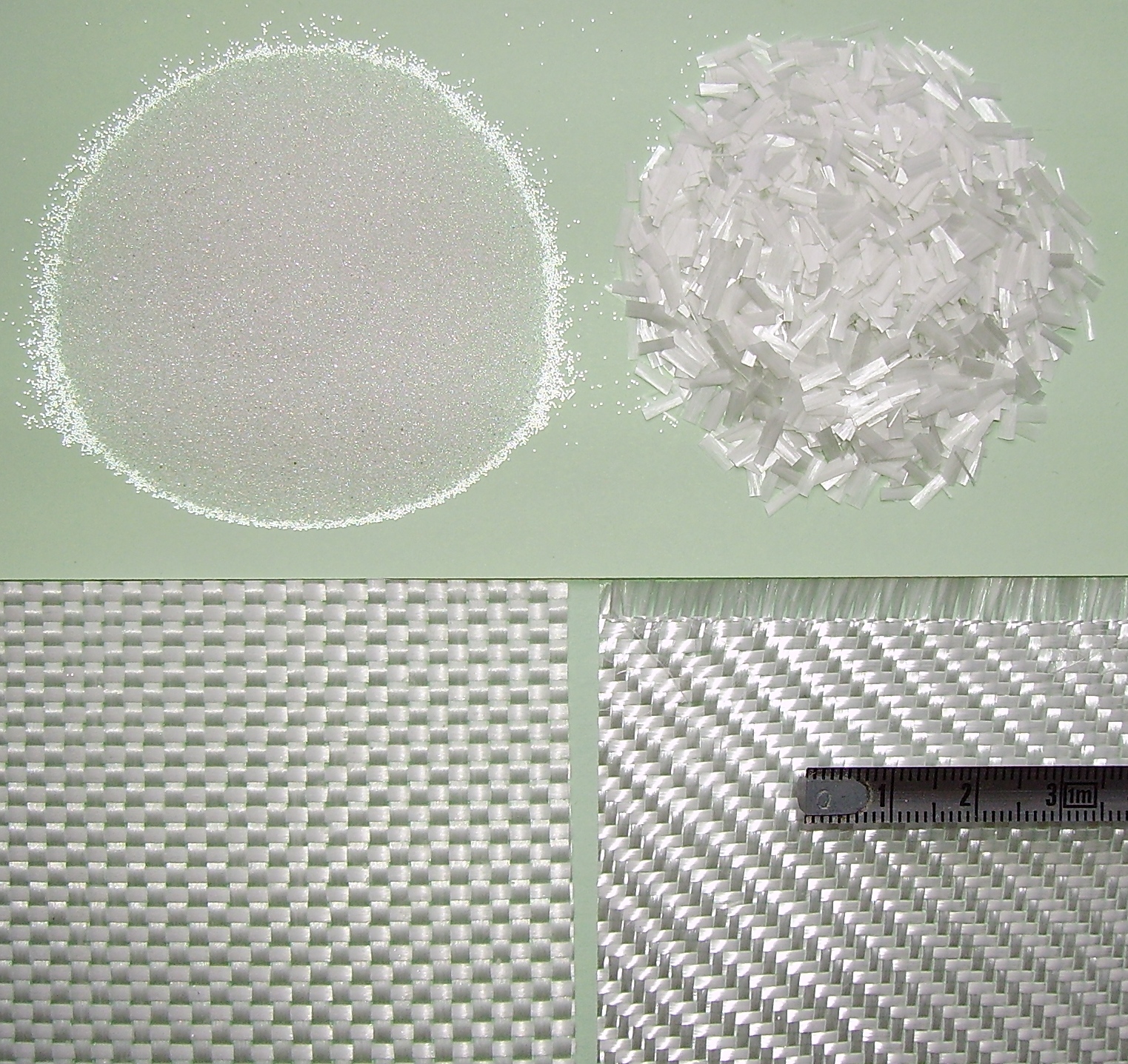

) is a common type of fiber-reinforced plastic using glass fiber

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the inventio ...

. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic

Plastics are a wide range of synthetic polymers, synthetic or Semisynthesis, semisynthetic materials composed primarily of Polymer, polymers. Their defining characteristic, Plasticity (physics), plasticity, allows them to be Injection moulding ...

matrix

Matrix (: matrices or matrixes) or MATRIX may refer to:

Science and mathematics

* Matrix (mathematics), a rectangular array of numbers, symbols or expressions

* Matrix (logic), part of a formula in prenex normal form

* Matrix (biology), the m ...

may be a thermoset polymer matrix—most often based on thermosetting polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

s such as epoxy

Epoxy is the family of basic components or Curing (chemistry), cured end products of epoxy Resin, resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide fun ...

, polyester resin

Polyester resins are synthetic resins formed by the reaction of dibasic organic acids and polyhydric alcohols. Maleic anhydride is a commonly used raw material with diacid functionality in unsaturated polyester resins. Unsaturated polyester r ...

, or vinyl ester resin

Vinyl ester resin, or often just vinyl ester, is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids. The "vinyl" groups refer to these ester substituents, which are prone to polymerize and thus an inhibito ...

—or a thermoplastic

A thermoplastic, or thermosoftening plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains as ...

.

Cheaper and more flexible than carbon fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers ( Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon comp ...

, it is stronger than many metals by weight, non-magnetic

Magnetism is the class of physical attributes that occur through a magnetic field, which allows objects to attract or repel each other. Because both electric currents and magnetic moments of elementary particles give rise to a magnetic field, m ...

, non-conductive

In physics and electrical engineering, a conductor is an object or type of material that allows the flow of Electric charge, charge (electric current) in one or more directions. Materials made of metal are common electrical conductors. The flow ...

, transparent to electromagnetic radiation

In physics, electromagnetic radiation (EMR) is a self-propagating wave of the electromagnetic field that carries momentum and radiant energy through space. It encompasses a broad spectrum, classified by frequency or its inverse, wavelength ...

, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools

A swimming pool, swimming bath, wading pool, paddling pool, or simply pool, is a structure designed to hold water to enable Human swimming, swimming and associated activities. Pools can be built into the ground (in-ground pools) or built abo ...

, hot tub

A hot tub is a large tub full of water used for hydrotherapy, relaxation or pleasure. Some have powerful jets for massage purposes. Hot tubs are sometimes also known as "spas" or by the trade name Jacuzzi. Hot tubs may be located outdoors or ...

s, septic tank

A septic tank is an underground chamber made of concrete, fiberglass, or plastic through which domestic wastewater (sewage) flows for basic sewage treatment. Settling and anaerobic digestion processes reduce solids and organics, but the treatment ...

s, water tank

A water tank is a container for Water storage, storing water, for many applications, drinking water, irrigation, fire suppression, farming, both for plants and livestock, chemical manufacturing, food preparation as well as many other uses. Water ...

s, roofing, pipes, cladding, orthopedic cast

An orthopedic cast, commonly referred to simply as a cast, is a form of medical treatment used to immobilize and support bones and soft tissues during the healing process after fractures, surgeries, or severe injuries. By restricting movement, ...

s, surfboard

A surfboard is a narrow plank used in surfing. Surfboards are relatively light, but are strong enough to support an individual standing on them while riding an ocean wave. They were invented in ancient Hawaii, where they were known as ''papa hee ...

s, and external door skins.

Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK (from ). Because glass fiber itself is sometimes referred to as "fiberglass", the composite is also called fiberglass-reinforced plastic (FRP). This article uses "fiberglass" to refer to the complete fiber-reinforced composite material, rather than only to the glass fiber within it.

History

Glass fibers have been produced for centuries, but the earliest patent was awarded to the Prussian inventorHermann Hammesfahr

Hermann Hammesfahr (February 20, 1845 – November 23, 1914) was a Prussian-American inventor who invented a type of fiberglass cloth in which glass was interwoven with silk. He was awarded the patent by the United States Patent Office in 1880. ...

(1845–1914) in the U.S. in 1880.

Mass production

Mass production, also known as mass production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines ...

of glass strands was accidentally discovered in 1932 when Games Slayter

Games Slayter (9 December 1896 – 15 October 1964) was a prolific United States, U.S. engineer and inventor. He is best known for developing fiberglass, starting with a new method of producing glass wool in 1933.

Biography

Slayter was bor ...

, a researcher at Owens-Illinois

O-I Glass, Inc. is an American company that specializes in container glass products. It is the largest manufacturer of glass containers in North America, South America, Asia-Pacific and Europe (after acquiring BSN Glasspack in 2004).

Company ...

, directed a jet of compressed air at a stream of molten glass and produced fibers. A patent for this method of producing glass wool

Glass wool is an Thermal insulation, insulating material made from glass fiber arranged using a Binder (material), binder into a texture similar to wool. The process traps many small pockets of air between the glass, and these small air pockets r ...

was first applied for in 1933. Owens joined with the Corning company in 1935 and the method was adapted by Owens Corning

Owens Corning is an American company that develops and produces insulation, roofing, and fiberglass composites and related products. It is the world's largest manufacturer of fiberglass composites. It was formed in 1935 as a partnership between ...

to produce its patented "Fiberglas" (spelled with one "s") in 1936. Originally, Fiberglas was a glass wool with fibers entrapping a great deal of gas, making it useful as an insulator, especially at high temperatures.

A suitable resin for combining the fiberglass with a plastic to produce a composite material was developed in 1936 by DuPont

Dupont, DuPont, Du Pont, duPont, or du Pont may refer to:

People

* Dupont (surname) Dupont, also spelled as DuPont, duPont, Du Pont, or du Pont is a French surname meaning "of the bridge", historically indicating that the holder of the surname re ...

. The first ancestor of modern polyester resins is Cyanamid's resin of 1942. Peroxide

In chemistry, peroxides are a group of Chemical compound, compounds with the structure , where the R's represent a radical (a portion of a complete molecule; not necessarily a free radical) and O's are single oxygen atoms. Oxygen atoms are joined ...

curing systems were used by then. With the combination of fiberglass and resin the gas content of the material was replaced by plastic. This reduced the insulation properties to values typical of the plastic, but now for the first time, the composite showed great strength and promise as a structural and building material. Many glass fiber composites continued to be called "fiberglass" (as a generic name) and the name was also used for the low-density glass wool product containing gas instead of plastic.

Ray Greene of Owens Corning is credited with producing the first composite boat in 1937 but did not proceed further at the time because of the brittle nature of the plastic used. In 1939 the Soviet Union was reported to have constructed a passenger boat of plastic materials, and the United States a fuselage and wings of an aircraft. The first car to have a fiberglass body was a 1946 prototype of the Stout Scarab, but the model did not enter production.

Fiber

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

s. If a bulk piece of glass were defect-free, it would be as strong as glass fibers; however, it is generally impractical to produce and maintain bulk material in a defect-free state outside of laboratory conditions.

Production

The process of manufacturing fiberglass is calledpultrusion

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls th ...

. The manufacturing process for glass fibers suitable for reinforcement uses large furnaces to gradually melt the silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

sand, limestone

Limestone is a type of carbonate rock, carbonate sedimentary rock which is the main source of the material Lime (material), lime. It is composed mostly of the minerals calcite and aragonite, which are different Polymorphism (materials science) ...

, kaolin clay, fluorspar

Fluorite (also called fluorspar) is the mineral form of calcium fluoride, CaF2. It belongs to the halide minerals. It crystallizes in isometric cubic habit, although octahedral and more complex isometric forms are not uncommon.

The Mohs scal ...

, colemanite, dolomite and other minerals

In geology and mineralogy, a mineral or mineral species is, broadly speaking, a solid substance with a fairly well-defined chemical composition and a specific crystal structure that occurs naturally in pure form.John P. Rafferty, ed. (2011): M ...

until a liquid forms. It is then extruded through bushings (spinneret

A spinneret is a silk-spinning organ of a spider or the larva of an insect. Some adult insects also have spinnerets, such as those borne on the forelegs of Embioptera. Spinnerets are usually on the underside of a spider's opisthosoma, and ar ...

), which are bundles of very small orifices (typically 5–25 micrometres in diameter for E-Glass, 9 micrometres for S-Glass).

These filaments are then ''sized'' (coated) with a chemical solution. The individual filaments are now bundled in large numbers to provide a roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialise ...

. The diameter of the filaments, and the number of filaments in the roving, determine its ''weight'', typically expressed in one of two measurement systems:

*''yield'', or yards per pound (the number of yards of fiber in one pound of material; thus a smaller number means a heavier roving). Examples of standard yields are 225yield, 450yield, 675yield.

*''tex'', or grams per km (how many grams 1 km of roving weighs, inverted from yield; thus a smaller number means a lighter roving). Examples of standard tex are 750tex, 1100tex, 2200tex.

These rovings are then either used directly in a composite application such as pultrusion

Pultrusion is a continuous process for manufacture of fibre-reinforced plastics with constant cross-section. The term is a portmanteau word, combining "pull" and "extrusion". As opposed to extrusion, which pushes the material, pultrusion pulls th ...

, filament winding

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates ar ...

(pipe), gun roving (where an automated gun chops the glass into short lengths and drops it into a jet of resin, projected onto the surface of a mold), or in an intermediary step, to manufacture fabrics such as ''chopped strand mat'' (CSM) (made of randomly oriented small cut lengths of fiber all bonded together), woven fabrics, knit fabrics or unidirectional fabrics.

Chopped strand mat

Chopped strand mat (CSM) is a form of reinforcement used in fiberglass. It consists of glass fibers laid randomly across each other and held together by a binder. It is typically processed using the hand lay-up technique, where sheets of material are placed on a mold and brushed with resin. Because the binder dissolves in resin, the material easily conforms to different shapes when wetted out. After the resin cures, the hardened product can be taken from the mold and finished. Using chopped strand mat gives the fiberglassisotropic

In physics and geometry, isotropy () is uniformity in all orientations. Precise definitions depend on the subject area. Exceptions, or inequalities, are frequently indicated by the prefix ' or ', hence '' anisotropy''. ''Anisotropy'' is also ...

in-plane material properties.

Sizing

A coating or primer is applied to the roving to help protect the glass filaments for processing and manipulation and to ensure proper bonding to the resin matrix, thus allowing for the transfer of shear loads from the glass fibers to the thermoset plastic. Without this bonding, the fibers can 'slip' in the matrix causing localized failure.Properties

An individual structural glass fiber is both stiff and strong in tension andcompression

Compression may refer to:

Physical science

*Compression (physics), size reduction due to forces

*Compression member, a structural element such as a column

*Compressibility, susceptibility to compression

* Gas compression

*Compression ratio, of a ...

—that is, ''along'' its axis. Although it might be assumed that the fiber is weak in compression, it is actually only the long aspect ratio

The aspect ratio of a geometry, geometric shape is the ratio of its sizes in different dimensions. For example, the aspect ratio of a rectangle is the ratio of its longer side to its shorter side—the ratio of width to height, when the rectangl ...

of the fiber which makes it seem so; i.e., because a typical fiber is long and narrow, it buckles easily. On the other hand, the glass fiber is weak in shear—that is, ''across'' its axis. Therefore, if a collection of fibers can be arranged permanently in a preferred direction within a material, and if they can be prevented from buckling

In structural engineering, buckling is the sudden change in shape (Deformation (engineering), deformation) of a structural component under Structural load, load, such as the bowing of a column under Compression (physics), compression or the wrin ...

in compression, the material will be preferentially strong in that direction.

Furthermore, by laying multiple layers of fiber on top of one another, with each layer oriented in various preferred directions, the material's overall stiffness and strength can be efficiently controlled. In fiberglass, it is the plastic matrix which permanently constrains the structural glass fibers to directions chosen by the designer. With chopped strand mat, this directionality is essentially an entire two-dimensional plane; with woven fabrics or unidirectional layers, directionality of stiffness and strength can be more precisely controlled within the plane.

A fiberglass component is typically of a thin "shell" construction, sometimes filled on the inside with structural foam, as in the case of surfboards. The component may be of nearly arbitrary shape, limited only by the complexity and tolerances of the mold

A mold () or mould () is one of the structures that certain fungus, fungi can form. The dust-like, colored appearance of molds is due to the formation of Spore#Fungi, spores containing Secondary metabolite#Fungal secondary metabolites, fungal ...

used for manufacturing the shell.

The mechanical functionality of materials is heavily reliant on the combined performances of both the resin (AKA matrix) and fibers. For example, in severe temperature conditions (over 180 °C), the resin component of the composite may lose its functionality, partially due to bond deterioration of resin and fiber. However, GFRPs can still show significant residual strength after experiencing high temperatures (200 °C).

One notable feature of fiberglass is that the resins used are subject to contraction during the curing process. For polyester this contraction is often 5–6%; for epoxy, about 2%. Because the fibers do not contract, this differential can create changes in the shape of the part during curing. Distortions can appear hours, days, or weeks after the resin has set. While this distortion can be minimized by symmetric use of the fibers in the design, a certain amount of internal stress is created; and if it becomes too great, cracks form.

Types

The most common types of glass fiber used in fiberglass isE-glass

Glass fiber (American and British English spelling differences, or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of gl ...

, which is alumino-borosilicate glass with less than 1% w/w alkali oxides, mainly used for glass-reinforced plastics. Other types of glass used are A-glass (Alkali-lime glass with little or no boron oxide), E-CR-glass (Electrical/Chemical Resistance; alumino-lime silicate with less than 1% w/w alkali oxides, with high acid resistance), C-glass (alkali-lime glass with high boron oxide content, used for glass staple fibers and insulation), D-glass (borosilicate glass, named for its low Dielectric constant), R-glass (alumino silicate glass without MgO and CaO with high mechanical requirements as Reinforcement), and S-glass (alumino silicate glass without CaO but with high MgO content with high tensile strength).

Pure silica

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...

(silicon dioxide), when cooled as fused quartz

Fused quartz, fused silica or quartz glass is a glass consisting of almost pure silica (silicon dioxide, SiO2) in amorphous (non-crystalline) form. This differs from all other commercial glasses, such as soda-lime glass, lead glass, or borosi ...

into a glass

Glass is an amorphous (non-crystalline solid, non-crystalline) solid. Because it is often transparency and translucency, transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window pane ...

with no true melting point, can be used as a glass fiber for fiberglass but has the drawback that it must be worked at very high temperatures. In order to lower the necessary work temperature, other materials are introduced as "fluxing agents" (i.e., components to lower the melting point). Ordinary A-glass ("A" for "alkali-lime") or soda lime glass, crushed and ready to be remelted, as so-called cullet glass, was the first type of glass used for fiberglass. E-glass ("E" because of initial Electrical application), is alkali-free and was the first glass formulation used for continuous filament formation. It now makes up most of the fiberglass production in the world, and also is the single largest consumer of boron

Boron is a chemical element; it has symbol B and atomic number 5. In its crystalline form it is a brittle, dark, lustrous metalloid; in its amorphous form it is a brown powder. As the lightest element of the boron group it has three ...

minerals globally. It is susceptible to chloride ion attack and is a poor choice for marine applications. S-glass ("S" for "stiff") is used when tensile strength (high modulus) is important and is thus an important building and aircraft epoxy composite (it is called R-glass, "R" for "reinforcement" in Europe). C-glass ("C" for "chemical resistance") and T-glass ("T" is for "thermal insulator"—a North American variant of C-glass) are resistant to chemical attack; both are often found in insulation-grades of blown fiberglass.

Table of some common fiberglass types

Applications

Fiberglass is versatile because it is lightweight, strong, weather-resistant, and can have a variety of surface textures.

During World War II, fiberglass was developed as a replacement for the molded plywood used in aircraft

Fiberglass is versatile because it is lightweight, strong, weather-resistant, and can have a variety of surface textures.

During World War II, fiberglass was developed as a replacement for the molded plywood used in aircraft radome

A radome (a portmanteau of "radar" and "dome") is a structural, weatherproof enclosure that protects a radar antenna (radio), antenna. The radome is constructed of material transparent to radio waves. Radomes protect the antenna from weathe ...

s (fiberglass being transparent to microwaves

Microwave is a form of electromagnetic radiation with wavelengths shorter than other radio waves but longer than infrared waves. Its wavelength ranges from about one meter to one millimeter, corresponding to frequencies between 300 MHz an ...

). Its first main civilian application was for the building of boat

A boat is a watercraft of a large range of types and sizes, but generally smaller than a ship, which is distinguished by its larger size or capacity, its shape, or its ability to carry boats.

Small boats are typically used on inland waterways s ...

s and sports car bodies, where it gained acceptance in the 1950s. Its use has broadened to the automotive and sport equipment sectors. In the production of some products, such as aircraft, carbon fiber is now used instead of fiberglass, which is stronger by volume and weight.

Advanced manufacturing techniques such as pre-preg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave ...

s and fiber

Fiber (spelled fibre in British English; from ) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often inco ...

roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialise ...

s extend fiberglass's applications and the tensile strength possible with fiber-reinforced plastics.

Fiberglass is also used in the telecommunications

Telecommunication, often used in its plural form or abbreviated as telecom, is the transmission of information over a distance using electronic means, typically through cables, radio waves, or other communication technologies. These means of ...

industry for shroud

Shroud usually refers to an item, such as a cloth, that covers or protects some other object. The term is most often used in reference to ''burial sheets'', mound shroud, grave clothes, winding-cloths or winding-sheets, such as the Jewish '' ...

ing antennas

In radio-frequency engineering, an antenna (American English) or aerial (British English) is an electronic device that converts an alternating electric current into radio waves (transmitting), or radio waves into an electric current (receivi ...

, due to its RF permeability and low signal attenuation

In physics, attenuation (in some contexts, extinction) is the gradual loss of flux intensity through a Transmission medium, medium. For instance, dark glasses attenuate sunlight, lead attenuates X-rays, and water and air attenuate both light and ...

properties. It may also be used to conceal other equipment where no signal permeability is required, such as equipment cabinets and steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

support structures, due to the ease with which it can be molded and painted to blend with existing structures and surfaces. Other uses include sheet-form electrical insulators and structural components commonly found in power-industry products. Because of fiberglass's lightweight and durability, it is often used in protective equipment such as helmets. Many sports use fiberglass protective gear, such as goaltenders' and catchers' masks.

Storage tanks

Storage tank

Storage tanks are containers that hold liquids or compressed gases. The term can be used for reservoirs (artificial lakes and ponds), and for manufactured containers. The usage of the word "tank" for reservoirs is uncommon in American English ...

s can be made of fiberglass with capacities up to about 300 tonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1,000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton in the United States to distinguish it from the non-metric units of the s ...

s. Smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform during construction. Much more reliable tanks are made using woven mat or filament wound fiber, with the fiber orientation at right angles to the hoop stress imposed in the sidewall by the contents. Such tanks tend to be used for chemical storage because the plastic liner (often polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer Propene, propylene.

Polypropylene belongs to the group of polyolefin ...

) is resistant to a wide range of corrosive chemicals. Fiberglass is also used for septic tank

A septic tank is an underground chamber made of concrete, fiberglass, or plastic through which domestic wastewater (sewage) flows for basic sewage treatment. Settling and anaerobic digestion processes reduce solids and organics, but the treatment ...

s.

House building

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys,

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping

Coping refers to conscious or unconscious strategies used to reduce and manage unpleasant emotions. Coping strategies can be cognitions or behaviors and can be individual or social. To cope is to deal with struggles and difficulties in life. It ...

systems, and heads with keystones and sills. The material's reduced weight and easier handling, compared to wood or metal, allows faster installation. Mass-produced fiberglass brick-effect panels can be used in the construction of composite housing, and can include insulation to reduce heat loss.

Oil and gas artificial lift systems

In rod pumping applications, fiberglass rods are often used for their high tensile strength to weight ratio. Fiberglass rods provide an advantage over steel rods because they stretch more elastically (lowerYoung's modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Youn ...

) than steel for a given weight, meaning more oil can be lifted from the hydrocarbon reservoir to the surface with each stroke, all while reducing the load on the pumping unit.

Fiberglass rods must be kept in tension, however, as they frequently part if placed in even a small amount of compression. The buoyancy of the rods within a fluid amplifies this tendency.

Piping

GRP and GRE pipe can be used in a variety of above- and below-ground systems, including those for desalination, water treatment, water distribution networks, chemical process plants, water used for firefighting, hot and cold drinking water, wastewater/sewage, municipal waste andliquified petroleum gas

Liquefied petroleum gas, also referred to as liquid petroleum gas (LPG or LP gas), is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, ''n''-butane and isobutane. It can also contain some propyl ...

.

Boating

Fiberglass composite boats have been made since the early 1940s, and many sailing vessels made after 1950 were built using the fiberglass lay-up process. As of 2022, boats continue to be made with fiberglass, though more advanced techniques such as vacuum bag moulding are used in the construction process.Armour

Though most bullet-resistant armours are made using different textiles, fiberglass composites have been shown to be effective as ballistic armor.Construction methods

Filament winding

Filament winding

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed end structures (pressure vessels or tanks). This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates ar ...

is a fabrication technique mainly used for manufacturing open (cylinders) or closed-end structures (pressure vessels or tanks). The process involves winding filaments under tension over a male mandrel. The mandrel rotates while a wind eye on a carriage moves horizontally, laying down fibers in the desired pattern. The most common filaments are carbon or glass fiber and are coated with synthetic resin as they are wound. Once the mandrel is completely covered to the desired thickness, the resin is cured; often the mandrel is placed in an oven to achieve this, though sometimes radiant heaters are used with the mandrel still turning in the machine. Once the resin has cured, the mandrel is removed, leaving the hollow final product. For some products such as gas bottles, the 'mandrel' is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored.

Filament winding is well suited to automation, and there are many applications, such as pipe and small pressure vessels that are wound and cured without any human intervention. The controlled variables for winding are fiber type, resin content, wind angle, tow or bandwidth and thickness of the fiber bundle. The angle at which the fiber has an effect on the properties of the final product. A high angle "hoop" will provide circumferential or "burst" strength, while lower angle patterns (polar or helical) will provide greater longitudinal tensile strength.

Products currently being produced using this technique range from pipes, golf clubs, Reverse Osmosis Membrane Housings, oars, bicycle forks, bicycle rims, power and transmission poles, pressure vessels to missile casings, aircraft fuselages and lamp posts and yacht masts.

Fiberglass hand lay-up operation

A release agent, usually in either wax or liquid form, is applied to the chosen mold to allow the finished product to be cleanly removed from the mold. Resin—typically a 2-partthermoset

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and ...

polyester, vinyl, or epoxy—is mixed with its hardener and applied to the surface. Sheets of fiberglass matting are laid into the mold, then more resin mixture is added using a brush or roller. The material must conform to the mold, and air must not be trapped between the fiberglass and the mold. Additional resin is applied and possibly additional sheets of fiberglass. Hand pressure, vacuum or rollers are used to be sure the resin saturates and fully wets all layers, and that any air pockets are removed. The work must be done quickly before the resin starts to cure unless high-temperature resins are used which will not cure until the part is warmed in an oven. In some cases, the work is covered with plastic sheets and vacuum is drawn on the work to remove air bubbles and press the fiberglass to the shape of the mold.

Fiberglass spray lay-up operation

The fiberglass spray lay-up process is similar to the hand lay-up process but differs in the application of the fiber and resin to the mold. Spray-up is an open-molding composites fabrication process where resin and reinforcements are sprayed onto a mold. The resin and glass may be applied separately or simultaneously "chopped" in a combined stream from a chopper gun. Workers roll out the spray-up to compact the laminate. Wood, foam or other core material may then be added, and a secondary spray-up layer imbeds the core between the laminates. The part is then cured, cooled, and removed from the reusable mold.Pultrusion operation

Pultrusion is a manufacturing method used to make strong, lightweight composite materials. In pultrusion, material is pulled through forming machinery using either a hand-over-hand method or a continuous-roller method (as opposed toextrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing pro ...

, where the material is pushed through dies).

In fiberglass pultrusion, fibers (the glass material) are pulled from spools through a device that coats them with a resin. They are then typically heat-treated and cut to length. Fiberglass produced this way can be made in a variety of shapes and cross-sections, such as W or S cross-sections.

Health hazards

Exposure

People can be exposed to fiberglass in the workplace during its fabrication, installation or removal, by breathing it in, by skin contact, or by eye contact. Furthermore, in the manufacturing process of fiberglass,styrene

Styrene is an organic compound with the chemical formula C6H5CH=CH2. Its structure consists of a vinyl group as substituent on benzene. Styrene is a colorless, oily liquid, although aged samples can appear yellowish. The compound evaporates easi ...

vapors are released while the resins are cured. These are also irritating to mucous membranes and respiratory tract.Türschmann, V.; Jakschik, C.; Rother, H.-J. (March 2011White Paper, Topic: "Clean Air in the Manufacture of Glass Fibre Reinforced Plastic (GRP) Parts"

GRP Technique & Service The general population can get exposed to fibreglass from insulation and building materials or from fibers in the air near manufacturing facilities or when they are near building fires or implosions. The

American Lung Association

The American Lung Association is a voluntary health organization whose mission is to save lives by improving lung health and preventing lung disease through education, advocacy and research.

History

1904–1918: Founding

The organization was ...

advises that fiberglass insulation should never be left exposed in an occupied area. Since work practices are not always followed, and fiberglass is often left exposed in basements that later become occupied, people can get exposed. No readily usable biological or clinical indices of exposure exist.

Symptoms and signs, health effects

Fiberglass will irritate the eyes, skin, and the respiratory system. Hence, symptoms can include itchy eyes, skin, nose, sore throat, hoarseness,dyspnea

Shortness of breath (SOB), known as dyspnea (in AmE) or dyspnoea (in BrE), is an uncomfortable feeling of not being able to breathe well enough. The American Thoracic Society defines it as "a subjective experience of breathing discomfort that ...

(breathing difficulty) and cough. Peak alveolar deposition was observed in rodents and humans for fibers with diameters of 1 to 2 μm.

In animal experiments, adverse lung effects such as lung inflammation and lung fibrosis

Pulmonary fibrosis is a condition in which the lungs become scarred over time. Symptoms include shortness of breath, a dry cough, feeling tired, weight loss, and nail clubbing. Complications may include pulmonary hypertension, respiratory fail ...

have occurred, and increased incidences of mesothelioma

Mesothelioma is a type of cancer that develops from the thin layer of tissue that covers many of the internal organs (known as the mesothelium). The area most commonly affected is the lining of the lungs and chest wall. Less commonly the lini ...

, pleural sarcoma

A sarcoma is a rare type of cancer that arises from cells of mesenchymal origin. Originating from mesenchymal cells means that sarcomas are cancers of connective tissues such as bone, cartilage, muscle, fat, or vascular tissues.

Sarcom ...

, and lung carcinoma had been found with intrapleural or intratracheal instillations in rats.

As of 2001, in humans only the more biopersistent materials like ceramic fibres, which are used industrially as insulation in high-temperature environments such as blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure.

In a ...

s, and certain special-purpose glass wools not used as insulating materials remain classified as possible carcinogens (IARC Group 2B

IARC group 2B substances, mixtures and exposure circumstances are those that have been classified as "possibly carcinogenic to humans" by the International Agency for Research on Cancer (IARC) as This category is used when there is level of evide ...

). The more commonly used glass fibre wools including insulation glass wool

Glass wool is an Thermal insulation, insulating material made from glass fiber arranged using a Binder (material), binder into a texture similar to wool. The process traps many small pockets of air between the glass, and these small air pockets r ...

, rock wool

Rock most often refers to:

* Rock (geology), a naturally occurring solid aggregate of minerals or mineraloids

* Rock music, a genre of popular music

Rock or Rocks may also refer to:

Places United Kingdom

* Rock, Caerphilly, a location in Wale ...

and slag wool are considered not classifiable as to carcinogenicity to humans (IARC Group 3

IARC group 3 substances, chemical mixtures and exposure circumstances are those that can not be classified in regard to their carcinogenicity to humans by the International Agency for Research on Cancer (IARC). This category is used most commonly ...

).

In October 2001, all fiberglass wools commonly used for thermal and acoustical insulation were reclassified by the International Agency for Research on Cancer

The International Agency for Research on Cancer (IARC; ) is an intergovernmental agency forming part of the World Health Organization of the United Nations.

Its role is to conduct and coordinate research into the causes of cancer. It also cance ...

(IARC) as "not classifiable as to carcinogenicity to humans" (IARC group 3

IARC group 3 substances, chemical mixtures and exposure circumstances are those that can not be classified in regard to their carcinogenicity to humans by the International Agency for Research on Cancer (IARC). This category is used most commonly ...

). "Epidemiologic studies published during the 15 years since the previous IARC monographs review of these fibers in 1988 provide no evidence of increased risks of lung cancer or mesothelioma

Mesothelioma is a type of cancer that develops from the thin layer of tissue that covers many of the internal organs (known as the mesothelium). The area most commonly affected is the lining of the lungs and chest wall. Less commonly the lini ...

(cancer of the lining of the body cavities) from occupational exposures during the manufacture of these materials, and inadequate evidence overall of any cancer risk."

In June 2011, the US National Toxicology Program

The National Toxicology Program (NTP) is an inter-agency program run by the United States Department of Health and Human Services to coordinate, evaluate, and report on toxicology within public agencies.

The National Toxicology Program is head ...

(NTP) removed from its Report on Carcinogen

A carcinogen () is any agent that promotes the development of cancer. Carcinogens can include synthetic chemicals, naturally occurring substances, physical agents such as ionizing and non-ionizing radiation, and biologic agents such as viruse ...

s all biosoluble glass wool used in home and building insulation

Building insulation is material used in a building (specifically the building envelope) to reduce the flow of thermal energy. While the majority of insulation in buildings is for thermal insulation, thermal purposes, the term also applies to ...

and for non-insulation products. However, NTP still considers fibrous glass dust to be "reasonably anticipated sa human carcinogen (Certain Glass Wool Fibers (Inhalable))". Similarly, California's Office of Environmental Health Hazard Assessment (OEHHA) published a November, 2011 modification to its Proposition 65 listing to include only "Glass wool fibers (inhalable and biopersistent)." Therefore a cancer warning label for biosoluble fiber glass home and building insulation is no longer required under federal or California law. As of 2012, the North American Insulation Manufacturers Association stated that fiberglass is safe to manufacture, install and use when recommended work practices are followed to reduce temporary mechanical irritation.

As of 2012, the European Union and Germany have classified synthetic glass fibers as possibly or probably carcinogenic, but fibers can be exempt from this classification if they pass specific tests. A 2012 health hazard review for the European Commission stated that inhalation of fiberglass at concentrations of 3, 16 and 30 mg/m3 "did not induce fibrosis nor tumours except transient lung inflammation that disappeared after a post-exposure recovery period."

Historic reviews of the epidemiology studies had been conducted by Harvard's Medical and Public Health Schools in 1995, the National Academy of Sciences

The National Academy of Sciences (NAS) is a United States nonprofit, NGO, non-governmental organization. NAS is part of the National Academies of Sciences, Engineering, and Medicine, along with the National Academy of Engineering (NAE) and the ...

in 2000, the Agency for Toxic Substances and Disease Registry

The Agency for Toxic Substances and Disease Registry (ATSDR) is a federal public health agency within the U.S. Department of Health and Human Services (HHS). The agency focuses on minimizing human health risks associated with exposure to hazar ...

("ATSDR") in 2004, and the National Toxicology Program

The National Toxicology Program (NTP) is an inter-agency program run by the United States Department of Health and Human Services to coordinate, evaluate, and report on toxicology within public agencies.

The National Toxicology Program is head ...

in 2011. which reached the same conclusion as IARC that there is no evidence of increased risk from occupational exposure to glass wool fibers.

Pathophysiology

Genetic and toxic effects are exerted through production ofreactive oxygen species

In chemistry and biology, reactive oxygen species (ROS) are highly Reactivity (chemistry), reactive chemicals formed from diatomic oxygen (), water, and hydrogen peroxide. Some prominent ROS are hydroperoxide (H2O2), superoxide (O2−), hydroxyl ...

, which can damage DNA, and cause chromosomal aberrations, nuclear abnormalities, mutations, gene amplification in proto-oncogenes

An oncogene is a gene that has the potential to cause cancer. In tumor cells, these genes are often mutated, or expressed at high levels.

, and cell transformation in mammalian cells. There is also indirect, inflammation-driven genotoxicity through reactive oxygen species by inflammatory cells. The longer and thinner as well as the more durable (biopersistent) fibers were, the more potent they were in damage.

Regulation, exposure limits

In the US, finemineral fiber

Fiber (spelled fibre in British English; from ) is a natural or artificial substance that is significantly longer than it is wide. Fibers are often used in the manufacture of other materials. The strongest engineering materials often incorp ...

emissions have been regulated by the EPA, but respirable fibers (“particulates not otherwise regulated”) are regulated by Occupational Safety and Health Administration

The Occupational Safety and Health Administration (OSHA; ) is a regulatory agency of the United States Department of Labor that originally had federal visitorial powers to inspect and examine workplaces. The United States Congress established ...

(OSHA); OSHA has set the legal limit (permissible exposure limit

The permissible exposure limit (PEL or OSHA PEL) is a legal limit in the United States for exposure of an employee to a chemical substance or physical agents such as high level noise. Permissible exposure limits were established by the Occupational ...

) for fiberglass exposure in the workplace as 15 mg/m3 total and 5 mg/m3 in respiratory exposure over an 8-hour workday. The National Institute for Occupational Safety and Health

The National Institute for Occupational Safety and Health (NIOSH, ) is the List of United States federal agencies, United States federal agency responsible for conducting research and making recommendations for the prevention of work-related occ ...

(NIOSH) has set a recommended exposure limit

A recommended exposure limit (REL) is an occupational exposure limit that has been recommended by the United States National Institute for Occupational Safety and Health. The REL is a level that NIOSH believes would be protective of worker safety ...

(REL) of 3 fibers/cm3 (less than 3.5 micrometers in diameter and greater than 10 micrometers in length) as a time-weighted average over an 8-hour workday, and a 5 mg/m3 total limit.

As of 2001, the Hazardous Substances Ordinance in Germany dictates a maximum occupational exposure limit of 86 mg/m3. In certain concentrations, a potentially explosive mixture may occur. Further manufacture of GRP components (grinding, cutting, sawing) creates fine dust and chips containing glass filaments, as well as tacky dust, in quantities high enough to affect health and the functionality of machines and equipment. The installation of effective extraction and filtration equipment is required to ensure safety and efficiency.

See also

* Bulk moulding compound * Fiberglass sheet laminating * G-10 (material) * Glass fiber reinforced concrete *Hobas

HOBAS is a manufacturer of centrifugal casting (industrial), centrifugally cast glassfiber reinforced (GRP) pipe systems made of unsaturated polyester resin with diameters ranging from 150 mm to 3600 mm. The company was founded in Bas ...

* Ignace Dubus-Bonnel

* Sheet moulding compound

*Carbon-fiber-reinforced polymers

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

reinforcement with carbon fibers.

References

External links

* {{DEFAULTSORT:Fiberglass American inventions Composite materials Fibre-reinforced polymers Glass applications