Brickfield on:

[Wikipedia]

[Google]

[Amazon]

A brickfield is a field or other open site where bricks are made. Land may be leased by an owner to a brickmaster, by whom the manufacture of bricks may be conducted.

Historically, the

A brickfield is a field or other open site where bricks are made. Land may be leased by an owner to a brickmaster, by whom the manufacture of bricks may be conducted.

Historically, the

A field was leased from the farmer and it was 'uncallowed' (the topsoil removed). The soil had been farmed and in the

A field was leased from the farmer and it was 'uncallowed' (the topsoil removed). The soil had been farmed and in the

A brickfield is a field or other open site where bricks are made. Land may be leased by an owner to a brickmaster, by whom the manufacture of bricks may be conducted.

Historically, the

A brickfield is a field or other open site where bricks are made. Land may be leased by an owner to a brickmaster, by whom the manufacture of bricks may be conducted.

Historically, the topsoil

Topsoil is the upper layer of soil. It has the highest concentration of organic matter and microorganisms and is where most of the Earth's biological soil activity occurs.

Description

Topsoil is composed of mineral particles and organic matt ...

was typically removed and the clay

Clay is a type of fine-grained natural soil material containing clay minerals (hydrous aluminium phyllosilicates, e.g. kaolin, Al2 Si2 O5( OH)4).

Clays develop plasticity when wet, due to a molecular film of water surrounding the clay par ...

beneath was stripped and mixed with chalk

Chalk is a soft, white, porous, sedimentary carbonate rock. It is a form of limestone composed of the mineral calcite and originally formed deep under the sea by the compression of microscopic plankton that had settled to the sea floor. Chalk ...

and ash

Ash or ashes are the solid remnants of fires. Specifically, ''ash'' refers to all non-aqueous, non- gaseous residues that remain after something burns. In analytical chemistry, to analyse the mineral and metal content of chemical samples, ash ...

to make brick

A brick is a type of block used to build walls, pavements and other elements in masonry construction. Properly, the term ''brick'' denotes a block composed of dried clay, but is now also used informally to denote other chemically cured cons ...

s. In pre-19th-century England,

most areas the brickfield owner hired a brickmaster at a price per thousand bricks to superintend the site and take full responsibility for the output of the operations. He in turn contracted with moulders to temper, mould and hack the bricks. Each moulder then hired his own 'gang' of subsidiary labourers and acted as their employer.Subsequently, the field (if not too damaged ecologically) could be used for

horticulture

Horticulture is the branch of agriculture that deals with the art, science, technology, and business of plant cultivation. It includes the cultivation of fruits, vegetables, nuts, seeds, herbs, sprouts, mushrooms, algae, flowers, seaweeds and no ...

. In Kent

Kent is a county in South East England and one of the home counties. It borders Greater London to the north-west, Surrey to the west and East Sussex to the south-west, and Essex to the north across the estuary of the River Thames; it faces ...

such fields were often planted with fruit trees. Brickfields were mainly created from 1770 to 1881, when a new shaly clay was discovered at Fletton

Fletton is an area of the city of Peterborough, in the Peterborough district, in the ceremonial county of Cambridgeshire, England, south of the River Nene.

Notable for its large brickworks, the area has given its name to "Fletton bricks",

Admin ...

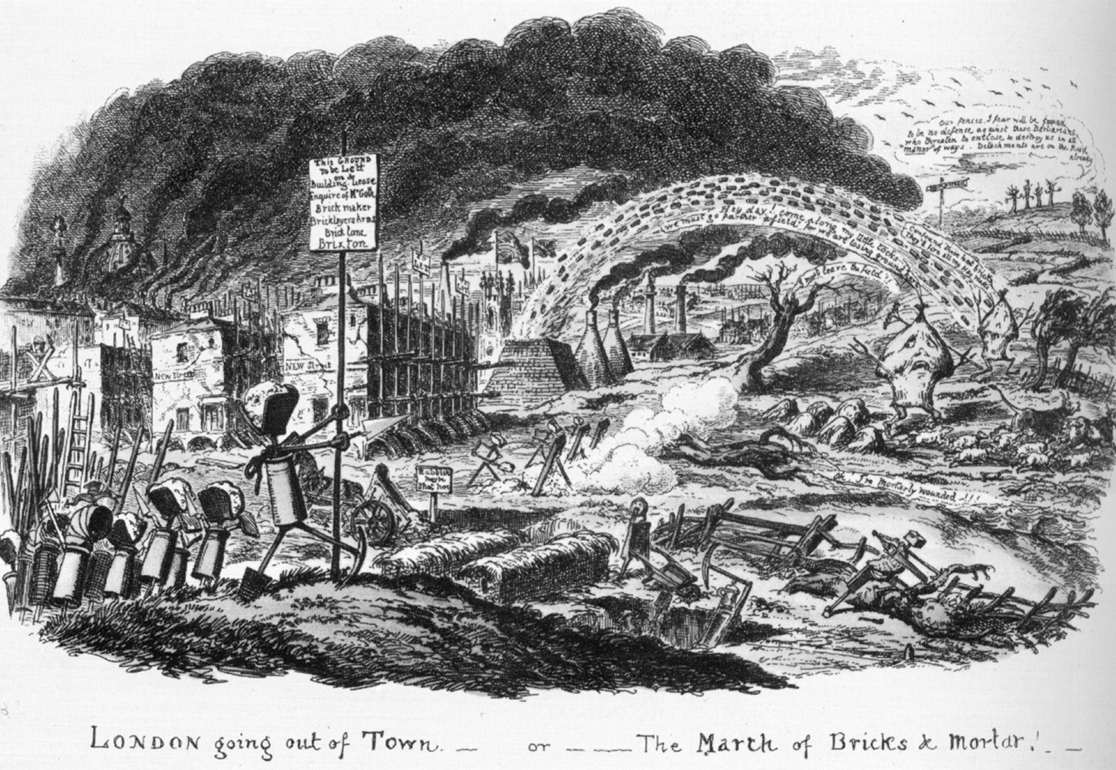

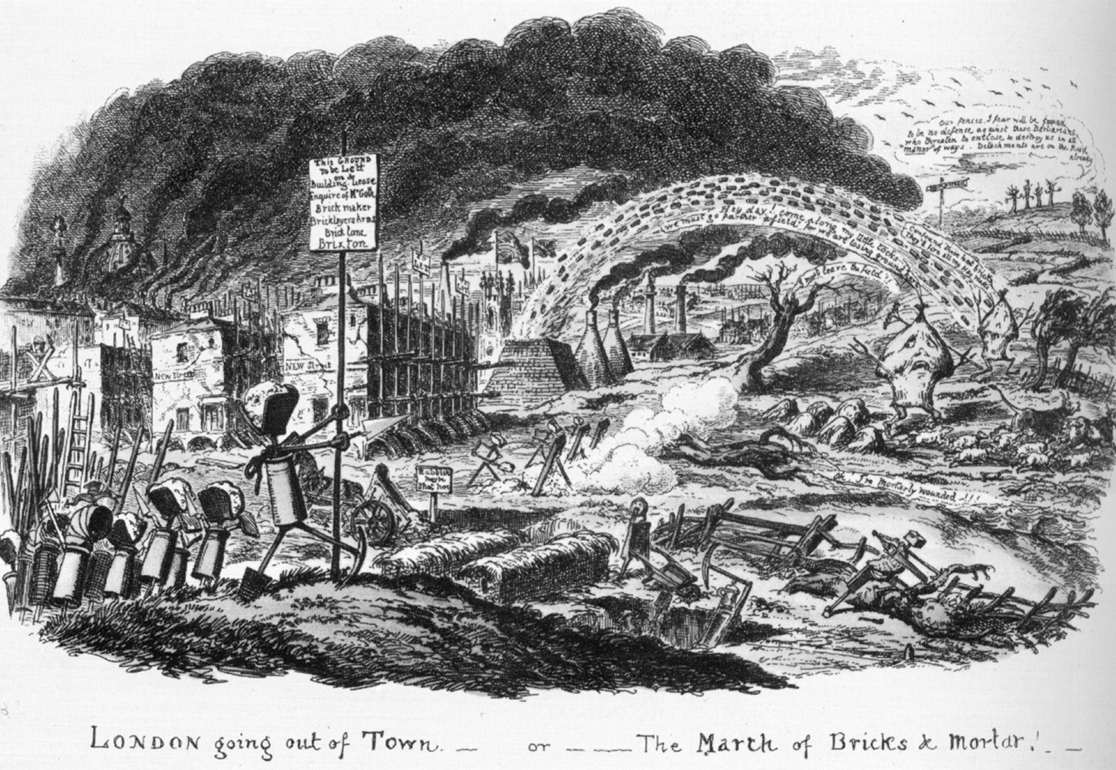

. This period coincided with the housing and railway boom in London

London is the capital and largest city of England and the United Kingdom, with a population of just under 9 million. It stands on the River Thames in south-east England at the head of a estuary down to the North Sea, and has been a majo ...

and cheap river-transport in Thames sailing barge

A Thames sailing barge is a type of commercial sailing boat once common on the River Thames in London. The flat-bottomed barges with a shallow draught and leeboards, were perfectly adapted to the Thames Estuary, with its shallow waters and narr ...

s. Brickfields existed elsewhere, but often the clay layer was deeper or there was no chalk nearby. In modern times bricks are made at a brickworks

A brickworks, also known as a brick factory, is a factory for the manufacturing of bricks, from clay or shale. Usually a brickworks is located on a clay bedrock (the most common material from which bricks are made), often with a quarry for cl ...

.

"Brickyard

A brickyard or brickfield is a place or yard where bricks are made, fired, and stored, or sometimes sold or otherwise distributed from. Brick makers work in a brick yard. A brick yard may be constructed near natural sources of clay or on o ...

" can serve as a synonym of "brickfield".

Brickfield or Brickfields became a common place name in southeast England

South East England is one of the nine official regions of England at the first level of ITL for statistical purposes. It consists of the counties of Buckinghamshire, East Sussex, Hampshire, the Isle of Wight, Kent, Oxfordshire, Berkshire, ...

.

Geology

The southeast of England consists of rock strata that are more recent than most of Great Britain. It consists of a large denuded anticline, an anticline that has been eroded away leaving a series ofescarpment

An escarpment is a steep slope or long cliff that forms as a result of faulting or erosion and separates two relatively level areas having different elevations.

The terms ''scarp'' and ''scarp face'' are often used interchangeably with ''escar ...

s separated by low lying vales, The Cretaceous

The Cretaceous ( ) is a geological period that lasted from about 145 to 66 million years ago (Mya). It is the third and final period of the Mesozoic Era, as well as the longest. At around 79 million years, it is the longest geological period of th ...

ridges are known as the North Downs

The North Downs are a ridge of chalk hills in south east England that stretch from Farnham in Surrey to the White Cliffs of Dover in Kent. Much of the North Downs comprises two Areas of Outstanding Natural Beauty (AONBs): the Surrey Hills a ...

and South Downs

The South Downs are a range of chalk hills that extends for about across the south-eastern coastal counties of England from the Itchen valley of Hampshire in the west to Beachy Head, in the Eastbourne Downland Estate, East Sussex, in the east. ...

. The Downs have been cut through, with the Medway Valley being the most prominent. The Hoo peninsula

The Hoo Peninsula is a peninsula in Kent, England, separating the estuaries of the rivers Thames and Medway. It is dominated by a line of chalk, clay and sand hills, surrounded by an extensive area of marshland composed of alluvial silt. The n ...

is an Eocene

The Eocene ( ) Epoch is a geological epoch (geology), epoch that lasted from about 56 to 33.9 million years ago (mya). It is the second epoch of the Paleogene Period (geology), Period in the modern Cenozoic Era (geology), Era. The name ''Eocene' ...

( Thanet sands) ridge. The London basin

The London Basin is an elongated, roughly triangular sedimentary basin approximately long which underlies London and a large area of south east England, south eastern East Anglia and the adjacent North Sea. The basin formed as a result of compre ...

is an Eocene structure composed of London Clay

The London Clay Formation is a marine geological formation of Ypresian (early Eocene Epoch, c. 56–49 million years ago) age which crops out in the southeast of England. The London Clay is well known for its fossil content. The fossils from t ...

. All this solid geology is covered with a layer of brown structureless loam

Loam (in geology and soil science) is soil composed mostly of sand (particle size > ), silt (particle size > ), and a smaller amount of clay (particle size < ). By weight, its mineral composition is about 40–40–20% concentration of sand–sil ...

(Head), and muds deposited by the rivers. Both the head and the fluvial mud are called brickearth

Brickearth is a term originally used to describe superficial windblown deposits found in southern England. The term has been employed in English-speaking regions to describe similar deposits.

Brickearths are periglacial loess, a wind-b ...

. Water is also needed, the rivers are saline so wells and boreholes need to be dug through the three Cretaceous

The Cretaceous ( ) is a geological period that lasted from about 145 to 66 million years ago (Mya). It is the third and final period of the Mesozoic Era, as well as the longest. At around 79 million years, it is the longest geological period of th ...

chalk layers to the impermeable Gault Clay

The Gault Formation is a geological formation of stiff blue clay deposited in a calm, fairly deep-water marine environment during the Lower Cretaceous Period (Upper and Middle Albian). It is well exposed in the coastal cliffs at Copt Point in ...

.

Taking the parish of Frindsbury

Frindsbury is part of the Medway Towns conurbation in Kent, southern England. It lies on the opposite side of the River Medway to Rochester, Kent, Rochester, and at various times in its history has been considered fully or partially part of the ...

as a referenced example: about of acidic topsoil covers about of head, which lies on the alkaline Thanet Sands. There are five layers of sands with different properties – the light grey sands are themselves marketable and are used in the brickmaking process, and as moulding sand for metal foundries.

Process

A field was leased from the farmer and it was 'uncallowed' (the topsoil removed). The soil had been farmed and in the

A field was leased from the farmer and it was 'uncallowed' (the topsoil removed). The soil had been farmed and in the Medway

Medway is a unitary authority district and conurbation in Kent, South East England. It had a population of 278,016 in 2019. The unitary authority was formed in 1998 when Rochester-upon-Medway amalgamated with the Borough of Gillingham to for ...

area it had been chalked every five years with 'fat chalk' extracted from the ' dene holes'. The head, or clay was now dug from the field in winter by workers (diggers) on piecework rates. This was calculated on the volume extracted. 44 ft by 8 ft by 6 ft would make 33000 bricks. The dug clay was left exposed in heaps to weather.

Washmill

The washmill was usually a sunken circular pit that was brick lined. It was deep, and in diameter. A horse pulled a centrally pivoted beam with rakes that broke up the weathered clay and mixed it into a slurry. It was here that the correct proportion of chalk, some river mud and even rags were added. The rags would help the combustion. Clay alone would be too brittle. The popular Kentish yellows (London stock brick

London stock brick is the type of handmade brick which was used for the majority of building work in London and South East England until the growth in the use of Flettons and other machine-made bricks in the early 20th century. Its distinctive ...

s) used 10-17% of chalk. The surface of the porous yellow stock, reacted chemically with the sulphur dioxide in the polluted air to form an impermeable glaze as well as an attractive colour.

Washback

When the liquid slurry was ready it was 'laundered' along wooden pipes into square washbacks, the water seeped away leaving a stiff clay mix . This process was dependent on the weather.Brickmoulding

The brickmaking was done by 'gangs' of persons who were usually a family unit. They each had a 'berth', situated in front of a washback. It contained a bench with apugmill

A pugmill or pug mill is a machine in which clay or other materials are mixed into a plastic state or a similar machine for the trituration of ore. Industrial applications are found in pottery, bricks, cement and some parts of the concrete and asp ...

behind. The pugmill had an inlet hopper, and moved the clay mix along a six-foot tube using an Archimedes screw

The Archimedes screw, also known as the Archimedean screw, hydrodynamic screw, water screw or Egyptian screw, is one of the earliest hydraulic machines. Using Archimedes screws as water pumps (Archimedes screw pump (ASP) or screw pump) dates back ...

. The pugging process cut up the clay and made it more pliable. Pugmills were attached to a power source by lineshafts and belting.

The gang consisted of a 'temperer', who cut the clay out of the washback and loaded it into a wheeled barrow, and took it to the berth where he emptied it into the hopper. The 'flatie' took the extruded clay and rolled it in sand, and handed it to the moulder. The moulder had a rectangular mould that he sprinkled with sand, that slotted onto a base on the bench. The clay was thrown into the mould with great force. That done, tapping the mould release the newly formed brick (green brick). They were removed from the bench by the 'off bearer' who staked them next to the bench. A 'barrow loader' stacked 30 green bricks in a barrow. The 'pusher outer' wheeled the green bricks to a 'hack' where they would dry off. The hack would contain 1000 bricks stacked on boards, seven courses high. These were dried for 5 weeks losing about in weight- these were now called 'white bricks'.

Cowl

The traditional method of firing bricks was to use a cowl (or clamp). A cowl was a stack of 750 'white bricks' laid on edge, and about apart leaving channels for the fuel. The stack would be 32 courses high. The white brick stack was covered with rejected bricks that would help retain the heat. The fuel was known as 'rough stuff' or 'London mixture'. It was made in winter by 'scrying' sifting out the half burnt coal from domestic rubbish which had been retrieved from London by barge, then left to rot for a year or so. The finer ash was added to the slurry, and the larger remains used in the cowls. The cowl was fired and a 'scintler' moved outer bricks during the firing to aid airflow. The centre of the cowl fired at 900 deg C. When the firing was complete, 'sorters' dismantled the cowl. Bricks were sorted into: * First stocks – yellow facings * Second stocks – straw facings * Third stocks – interior walls * Roughs – used for footings * Burrs – used for hardcore * Chuffs – rejected Later, in the larger brickfields these cowls were replaced by permanentkiln

A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay int ...

s.

Scotch kilns

The ''updraught kiln'', also called a ''Scotch Kiln'', was rectangular and open-topped with fire holes along the bottom; it was a permanent cowl. It was filled with bricks and it allowed the hot gases to rise amongst them. The ''downdraught kiln'' was circular and about 15 ft in diameter; the hot gases rose but were deflected back down onto the bricks. This was more efficient in fuel consumption; opening ports in the roof allowed more fuel to be introduced during the firing when necessary. The Hoffmann Continuous Kiln was the first move towards mass production. It was a series of downdraught kilns, connected in a circle or in a long rectangle. Each kiln had an access channel to the next so as soon as the one kiln was fully firing process, the waste heat would begin to fire the next. The fires would thus burn around in sequence. When the firing was complete, the bricks had time to cool before they were removed. the kiln was reloaded with green bricks and in turn the kiln would be fired once more. There was always an empty kiln ready to take fresh green bricks so production was not interrupted by waiting for a firing to be completed. A kiln of this type is still in use at a brickworks in Rainham. The next development was the Long Continuous Kiln where bricks were stacked on flat wagons which were slowly passed through a chamber where hot gases could circulate around them.Brickmakers

* Eastwoods – Medway. *London Brick Company

The London Brick Company, owned by Forterra plc, is a leading British manufacturer of bricks.

History

The London Brick Company owes its origins to John Cathles Hill, a developer-architect who built houses in London and Peterborough. In 1889, H ...

References

Sources

* *{{cite report, last1=Pearce, first1=Adrian, last2=Long, first2=D, title=Chalk Mining & Associated Industries of Frindsbury, Kent, url=http://shropshirehistory.com/misc/frindsbury.pdf, archive-url=https://web.archive.org/web/20190706074425/http://shropshirehistory.com/misc/frindsbury.pdf, archive-date=6 July 2019, year=1987, id=3, website=Shropshire History, publisher=Kent Underground Research Group of the Kent Archaeological Society, oclc=18948628 Bricks 18th century in London 19th century in London