A loom is a device used to

weave cloth and

tapestry

Tapestry is a form of Textile arts, textile art which was traditionally Weaving, woven by hand on a loom. Normally it is used to create images rather than patterns. Tapestry is relatively fragile, and difficult to make, so most historical piece ...

. The basic purpose of any loom is to hold the

warp threads under

tension to facilitate the interweaving of the

weft

In the manufacture of cloth, warp and weft are the two basic components in weaving to transform thread (yarn), thread and yarn into textile fabrics. The vertical ''warp'' yarns are held stationary in tension on a loom (frame) while the horizo ...

threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Etymology and usage

The word "loom" derives from the

Old English

Old English ( or , or ), or Anglo-Saxon, is the earliest recorded form of the English language, spoken in England and southern and eastern Scotland in the Early Middle Ages. It developed from the languages brought to Great Britain by Anglo-S ...

''geloma'', formed from ''ge-'' (perfective prefix) and ''loma'', a root of unknown origin; the whole word ''geloma'' meant a utensil, tool, or machine of any kind. In 1404 "lome" was used to mean a machine to enable weaving thread into cloth.

By 1838 "loom" had gained the additional meaning of a machine for interlacing thread.

Components and actions

Basic structure

File:Simple_treadle_floorloom,_line_drawing.png, upright=1.5, left, A simple treadle floor loom. Mouse over components for pop-up links. The warp runs horizontally. On the left the warp beam, held from turning by with a weighted trough to keep the warp taut; on the right, the cloth beam (also called a ''breast beam'' on this type of loom), with a pawl and ratchet to allow the weaver to roll up the fell. In the center, devices for performing the motions of weaving.

poly 735 1063 1335 731 1488 825 1016 1148 Lease rods

poly 1360 808 1904 553 1921 1152 1399 1437 Heddles and heddle frames or harness

poly 2036 510 1998 1386 2678 812 2614 315 Batten bar or beater bar

poly 2155 1063 2538 799 2542 888 2164 1161 Reed

Reed or Reeds may refer to:

Science, technology, biology, and medicine

* Reed bird (disambiguation)

* Reed pen, writing implement in use since ancient times

* Reed (plant), one of several tall, grass-like wetland plants of the order Poales

* Re ...

poly 2648 816 2559 922 2627 961 2721 876 Shuttle

poly 1611 1590 1462 1836 2780 2023 2993 1768 Treadle

A treadle (from , "to tread") is a foot-powered lever mechanism; it is operated by treading on it repeatedly. A treadle, unlike some other types of pedals, is not directly mounted on the crank (see treadle bicycle for a clear example).

Most ...

s

poly 2729 829 2470 1058 2491 1271 2835 969 2831 820 Breast beam

poly 327 990 336 1186 999 897 1024 799 973 723 Warp beam

desc bottom-left

Weaving is done on two sets of threads or yarns, which cross one another. The

warp threads are the ones stretched on the loom (from the

Proto-Indo-European

Proto-Indo-European (PIE) is the reconstructed common ancestor of the Indo-European language family. No direct record of Proto-Indo-European exists; its proposed features have been derived by linguistic reconstruction from documented Indo-Euro ...

*''

werp'', "to bend"). Each thread of the

weft

In the manufacture of cloth, warp and weft are the two basic components in weaving to transform thread (yarn), thread and yarn into textile fabrics. The vertical ''warp'' yarns are held stationary in tension on a loom (frame) while the horizo ...

(i.e. "that which is woven") is inserted so that it passes over and under the warp threads.

The ends of the warp threads are usually fastened to beams. One end is fastened to one beam, the other end to a second beam, so that the warp threads all lie parallel and are all the same length. The beams are held apart to keep the warp threads taut.

The textile is woven starting at one end of the warp threads, and progressing towards the other end. The beam on the finished-fabric end is called the ''cloth beam''. The other beam is called the ''warp beam''.

Beams may be used as rollers to allow the weaver to weave a piece of cloth longer than the loom. As the cloth is woven, the warp threads are gradually unrolled from the warp beam, and the woven portion of the cloth is rolled up onto the cloth beam (which is also called the ''takeup roll''). The portion of the fabric that has already been formed but not yet rolled up on the takeup roll is called the ''fell''.

Not all looms have two beams. For instance, warp-weighted looms have only one beam; the warp yarns hang from this beam. The bottom ends of the warp yarns are tied to dangling loom weights.

File:Weaving demonstrated on a historic loom in Leiden.webm, thumbtime=12, Weaving demonstration on an 1830 handloom in the weaving museum in Leiden

Leiden ( ; ; in English language, English and Archaism, archaic Dutch language, Dutch also Leyden) is a List of cities in the Netherlands by province, city and List of municipalities of the Netherlands, municipality in the Provinces of the Nethe ...

Motions

A loom has to perform three principal motions: shedding, picking, and battening.

*Shedding. Shedding is pulling part of the

warp threads aside to form a

shed

A shed is typically a simple, single-storey (though some sheds may have two or more stories and or a loft) roofed structure, often used for storage, for hobby, hobbies, or as a workshop, and typically serving as outbuilding, such as in a bac ...

(the space between the raised and unraised warp yarns). The shed is the space through which the filling yarn, carried by the shuttle, can be inserted, forming the weft.

**Sheds may be simple: for instance, lifting all the odd threads and all the even threads alternately produces a

tabby weave (the two sheds are called the shed and countershed). More intricate shedding sequences can produce more complex weaves, such as

twill

Twill is a type of textile

Textile is an Hyponymy and hypernymy, umbrella term that includes various Fiber, fiber-based materials, including fibers, yarns, Staple (textiles)#Filament fiber, filaments, Thread (yarn), threads, and d ...

.

*Picking. A single crossing of the weft thread from one side of the loom to the other, through the shed, is known as a pick. Picking is passing the weft through the shed. A new shed is then formed before a new pick is inserted.

**Conventional shuttle looms can operate at speeds of about 150 to 160 picks per minute.

[.]

*Battening. After the pick, the new pass of weft thread has to be tamped up against the fell, to avoid making a fabric with large, irregular gaps between the weft threads. This compression of the weft threads is called battening.

There are also usually two secondary motions, because the newly constructed fabric must be wound onto cloth beam. This process is called taking up. At the same time, the warp yarns must be let off or released from the warp beam, unwinding from it. To become fully automatic, a loom needs a tertiary motion, the filling stop motion. This will brake the loom if the weft thread breaks.

An automatic loom requires 0.125 hp to 0.5 hp to operate (100W to 400W).

Components

A loom, then, usually needs two beams, and some way to hold them apart. It generally has additional components to make shedding, picking, and battening faster and easier. There are also often components to help take up the fell.

The nature of the loom frame and the shedding, picking, and battening devices vary. Looms come in a wide variety of types, many of them specialized for specific types of weaving. They are also specialized for the lifestyle of the weaver. For instance, nomadic weavers tend to use lighter, more portable looms, while weavers living in cramped city dwellings are more likely to use a tall upright loom, or a loom that folds into a narrow space when not in use.

Shedding methods

It is possible to weave by manually threading the weft over and under the warp threads, but this is slow. Some tapestry techniques use manual shedding.

Pin loom

Pin weaving is a form of small-scale weaving traditionally done on a frame made of pins; the warp and weft are wrapped around the pins. Pin-woven textiles have a selvage edge all the way around.

Pin looms were popular from the 1930s to the 1960 ...

s and

peg loom

A peg loom is a simple weaving loom. Handheld weaving sticks use the same principle.

A peg loom is a board, usually wooden, with one or more rows of holes, and a set of wooden or nylon pegs which fit into these holes. Each peg is a dowel with a h ...

s also generally have no shedding devices.

Pile carpets generally do not use shedding for the pile, because each pile thread is individually knotted onto the warps, but there may be shedding for the weft holding the carpet together.

Usually weaving uses shedding devices. These devices pull some of the warp threads to each side, so that a shed is formed between them, and the weft is passed through the shed. There are a variety of methods for forming the shed. At least two sheds must be formed, the shed and the countershed. Two sheds is enough for

tabby weave; more complex weaves, such as

twill weaves,

satin weave

A satin weave is a type of fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamental types ...

s,

diaper weaves, and figured (picture-forming) weaves, require more sheds.

Heddle-bar and shed-rod

Heddle-rods and shedding-sticks are not the fastest way to weave, but they are very simple to make, needing only sticks and yarn. They are often used on vertical

and backstrap looms.

They allow the creation of elaborate supplementary-weft

brocade

Brocade () is a class of richly decorative shuttle (weaving), shuttle-woven fabrics, often made in coloured silks and sometimes with gold and silver threads. The name, related to the same root as the word "broccoli", comes from Italian langua ...

s.

They are also used on modern tapestry looms; the frequent changing of weft colour in tapestry makes weaving tapestry slow, so using faster, more complex shedding systems isn't worthwhile. The same is true of looms for handmade

knotted-pile carpet; hand-knotting each pile thread to the warp takes far more time than weaving a couple of weft threads to hold the pile in place.

At its simplest, a heddle-bar is simply a stick placed across the warp and tied to individual warp threads. It is not tied to ''all'' of the warp threads; for a plain

tabby weave, it is tied to every other thread. The little loops of string used to tie the wraps to the heddle bar are called ''heddles'' or ''leashes''. When the heddle-bar is pulled perpendicular to the warp, it pulls the warp threads it is tied to out of position, creating a shed.

A

warp-weighted loom (see diagram) typically uses a heddle-bar, or several. It has two upright ''posts'' (C); they support a horizontal ''beam'' (D), which is cylindrical so that the finished cloth can be rolled around it, allowing the loom to be used to weave a piece of cloth taller than the loom, and preserving an ergonomic working height. The warp threads (F, and A and B) hang from the beam and rest against the ''shed rod'' (E). The ''heddle-bar'' (G) is tied to some of the warp threads (A, but not B), using loops of string called ''leashes'' (H). So when the heddle rod is pulled out and placed in the forked sticks protruding from the posts (not lettered, no technical term given in citation), the ''shed'' (1) is replaced by the ''counter-shed'' (2). By passing the weft through the shed and the counter-shed, alternately, cloth is woven.

Several heddle-bars can be used side-by-side; three or more can be used to weave

twill weaves, for instance.

There are also other ways to create counter-sheds. A shed-rod is simpler and easier to set up than a heddle-bar, and can make a counter-shed. A shed-rod (shedding stick, shed roll) is simply a stick woven through the warp threads. When pulled perpendicular to the threads (or rotated to stand on edge, for wide, flat shedding rods), it creates a counter shed. The combination of a heddle-bar and a shedding-stick can create the shed and countershed needed for a plain tabby weave, as in the video.

There are also slitted heddle-rods, which are sawn partway through, with evenly-placed slits. Each warp thread goes in a slit. The odd-numbered slits are at 90 degrees to the even slits. The rod is rotated back and forth to create the shed and countershed,

so it is often large-diameter.

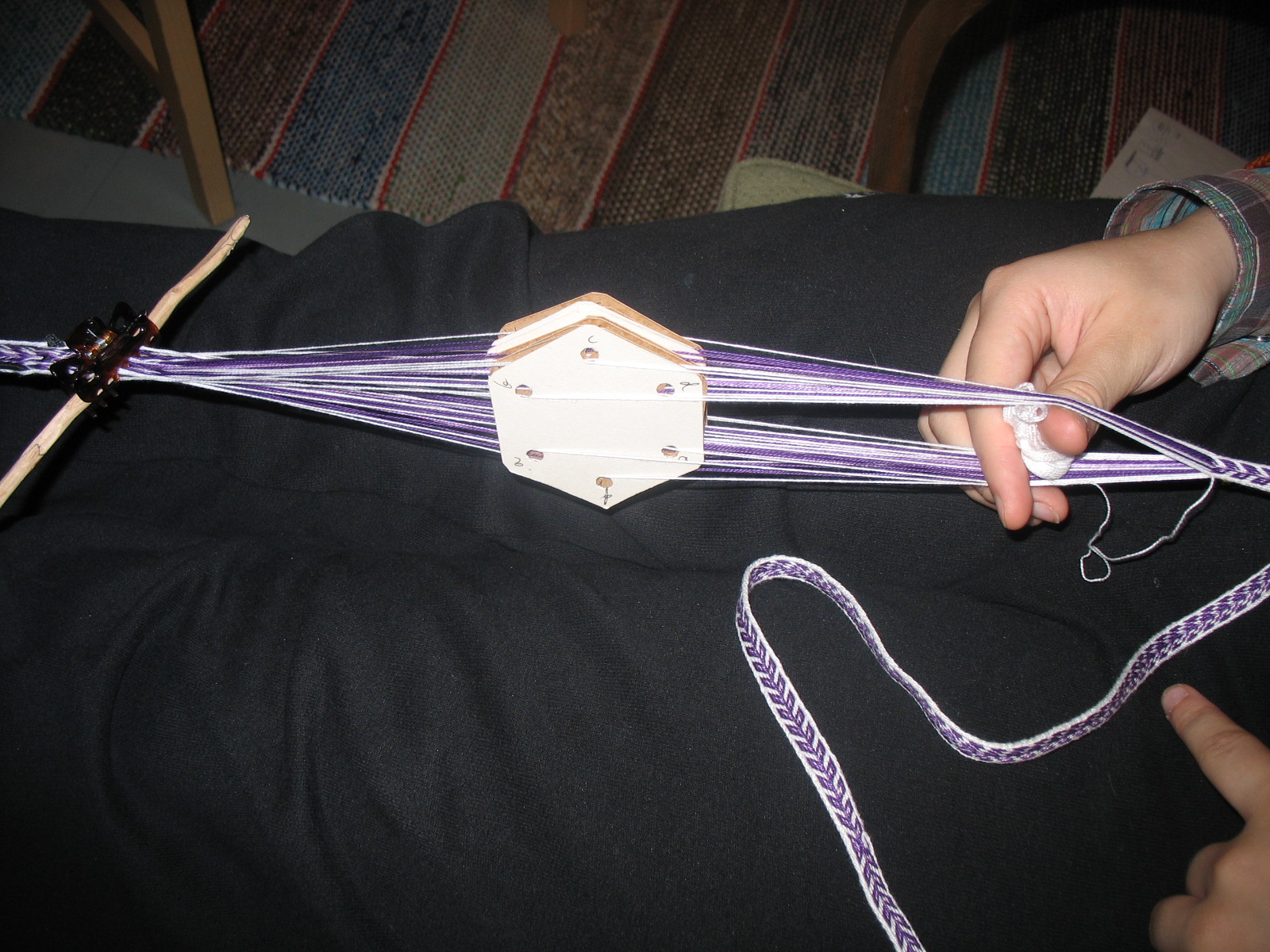

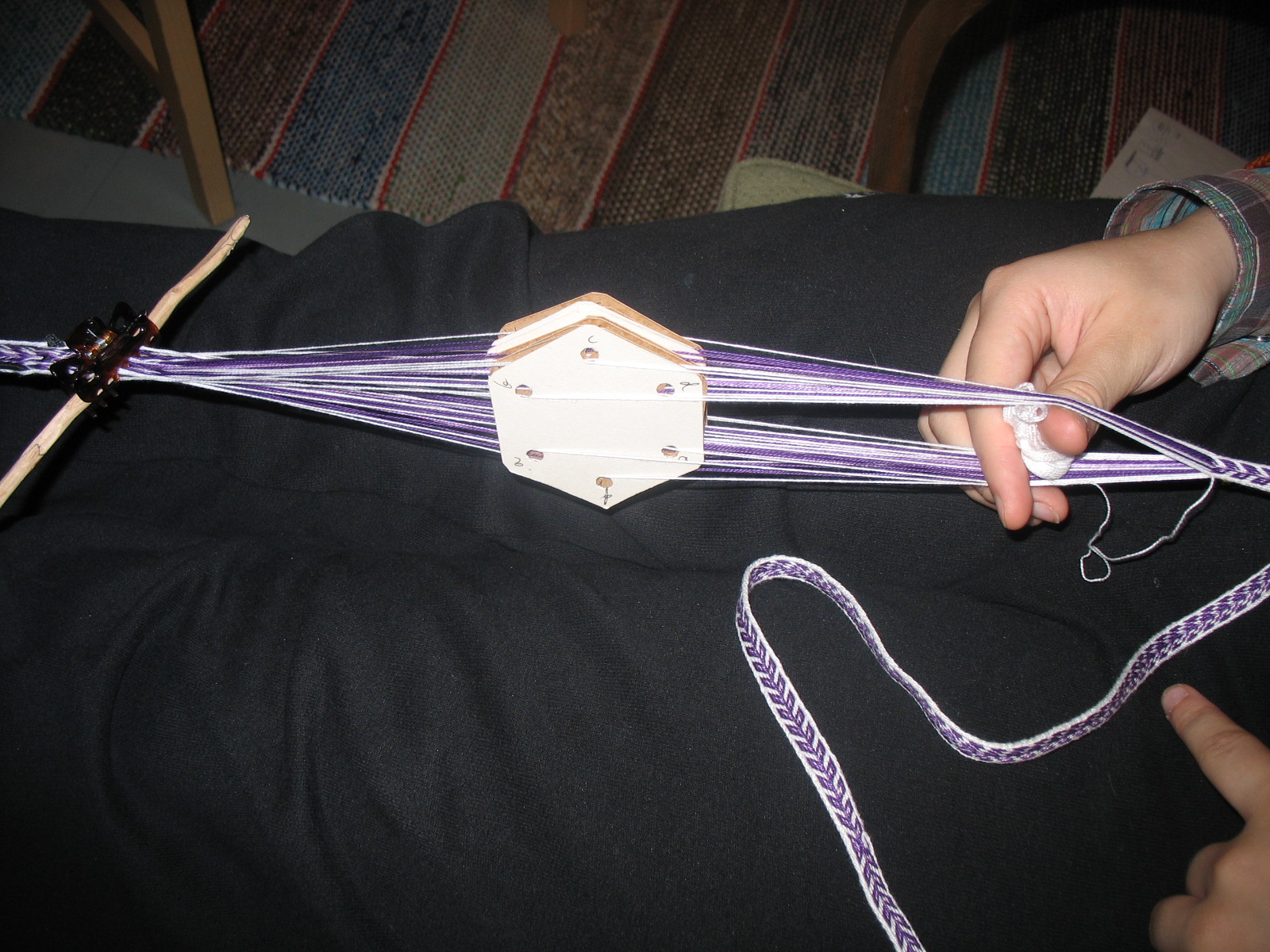

Tablet weaving

Tablet weaving

Tablet weaving (often card weaving in the United States) is a weaving technique where ''tablets'' or ''cards'' are used to create the Shed (weaving), shed through which the weft is passed. As the materials and tools are relatively cheap and ea ...

uses cards punched with holes. The warp threads pass through the holes, and the cards are twisted and shifted to created varied sheds. This shedding technique is used for

narrow work. It is also used to finish edges, weaving decorative selvage bands instead of hemming.

Rotating-hook heddles

There are heddles made of flip-flopping rotating hooks, which raise and lower the warp, creating

sheds. The hooks, when vertical, have the weft threads looped around them horizontally. If the hooks are flopped over on side or another, the loop of weft twists, raising one or the other side of the loop, which creates the

shed

A shed is typically a simple, single-storey (though some sheds may have two or more stories and or a loft) roofed structure, often used for storage, for hobby, hobbies, or as a workshop, and typically serving as outbuilding, such as in a bac ...

and countershed.

Rigid heddles

Rigid

heddle

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." '' ...

s are generally used on single-shaft looms. Odd warp threads go through the slots, and even ones through the circular holes, or vice versa. The shed is formed by lifting the heddle, and the countershed by depressing it. The warp threads in the slots stay where they are, and the ones in the circular holes are pulled back and forth. A single rigid heddle can hold all the warp threads, though sometimes multiple rigid heddles are used.

Treadles may be used to drive the rigid heddle up and down.

Non-rigid heddles

File:QSMM Heald making 2623sc.JPG, String healds, with a small eyelet called a mail in the middle of the red section, and larger lops on either side

File:QSMM Drawing-in 2653.JPG, Very similar healds, with the wooden staves threaded through them top and bottom, and the warp threads in the process of being ''drawn in'' (that is, threaded through the eyes of the healds)

File:Solv med öga.svg, How healds can thread onto staves and the warp threads (Swedish caption shows eye, and warp thread)

File:QSMM Pemberton loom 2581c.JPG, Wire healds on wire staves. A few extra healds have not had warp threads drawn in through them.

File:Heddle4.jpg, A variety of metal healds, made from wire and straps

Rigid heddles or (above) are called "rigid" to distinguish them from string and wire heddles. Rigid heddles are one-piece, by non-rigid ones are multi-piece. Each warp thread has its own heald (also, confusingly, called a heddle). The heald has an eyelet at each end (for the staves, also called shafts) and one in the middle, called the mail, (for the warp thread). A row of these healds is slid onto two staves, the upper and lower staves; the staves together, or the staves together with the healds, may be called a ''heald frame'', which is, confusingly, also called a shaft and a harness. Replaceable, interchangeable healds can be smaller, allowing finer weaves.

Unlike a rigid heddle, a flexible heddle cannot push the warp thread. This means that two heald frames are needed even for a plain

tabby weave.

Twill weaves require three or more heald frames (depending on the type of twill), and more complex figured weaves require still more frames.

The different heald frames must be controlled by some mechanism, and the mechanism must be able to pull them in both directions. They are mostly controlled by treadles; creating the shed with the feet leaves the hands free to ply the shuttle. However in some tabletop looms, heald frames are also controlled by levers.

Treadle-controlled looms

In treadle looms, the weaver controls the shedding with their feet, by treading on

treadle

A treadle (from , "to tread") is a foot-powered lever mechanism; it is operated by treading on it repeatedly. A treadle, unlike some other types of pedals, is not directly mounted on the crank (see treadle bicycle for a clear example).

Most ...

s. Different treadles and combinations of treadles produce different sheds. The weaver must remember the sequence of treadling needed to produce the pattern.

The precise mechanism by which the treadles control the heddles varies. Rigid-heddle treadle looms do exist, but the heddles are usually flexible. Sometimes, the treadles are tied directly to the staves (with a Y-shaped bridle so they stay level). Alternately, they may be tied to a stick called a ''lamm'', which in turn is tied to the stave, to make the motion more controlled and regular. The lamm may pivot or slide.

Counterbalance looms are the most common type of treadle loom globally, as they are simple and give a smooth, quiet, quick motion.

The heald frames are joined together in pairs, by a cord running over heddle pulleys or a heddle roller. When one heald frame rises, the other falls. It takes a pair of treadles to control a pair of frames. Counterbalance looms are usually used with two or four frames, though some have as many as ten.

In theory each pair of heald frames has to have an equal number to warps pulled by each frame, so the patterns that can be made on them are limited.

In practice, fairly unbalanced tie-ups just make the shed a bit smaller, and as the shed on a counterbalance loom is adjustable in size and quite large to start with (compared to other types of loom), so it is entirely possible to weave good cloth on a counterbalance loom with unbalanced heald frames,

unless the loom is extremely shallow (that is, the length of warp being pulled on is short, less than 1 meter or 3 feet), which exacerbates the slightly uneven tension.

Limited patterns are not, of course, a disadvantage when weaving plainer patterns, such as tabbies and twills.

Jack looms (also called single-tieup-looms and rising-shed looms

), have their treadles connected to jacks, levers that push or pull the heald frames up; the harnesses are weighted to fall back into place by gravity. Several frames can be connected to a single treadle. Frames can also be raised by more than one treadle. This allows treadles to control arbitrary

combination

In mathematics, a combination is a selection of items from a set that has distinct members, such that the order of selection does not matter (unlike permutations). For example, given three fruits, say an apple, an orange and a pear, there are ...

s of frames, which vastly increases the number of different sheds that can be created from the same number of frames. Any number of treadles can also be engaged at once, meaning that the number of different sheds that can be selected is two

to the power of the number of treadles. Eight is a large but reasonable number of treadles, giving a maximum of 2

8=256 sheds (some of which will probably not have enough threads on one side to be useful). Having more possible sheds allows more complex patterns,

such as

diaper weaves.

Jack looms are easy to make and to tie up (if not quite as easy as counterbalance looms). The gravity return makes jack looms heavy to operate. The shed of a jack loom is smaller for a given length of warp being pulled aside by the heddles (loom depth). The warp threads being pulled up by the jacks are also tauter than the other warp threads (unlike a counter balance loom, where the threads are pulled an equal amount in opposite directions). Uneven tension makes weaving evenly harder. It also lowers the maximum tension at which one can practically weave.

If the threads are rough, closely-spaced, very long or numerous, it can be hard to open the sheds on the jack loom.

Jack looms without castles (the superstructure above the weft) have to lift the heald frames from below, and are noiser due to the impact of wood on wood;

elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''ela ...

pads can reduce the noise.

In

countermarch looms, the treadles are tied to lamms,

which may pivot at one end or slide up and down. Half of the lamms in turn connect to jacks, which also pivot, and push or pull the staves up or down.

Some countermarches have two horizontal jacks per shaft, others a single vertical jack.

Each treadle is tied to ''all'' of the heald frames, moving some of them up and the rest of them down.

This allows the complex

combinatorial

Combinatorics is an area of mathematics primarily concerned with counting, both as a means and as an end to obtaining results, and certain properties of finite structures. It is closely related to many other areas of mathematics and has many ...

treadles of a jack loom, with the large shed and balanced, even tension of a counterbalance loom, with its quiet, light operation. Unfortunately, countermarch looms are more complex, harder to build, slower to tie up,

and more prone to malfunction.

Figure harness and the drawloom

A drawloom is for weaving figured cloth. In a drawloom, a "figure harness" is used to control each warp thread separately, allowing very complex patterns. A drawloom requires two operators, the weaver, and an assistant called a "drawboy" to manage the figure harness.

The earliest confirmed drawloom fabrics come from the

State of Chu

Chu (, Old Chinese: ''*s-r̥aʔ'') was an Ancient Chinese states, ancient Chinese state during the Zhou dynasty. Their first ruler was King Wu of Chu in the early 8th century BC. Chu was located in the south of the Zhou heartland and lasted ...

and date c. 400 BC.

[.] Some scholars speculate an independent invention in ancient

Syria

Syria, officially the Syrian Arab Republic, is a country in West Asia located in the Eastern Mediterranean and the Levant. It borders the Mediterranean Sea to the west, Turkey to Syria–Turkey border, the north, Iraq to Iraq–Syria border, t ...

, since drawloom fabrics found in

Dura-Europas are thought to date before 256 AD.

The draw loom was invented in China during the Han dynasty (

State of Liu

State most commonly refers to:

* State (polity), a centralized political organization that regulates law and society within a territory

**Sovereign state, a sovereign polity in international law, commonly referred to as a country

**Nation state, a ...

?);

foot-powered multi-harness looms and jacquard looms were used for silk weaving and embroidery, both of which were cottage industries with imperial workshops. The drawloom enhanced and sped up the production of silk and played a significant role in Chinese silk weaving. The loom was introduced to Persia, India, and Europe.

Dobby head

A dobby head is a device that replaces the drawboy, the weaver's helper who used to control the warp threads by pulling on draw threads. "Dobby" is a corruption of "draw boy". Mechanical dobbies pull on the draw threads using pegs in bars to lift a set of levers. The placement of the pegs determines which levers are lifted. The sequence of bars (they are strung together) effectively remembers the sequence for the weaver. Computer-controlled dobbies use

solenoid

upright=1.20, An illustration of a solenoid

upright=1.20, Magnetic field created by a seven-loop solenoid (cross-sectional view) described using field lines

A solenoid () is a type of electromagnet formed by a helix, helical coil of wire whos ...

s instead of pegs.

Jacquard head

The Jacquard loom is a mechanical loom, invented by

Joseph Marie Jacquard

Joseph Marie Charles ''dit'' (called or nicknamed) Jacquard (; 7 July 1752 – 7 August 1834) was a French weaver and merchant. He played an important role in the development of the earliest programmable loom (the "Jacquard loom"), which in tur ...

in 1801, which simplifies the process of manufacturing figured textiles with complex patterns such as

brocade

Brocade () is a class of richly decorative shuttle (weaving), shuttle-woven fabrics, often made in coloured silks and sometimes with gold and silver threads. The name, related to the same root as the word "broccoli", comes from Italian langua ...

,

damask

Damask (; ) is a woven, Reversible garment, reversible patterned Textile, fabric. Damasks are woven by periodically reversing the action of the warp and weft threads. The pattern is most commonly created with a warp-faced satin weave and the gro ...

, and

matelasse. The loom is controlled by

punched card

A punched card (also punch card or punched-card) is a stiff paper-based medium used to store digital information via the presence or absence of holes in predefined positions. Developed over the 18th to 20th centuries, punched cards were widel ...

s with punched holes, each row of which corresponds to one row of the design. Multiple rows of holes are punched on each card and the many cards that compose the design of the textile are strung together in order. It is based on earlier inventions by the Frenchmen

Basile Bouchon

Basile Bouchon () (or Boachon) was a textile worker in the silk center in Lyon who invented a way to control a loom with a perforated paper tape in 1725. The son of an organ (music), organ maker, Bouchon partially automated the tedious setting u ...

(1725), Jean Baptiste Falcon (1728), and

Jacques Vaucanson

Jacques de Vaucanson (; February 24, 1709 – November 21, 1782) was a French people, French inventor and artist who built the first all-metal lathe. This invention was crucial for the Industrial Revolution. The lathe is known as the mother of ma ...

(1740). To call it a loom is a misnomer. A Jacquard head could be attached to a power loom or a handloom, the head controlling which warp thread was raised during shedding. Multiple shuttles could be used to control the colour of the weft during picking. The Jacquard loom is the predecessor to the

computer punched card readers of the 19th and 20th centuries.

File:Loom.jpg, The punched-card control mechanism of a Jacquard loom

The Jacquard machine () is a device fitted to a loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask and matelassé. The resulting ensemble of the loom and Jacquard machine is then called a Jac ...

in use in 2009, Varanasi

Varanasi (, also Benares, Banaras ) or Kashi, is a city on the Ganges river in northern India that has a central place in the traditions of pilgrimage, death, and mourning in the Hindu world.*

*

*

* The city has a syncretic tradition of I ...

, Uttar Pradesh

Uttar Pradesh ( ; UP) is a States and union territories of India, state in North India, northern India. With over 241 million inhabitants, it is the List of states and union territories of India by population, most populated state in In ...

, India.

File:JacquardLoomsSAFALodzPoland.jpg, Hand operated Jacquard looms in the Textile Department of the Strzemiński Academy of Fine Arts in Łódź

Łódź is a city in central Poland and a former industrial centre. It is the capital of Łódź Voivodeship, and is located south-west of Warsaw. Łódź has a population of 655,279, making it the country's List of cities and towns in Polan ...

, Poland.

File:JacquardWeavingPoland.jpg, Battening on a Jacquard loom in Łódź.

File:Industry during the First World War- Leicestershire Q28124.jpg, A female worker changing jacquard cards in a lace machine in a Nottingham factory (1918).

File:Indian boy and looms.jpg, Boy next to two weaving looms with the weaving pattern on reams of paper (India).

File:PunchingJacquardCardPoland.jpg, Following the pattern, holes are punched in the appropriate places on a Jacquard card.

File:Telar manual y máquina de Jacquard 12.jpg, Manual loom with double width and Jacquard loom, Colegio del Arte Mayor de la Seda of Valencia.

File:Masson Mills WTM 13 Hattersley Jacquard 5976.JPG, The Jacquard cards control the heads on a loom.

Picking (weft insertion)

The weft may be passed across the shed as a ball of yarn, but usually this is too bulky and unergonomic. Shuttles are designed to be slim, so they pass through the shed; to carry a lot of yarn, so the weaver does not need to refill them too often; and to be an ergonomic size and shape for the particular weaver, loom, and yarn. They may also be designed for low friction.

Stick shuttles

Unnotched stick shuttles

At their simplest, these are just sticks wrapped with yarn. They may be specially shaped, as with the bobbins and bones used in tapestry-making (bobbins are used on vertical warps, and bones on horizontal ones).

File:Greekurnwithweavers (cropped to warp-weighted loom).jpg, Shuttles are passed, not thrown, through warp-weighted looms. These Ancient Greek weavers have a yarn-wrapped stick.[Article describing the experimental reconstruction of the 6th-7th centur]

Anglo-Saxon warp-weighted loom from Pakenham, Suffolk

/ref>

File:Rea-Menzies in studio.jpg, Tapestry bobbins are used on vertical-warp looms.

File:Nécessaire du licier (haute lice).jpg, Tapestry bobbins, empty and full

Principaux outils de la tapisserie de basse lisse sur le métier à tisser (flûtes, grattoir, peigne, poinçon).jpg, Tapestry bones are used on horizontal-warp looms

File:Chantier de fouilles à Morigny-Champigny en juin 2012 24 (cropped to bones).jpg, Tapestry bones actually made from cannonbones (those in the last image are wooden)

File:Dhaka weaving machine.JPG, Paper quills (paper bobbins) used as tapestry bones in Dhaka

Dhaka ( or ; , ), List of renamed places in Bangladesh, formerly known as Dacca, is the capital city, capital and list of cities and towns in Bangladesh, largest city of Bangladesh. It is one of the list of largest cities, largest and list o ...

, Bangladesh.

Notched stick shuttles, rag shuttles, and ski shuttles

File:Navette tess.JPG,

File:RugMakingWomanPassesShuttle (cropped).jpg, Stick shuttles must be passed, not thrown, which is inconvenient for wide warps.

File:Chantier de fouilles à Morigny-Champigny en juin 2012 20.jpg, Belt or band shuttle, a short shuttle used for inkle weaving. This extra-sturdy shuttle is also used at a batten, to beat the newly woven weft against the previously woven fell.netting

In law, set-off or netting is a legal technique applied between persons or businesses with mutual rights and Liability (financial accounting), liabilities, replacing gross positions with net positions. It permits the rights to be used to discharg ...

.

File:Väv, Mattgarnsskyttel.jpg, Ski shuttle.[

File:Stick shuttles.jpg, Stick shuttles wound in a figure-of-eight.

]

Boat shuttles

Boat shuttles may be closed (central hollow with a solid bottom) or open (central hole goes right through). The yarn may be side-feed or end-feed.

They are commonly made for 10-cm (4-inch) and 15-cm (6-inch) bobbin lengths.

Rhode Island

Rhode Island ( ) is a state in the New England region of the Northeastern United States. It borders Connecticut to its west; Massachusetts to its north and east; and the Atlantic Ocean to its south via Rhode Island Sound and Block Is ...

, USA.

File:Navettes de métier.JPG, Boats with square-ended recesses are intended for bobbins with end flanges. Other shuttles have round-cornered recesses. They are often intended for use with paper quills (tubes of rolled paper).

File:%D0%A1%D0%BE%D0%BB%D0%BA%D0%B8_1.JPG, Macedonian open shuttles with paper quills.

File:Човники для ткацьких верстатів в етнопарку "Ладомирія" 2.jpg, A collection of open and closed shuttles in Ukraine, some clearly handmade.

File:Balint-napra keszitett kalotaszegi vetelo 1883-bol.jpg, This Transylvanian shuttle was a Valentine's Day gift.

File:মাকো.jpg, These Assamese shuttles, presumably for very fine silk, are slender and do not hold much volume.

File:Shuttle for silk weaving. Khotan, Xinjiang. 2010.jpg, Asymmetric open boat shuttle, Khotan

Hotan (also known by #Etymology, other names) is a major oasis town in southwestern Xinjiang, an Autonomous regions of China, autonomous region in Northwestern China. The city proper of Hotan broke off from the larger Hotan County to become an ...

.

File:Bobbins used inside shuttles.JPG, Two end-feed pirns and a side-feed bobbin (bottom)

File:Rebozo-Weberei in San Luis Potosí, Mexico.jpg, Simple closed, side-feed boat shuttle with a paper bobbin, Mexico

File:Shuttle with bobbin.JPG, How the conical pirn loads on an end-feed shuttle.

File:Kangasteljed Vormsi rahvamajas.jpg, Using two shuttles for weft stripes, Estonia

Estonia, officially the Republic of Estonia, is a country in Northern Europe. It is bordered to the north by the Gulf of Finland across from Finland, to the west by the Baltic Sea across from Sweden, to the south by Latvia, and to the east by Ru ...

File:CSM Textiles2.jpg, Weaving with three shuttles

Flying shuttle

File:Handloom Telar artesanal Webstuhl 02.ogv, Handloom with a flying shuttle. The shuttle runs in a shuttle race attached to the front of the beater bar. Subtitles describe step-by-step.

File:Narrow shuttle loom.webm, An early fully-automated loom. The arms at the sides can be seen swinging to bash the flying shuttle back and forth.

File:Jacquard weefgetouw in actie.webm, The automated shuttle moves almost too fast to see

File:QSMM Shuttles 2630ca.JPG, Manufacture of a cornelwood flying shuttle

File:Großschönau - muzeum damaškové a smyčkové tkaniny 7787.jpg, In the shuttle race.

19C (late) Japanese hand loom with flying shuttle.jpg, Narrow tanmono

A is a bolt (cloth), bolt of culture of Japan, traditional Japanese Narrow cloth, narrow-loomed textile, cloth. It is used to make Japanese clothing, traditional Japanese clothes, textile list of partitions of traditional Japanese architecture ...

loom with a shuttle race. Late 18-hundreds Japan.

Hand weavers who threw a shuttle could only weave

a cloth as wide as their armspan. If cloth needed to be wider, two people would do the task (often this would be an adult with a child).

John Kay (1704–1779) patented the

flying shuttle

The flying shuttle is a type of weaving shuttle. It was a pivotal advancement in the mechanisation of weaving during the initial stages of the Industrial Revolution, and facilitated the weaving of considerably broader fabrics, enabling the p ...

in 1733. The weaver held a picking stick that was attached by cords to a device at both ends of the shed. With a flick of the wrist, one cord was pulled and the shuttle was propelled through the shed to the other end with considerable force, speed and efficiency. A flick in the opposite direction and the shuttle was propelled back. A single weaver had control of this motion but the flying shuttle could weave much wider fabric than an arm's length at much greater speeds than had been achieved with the hand thrown shuttle.

The ''flying shuttle'' was one of the key developments in

weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

that helped fuel the

Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succee ...

. The whole picking motion no longer relied on manual skill and it was just a matter of time before it could be powered by something other than a human.

Weft insertion in power looms

Different types of power looms are most often defined by the way that the weft, or pick, is inserted into the warp. Many advances in weft insertion have been made in order to make manufactured cloth more cost effective. Weft insertion rate is a limiting factor in production speed. , industrial looms can weave at 2,000

weft insertions per minute.

There are five main types of weft insertion and they are as follows:

* Shuttle: The first-ever powered looms were shuttle-type looms. Spools of weft are unravelled as the shuttle travels across the shed. This is very similar to projectile methods of weaving, except that the weft spool is stored on the shuttle. These looms are considered obsolete in modern industrial fabric manufacturing because they can only reach a maximum of 300 picks per minute.

* Air jet: An

air-jet loom uses short quick bursts of compressed air to propel the weft through the shed in order to complete the weave. Air jets are the fastest traditional method of weaving in modern manufacturing and they are able to achieve up to 1,500 picks per minute. However, the amounts of compressed air required to run these looms, as well as the complexity in the way the air jets are positioned, make them more costly than other looms.

* Water jet: Water-jet looms use the same principle as air-jet looms, but they take advantage of pressurized water to propel the weft. The advantage of this type of weaving is that water power is cheaper where water is directly available on site. Picks per minute can reach as high as 1,000.

*

Rapier loom: This type of weaving is very versatile, in that rapier looms can weave using a large variety of threads. There are several types of rapiers, but they all use a hook system attached to a rod or metal band to pass the pick across the shed. These machines regularly reach 700 picks per minute in normal production.

* Projectile:

Projectile looms utilize an object that is propelled across the shed, usually by spring power, and is guided across the width of the cloth by a series of reeds. The projectile is then removed from the weft fibre and it is returned to the opposite side of the machine so it can be reused. Multiple projectiles are in use in order to increase the pick speed. Maximum speeds on these machines can be as high as 1,050 ppm.

* Circular: Modern circular looms use up to ten shuttles, driven in a circular motion from below by electromagnets, for the weft yarns, and cams to control the warp threads. The warps rise and fall with each shuttle passage, unlike the common practice of lifting all of them at once. Circular looms are used to create seamless tubes of fabric for products such as hosiery, sacks, clothing, fabric hoses (such as fire hoses) and the like.

Battening

File:Salish Baton.JPG, Coast Salish

The Coast Salish peoples are a group of ethnically and linguistically related Indigenous peoples of the Pacific Northwest Coast, living in the Canadian province of British Columbia and the U.S. states of Washington and Oregon. They speak on ...

sword beater, North American west coast

File:Greekurnwithweavers (cropped to warp-weighted loom).jpg, Sword beaters (or battens) on upright looms are indeed swung like a sword

File:Egypt - Weaving.jpg, Sword beater on an Ancient Egyptian horizontal ground-pegged loom, being held by two people

Weaving in Braga (cropped to weaving).JPG, Weaving comb used for battening, Braga, Portugal

File:QSMM Pemberton loom 2582.JPG, Reed beater mounted in a beater bar

File:Pettine-liccio.JPG, Rigid heddles are a shedding device that can also act as a reed.

The newest weft thread must be beaten against the fell. Battening can be done with a long stick placed in the shed parallel to the weft (a sword batten), a shorter stick threaded between the warp threads perpendicular to warp and weft (a pin batten), a comb, or a reed (a comb with both ends closed, so that it has to be sleyed, that is have the warp threads threaded through it, when the loom is warped). For rigid-heddle looms, the heddle may be used as a reed.

Secondary motions

Dandy mechanism

Patented in 1802,

dandy looms automatically rolled up the finished cloth, keeping the fell always the same length. They significantly speeded up hand weaving (still a major part of the textile industry in the 1800s). Similar mechanisms were used in power looms.

Temples

The temples act to keep the cloth from shrinking sideways as it is woven. Some warp-weighted looms had temples made of

loom weights, suspended by strings so that they pulled the cloth breadthwise.

[ Other looms may have temples tied to the frame, or temples that are hooks with an adjustable shaft between them. Power looms may use temple cylinders. Pins can leave a series of holes in the selvages (these may be from stenter pins used in post-processing).

]

Frames

Loom frames can be roughly divided, by the orientation of the warp threads, into horizontal looms and vertical looms. There are many finer divisions. Most handloom frame designs can be constructed fairly simply.

Backstrap loom

The back-strap loom (also known as belt loom) is a simple loom with ancient roots, still used in many cultures around the world (as in the weaving of Andean textiles, and in Central, East and South Asia).abacá

Abacá ( ; ), also known as Manila hemp, is a species of banana, ''Musa textilis'', endemic to the Philippines. The plant grows to , and averages about . The plant has great economic importance, being harvested for its fiber extracted from t ...

fiber. One bar is attached to the ceiling of the traditional T'boli longhouse, while the other is attached to the lower back. The cloth is being patterned by dying the warp, so the loom equipment is simple; a heddle rod, a shedding stick, and a batten. She is also using a footrest. Philippines.

File:Traditional weaveing of the Li Ethnic Group.jpg, This Hlai weaver tensions her traditional backstrap loom with her feet. She is using a large number of slim heddle rods, attached to only a few warp threads; these are sometimes called ''pattern rods''. Hainan Island

Hainan is an island province and the southernmost province of China. It consists of the eponymous Hainan Island and various smaller islands in the South China Sea under the province's administration. The name literally means "South of the Sea ...

, Southern People's Republic of China

China, officially the People's Republic of China (PRC), is a country in East Asia. With population of China, a population exceeding 1.4 billion, it is the list of countries by population (United Nations), second-most populous country after ...

.

File:Vevlærer Edel Hætta Eriksen med båndgrindveving. Kautokeino 1956 - Norsk folkemuseum - NF.05535-221.jpg, A Sámi

Acronyms

* SAMI, ''Synchronized Accessible Media Interchange'', a closed-captioning format developed by Microsoft

* Saudi Arabian Military Industries, a government-owned defence company

* South African Malaria Initiative, a virtual expertise ...

weaver doing inkle weaving on a backstrap loom with a rigid heddle

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." '' ...

. She seems to be using a hollow half-bone as a beater and as a race for a bobbin. Norway, 1956.

File:Spjaldvefnadur.png, An Icelandic backstrap loom, 1903. The inkle workpiece is so narrow that no beams are needed; the warp ends are simply tied as one. Tablets are used for the shedding.

Warp-weighted loom

The warp-weighted loom is a vertical loom that may have originated in the

The warp-weighted loom is a vertical loom that may have originated in the Neolithic

The Neolithic or New Stone Age (from Ancient Greek, Greek 'new' and 'stone') is an archaeological period, the final division of the Stone Age in Mesopotamia, Asia, Europe and Africa (c. 10,000 BCE to c. 2,000 BCE). It saw the Neolithic Revo ...

period. Its defining characteristic is hanging weights (loom weights) which keep bundles of the warp threads taut. Frequently, extra warp thread is wound around the weights. When a weaver has woven far enough down, the completed section (fell) can be rolled around the top beam, and additional lengths of warp threads can be unwound from the weights to continue. This frees the weaver from vertical size constraint. Horizontally, breadth is limited by armspan; making broadwoven cloth requires two weavers, standing side by side at the loom.

Simple weaves, and complex weaves that need more than two different sheds, can both be woven on a warp-weighted loom. They can also be used to produce tapestries.

Pegged or floor loom

In pegged looms, the beams can be simply held apart by hooking them behind pegs driven into the ground, with wedges or lashings used to adjust the tension. Pegged looms may, however, also have horizontal sidepieces holding the beams apart.

Such looms are easy to set up and dismantle, and are easy to transport, so they are popular with nomadic weavers. They are generally only used for comparatively small woven articles.

Treadle loom

In a treadle loom, the shedding is controlled by the feet, which tread on the

In a treadle loom, the shedding is controlled by the feet, which tread on the treadle

A treadle (from , "to tread") is a foot-powered lever mechanism; it is operated by treading on it repeatedly. A treadle, unlike some other types of pedals, is not directly mounted on the crank (see treadle bicycle for a clear example).

Most ...

s.

The earliest evidence of a horizontal loom is found on a pottery dish in ancient Egypt

Ancient Egypt () was a cradle of civilization concentrated along the lower reaches of the Nile River in Northeast Africa. It emerged from prehistoric Egypt around 3150BC (according to conventional Egyptian chronology), when Upper and Lower E ...

, dated to 4400 BC. It was a frame loom, equipped with treadles to lift the warp threads, leaving the weaver's hands free to pass and beat the weft thread.

A pit loom has a pit for the treadles, reducing the stress transmitted through the much shorter frame.heddle

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." '' ...

s are fixed in place in the shaft. The warp threads pass alternately through a heddle, and through a space between the heddles (the shed

A shed is typically a simple, single-storey (though some sheds may have two or more stories and or a loft) roofed structure, often used for storage, for hobby, hobbies, or as a workshop, and typically serving as outbuilding, such as in a bac ...

), so that raising the shaft raises half the threads (those passing through the heddles), and lowering the shaft lowers the same threads — the threads passing through the spaces between the heddles remain in place.

A treadle loom for figured weaving may have a large number of harnesses or a control head. It can, for instance, have a Jacquard machine

The Jacquard machine () is a device fitted to a loom that simplifies the process of manufacturing textiles with such complex patterns as brocade, damask and matelassé. The resulting ensemble of the loom and Jacquard machine is then called a Jac ...

attached to it .

File:Traditional loom at Ranipauwa-Muktinath, Nepal-WLV-1197.jpg, Traditional treadle loom at Ranipauwa Muktinath, Nepal ( another image)

File:Japaneseweavera.jpg, Japanese treadle loom, late 1820s-early 1830s

File:Silk Loom (5453100710).jpg, Weaving at a pit loom; the frame is built shorter, but set over a pit, so that the treadles are below ground level. Herat

Herāt (; Dari/Pashto: هرات) is an oasis city and the third-largest city in Afghanistan. In 2020, it had an estimated population of 574,276, and serves as the capital of Herat Province, situated south of the Paropamisus Mountains (''Se ...

, Afghanistan.

File:Studies in primitive looms (1918) (14784096942).jpg, A simple tripod frame supports, not a heddle pulley, but a horse (a sort of teeter-totter); from each heddle frame hangs a treadle, trod alternately to form shed and countershed. West African loom, early 20th century

Tapestry looms

Tapestry can have extremely complex wefts, as different strands of wefts of different colours are used to form the pattern. Speed is lower, and shedding and picking devices may be simpler. Looms used for weaving traditional

Tapestry can have extremely complex wefts, as different strands of wefts of different colours are used to form the pattern. Speed is lower, and shedding and picking devices may be simpler. Looms used for weaving traditional tapestry

Tapestry is a form of Textile arts, textile art which was traditionally Weaving, woven by hand on a loom. Normally it is used to create images rather than patterns. Tapestry is relatively fragile, and difficult to make, so most historical piece ...

are called not as "vertical-warp" and "horizontal-warp", but as "high-warp" or "low-warp" (the French terms '' haute-lisse'' and are also used in English).

File:Rea-Menzies in studio.jpg, Haut-lisse tapestry loom, 2022, New Zealand

File:Loom haute lisse DSC08774.jpg, Commercial haut-lisse tapestry loom, 2004

File:Loom basse lisse DSC08828.jpg, A commercial basse-lisse tapestry loom in the same factory, 2004

File:Principaux outils de la tapisserie de basse lisse sur le métier à tisser (flûtes, grattoir, peigne, poinçon).jpg, Tapestry tools, on the loom. Bobbin

A bobbin or spool is a spindle or cylinder, with or without flanges, on which yarn, thread, wire, tape or film is wound. Bobbins are typically found in industrial textile machinery, as well as in sewing machines, fishing reels, tape measures ...

s, scrapper (with short teeth), comb (double-ended), and awl (tip hidden).

File:Wandtapijt Nieuwe Kerk Middelburg.webm, A power loom in the TextielMuseum Tilburg weaving a tapestry for the Niewe Kerk Middelburg; note that the threads do not vary in colour along their length.

Ribbon, Band, and Inkle weaving

Inkle looms are narrow looms used for narrow work. They are used to make narrow warp-faced strips such as ribbons, bands, or tape. They are often quite small; some are used on a tabletop. others are backstraps looms with a rigid heddle

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." '' ...

, and very portable.

Darning looms

There exist very small hand-held looms known as darning looms. They are made to fit under the fabric being mended, and are often held in place by an elastic band on one side of the cloth and a groove around the loom's darning-egg portion on the other. They may have heddles made of flip-flopping rotating hooks . Other devices sold as darning looms are just a darning egg and a separate comb-like piece with teeth to hook the warp over; these are used for repairing knitted garments and are like a linear knitting spool. Darning looms were sold during World War Two clothing rationing in the United Kingdom and Canada, and some are homemade.

Circular handlooms

Circular looms are used to create seamless tubes of fabric for products such as hosiery, sacks, clothing, fabric hoses (such as fire hoses) and the like. Tablet weaving

Tablet weaving (often card weaving in the United States) is a weaving technique where ''tablets'' or ''cards'' are used to create the Shed (weaving), shed through which the weft is passed. As the materials and tools are relatively cheap and ea ...

can be used to knit tubes, including tubes that split and join.

Small jigs also used for circular knitting are also sometimes called circular looms, but they are used for knitting, not weaving.

Handlooms to power looms

A power loom is a loom powered by a source of energy other than the weaver's muscles. When power looms were developed, other looms came to be referred to as ''handlooms''. Most cloth is now woven on power looms, but some is still woven on handlooms.power loom

A power loom is a mechanized loom.

Shuttle looms

The main components of the loom are the warp beam, heddles, harnesses, shuttle, reed, and takeup roll. In the loom, yarn processing includes shedding, picking, battening and taking-up operations ...

in 1785, and it was this that was adopted by the nascent cotton industry in England. The silk loom made by Jacques Vaucanson

Jacques de Vaucanson (; February 24, 1709 – November 21, 1782) was a French people, French inventor and artist who built the first all-metal lathe. This invention was crucial for the Industrial Revolution. The lathe is known as the mother of ma ...

in 1745 operated on the same principles but was not developed further. The invention of the flying shuttle

The flying shuttle is a type of weaving shuttle. It was a pivotal advancement in the mechanisation of weaving during the initial stages of the Industrial Revolution, and facilitated the weaving of considerably broader fabrics, enabling the p ...

by John Kay allowed a hand weaver to weave broadwoven cloth without an assistant, and was also critical to the development of a commercially successful power loom. Cartwright's loom was impractical but the ideas behind it were developed by numerous inventors in the Manchester area of England. By 1818, there were 32 factories containing 5,732 looms in the region.

The Horrocks loom was viable, but it was the Roberts Loom in 1830 that marked the turning point. Incremental changes to the three motions continued to be made. The problems of sizing, stop-motions, consistent take-up, and a temple

A temple (from the Latin ) is a place of worship, a building used for spiritual rituals and activities such as prayer and sacrifice. By convention, the specially built places of worship of some religions are commonly called "temples" in Engli ...

to maintain the width remained. In 1841, Kenworthy and Bullough produced the Lancashire Loom

The Lancashire Loom was a semi-automatic power loom invented by James Bullough and William Kenworthy in 1842. Although it is self-acting, it has to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a ...

which was self-acting or semi-automatic. This enabled a youngster to run six looms at the same time. Thus, for simple calicos, the power loom became more economical to run than the handloom – with complex patterning that used a dobby or Jacquard head, jobs were still put out to handloom weavers until the 1870s. Incremental changes were made such as the Dickinson Loom, culminating in the fully automatic Northrop Loom

The Northrop Loom was a fully automatic power loom marketed by George Draper and Sons, Hopedale, Massachusetts beginning in 1895. It was named after James Henry Northrop who invented the shuttle-charging mechanism.

Background

James Henry North ...

, developed by the Keighley

Keighley ( ) is a market town and a civil parishes in England, civil parish

in the City of Bradford Borough of West Yorkshire, England. It is the second-largest settlement in the borough, after Bradford.

Keighley is north-west of Bradford, n ...

-born inventor Northrop, who was working for the Draper Corporation in Hopedale. This loom recharged the shuttle when the pirn

A pirn is a rod onto which weft thread is wound for use in weaving. Unlike a bobbin, it is fixed in place, and the thread is delivered off the end of the pirn rather than from the centre. A typical pirn is made of wood or plastic and is slightly ...

was empty. The Draper E and X models became the leading products from 1909. They were challenged by synthetic fibres such as rayon

Rayon, also called viscose and commercialised in some countries as sabra silk or cactus silk, is a semi-synthetic fiber made from natural sources of regenerated cellulose fiber, cellulose, such as wood and related agricultural products. It has t ...

.

By 1942, faster, more efficient, and shuttleless Sulzer and rapier looms had been introduced.

Symbolism and cultural significance

The loom is a symbol of cosmic creation and the structure upon which individual destiny is woven. This symbolism is encapsulated in the classical myth

Classical mythology, also known as Greco-Roman mythology or Greek and Roman mythology, is the collective body and study of myths from the ancient Greeks and ancient Romans. Mythology, along with philosophy and political thought, is one of the ma ...

of Arachne

Arachne (; from , cognate with Latin ) is the protagonist of a tale in classical mythology known primarily from the version told by the Roman poet Ovid (43 BCE–17 CE). In Book Six of his epic poem ''Metamorphoses'', Ovid recounts how ...

who was changed into a spider by the goddess Athena

Athena or Athene, often given the epithet Pallas, is an ancient Greek religion, ancient Greek goddess associated with wisdom, warfare, and handicraft who was later syncretism, syncretized with the Roman goddess Minerva. Athena was regarde ...

, who was jealous of her skill at the godlike craft of weaving. In Maya civilization

The Maya civilization () was a Mesoamerican civilization that existed from antiquity to the early modern period. It is known by its ancient temples and glyphs (script). The Maya script is the most sophisticated and highly developed writin ...

the goddess Ixchel

Ixchel or Ix Chel is the 16th-century name of the aged jaguar goddess of midwifery and medicine in ancient Maya culture.

She corresponds to Toci, an Aztec earth goddess inhabiting the sweatbath. She is related to another Aztec goddess invo ...

taught the first woman how to weave at the beginning of time.

Gallery

File:Model of Loom, late 19th century. (square).jpg, ''Model of Navajo Loom'', late 19th century, Brooklyn Museum

The Brooklyn Museum is an art museum in the New York City borough (New York City), borough of Brooklyn. At , the museum is New York City's second largest and contains an art collection with around 500,000 objects. Located near the Prospect Heig ...

File:Japaneseweavera.jpg, An early nineteenth century Japan

Japan is an island country in East Asia. Located in the Pacific Ocean off the northeast coast of the Asia, Asian mainland, it is bordered on the west by the Sea of Japan and extends from the Sea of Okhotsk in the north to the East China Sea ...

ese loom with several heddles, which the weaver controls with her foot

File:JakaltekBackstrapWeaving.jpg, A Jakaltek Maya brocades a hair sash on a back strap loom.

File:Hjerl Hede, krosno tkackie, ubt.jpeg, Handloom at Hjerl Hede, Denmark

Denmark is a Nordic countries, Nordic country in Northern Europe. It is the metropole and most populous constituent of the Kingdom of Denmark,, . also known as the Danish Realm, a constitutionally unitary state that includes the Autonomous a ...

, showing grayish warp threads (back) and cloth woven with red filling yarn (front)

File:Alberto Sa¦ünchez Marti¦ünez working.tiff, Oaxacan artisan Alberto Sanchez Martinez at loom

File:The Korkosz Croft in Czarna Góra 01.jpg, Handloom at the Korkosz Croft in Czarna Góra, Poland, 19th century

File:Stelles Slutišķu vecticībnieku lauku sētā.jpg, A loom in an Old Believer

Old Believers or Old Ritualists (Russian: староверы, ''starovery'' or старообрядцы, ''staroobryadtsy'') is the common term for several religious groups, which maintain the old liturgical and ritual practices of the Russian ...

homestead in Slutiški, Latvia

File:Handloom Weaver in an exhibition 1.jpg, Weaver from India showing handloom during an exhibition

File:Greekurnwithweavers.jpg, A Grecian urn showing a warp-weighted loom

See also

*'' Bunkar: The Last of the Varanasi Weavers'' (documentary film)

* Fashion and Textile Museum

*Textile manufacturing

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful good ...

* Timeline of clothing and textiles technology

*Weaving (mythology)

Mention of textiles in folklore is ancient, and its lost mythic lore probably accompanied the early spread of this art. Textiles have also been associated in several cultures with spiders in mythology.

Weaving begins with spinning. Until the ...

*Luddite

The Luddites were members of a 19th-century movement of English textile workers who opposed the use of certain types of automated machinery due to concerns relating to worker pay and output quality. They often destroyed the machines in organ ...

References

Bibliography

*

*

*

*

*

*

*

*

*

*

*

External links

Loom demonstration video

* The Medieval Technology Pages

{{Authority control

Articles containing video clips

Egyptian inventions

Han dynasty

Machines

Textile industry

Textile engineering

Weaving equipment

A loom is a device used to weave cloth and

A loom is a device used to weave cloth and  Weaving is done on two sets of threads or yarns, which cross one another. The warp threads are the ones stretched on the loom (from the

Weaving is done on two sets of threads or yarns, which cross one another. The warp threads are the ones stretched on the loom (from the  A loom has to perform three principal motions: shedding, picking, and battening.

*Shedding. Shedding is pulling part of the warp threads aside to form a

A loom has to perform three principal motions: shedding, picking, and battening.

*Shedding. Shedding is pulling part of the warp threads aside to form a  Rigid

Rigid  A dobby head is a device that replaces the drawboy, the weaver's helper who used to control the warp threads by pulling on draw threads. "Dobby" is a corruption of "draw boy". Mechanical dobbies pull on the draw threads using pegs in bars to lift a set of levers. The placement of the pegs determines which levers are lifted. The sequence of bars (they are strung together) effectively remembers the sequence for the weaver. Computer-controlled dobbies use

A dobby head is a device that replaces the drawboy, the weaver's helper who used to control the warp threads by pulling on draw threads. "Dobby" is a corruption of "draw boy". Mechanical dobbies pull on the draw threads using pegs in bars to lift a set of levers. The placement of the pegs determines which levers are lifted. The sequence of bars (they are strung together) effectively remembers the sequence for the weaver. Computer-controlled dobbies use  The weft may be passed across the shed as a ball of yarn, but usually this is too bulky and unergonomic. Shuttles are designed to be slim, so they pass through the shed; to carry a lot of yarn, so the weaver does not need to refill them too often; and to be an ergonomic size and shape for the particular weaver, loom, and yarn. They may also be designed for low friction.

The weft may be passed across the shed as a ball of yarn, but usually this is too bulky and unergonomic. Shuttles are designed to be slim, so they pass through the shed; to carry a lot of yarn, so the weaver does not need to refill them too often; and to be an ergonomic size and shape for the particular weaver, loom, and yarn. They may also be designed for low friction.

Different types of power looms are most often defined by the way that the weft, or pick, is inserted into the warp. Many advances in weft insertion have been made in order to make manufactured cloth more cost effective. Weft insertion rate is a limiting factor in production speed. , industrial looms can weave at 2,000 weft insertions per minute.

There are five main types of weft insertion and they are as follows:

* Shuttle: The first-ever powered looms were shuttle-type looms. Spools of weft are unravelled as the shuttle travels across the shed. This is very similar to projectile methods of weaving, except that the weft spool is stored on the shuttle. These looms are considered obsolete in modern industrial fabric manufacturing because they can only reach a maximum of 300 picks per minute.

* Air jet: An air-jet loom uses short quick bursts of compressed air to propel the weft through the shed in order to complete the weave. Air jets are the fastest traditional method of weaving in modern manufacturing and they are able to achieve up to 1,500 picks per minute. However, the amounts of compressed air required to run these looms, as well as the complexity in the way the air jets are positioned, make them more costly than other looms.

* Water jet: Water-jet looms use the same principle as air-jet looms, but they take advantage of pressurized water to propel the weft. The advantage of this type of weaving is that water power is cheaper where water is directly available on site. Picks per minute can reach as high as 1,000.

* Rapier loom: This type of weaving is very versatile, in that rapier looms can weave using a large variety of threads. There are several types of rapiers, but they all use a hook system attached to a rod or metal band to pass the pick across the shed. These machines regularly reach 700 picks per minute in normal production.

* Projectile: Projectile looms utilize an object that is propelled across the shed, usually by spring power, and is guided across the width of the cloth by a series of reeds. The projectile is then removed from the weft fibre and it is returned to the opposite side of the machine so it can be reused. Multiple projectiles are in use in order to increase the pick speed. Maximum speeds on these machines can be as high as 1,050 ppm.

* Circular: Modern circular looms use up to ten shuttles, driven in a circular motion from below by electromagnets, for the weft yarns, and cams to control the warp threads. The warps rise and fall with each shuttle passage, unlike the common practice of lifting all of them at once. Circular looms are used to create seamless tubes of fabric for products such as hosiery, sacks, clothing, fabric hoses (such as fire hoses) and the like.

Different types of power looms are most often defined by the way that the weft, or pick, is inserted into the warp. Many advances in weft insertion have been made in order to make manufactured cloth more cost effective. Weft insertion rate is a limiting factor in production speed. , industrial looms can weave at 2,000 weft insertions per minute.

There are five main types of weft insertion and they are as follows:

* Shuttle: The first-ever powered looms were shuttle-type looms. Spools of weft are unravelled as the shuttle travels across the shed. This is very similar to projectile methods of weaving, except that the weft spool is stored on the shuttle. These looms are considered obsolete in modern industrial fabric manufacturing because they can only reach a maximum of 300 picks per minute.

* Air jet: An air-jet loom uses short quick bursts of compressed air to propel the weft through the shed in order to complete the weave. Air jets are the fastest traditional method of weaving in modern manufacturing and they are able to achieve up to 1,500 picks per minute. However, the amounts of compressed air required to run these looms, as well as the complexity in the way the air jets are positioned, make them more costly than other looms.

* Water jet: Water-jet looms use the same principle as air-jet looms, but they take advantage of pressurized water to propel the weft. The advantage of this type of weaving is that water power is cheaper where water is directly available on site. Picks per minute can reach as high as 1,000.

* Rapier loom: This type of weaving is very versatile, in that rapier looms can weave using a large variety of threads. There are several types of rapiers, but they all use a hook system attached to a rod or metal band to pass the pick across the shed. These machines regularly reach 700 picks per minute in normal production.

* Projectile: Projectile looms utilize an object that is propelled across the shed, usually by spring power, and is guided across the width of the cloth by a series of reeds. The projectile is then removed from the weft fibre and it is returned to the opposite side of the machine so it can be reused. Multiple projectiles are in use in order to increase the pick speed. Maximum speeds on these machines can be as high as 1,050 ppm.

* Circular: Modern circular looms use up to ten shuttles, driven in a circular motion from below by electromagnets, for the weft yarns, and cams to control the warp threads. The warps rise and fall with each shuttle passage, unlike the common practice of lifting all of them at once. Circular looms are used to create seamless tubes of fabric for products such as hosiery, sacks, clothing, fabric hoses (such as fire hoses) and the like.

The warp-weighted loom is a vertical loom that may have originated in the

The warp-weighted loom is a vertical loom that may have originated in the