boiler explosion on:

[Wikipedia]

[Google]

[Amazon]

A boiler explosion is a

There are many causes for boiler explosions such as poor water treatment causing scaling and over heating of the plates, low water level, a stuck safety valve, or even a furnace explosion that in turn, if severe enough, can cause a boiler explosion. Poor operator training resulting in neglect or other mishandling of the boiler has been a frequent cause of explosions since the beginning of the industrial revolution. In the late 19th and early 20th century, the inspection records of various sources in the U.S., UK, and Europe showed that the most frequent cause of boiler explosions was weakening of boilers through simple rusting, by anywhere from two to five times more than all other causes.

Before materials science, inspection standards, and quality control caught up with the rapidly growing boiler manufacturing industry, a significant number of boiler explosions were directly traceable to poor design, workmanship, and undetected flaws in poor quality materials. The alarming frequency of boiler failures in the U.S. due to defects in materials and design were attracting the attention of international engineering standards organizations, such as the

There are many causes for boiler explosions such as poor water treatment causing scaling and over heating of the plates, low water level, a stuck safety valve, or even a furnace explosion that in turn, if severe enough, can cause a boiler explosion. Poor operator training resulting in neglect or other mishandling of the boiler has been a frequent cause of explosions since the beginning of the industrial revolution. In the late 19th and early 20th century, the inspection records of various sources in the U.S., UK, and Europe showed that the most frequent cause of boiler explosions was weakening of boilers through simple rusting, by anywhere from two to five times more than all other causes.

Before materials science, inspection standards, and quality control caught up with the rapidly growing boiler manufacturing industry, a significant number of boiler explosions were directly traceable to poor design, workmanship, and undetected flaws in poor quality materials. The alarming frequency of boiler failures in the U.S. due to defects in materials and design were attracting the attention of international engineering standards organizations, such as the

Hewison (1983) gives a comprehensive account of British boiler explosions, listing 137 between 1815 and 1962. It is noteworthy that 122 of these were in the 19th century and only 15 in the 20th century.

Boiler explosions generally fell into two categories. The first is the breakage of the boiler barrel itself, through weakness/damage or excessive internal pressure, resulting in sudden discharge of steam over a wide area. Stress corrosion cracking at the lap joints was a common cause of early boiler explosions, probably caused by caustic embrittlement. The water used in boilers was not often closely controlled, and if acidic, could corrode the

Hewison (1983) gives a comprehensive account of British boiler explosions, listing 137 between 1815 and 1962. It is noteworthy that 122 of these were in the 19th century and only 15 in the 20th century.

Boiler explosions generally fell into two categories. The first is the breakage of the boiler barrel itself, through weakness/damage or excessive internal pressure, resulting in sudden discharge of steam over a wide area. Stress corrosion cracking at the lap joints was a common cause of early boiler explosions, probably caused by caustic embrittlement. The water used in boilers was not often closely controlled, and if acidic, could corrode the

The ''

The ''

catastrophic failure

A catastrophic failure is a sudden and total failure from which recovery is impossible. Catastrophic failures often lead to cascading systems failure. The term is most commonly used for structural failures, but has often been extended to many ot ...

of a boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centra ...

.

There are two types of boiler explosions. One type is a failure of the pressure parts of the steam

Steam is water vapor, often mixed with air or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Saturated or superheated steam is inv ...

and water

Water is an inorganic compound with the chemical formula . It is a transparent, tasteless, odorless, and Color of water, nearly colorless chemical substance. It is the main constituent of Earth's hydrosphere and the fluids of all known liv ...

sides. There can be many different causes, such as failure of the safety valve, corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

of critical parts of the boiler, or low water level. Corrosion along the edges of lap joints was a common cause of early boiler explosions. In steam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, Fuel oil, oil or, rarely, Wood fuel, wood) to heat ...

boilers, as knowledge was gained by trial and error

Trial and error is a fundamental method of problem-solving characterized by repeated, varied attempts which are continued until success, or until the practicer stops trying.

According to W.H. Thorpe, the term was devised by C. Lloyd Morgan ( ...

in early days, the explosive situations and consequent damage due to explosions were inevitable. However, improved design and maintenance

The technical meaning of maintenance involves functional checks, servicing, repairing or replacing of necessary devices, equipment, machinery, building infrastructure and supporting utilities in industrial, business, and residential installa ...

markedly reduced the number of boiler explosions by the end of the 19th century. Further improvements continued in the 20th century. On land-based boilers, explosions of the pressure systems happened regularly in stationary steam boilers in the Victorian era

In the history of the United Kingdom and the British Empire, the Victorian era was the reign of Queen Victoria, from 20 June 1837 until her death on 22 January 1901. Slightly different definitions are sometimes used. The era followed the ...

, but are now very rare because of the various protections provided, and because of regular inspections compelled by governmental

A government is the system or group of people governing an organized community, generally a State (polity), state.

In the case of its broad associative definition, government normally consists of legislature, executive (government), execu ...

and industry requirements.

The second kind is a fuel/air explosion in the furnace, which would more properly be termed a firebox explosion. Firebox explosions in solid-fuel-fired boilers are rare, but firebox explosions in gas or oil-fired boilers are still a potential hazard.

Principle

Boiler steam explosions

Many shell-type boilers carry a large bath of liquid water which is heated to a higher temperature and pressure (enthalpy

Enthalpy () is the sum of a thermodynamic system's internal energy and the product of its pressure and volume. It is a state function in thermodynamics used in many measurements in chemical, biological, and physical systems at a constant extern ...

) than boiling water would be at atmospheric pressure. During normal operation, the liquid water remains in the bottom of the boiler due to gravity, steam bubbles rise through the liquid water and collect at the top for use until saturation pressure is reached, then the boiling stops. If some pressure is released, boiling begins again, and so on.

If steam is released normally, say by opening a throttle valve, the bubbling action of the water remains moderate and relatively dry steam can be drawn from the highest point in the vessel.

If steam is released more quickly, the more vigorous boiling action that results can throw a fine spray of droplets up as "wet steam" which can cause damage to piping, engines, turbines and other equipment downstream.

If a large crack or other opening in the boiler vessel allows the internal pressure to drop very suddenly, the heat energy remaining in the water will cause even more of the liquid to flash into steam bubbles, which then rapidly displace the remaining liquid. The potential energy of the escaping steam and water are now transformed into work, just as they would have done in an engine; with enough force to peel back the material around the break, severely distorting the shape of the plate which was formerly held in place by stays, or self-supported by its original cylindrical shape. The rapid release of steam and water can provide a very potent blast, and cause great damage to surrounding property or personnel. A failure of this type qualifies as a boiling liquid expanding vapor explosion

A boiling liquid expanding vapor explosion (BLEVE, ) is an explosion caused by the rupture of a Pressure vessel, vessel containing a Compressed fluid, pressurized liquid that has attained a temperature sufficiently higher than its boiling po ...

(BLEVE).

The rapidly expanding steam bubbles can also perform work by throwing large "slugs" of water inside the boiler in the direction of the opening, and at astonishing velocities. A fast-moving mass of water carries a great deal of kinetic energy, and in collision with the shell of the boiler results in a violent destructive effect. This can greatly enlarge the original rupture, or tear the shell in two.

Many plumbers, firefighters, and steamfitters are aware of this phenomenon, which is called "water hammer

Hydraulic shock ( colloquial: water hammer; fluid hammer) is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly: a momentum change. It is usually observed in a liquid but gases can also be aff ...

". A several-ounce "slug" of water passing through a steam line at high velocity and striking a 90-degree elbow can instantly fracture a fitting that is otherwise capable of handling several times the normal static pressure. It can then be understood that a few hundred, or even a few thousand pounds of water ''moving at the same velocity'' inside a boiler shell can easily blow out a tube sheet, collapse a firebox, even toss the entire boiler a surprising distance through reaction as the water exits the boiler, like the recoil

Recoil (often called knockback, kickback or simply kick) is the rearward thrust generated when a gun is being discharged. In technical terms, the recoil is a result of conservation of momentum, for according to Newton's third law the force requ ...

of a heavy cannon firing a ball.

Several accounts of the SL-1 experimental reactor accident vividly describe the incredibly powerful effect of water hammer on a pressure vessel:

A steam locomotive operating at would have a temperature of about , and a specific enthalpy of . Since standard pressure saturated water has a specific enthalpy of just , the difference between the two specific enthalpies, , is the total energy expended in the explosion. So in the case of a large locomotive which can hold as much as of water at a high pressure and temperature state, this explosion would have a theoretical energy release equal to about of TNT.

Firebox explosions

In the case of a firebox explosion, these typically occur after a burner flameout. Oil fumes, natural gas, propane, coal, or any other fuel can build up inside the combustion chamber. This is especially of concern when the vessel is hot; the fuels will rapidly volatilize due to the temperature. Once the lower explosive limit (LEL) is reached, any source of ignition will cause an explosion of the vapors. A fuel explosion within the confines of the firebox may damage the pressurized boiler tubes and interior shell, potentially triggering structural failure, steam or water leakage, and/or a secondary boiler shell failure andsteam explosion

A steam explosion is an explosion caused by violent boiling or flashing of water or ice into steam, occurring when water or ice is either superheated, rapidly heated by fine hot debris produced within it, or heated by the interaction of molten ...

.

A common form of minor firebox "explosion" is known as "drumming" and can occur with any type of fuel. Instead of the normal "roar" of the fire, a rhythmic series of "thumps" and flashes of fire below the grate and through the firedoor indicate that the combustion of the fuel is proceeding through a rapid series of detonations, caused by an inappropriate air/fuel mixture with regard to the level of draft available. This usually causes no damage in locomotive type boilers, but can cause cracks in masonry boiler settings if allowed to continue.

Grooving

The plates of early locomotive boilers were joined by simple overlapping joints. This practice was satisfactory for the annular joints, running around the boiler, but in longitudinal joints, along the length of the boiler, the overlap of the plates diverted the boiler cross-section from its ideal circular shape. Under pressure the boiler strained to reach, as nearly as possible, the circular cross-section. Because the double-thickness overlap was stronger than the surrounding metal, the repeated bending and release caused by the variations in boiler pressure caused internal cracks, or grooves (deep pitting), along the length of the joint. The cracks offered a starting point for internal corrosion, which could hasten failure. It was eventually found that this internal corrosion could be reduced by using plates of sufficient size so that no joints were situated below the water level.Hewison (1983: 15) Eventually the simple lap seam was replaced by the single or double butt-strap seams, which do not suffer from this defect. Due to the constant expansion and contraction of the firebox a similar form of "stress corrosion" can take place at the ends of staybolts where they enter the firebox plates, and is accelerated by poor water quality. Often referred to as "necking", this type of corrosion can reduce the strength of the staybolts until they are incapable of supporting the firebox at normal pressure. Grooving (deep, localized pitting) also occurs near the waterline, particularly in boilers that are fed with water that has not been de-aerated or treated with oxygen scavenging agents. All "natural" sources of water contain dissolved air, which is released as a gas when the water is heated. The air (which contains oxygen) collects in a layer near the surface of the water and greatly accelerates corrosion of the boiler plates in that area.Firebox

The intricate shape of a locomotive firebox, whether made of soft copper or of steel, can only resist the steam pressure on its internal walls if these are supported by stays attached to internal girders and the outer walls. They are liable to fail throughfatigue

Fatigue is a state of tiredness (which is not sleepiness), exhaustion or loss of energy. It is a signs and symptoms, symptom of any of various diseases; it is not a disease in itself.

Fatigue (in the medical sense) is sometimes associated wit ...

(because the inner and outer walls expand at different rates under the heat of the fire), from corrosion, or from wasting as the heads of the stays exposed to the fire are burned away. If the stays fail the firebox will explode inwards. Regular visual inspection, internally and externally, is employed to prevent this. Even a well-maintained firebox will fail explosively if the water level in the boiler is allowed to fall far enough to leave the top plate of the firebox (crown sheet) uncovered. This can occur when crossing the summit of the hill, as the water flows to the front part of the boiler and can expose the firebox crown sheet. The majority of locomotive explosions are firebox explosions caused by such crown sheet uncovering.

Causes

There are many causes for boiler explosions such as poor water treatment causing scaling and over heating of the plates, low water level, a stuck safety valve, or even a furnace explosion that in turn, if severe enough, can cause a boiler explosion. Poor operator training resulting in neglect or other mishandling of the boiler has been a frequent cause of explosions since the beginning of the industrial revolution. In the late 19th and early 20th century, the inspection records of various sources in the U.S., UK, and Europe showed that the most frequent cause of boiler explosions was weakening of boilers through simple rusting, by anywhere from two to five times more than all other causes.

Before materials science, inspection standards, and quality control caught up with the rapidly growing boiler manufacturing industry, a significant number of boiler explosions were directly traceable to poor design, workmanship, and undetected flaws in poor quality materials. The alarming frequency of boiler failures in the U.S. due to defects in materials and design were attracting the attention of international engineering standards organizations, such as the

There are many causes for boiler explosions such as poor water treatment causing scaling and over heating of the plates, low water level, a stuck safety valve, or even a furnace explosion that in turn, if severe enough, can cause a boiler explosion. Poor operator training resulting in neglect or other mishandling of the boiler has been a frequent cause of explosions since the beginning of the industrial revolution. In the late 19th and early 20th century, the inspection records of various sources in the U.S., UK, and Europe showed that the most frequent cause of boiler explosions was weakening of boilers through simple rusting, by anywhere from two to five times more than all other causes.

Before materials science, inspection standards, and quality control caught up with the rapidly growing boiler manufacturing industry, a significant number of boiler explosions were directly traceable to poor design, workmanship, and undetected flaws in poor quality materials. The alarming frequency of boiler failures in the U.S. due to defects in materials and design were attracting the attention of international engineering standards organizations, such as the ASME

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing edu ...

, which established their first Boiler Testing Code in 1884. The boiler explosion that caused the Grover Shoe Factory disaster in Brockton, Massachusetts, on 10 March 1905, resulted in 58 deaths and 150 injuries, and inspired the state of Massachusetts to publish its first boiler laws in 1908.

Several written sources provide a concise description of the causes of boiler explosions:

And:

Early investigations into causes

Thestationary steam engine

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam car ...

s used to power machinery first came to prominence during the Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

, and in the early days there were many boiler explosions from a variety of causes. One of the first investigators of the problem was William Fairbairn, who helped establish the first insurance company dealing with the losses such explosions could cause. He also established experimentally that the hoop stress in a cylindrical pressure vessel like a boiler was twice the longitudinal stress. Fairbairn's theoretical calculation assumes that the cylindrical vessel is much longer than its diameter. In practice, this is a viable approximation for any boiler that is a right cylinder or longer. Even for a short, squat boiler such as the Scotch, the reduced end area due to the tubes and their staying effect on the end-plates means that the principal stress is still this hoop stress. Such investigations helped him and others explain the importance of stress concentrations in weakening boilers.

While deterioration and mishandling are probably the most common ''causes'' of boiler explosions, the actual ''mechanism'' of a catastrophic boiler failure was not well documented until extensive experimentation was undertaken by U.S. boiler inspectors in the early 20th century. Several different attempts were made to cause a boiler to explode by various means, but one of the most interesting experiments demonstrated that in certain circumstances, if a sudden opening in the boiler allowed steam to escape too rapidly, water hammer

Hydraulic shock ( colloquial: water hammer; fluid hammer) is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly: a momentum change. It is usually observed in a liquid but gases can also be aff ...

could cause destruction of the entire pressure vessel:

But the highly destructive mechanism of water hammer

Hydraulic shock ( colloquial: water hammer; fluid hammer) is a pressure surge or wave caused when a fluid in motion is forced to stop or change direction suddenly: a momentum change. It is usually observed in a liquid but gases can also be aff ...

in boiler explosions was understood long before then, as D. K. Clark wrote on 10 February 1860, in a letter to the editors of ''Mechanics Magazine'':

Boiler explosions are common in sinking ships once the hot boiler touches cold sea water, as the sudden cooling of the hot metal causes it to crack; for instance, when the was torpedoed by a U-boat, the torpedoes and resulting boiler explosion caused the ship to go down in two minutes, leaving Poon Lim as the only survivor in a complement of 53 crew.

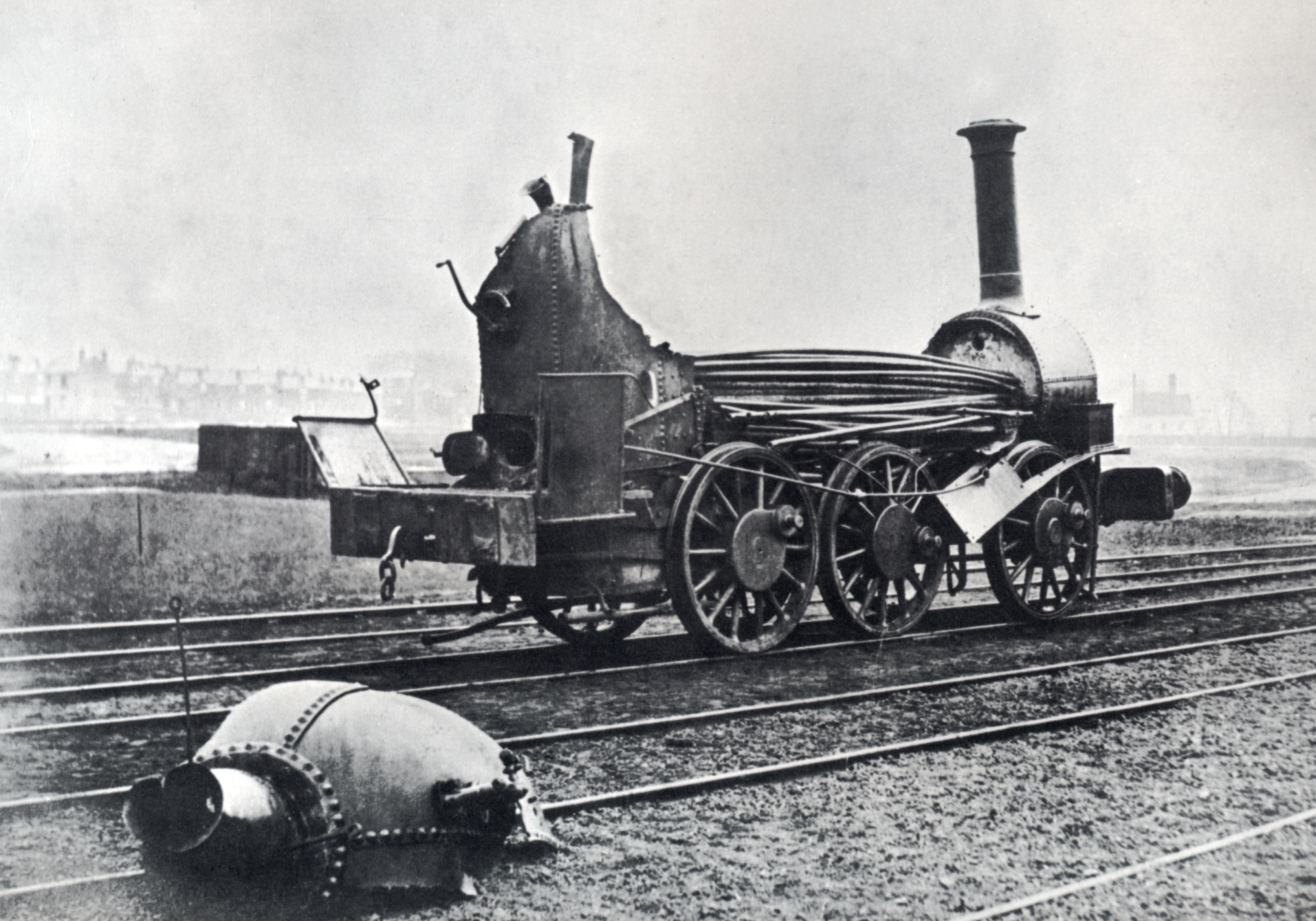

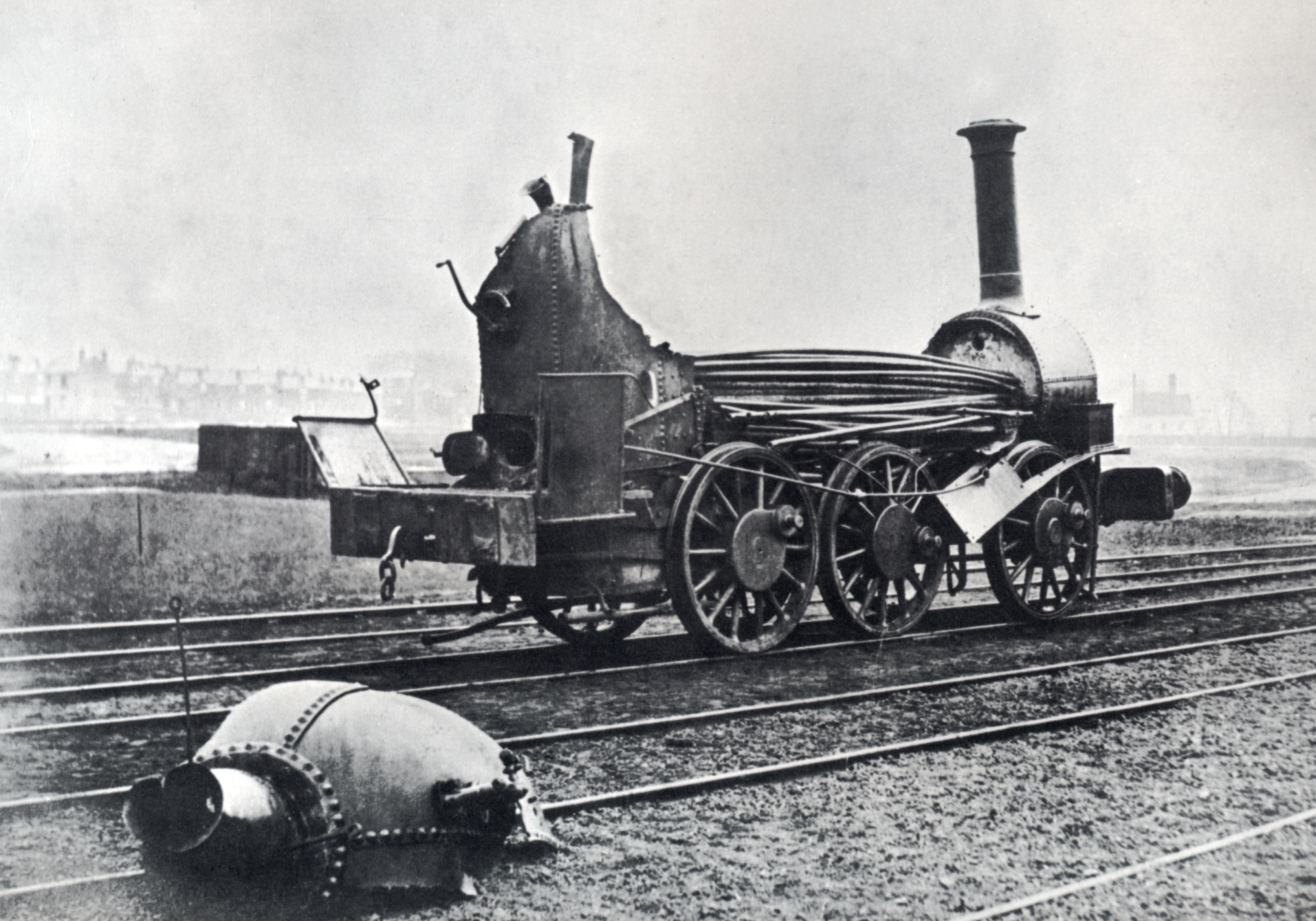

In locomotives

Boiler explosions are of a particular danger in (locomotive-type) fire tube boilers because the top of the firebox (crown sheet) must be covered with some amount of water at all times; or the heat of the fire can weaken the crown sheet or crown stays to the point of failure, ''even at normal working pressure''. This was the cause of the Gettysburg Railroad firebox explosion near Gardners, Pennsylvania, in 1995, where low water allowed the front of the crown sheet to overheat until the regular crown stays pulled through the sheet, releasing a great deal of steam and water under full boiler pressure into the firebox. The crown sheet design included several alternating rows of button-head safety stays, which limited the failure of the crown sheet to the first five or six rows of conventional stays, preventing a collapse of the entire crown sheet. This type of failure is not limited to railway engines, as locomotive-type boilers have been used for traction engines, portable engines, skid engines used for mining or logging, stationary engines for sawmills and factories, for heating, and as package boilers providing steam for other processes. In all applications, maintaining the proper water level is essential for safe operation. Hewison (1983) gives a comprehensive account of British boiler explosions, listing 137 between 1815 and 1962. It is noteworthy that 122 of these were in the 19th century and only 15 in the 20th century.

Boiler explosions generally fell into two categories. The first is the breakage of the boiler barrel itself, through weakness/damage or excessive internal pressure, resulting in sudden discharge of steam over a wide area. Stress corrosion cracking at the lap joints was a common cause of early boiler explosions, probably caused by caustic embrittlement. The water used in boilers was not often closely controlled, and if acidic, could corrode the

Hewison (1983) gives a comprehensive account of British boiler explosions, listing 137 between 1815 and 1962. It is noteworthy that 122 of these were in the 19th century and only 15 in the 20th century.

Boiler explosions generally fell into two categories. The first is the breakage of the boiler barrel itself, through weakness/damage or excessive internal pressure, resulting in sudden discharge of steam over a wide area. Stress corrosion cracking at the lap joints was a common cause of early boiler explosions, probably caused by caustic embrittlement. The water used in boilers was not often closely controlled, and if acidic, could corrode the wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.05%) in contrast to that of cast iron (2.1% to 4.5%), or 0.25 for low carbon "mild" steel. Wrought iron is manufactured by heating and melting high carbon cast iron in an ...

boiler plates. Galvanic corrosion

Galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, different metal, when both in the prese ...

was an additional problem where copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

and iron were in contact. Boiler plates have been thrown up to a quarter of a mile (Hewison, Rolt). The second type is the collapse of the firebox under steam pressure from the adjoining boiler, releasing flames and hot gases into the cab. Improved design and maintenance almost totally eliminated the first type, but the second type is always possible if the driver and fireman do not maintain the water level in the boiler.

Boiler barrels could explode if the internal pressure became too high. To prevent this, safety valves were installed to release the pressure at a set level. Early examples were spring-loaded, but John Ramsbottom invented a tamper-proof valve which was universally adopted. The other common cause of explosions was internal corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

which weakened the boiler barrel so that it could not withstand normal operating pressure. In particular, grooves could occur along horizontal seams (lap joints) below water level. Dozens of explosions resulted, but were eliminated by 1900 by the adoption of butt joints, plus improved maintenance schedules and regular hydraulic testing.

Fireboxes were generally made of copper

Copper is a chemical element; it has symbol Cu (from Latin ) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orang ...

, though later locomotives had steel

Steel is an alloy of iron and carbon that demonstrates improved mechanical properties compared to the pure form of iron. Due to steel's high Young's modulus, elastic modulus, Yield (engineering), yield strength, Fracture, fracture strength a ...

fireboxes. They were held to the outer part of the boiler by stays (numerous small supports). Parts of the firebox in contact with full steam pressure have to be kept covered with water, to stop them overheating and weakening. The usual cause of firebox collapses is that the boiler water level falls too low and the top of the firebox (crown sheet) becomes uncovered and overheats. This occurs if the fireman has failed to maintain water level or the level indicator (gauge glass) is faulty. A less common reason is breakage of large numbers of stays, due to corrosion or unsuitable material.

Throughout the 20th century, two boiler barrel failures and thirteen firebox collapses occurred in the UK. The boiler barrel failures occurred at Cardiff in 1909 and Buxton in 1921; both were caused by misassembly of the safety valves causing the boilers to exceed their design pressures. Of the 13 firebox collapses, four were due to broken stays, one to scale buildup on the firebox, and the rest were due to low water level.

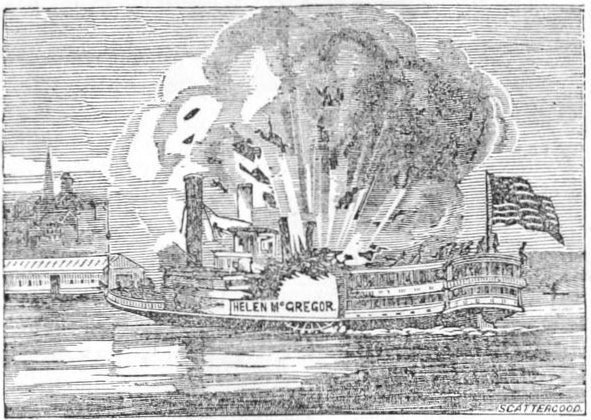

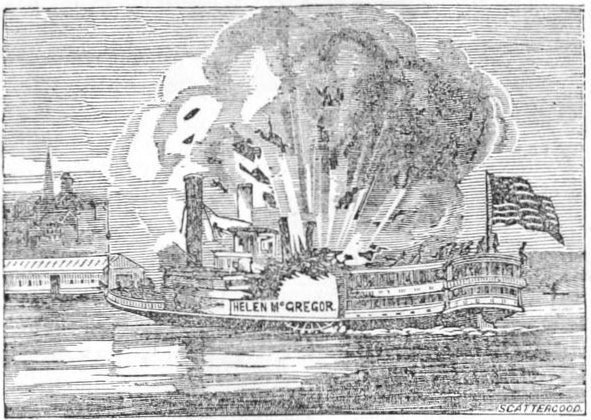

Steamboat boilers

The ''

The ''Pennsylvania

Pennsylvania, officially the Commonwealth of Pennsylvania, is a U.S. state, state spanning the Mid-Atlantic (United States), Mid-Atlantic, Northeastern United States, Northeastern, Appalachian, and Great Lakes region, Great Lakes regions o ...

'' was a side wheeler steamboat

A steamboat is a boat that is marine propulsion, propelled primarily by marine steam engine, steam power, typically driving propellers or Paddle steamer, paddlewheels. The term ''steamboat'' is used to refer to small steam-powered vessels worki ...

which suffered a boiler explosion in the Mississippi River and sank at Ship Island near Memphis, Tennessee

Memphis is a city in Shelby County, Tennessee, United States, and its county seat. Situated along the Mississippi River, it had a population of 633,104 at the 2020 United States census, 2020 census, making it the List of municipalities in Tenne ...

, on 13 June 1858. Of the 450 passengers on board more than 250 died, including Henry Clemens, the younger brother of the author Mark Twain

Samuel Langhorne Clemens (November 30, 1835 – April 21, 1910), known by the pen name Mark Twain, was an American writer, humorist, and essayist. He was praised as the "greatest humorist the United States has produced," with William Fau ...

.

, a small steamboat used to transfer passengers and cargo to and from the large coastal steamship

A steamship, often referred to as a steamer, is a type of steam-powered vessel, typically ocean-faring and seaworthy, that is propelled by one or more steam engines that typically move (turn) propellers or paddlewheels. The first steamships ...

s that stopped in San Pedro Harbor in the early 1860s, suffered disaster when its boiler exploded violently in San Pedro Bay, the port of Los Angeles

The Port of Los Angeles is a seaport managed by the Los Angeles Harbor Department, a unit of the Los Angeles, City of Los Angeles. It occupies of land and water with of waterfront and adjoins the separate Port of Long Beach. Promoted as "Amer ...

, near Wilmington, California, on 27 April 1863, killing twenty-six people and injuring many others of the fifty-three or more passengers on board.

The steamboat ''Sultana'' was destroyed in an explosion on 27 April 1865, resulting in the greatest maritime disaster in United States history. An estimated 1,549 passengers were killed when three of the ship's four boilers exploded and the ''Sultana'' burned and sank not far from Memphis, Tennessee. The cause was traced to a poorly executed repair to the shell of one boiler; the patch failed, and debris from that boiler ruptured two more.

Another US Civil War steamboat explosion was the steamer ''Eclipse'' on 27 January 1865, which was carrying members of the 9th Indiana Artillery. One official record reports 10 killed and 68 injured; a later report mentions that 27 were killed and 78 wounded. Fox's ''Regimental Losses'' reports 29 killed.

The boiler of Canada's '' PS Waubuno'' may have exploded on the ship's final voyage in 1879, though the cause of the sinking remains unknown. An explosion could have occurred due to negligent upkeep or to contact with the cold water of Georgian Bay while foundering in a storm.

Nuclear reactor explosions

A steam explosion can occur in any kind of a water heater, where a sufficient amount of energy is delivered and the steam created exceeds the strength of the vessel. When the heat delivery is sufficiently rapid, a localized superheating can occur, resulting in a water hammer destroying the vessel. The SL-1 nuclear reactor accident is an example of a superheated burst of steam. However, in the SL-1 example the pressure was released by the forced ejection of control rods which allowed the steam to be vented. The reactor did not explode, nor did the vessel rupture.Modern boilers

Modern boilers are designed with redundant pumps, valves, water level monitors, fuel cutoffs, automated controls, and pressure relief valves. In addition, the construction must adhere to strict engineering guidelines set by the relevant authorities. The NBIC,ASME

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing edu ...

, and others attempt to ensure safe boiler designs by publishing detailed standards. The result is a boiler unit which is less prone to catastrophic accidents.

Also improving safety is the increasing use of "package boilers". These are boilers which are built at a factory then shipped out as a complete unit to the job site. These typically have better quality and fewer issues than boilers which are site assembled tube-by-tube. A package boiler only needs the final connections to be made (electrical, breaching, condensate lines, etc.) to complete the installation.

Key safety developments

Notable accidents

See also

* Fusible plug * John Hick * Lists of rail accidentsNotes

Bibliography

* * *References

Further reading

* Bartrip, P. W. J. "The state and the steam boiler in Britain". ''International review of social history'' 25, 1980, 77–105. Government intervention and the role of interest groups in 19th century Britain in regard to stationary boilers. * Winship, I. R. "The decline in locomotive boiler explosions in Britain 1850–1900". ''Transactions – Newcomen Society'' 60, 1988–89, 73–94. Technical and other factors that reduced the incidence of explosions.External links

{{Rail accidents Boilers Explosion protection Steam power