|

Tappet

A tappet or valve lifter is a valve train component which converts rotational motion into linear motion in activating a valve. It is most commonly found in internal combustion engines, where it converts the rotational motion of the camshaft into linear motion of intake and exhaust valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. History The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets press ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Tappet

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a small clearance between the valve and its rocker or cam follower. This clearance prevents the parts from binding as they expand with the engine's heat, but can also lead to noisy operation and increased wear as the parts rattle against one another until they reach operating temperature. The hydraulic lifter was designed to compensate this, allowing the valve train to operate with zero clearance at all operating temperatures once the oil is warm—leading to quieter operation, longer engine life, and eliminating the need for periodic adjustment of valve clearance. During operation, it fills with oil, which provides hydraulic resistance to compression, eliminating "play" (also known as " lash" [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Valve Lifter

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a small clearance between the valve and its rocker or cam follower. This clearance prevents the parts from binding as they expand with the engine's heat, but can also lead to noisy operation and increased wear as the parts rattle against one another until they reach operating temperature. The hydraulic lifter was designed to compensate this, allowing the valve train to operate with zero clearance at all operating temperatures once the oil is warm—leading to quieter operation, longer engine life, and eliminating the need for periodic adjustment of valve clearance. During operation, it fills with oil, which provides hydraulic resistance to compression, eliminating "play" (also known as " lash" [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder banks. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Train

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above the cylinders or cylinder banks. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pushrod2

A valvetrain is a mechanical system that controls the operation of the intake and exhaust poppet valve, valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gases out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines, in order from oldest to newest, are: * Flathead engine: A single camshaft and the valves are located in the engine block below the cylinder (engine), cylinder or cylinder bank. * Overhead valve engine: A single camshaft remains in the block below the cylinder(s), however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: Both the valves and one or more camshafts are located in the cylinder head above t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

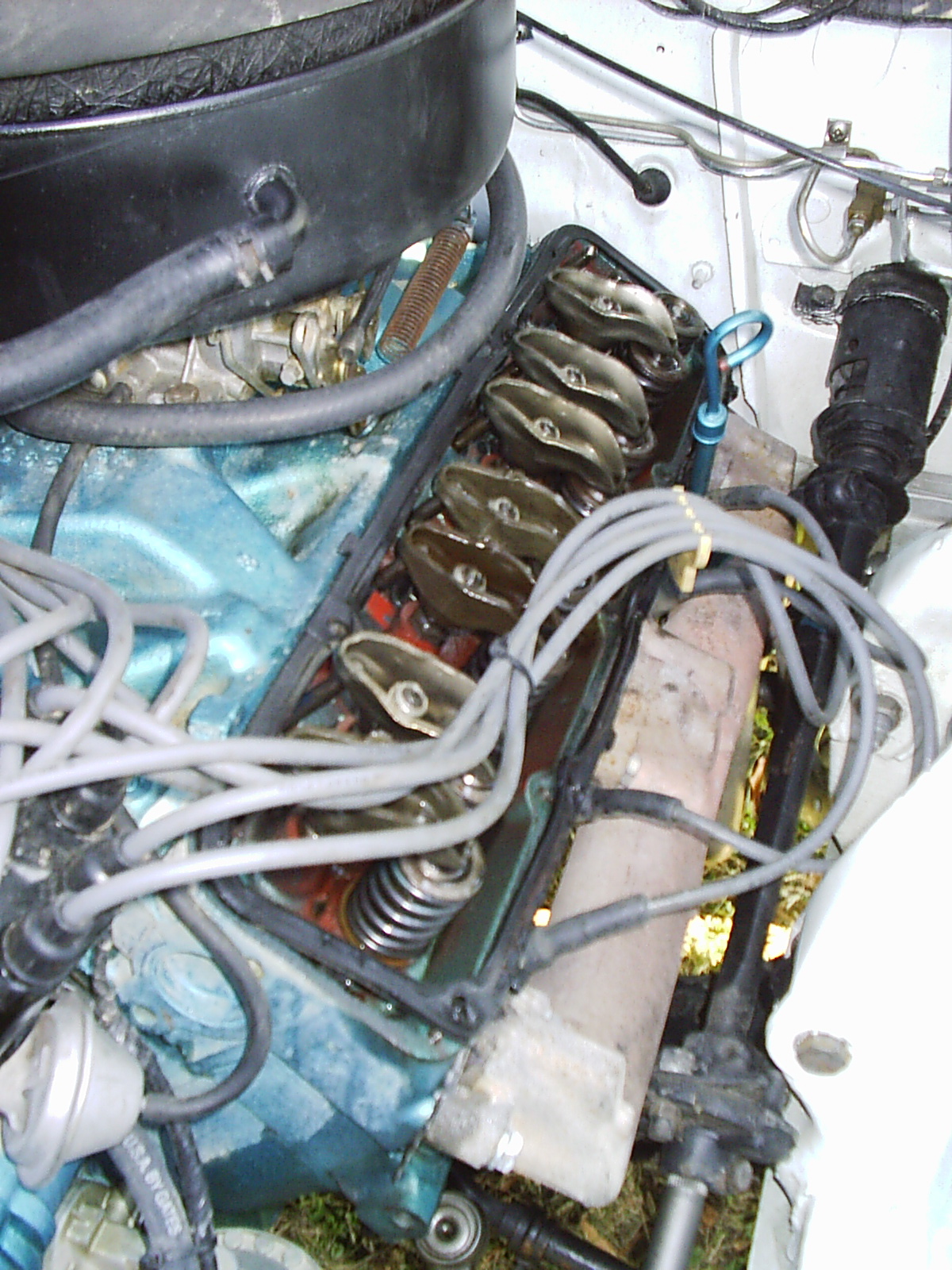

Opel Cam-in-head Engine

The Opel cam-in-head engine (CIH) is a family of automobile engines built by former General Motors subsidiary Opel from 1965 until 1998, appearing extensively in Opel/Vauxhall badged cars during this period. Both four- and six-cylinder inline configurations were produced. The name derives from the location of the camshaft, which was neither cam-in-block nor a true overhead camshaft. In the CIH engine the camshaft is located in the cylinder head but sits alongside the valves rather than above them, so therefore effectively is still an Overhead valve engine, overhead valve design. The valves are actuated through very short tappets and rocker arms. The engine first appeared in the Opel Rekord Series B, Opel Rekord B in 1965, and was largely replaced in four-cylinder form by the Family II engine, GM Family II unit as Opel/Vauxhall's core mid-size engine in the 1980s, with the six-cylinder versions continuing until 1994 in the Opel Omega, Omega A and Opel Senator, Senator B. A large ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dual Overhead Camshaft

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam") engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an O ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Camshaft Engine

An overhead camshaft (OHC) engine is a piston engine in which the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per cylinder bank, bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam") engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Daimler V8 Engines

V-8 engines were produced by the Daimler Company in displacements of (1959-1968) and (1959-1968). Designed for Daimler by Edward Turner, they were initially used in the SP250 sports car and the Majestic Major saloon respectively; ultimately, the 2.5 L was mostly used in the Daimler 2.5 V8 (later named V8-250) saloon made with Jaguar Mark 2 unit bodies from 1962 to 1969. Approximately 20,000 of the 2.5 L were used in the SP250 and the 250 saloon, and approximately 2,000 4.5 L in the Majestic Major saloon and its Daimler DR450 limousine variant which remained in production until 1968. Design and development Shortly after being appointed managing director (Chief Executive) of BSA's Automotive Division in 1956, Edward Turner was asked to design a saloon car powered by a V8 engine. Turner and his design engineer Jack Wickes began considering the initial concept of their new engine by examining the manual and spare parts list of a Cadillac V8 engine, a 90° design with an L- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Newcomen Atmospheric Engine

The atmospheric engine was invented by Thomas Newcomen in 1712, and is sometimes referred to as the Newcomen fire engine (see below) or Newcomen engine. The engine was operated by condensing steam being drawn into the cylinder, thereby creating a partial vacuum which allowed atmospheric pressure to push the piston into the cylinder. It is significant as the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mining, mines. Hundreds were constructed during the 18th century. James Watt's Watt steam engine, later engine design was an improved version of the Newcomen engine that roughly doubled fuel efficiency. Many atmospheric engines were converted to the Watt design. As a result, Watt is today better known than Newcomen in relation to the origin of the steam engine. Precursors Prior to Newcomen a number of small steam devices of various sorts had been made, but most were es ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

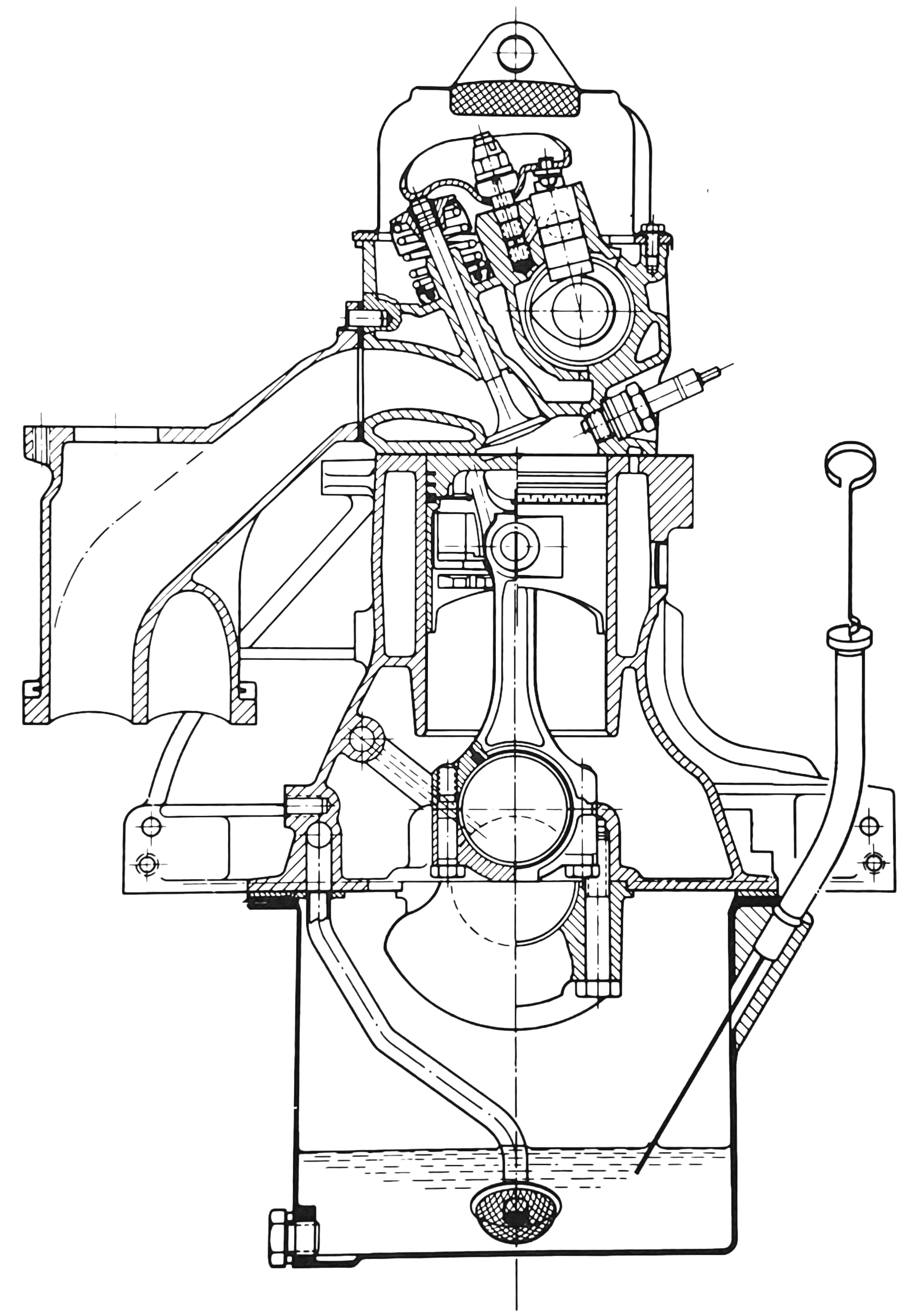

Sidevalve Engine With Forced Oil Lubrication To Crank And Oil Mist To Camshaft (Autocar Handbook, 13th Ed, 1935)

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine, is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine. Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1960s but were replaced by more efficient overhead valve and overhead camshaft engines. They are currently experiencing a revival in low-revving aero-engines such as the D-Motor. The side-valve design The valve gear comprises a camshaft sited low in the cylinder block which operates the poppet valves via tappets and short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for further valvetrain components such as lengthy pushrods, rocker arms, overhead valves or overhead camshafts. The sidevalves are typically adjacent, sited on one side of the cylinder(s), though som ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |