|

Valvetrain

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet or valve lifter is a valve train component which converts rotational motion into linear motion in activating a valve. It is most commonly found in internal combustion engines, where it converts the rotational motion of the camshaft into linear motion of intake and exhaust valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. History The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets press ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Camshaft Engine

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per cylinder bank, bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam") engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet or valve lifter is a valve train component which converts rotational motion into linear motion in activating a valve. It is most commonly found in internal combustion engines, where it converts the rotational motion of the camshaft into linear motion of intake and exhaust valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. History The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets press ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Valve

A rotary valve (also called rotary-motion valve) is a type of valve in which the rotation of a passage or passages in a transverse plug regulates the flow of liquid or gas through the attached pipes. The common stopcock is the simplest form of rotary valve. Rotary valves have been applied in numerous applications, including: * Changing the pitch of brass instruments. * Controlling the steam and exhaust ports of steam engines, most notably in the Corliss steam engine. * Periodically reversing the flow of air and fuel across the open hearth furnace. * Loading sample on chromatography columns. * Certain types of two-stroke and four-stroke engines. * Most hydraulic automotive power steering control valves. Use in brass instruments In the context of brass instruments, Brass instrument valve#Rotary valve, rotary valves are found on French horn, horns, trumpets, trombones, flugelhorns, and tubas. The cornet derived from the posthorn, by applying rotary valves to it in the 1820s in Fran ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han dynasty in China, and they were widespread by the medieval period. Camshafts were first described by Ismail al-Jazari in 1206. Once the rotative version of the steam engine was developed in the late 18th century, the operation of the valve gear was usually by an eccentric, which turned the rotation of the crankshaft i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

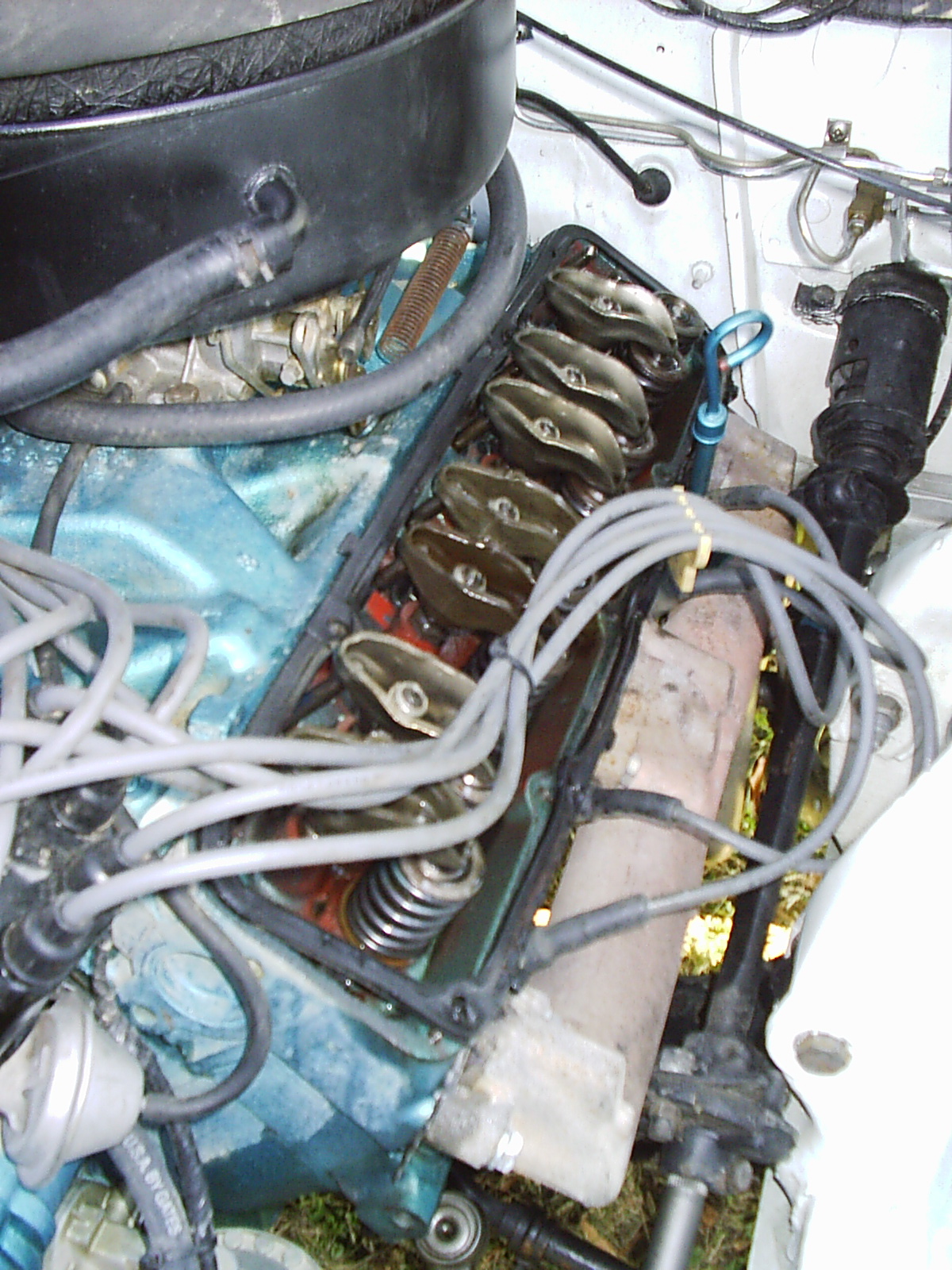

Rocker Arm

A rocker arm is a valvetrain component that typically transfers the motion of a pushrod in an overhead valve engine, overhead valve internal combustion engine to the corresponding intake/exhaust poppet valve, valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction there. Overview The most common use of a rocker arm is to transfer the up and down motion of a pushrod in an overhead valve engine, overhead valve (OHV) internal combustion engine to the corresponding intake/exhaust poppet valve, valve. In an OHV engine the camshaft located within the engine block below the cylinder bank(s) pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm located at the top of the cylinder head, which causes the rocker arm to pivot downward on the top of the valve, opening it. To redu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder banks. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rocker Arm

A rocker arm is a valvetrain component that typically transfers the motion of a pushrod in an overhead valve engine, overhead valve internal combustion engine to the corresponding intake/exhaust poppet valve, valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction there. Overview The most common use of a rocker arm is to transfer the up and down motion of a pushrod in an overhead valve engine, overhead valve (OHV) internal combustion engine to the corresponding intake/exhaust poppet valve, valve. In an OHV engine the camshaft located within the engine block below the cylinder bank(s) pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm located at the top of the cylinder head, which causes the rocker arm to pivot downward on the top of the valve, opening it. To redu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam-in-block

A cam-in-block engine is where the camshaft is located in the engine block In an internal combustion engine, the engine block is the structure that contains the cylinders and other components. The engine block in an early automotive engine consisted of just the cylinder block, to which a separate crankcase was attach .... Types of cam-in-block engines are: * F-Head Engine * Flathead engine * Overhead valve engine (the only type where the valves are above the combustion chamber) * T-head engine {{set index ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Guide

Valve guides are cylindrical metal bushes, pressed or integrally cast into the cylinder head of most types of reciprocating engines, to support the inlet valve and exhaust valve stems. So that they may make proper contact with its valve seat. Along with a corresponding valve spring, they are one component of an engine’s valve train. Guides also serve to conduct heat from the combustion process out from the exhaust valve and into the cylinder head where it may be taken up by the cooling system. Bronze is commonly used, as are various iron alloys; a balance between stiffness and wear on the valve is essential to achieve a useful service life. Powder metallurgy materials are also commonly used in the manufacture of valve guides, which have the advantages of flexible material composition and the self-lubricating properties. The clearance between the inner diameter of the valve guide and the outer diameter of the poppet valve stem is critical for the proper performance of an e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Float

Valve float is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valvetrain do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance. There is also a significant risk of severe engine damage that can include valve spring failure, pistons contacting the valves, or catastrophic lifter and cam lobe failure, especially with roller lifters. Similar conditions 'Valve lift' or "loft" is intentional, using controlled valve float to increase lift and duration of the valve open cycle. In some motorsports there are rules that limit camshaft lift, preventing this type of exploitation. Properly optimizing the valve duration avoids undue stresses to the camshaft lobes and tappets. 'Valve bounce' is a related condition where the valve does not stay seated because of the combined effects of the valve's inertia and resonance of metallic valve springs that reduce the closing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |