|

Steel Making

Steelmaking is the process of producing steel from iron ore and carbon/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of steel. Limiting dissolved gases such as nitrogen and oxygen and entrained impurities (termed "inclusions") in the steel is also important to ensure the quality of the products cast from the liquid steel. Steelmaking has existed for millennia, but it was not commercialized on a massive scale until the mid-19th century. An ancient process of steelmaking was the crucible process. In the 1850s and 1860s, the Bessemer process and the Siemens-Martin process turned steelmaking into a heavy industry. Today there are two major commercial processes for making steel, namely basic oxygen steelmaking, which has liquid pig-iron from the b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prentice Hall International

Prentice Hall was an American major educational publisher owned by Savvas Learning Company. Prentice Hall publishes print and digital content for the 6–12 and higher-education market, and distributes its technical titles through the Safari Books Online e-reference service. History On October 13, 1913, law professor Charles Gerstenberg and his student Richard Ettinger founded Prentice Hall. Gerstenberg and Ettinger took their mothers' maiden names, Prentice and Hall, to name their new company. Prentice Hall became known as a publisher of trade books by authors such as Norman Vincent Peale; elementary, secondary, and college textbooks; loose-leaf information services; and professional books. Prentice Hall acquired the training provider Deltak in 1979. Prentice Hall was acquired by Gulf+Western in 1984, and became part of that company's publishing division Simon & Schuster. S&S sold several Prentice Hall subsidiaries: Deltak and Resource Systems were sold to National Education ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

London

London is the capital and List of urban areas in the United Kingdom, largest city of England and the United Kingdom, with a population of just under 9 million. It stands on the River Thames in south-east England at the head of a estuary down to the North Sea, and has been a major settlement for two millennia. The City of London, its ancient core and financial centre, was founded by the Roman Empire, Romans as ''Londinium'' and retains its medieval boundaries.See also: Independent city#National capitals, Independent city § National capitals The City of Westminster, to the west of the City of London, has for centuries hosted the national Government of the United Kingdom, government and Parliament of the United Kingdom, parliament. Since the 19th century, the name "London" has also referred to the metropolis around this core, historically split between the Counties of England, counties of Middlesex, Essex, Surrey, Kent, and Hertfordshire, which largely comprises Greater London ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Institute Of Materials

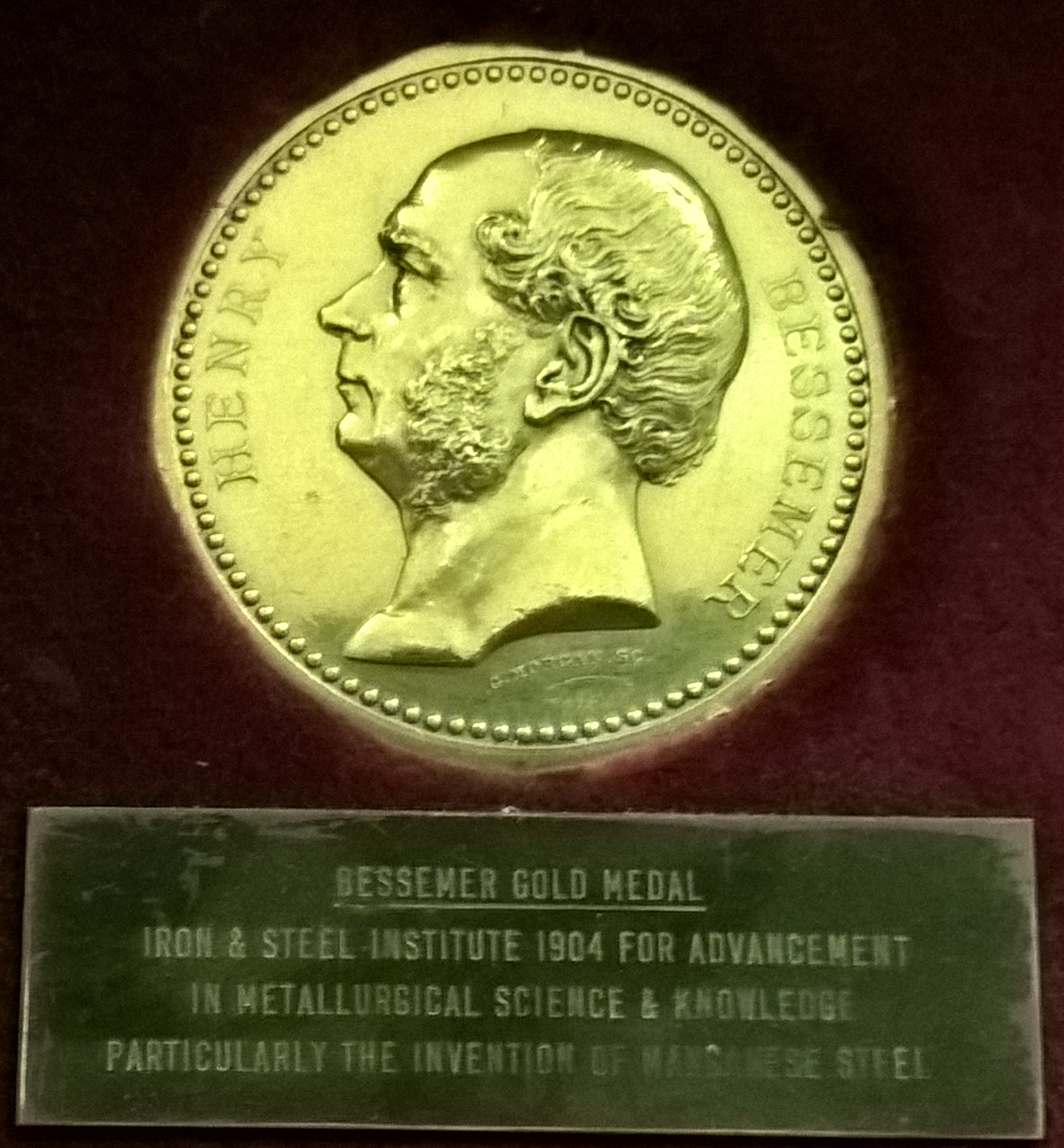

The Institute of Materials, Minerals and Mining (IOM3) is a UK engineering institution whose activities encompass the whole materials cycle, from exploration and extraction, through characterisation, processing, forming, finishing and application, to product recycling and land reuse. It exists to promote and develop all aspects of materials science and engineering, geology, mining and associated technologies, mineral and petroleum engineering and extraction metallurgy, as a leading authority in the worldwide materials and mining community. It is a registered charity governed by royal charter and in 2021 had a gross income of £3.86million. The institute is also a member of the UK Science Council. In 2019 the institute celebrated 150 years since the establishment of the Iron and Steel Institute, a learned society that IOM3 now encompasses. Structure Having resided at Carlton House Terrace off Pall Mall in St James's in central London since 2002, the institute moved to 297 Eu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Direct Reduced Iron

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) into iron by a reducing gas or elemental carbon produced from natural gas or coal. Many ores are suitable for direct reduction. Direct reduction refers to solid-state processes which reduce iron oxides to metallic iron at temperatures below the melting point of iron. Reduced iron derives its name from these processes, one example being heating iron ore in a furnace at a high temperature of in the presence of the reducing gas syngas, a mixture of hydrogen and carbon monoxide. Process Direct reduction processes can be divided roughly into two categories: gas-based, and coal-based. In both cases, the objective of the process is to remove the oxygen contained in various forms of iron ore (sized ore, concentrates, pellets, mill scale, furnace dust, etc.), in order to convert the ore to metallic iron, without melting it (below ). The dire ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Arc Furnace

An electric arc furnace (EAF) is a furnace that heats material by means of an electric arc. Industrial arc furnaces range in size from small units of approximately one-tonne capacity (used in foundries for producing cast iron products) up to about 400-tonne units used for secondary steelmaking. Arc furnaces used in research laboratories and by dentists may have a capacity of only a few dozen grams. Industrial electric arc furnace temperatures can reach , while laboratory units can exceed . In electric arc furnaces, the charged material (the material entered into the furnace for heating, not to be confused with electric charge) is directly exposed to an electric arc, and the current from the furnace terminals passes through the charged material. Arc furnaces differ from induction furnaces, in which the charge is heated instead by eddy currents. History In the 19th century, a number of people had employed an electric arc to melt iron. Sir Humphry Davy conducted an exper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Basic Oxygen Steelmaking

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter processBrock and Elzinga, p. 50. is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel. Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel. The process is known as ''basic'' because fluxes of burnt lime or dolomite, which are chemical '' bases'', are added to promote the removal of impurities and protect the lining of the converter. The process was invented in 1948 by Swiss engineer Robert Durrer and commercialized in 1952–1953 by the Austrian steelmaking company VOEST and ÖAMG. The LD converter, named after the Austrian towns Linz and Donawitz (a district of Leoben) is a refined version of the Bessemer converter where blowing of air is replaced with blowing oxygen. It reduced capital cost of the plants and smelting time, and increased labor productivity. Betwe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heavy Industry

Heavy industry is an industry that involves one or more characteristics such as large and heavy products; large and heavy equipment and facilities (such as heavy equipment, large machine tools, huge buildings and large-scale infrastructure); or complex or numerous processes. Because of those factors, heavy industry involves higher capital intensity than light industry does, and it is also often more heavily cyclical in investment and employment. Though important to economic development and industrialization of economies, heavy industry can also have significant negative side effects: both local communities and workers frequently encounter health risks, heavy industries tend to produce byproducts that both pollute the air and water, and the industrial supply chain is often involved in other environmental justice issues from mining and transportation. Because of their intensity, heavy industries are also significant contributors to greenhouse gas emissions that cause climate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Open Hearth Furnace

An open-hearth furnace or open hearth furnace is any of several kinds of industrial Industrial furnace, furnace in which excess carbon and other impurities are burnt out of pig iron to Steelmaking, produce steel. Because steel is difficult to manufacture owing to its high melting point, normal fuels and furnaces were insufficient for mass production of steel, and the open-hearth type of furnace was one of several technologies developed in the nineteenth century to overcome this difficulty. Compared with the Bessemer process, which it displaced, its main advantages were that it did not expose the steel to excessive nitrogen (which would cause the steel to become brittleness, brittle), was easier to control, and permitted the melting and refining of large amounts of scrap, scrap iron and steel. The open-hearth furnace was first developed by Germany, German-born engineer Carl Wilhelm Siemens. In 1865, the French engineer Pierre-Émile Martin took out a license from Siemens and first ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bessemer Process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation with air being blown through the molten iron. The oxidation also raises the temperature of the iron mass and keeps it molten. Related decarburizing with air processes had been used outside Europe for hundreds of years, but not on an industrial scale. One such process (similar to puddling) was known in the 11th century in East Asia, where the scholar Shen Kuo of that era described its use in the Chinese iron and steel industry. In the 17th century, accounts by European travelers detailed its possible use by the Japanese. The modern process is named after its inventor, the Englishman Henry Bessemer, who took out a patent on the process in 1856. The process was said to be independently discovered in 1851 by the American inventor Willi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crucible Steel

Crucible steel is steel made by melting pig iron (cast iron), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a crucible. In ancient times steel and iron were impossible to melt using charcoal or coal fires, which could not produce temperatures high enough. However, pig iron, having a higher carbon content and thus a lower melting point, could be melted, and by soaking wrought iron or steel in the liquid pig-iron for a long time, the carbon content of the pig iron could be reduced as it slowly diffused into the iron, turning both into steel. Crucible steel of this type was produced in South and Central Asia during the medieval era. This generally produced a very hard steel, but also a composite steel that was inhomogeneous, consisting of a very high-carbon steel (formerly the pig-iron) and a lower-carbon steel (formerly the wrought iron). This often resulted in an intricate pattern when the steel was forged, filed or polished, with possibly t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

19th Century

The 19th (nineteenth) century began on 1 January 1801 ( MDCCCI), and ended on 31 December 1900 ( MCM). The 19th century was the ninth century of the 2nd millennium. The 19th century was characterized by vast social upheaval. Slavery was abolished in much of Europe and the Americas. The First Industrial Revolution, though it began in the late 18th century, expanding beyond its British homeland for the first time during this century, particularly remaking the economies and societies of the Low Countries, the Rhineland, Northern Italy, and the Northeastern United States. A few decades later, the Second Industrial Revolution led to ever more massive urbanization and much higher levels of productivity, profit, and prosperity, a pattern that continued into the 20th century. The Islamic gunpowder empires fell into decline and European imperialism brought much of South Asia, Southeast Asia, and almost all of Africa under colonial rule. It was also marked by the collapse of the larg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |