|

Workbench

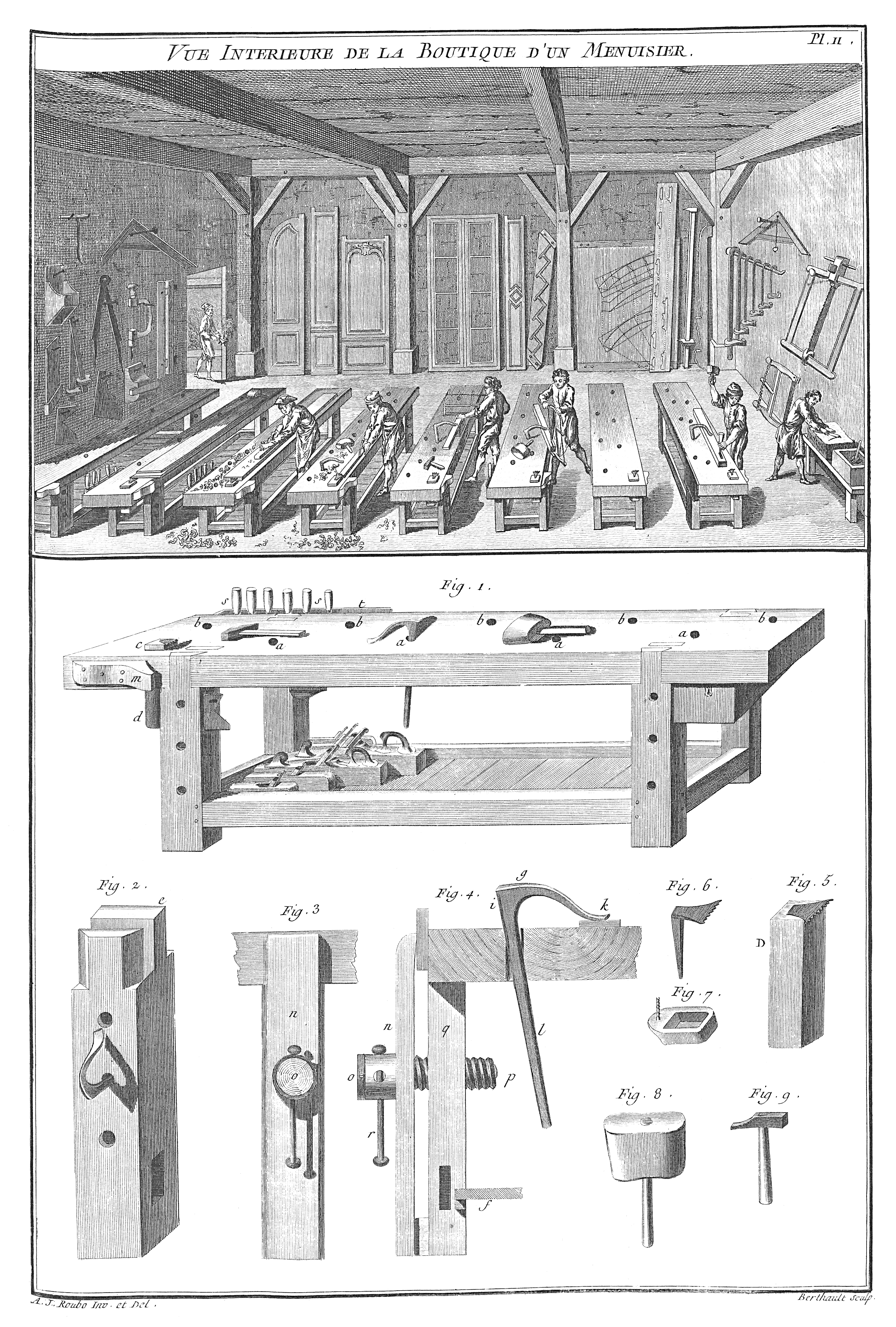

A workbench is a sturdy table at which manual work is done. They range from simple flat surfaces to very complex designs that may be considered tools in themselves. Workbenches vary in size from tiny jewellers benches to the huge benches used by staircase makers. Almost all workbenches are rectangular in shape, often using the surface, corners and edges as flat/square and dimension standards. Design is as varied as the type of work for which the benches are used but most share these attributes: * A comfortable height for working with provisions for seated or standing work * A way to fix the workpiece to the surface so that it may be worked with both hands * Provisions for mounting, storing and accessing tools Workbenches are made from many different materials including metal, wood, stone, and composites depending on the needs of the work. Types Workbench types may be divided according to the particular work they are designed to accommodate: ;Multi-purpose/portable: These be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workbench (AmigaOS)

Workbench is the desktop environment and graphical file manager of AmigaOS developed by Commodore International for their Amiga line of computers. Workbench provides the user with a graphical interface to work with file systems and launch applications. It uses a workbench metaphor (in place of the more common desktop metaphor) for representing file system organisation. "Workbench" was also the name originally given to the entire Amiga operating system up until version 3.1. From release 3.5 the operating system was renamed "AmigaOS" and subsequently "Workbench" refers to the native file manager only. Overview The Amiga Workbench uses the metaphor of a workbench (i.e. a workbench for manual labor), rather than the now-standard desktop metaphor, for representing file system organization. The desktop itself is called ''Workbench'' and uses the following representations: ''drawers'' (instead of folders) for directories, ''tools'' for executable programs, ''projects'' for data f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Black & Decker Workmate

The Black & Decker Workmate is a general purpose portable workbench and general carpentry tool manufactured under the brand Black & Decker. It is a folding table for portability, but when unfolded stands about tall. The table top consists of two wooden jaws, one of which is fixed and the other moveable on threaded rods operated by handles. It can be used as a bench vice to hold wood, metal and other parts, either clamped between the jaws or, using supplied bench dogs, clamped on the table top. The jaws are wide enough to hold most bench top tools, such as a drill press, planer, miter saw, etc. When invented, the designer Ron Hickman had difficulty convincing anyone to market the Workmate, and sold them himself at trade shows. He had his first breakthrough in 1968, after convincing a DIY magazine to let him exhibit at the Ideal Home Exhibition in London, which enabled him to sell 1,800 units that year. After seeing some success in 1971, Black & Decker decided to work with Hickm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vise (tool)

A vise or vice (British English) is a mechanical apparatus used to secure an object to allow work to be performed on it. Vises have two parallel jaws, one fixed and the other movable, threaded in and out by a screw and lever. A vise grip is not a vise but a pair of lever-actuated locking pliers. Types Face A face vise is the standard woodworking vise, always securely attached to a workbench flush with its work surface. Its jaws are made of wood or metal, the latter usually faced with wood, called cheeks, to avoid marring the work. The movable jaw may include a retractable dog to hold work against a bench dog. A "quick-release" woodworker's vise employs a split nut that allows the screw to engage or disengage with a half-turn of the handle. When disengaged the movable jaw may be moved in or out throughout its entire range of motion, vastly speeding up the process of adjustment. Common thread types are Acme and buttress. Traditional woodworking workbench vises are comm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Workpiece

A workpiece is a piece, often made of a single material, that is being processed into another desired shape (such as building blocks). The workpiece is usually a piece of relatively rigid material such as wood, metal, plastic, or stone. After a processing step, the workpiece may be moved on to further steps of processing. For example, a part can made out of bar stock and later become part of a semi-finished product. The workpiece is often attached to the tool being used via a jig or fixture, like for example to a milling machine via an angle plate, or to a lathe via a lathe faceplate. A vise is another example of a simple type of fixture used to fix workpieces. A workpiece may be subjected to various cutting operations, like truing, making fillets, chamfers, countersinking, counterboring, etc. It may also receive various surface treatments and finishes. The term "workpiece" has established itself within crafts and the manufacturing industry, and connects the work or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrician

An electrician is a tradesperson specializing in electrical wiring of buildings, transmission lines, stationary machines, and related equipment. Electricians may be employed in the installation of new electrical components or the maintenance and repair of existing electrical infrastructure. Electricians may also specialize in wiring ships, airplanes, and other mobile platforms, as well as data and cable lines. Terminology ''Electricians'' were originally people who demonstrated or studied the principles of electricity, often electrostatic generators of one form or another. In the United States, electricians are divided into two primary categories: lineperson, who work on electric utility company distribution systems at higher voltages, and wiremen, who work with the lower voltages utilized inside buildings. Wiremen are generally trained in one of five primary specialties: commercial, residential, light industrial, industrial, and low-voltage wiring, more commonly known ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laminate

Lamination is the technique/process of manufacturing a material in multiple layers, so that the composite material achieves improved strength, stability, sound insulation, appearance, or other properties from the use of the differing materials, such as plastic. A laminate is a permanently assembled object created using heat, pressure, welding, or adhesives. Various coating machines, machine presses and calendering equipment are used. Materials There are different lamination processes, depending primarily on the type or types of materials to be laminated. The materials used in laminates can be identical or different, depending on the process and the object to be laminated. Textile Laminated fabric are widely used in different fields of human activity, including medical and military. Woven fabrics (organic and inorganic based) are usually laminated by different chemical polymers to give them useful properties like chemical resistance, dust, grease, windproofness, photo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Melamine

Melamine is an organic compound with the formula C3H6N6. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton. Like cyanamide, it contains 67% nitrogen by mass, and its derivatives have fire retardant properties due to its release of nitrogen gas when burned or charred. Melamine can be combined with formaldehyde and other agents to produce melamine resins. Such resins are characteristically durable thermosetting plastic used in high pressure decorative laminates such as Formica, melamine dinnerware, laminate flooring, and dry erase boards. Melamine foam is used as insulation, soundproofing material and in polymeric cleaning products, such as Magic Eraser. Melamine was once illegally added to baby formula in China, in order to increase the apparent protein content. Ingestion of melamine may lead to reproductive damage, or bladder or kidney stones, and bladder cancer. It is also an irritant when inhaled or in contact with the skin or eyes. The Uni ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jig (tool)

A jig is a type of custom-made tool used to control the location and/or motion of parts or other tools. Description A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products.. An example of a jig is when a key is duplicated; the original is used as a jig so the new key can have the same path as the old one. Since the advent of automation and computer numerical controlled (CNC) machines, jigs are often not required because the tool path is digitally programmed and stored in memory. Jigs may be made for reforming plastics. Jigs or templates have been known long before the industrial age. There are many types of jigs, and each one is custom-tailored to do a specific job. Drill jig A ''drill jig'' is a type of jig that expedites repetitive hole center location on multiple interchangeable parts by acting as a template to guide the twist drill or other boring device into the precise location of each intended hole cente ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piece Work

Piece work (or piecework) is any type of employment in which a worker is paid a fixed piece rate for each unit produced or action performed, regardless of time. Context When paying a worker, employers can use various methods and combinations of methods. Some of the most prevalent methods are: paid a wage by the hour (known as "time work"); paid an annual salary; salary plus commission (common in sales jobs); base salary or hourly wages plus gratuities (common in service industries); salary plus a possible bonus (used for some managerial or executive positions); salary plus stock options (used for some executives and in start-ups and some high tech firms); salary pool systems; gainsharing (also known as "profit sharing"); paid by the piece – the number of things they make, or tasks they complete (known as ‘output work’); or paid in other ways (known as ‘unmeasured work’). Some industries where piece rate pay jobs are common are agricultural work, cable installation, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Handloading

Handloading, or reloading, is the practice of making firearm cartridges by assembling the individual components (case, primer, propellant, and projectile), rather than purchasing mass-assembled, factory-loaded ammunition. The term ''handloading'' is the more general term, and refers generically to the manual assembly of ammunition. ''Reloading'' refers more specifically to handloading using previously fired cases and shells. The terms are often used interchangeably however, as the techniques are largely the same, whether the handloader is using new or recycled components. The differences lie in the initial preparation of cases and shells; new components are generally ready to load, while previously fired components often need additional procedures, such as cleaning, removal of expended primers, or the reshaping and resizing of brass cases. Reasons for handloading Economy, increased performance and accuracy, commercial ammunition shortages, and hobby interests are all co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |