|

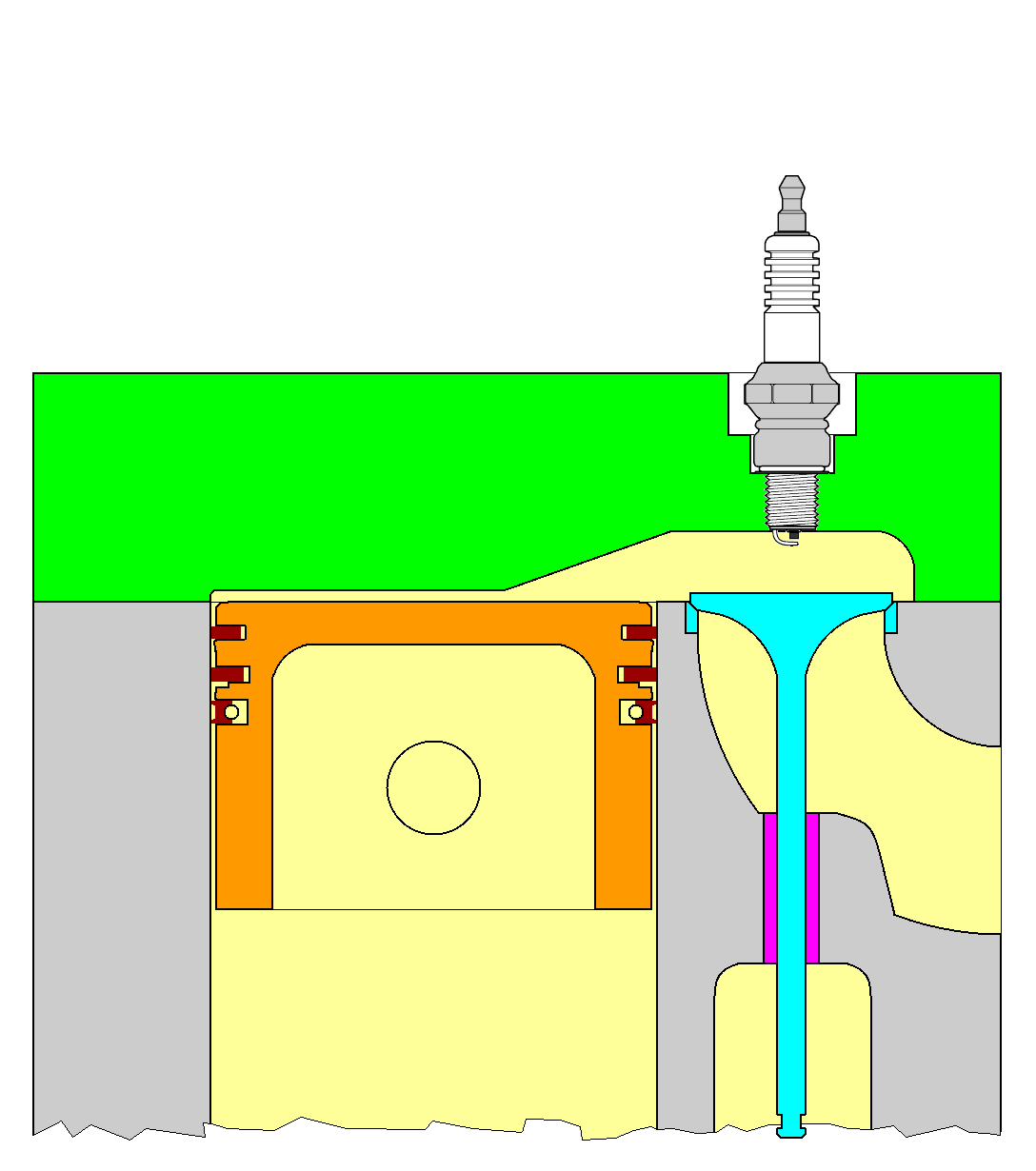

Squish (piston Engine)

Squish is an effect in internal combustion engines which creates sudden turbulence of the air-fuel mixture as the piston approaches top dead centre (TDC)."The Combustion Chamber" Retrieved 16 June 2013. In an engine designed to use the squish effect, at top dead centre the piston crown comes very close (typically less than 1 mm) to the cylinder head. The gases are suddenly "squished" out within the , creating turbulence which promotes thorough air-fuel mixing, a factor beneficial to efficient . Squish effect may be found in [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Squish Band

Squish is an effect in internal combustion engines which creates sudden turbulence of the air-fuel mixture as the piston approaches top dead centre (TDC)."The Combustion Chamber" Retrieved 16 June 2013. In an engine designed to use the squish effect, at top dead centre the piston crown comes very close (typically less than 1 mm) to the cylinder head. The gases are suddenly "squished" out within the , creating turbulence which promotes thorough air-fuel mixing, a factor beneficial to efficient . Squish effect may be found in |

Four-stroke Engine

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: #Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston. #Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are clos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air–fuel Ratio

Air–fuel ratio (AFR) is the mass ratio of air to a solid, liquid, or gaseous fuel present in a combustion process. The combustion may take place in a controlled manner such as in an internal combustion engine or industrial furnace, or may result in an explosion (e.g., a dust explosion, gas explosion, gas or vapor explosion or in a Thermobaric weapon#Fuel–air explosive, thermobaric weapon). The air–fuel ratio determines whether a mixture is combustible at all, how much energy is being released, and how much-unwanted pollutants are produced in the reaction. Typically a range of fuel to air ratios exists, outside of which ignition will not occur. These are known as the lower and upper explosive limits. In an internal combustion engine or industrial furnace, the air–fuel ratio is an important measure for anti-pollution and performance-tuning reasons. If exactly enough air is provided to completely burn all of the fuel, the ratio is known as the stoichiometric mixture, often ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Overhead Camshaft

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an OHV ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flathead Engine

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine. Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1950s but were replaced by more efficient overhead valve and overhead camshaft engines. They are currently experiencing a revival in low-revving aero-engines such as the D-Motor. The side-valve design The valve gear comprises a camshaft sited low in the cylinder block which operates the poppet valves via tappets and short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for further valvetrain components such as lengthy pushrods, rocker arms, overhead valves or overhead camshafts. The sidevalves are typically adjacent, sited on one side of the cylinder(s), though so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soot

Soot ( ) is a mass of impure carbon particles resulting from the incomplete combustion of hydrocarbons. It is more properly restricted to the product of the gas-phase combustion process but is commonly extended to include the residual pyrolysed fuel particles such as coal, cenospheres, charred wood, and petroleum coke that may become airborne during pyrolysis and that are more properly identified as cokes or char. Soot causes various types of cancer and lung disease. Sources Soot as an airborne contaminant in the environment has many different sources, all of which are results of some form of pyrolysis. They include soot from coal burning, internal-combustion engines, power-plant boilers, hog-fuel boilers, ship boilers, central steam-heat boilers, waste incineration, local field burning, house fires, forest fires, fireplaces, and furnaces. These exterior sources also contribute to the indoor environment sources such as smoking of plant matter, cooking, oil lamps, candles, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

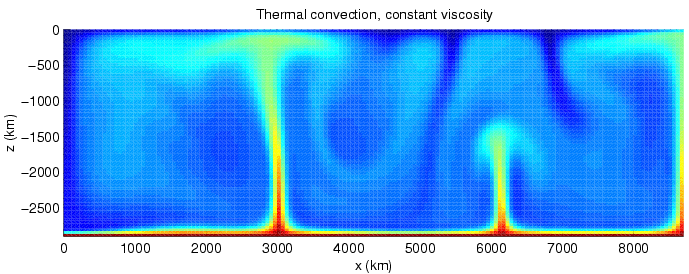

Heat Transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy (heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conduction, thermal convection, thermal radiation, and transfer of energy by phase changes. Engineers also consider the transfer of mass of differing chemical species (mass transfer in the form of advection), either cold or hot, to achieve heat transfer. While these mechanisms have distinct characteristics, they often occur simultaneously in the same system. Heat conduction, also called diffusion, is the direct microscopic exchanges of kinetic energy of particles (such as molecules) or quasiparticles (such as lattice waves) through the boundary between two systems. When an object is at a different temperature from another body or its surroundings, heat flows so that the body and the surroundings reach the same temperature, at which point they are in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Efficiency

In thermodynamics, the thermal efficiency (\eta_) is a dimensionless performance measure of a device that uses thermal energy, such as an internal combustion engine, steam turbine, steam engine, boiler, furnace, refrigerator, ACs etc. For a heat engine, thermal efficiency is the ratio of the net work output to the heat input; in the case of a heat pump, thermal efficiency (known as the ''coefficient of performance'') is the ratio of net heat output (for heating), or the net heat removed (for cooling) to the energy input (external work). The efficiency of a heat engine is fractional as the output is always less than the input while the COP of a heat pump is more than 1. These values are further restricted by the Carnot theorem. Overview In general, energy conversion efficiency is the ratio between the useful output of a device and the input, in energy terms. For thermal efficiency, the input, Q_, to the device is heat, or the heat-content of a fuel that is consumed. The de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Two-stroke Engine

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of the crankshaft. A four-stroke engine requires four strokes of the piston to complete a power cycle during two crankshaft revolutions. In a two-stroke engine, the end of the combustion stroke and the beginning of the compression stroke happen simultaneously, with the intake and exhaust (or scavenging) functions occurring at the same time. Two-stroke engines often have a high power-to-weight ratio, power being available in a narrow range of rotational speeds called the power band. Two-stroke engines have fewer moving parts than four-stroke engines. History The first commercial two-stroke engine involving cylinder compression is attributed to Scottish engineer Dugald Clerk, who patented his design in 1881. However, unlike most later two ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Side-valve Engine V2

A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as in an overhead valve engine. Flatheads were widely used internationally by automobile manufacturers from the late 1890s until the mid-1950s but were replaced by more efficient overhead valve and overhead camshaft engines. They are currently experiencing a revival in low-revving aero-engines such as the D-Motor. The side-valve design The valve gear comprises a camshaft sited low in the cylinder block which operates the poppet valves via tappets and short pushrods (or sometimes with no pushrods at all). The flathead system obviates the need for further valvetrain components such as lengthy pushrods, rocker arms, overhead valves or overhead camshafts. The sidevalves are typically adjacent, sited on one side of the cylinder(s), though some ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heron Cylinder Head

A Heron cylinder head, or simply Heron head, is a design for the combustion chambers of the cylinder head on an internal combustion piston engine, named for engine designer S.D.Heron. The head is machined flat, with recesses only for inlet and exhaust valves, spark plugs, injectors and so on. The combustion chamber itself is contained within a dished depression in the top of the piston. The Heron head is suitable for petrol and diesel engines, for ohv and ohc valve-gear, and for small and large engine displacement capacities. While a flat cylinder head could be combined with simple flat-top pistons, that option ignores the reasons for having a depression in the top of each piston, namely: (i) it provides a compact space for combustion to begin, allowing an optimal flame front; and (ii) it creates significant " squish" as the piston reaches TDC. This causes turbulence, which is desirable because it promotes more extensive mixing of the fuel/air mixture: cf: cf1, cf2, cf3. Having ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)