|

Steamfitter

A pipefitter or steamfitter is a tradesman who installs, assembles, fabricates, maintains, and repairs mechanical piping systems. Pipefitters usually begin as helpers or apprentices. Journeyman pipefitters deal with industrial/commercial/marine piping and heating/cooling systems. Typical industrial process pipe is under high pressure, which requires metals such as carbon steel, stainless steel, and many different alloy metals fused together through precise cutting, threading, grooving, bending, and welding. A plumber concentrates on lower pressure piping systems for sewage and potable tap water in the industrial, commercial, institutional, or residential atmosphere. Utility piping typically consists of copper, PVC, CPVC, polyethylene, and galvanized pipe, which is typically glued, soldered, or threaded. Other types of piping systems include steam, ventilation, hydraulics, chemicals, fuel, and oil. In Canada, pipefitting is classified as a compulsory trade, and carries a volunt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plumber

A plumber is a tradesperson who specializes in installing and maintaining systems used for potable (drinking) water, and for sewage and drainage in plumbing systems.Employment and Occupations in the Skilled Trades in Michigan , Michigan Department of Technology, Management, and Budget, Bureau of Labor Market Information and Strategic Initiatives (June 2013). History The origin of the word "plumber" dates from the . Roman roofs used lead in conduits and drain pipes and some were also covered with lead; lead was also used for[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Room

A mechanical room, boiler room or plant room is a room or space in a building dedicated to the mechanical equipment and its associated electrical equipment, as opposed to rooms intended for human occupancy or storage. Unless a building is served by a centralized heating plant, the size of the mechanical room is usually proportional to the size of the building. A small building or home may have at most a utility room but in larger buildings, mechanical rooms can be of considerable size, often requiring multiple rooms throughout the building, or even occupying one or more complete floors (see: mechanical floor). Equipment Mechanical rooms typically house the following equipment: *Air handlers *Boilers *Chillers *Heat exchangers * Water heaters and tanks *Water pumps (for domestic, heating/cooling, and firefighting water) *Main distribution piping and valves * Sprinkler distribution piping and pumps *Back-up electrical generators *Elevator machinery *Back-up batteries *Oth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Systems Drawing

{{Technical drawingsMechanical systems drawing is a type of technical drawing that shows information about heating, ventilating, air conditioning and transportation around the building (Elevators or Lifts and Escalator)."Building in Canada. The Requirements before Any Construction Project Begins" '''', Retrieved on 2011-01-29. It is a powerful tool that helps analyze complex systems. These drawings are often a set of detailed drawings used for construction projects; it is a requirement for all work. They are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

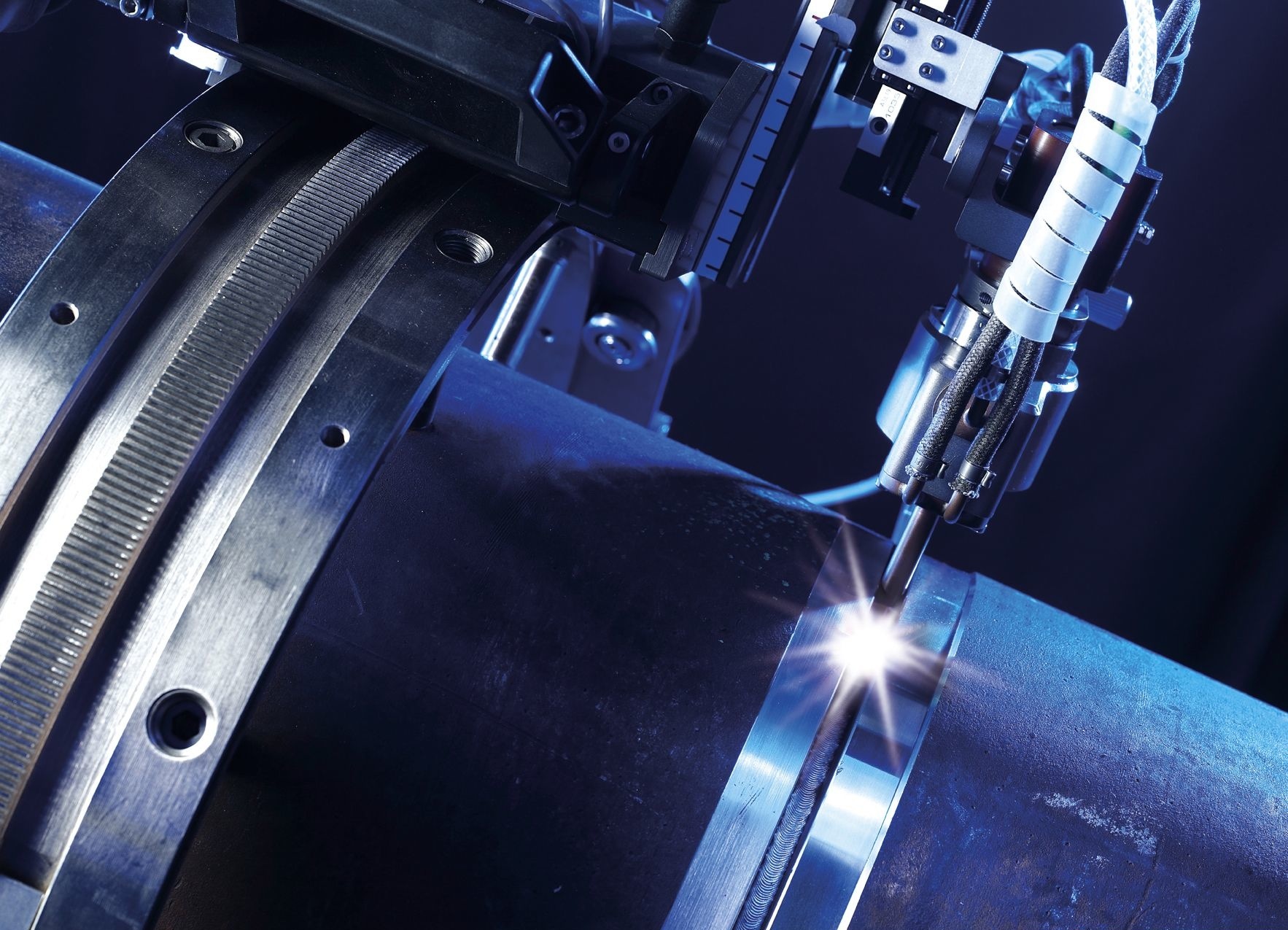

Orbital Welding

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically through 360° (180 degrees in double up welding) around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to address the issue of operator error in gas tungsten arc welding processes (GTAW), to support uniform welding around a pipe that would be significantly more difficult using a manual welding process, and to ensure high quality repeatable welds that would meet more stringent weld criteria set by ASME The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing .... In orbital welding, computer-controlled process runs with little intervention from the operator. History The orbital welding process was invented by Rodrick Rohrberg of North American Aviation to ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shielded Metal Arc Welding

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the weld. An electric current, in the form of either alternating current or direct current from a welding power supply, is used to form an electric arc between the electrode and the metals to be joined. The workpiece and the electrode melts forming a pool of molten metal ( weld pool) that cools to form a joint. As the weld is laid, the flux coating of the electrode disintegrates, giving off vapors that serve as a shielding gas and providing a layer of slag, both of which protect the weld area from atmospheric contamination. Because of the versatility of the process and the simplicity of its equipment and operation, shielded metal arc welding is one of the world's first and most popular welding processes. It dominates other welding processes in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Tungsten Arc Welding

Gas tungsten arc welding (GTAW), also known as tungsten inert gas (TIG) welding, is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area and electrode are protected from oxidation or other atmospheric contamination by an inert shielding gas (argon or helium). A filler metal is normally used, though some welds, known as ''autogenous welds'', or ''fusion welds'' do not require it. When helium is used, this is known as heliarc welding. A constant-current welding power supply produces electrical energy, which is conducted across the arc through a column of highly ionized gas and metal vapors known as a plasma. GTAW is most commonly used to weld thin sections of stainless steel and non-ferrous metals such as aluminum, magnesium, and copper alloys. The process grants the operator greater control over the weld than competing processes such as shielded metal arc welding and gas metal arc welding, allowing for stronger, higher quali ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Medical Gas Supply

Medical gas supply systems in hospitals and other healthcare facilities are utilized to supply specialized gases and gas mixtures to various parts of the facility. Products handled by such systems typically include: *Oxygen * Medical air *Nitrous oxide *Nitrogen *Carbon dioxide * Medical vacuum * Waste anaesthetic gas disposal (US) or anaesthetic gas scavenging system (ISO) Source equipment systems are generally required to be monitored by alarm systems at the point of supply for abnormal (high or low) gas pressure in areas such as general ward, operating theatres, intensive care units, recovery rooms, or major treatment rooms. Equipment is connected to the medical gas pipeline system via station outlets (US) or terminal units (ISO). Medical gas systems are commonly color coded to identify their contents, but as coding systems and requirements (such as those for bottled gas) vary by jurisdiction, the text or labeling is the most reliable guide to the contents. Emergency shut-o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll. The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves may regulate pressure or flow downstream and operate on sophisticated automation systems. Valves have many uses, including controlling water for irrigation, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tube Bending

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a die. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry. Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubricants ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

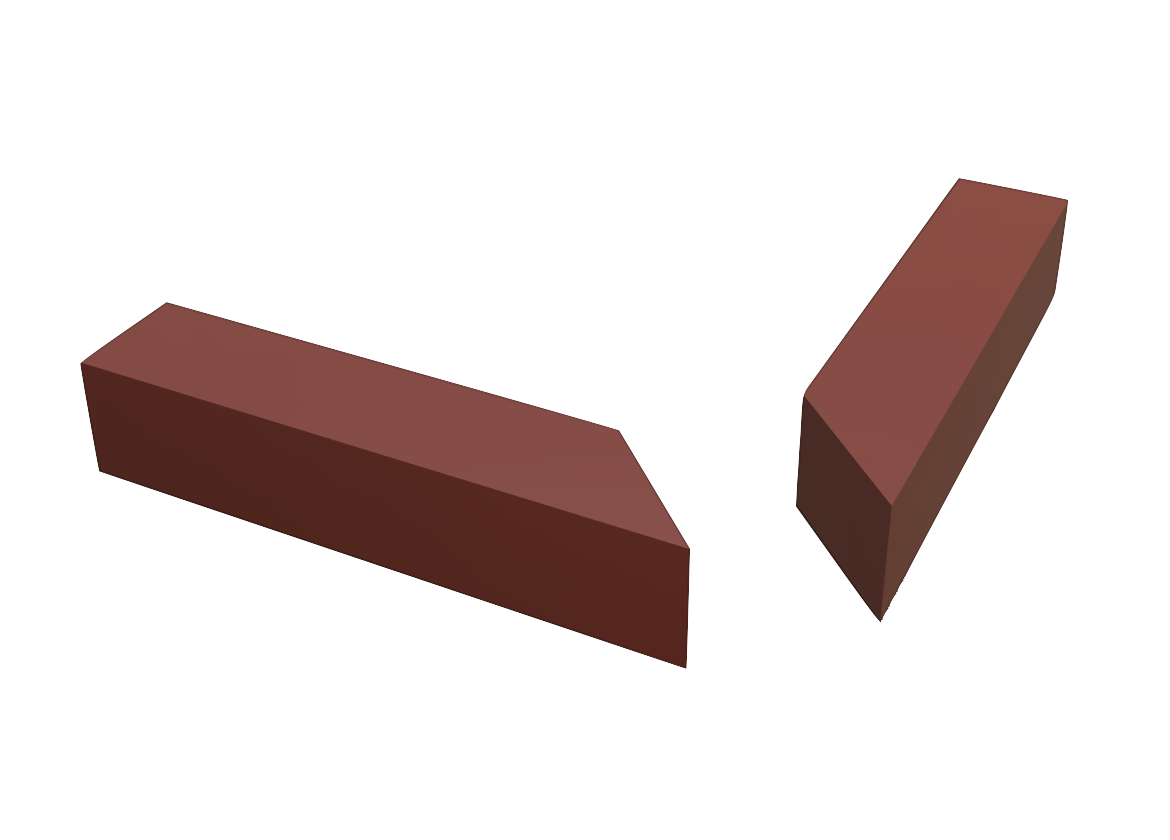

Miter Joint

A mitre joint (often miter in American English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a mitre joint. For woodworking, a disadvantage of a mitre joint is its weakness, but it can be strengthened with a spline (a thin wafer of wood inserted into a slot, usually arranged with the long grain of the spline across the short grain of the frame timber). There are two common variations of a splined mitre joint, one where the spline is long and runs the length of the mating surfaces and another where the spline is perpendicular to the joined edges. Common applications include picture frames, pipe Pipe(s), PIPE(S) or piping may refer to: Objects * Pipe (fluid conveyance), a hollow cylinder following certain di ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |