|

Superalloys

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Key characteristics of a superalloy include mechanical strength, Creep (deformation), thermal creep deformation resistance, surface stability, and corrosion and oxidation resistance. The crystal structure is typically face-centered cubic (FCC) austenitic. Examples of such alloys are Hastelloy, Inconel, Waspaloy, Rene 41, Rene alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys. Superalloy development relies on chemical and process innovations. Superalloys develop high temperature strength through solid solution strengthening and precipitation strengthening from secondary phase precipitates such as gamma prime and carbides. Oxidation or corrosion resistance is provided by elements such as aluminium and chromium. Superalloys are often cast as a single crystal in order to eliminate Grain boundary strengthening, grain boundaries, trading in strengt ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Creep (deformation)

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to undergo slow deformation while subject to persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material. Creep is more severe in materials that are subjected to heat for long periods and generally increases as they near their melting point. The rate of deformation is a function of the material's properties, exposure time, exposure temperature and the applied structural load. Depending on the magnitude of the applied stress and its duration, the deformation may become so large that a component can no longer perform its function – for example creep of a turbine blade could cause the blade to contact the casing, resulting in the failure of the blade. Creep is usually of concern to engineers and metallurgists when evaluating components that operate under high stresses or high temperatures ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine

A gas turbine or gas turbine engine is a type of Internal combustion engine#Continuous combustion, continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller (turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission (turboshaft), marine propeller or electric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium

Chromium is a chemical element; it has Symbol (chemistry), symbol Cr and atomic number 24. It is the first element in Group 6 element, group 6. It is a steely-grey, Luster (mineralogy), lustrous, hard, and brittle transition metal. Chromium is valued for its high corrosion resistance and hardness. A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic chromium to form stainless steel. Stainless steel and chrome plating (electroplating with chromium) together comprise 85% of the commercial use. Chromium is also greatly valued as a metal that is able to be highly polishing, polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, and almost 90% of infrared, infrared light. The name of the element is derived from the Ancient Greek, Greek word χρῶμα, ''chrōma'', meaning color, because many chromium compounds are intensely colored. Indust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metals

A metal () is a material that, when polished or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. These properties are all associated with having electrons available at the Fermi level, as against nonmetallic materials which do not. Metals are typically ductile (can be drawn into a wire) and malleable (can be shaped via hammering or pressing). A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polymeric sulfur nitride. The general science of metals is called metallurgy, a subtopic of materials science; aspects of the electronic and thermal properties are also within the scope of condensed matter physics and solid-state chemistry, it is a multidisciplinary topic. In colloquial use materials such as steel alloys are referred to as metals, while others such as polymers, wood or ceramics are nonmetallic materials. A metal conducts electricity at a temperature of absolute z ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Incoloy

Incoloy refers to a range of superalloys now produced by the Special Metals Corporation (SMC) group of companies and created with a trademark by the Inco company in 1952. Originally Inco protected these alloys by patent. In 2000, the SMC published a 61-page document entitled "High-Performance Alloys for Resistance to Aqueous Corrosion" highlighting Incoloy, as well as Monel and Inconel products, and their use in fluid environments such as sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, nitric acid, other acids as well as freshwater environments. Incoloy products are mostly chromium-based and mostly nickel-based, and designed for corrosion resistance as well as strength at high temperatures. Incoloy alloys belong to the category of super austenitic stainless steels. One advantage is that Incoloy alloys do not have to be heat treated after welding to restore the corrosion resistance. Types There are different alloys to resist particular chemical attacks or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waspaloy

Waspaloy is a registered trademark of United Technologies Corp that refers to an age hardening austenitic ( face-centred cubic) nickel-based superalloy. Waspaloy is typically used in high temperature applications, particularly in gas turbines. Nominal composition Nickel 58%, chromium 19%, cobalt 13%, molybdenum 4%, titanium 3%, aluminium 1.4% Chemistry Table Properties Waspaloy is an age-hardenable, nickel-based superalloy with excellent strength properties through temperatures of roughly 980°C (1800°F). Other characteristics of Waspaloy include good corrosion resistance, as well as being relatively impervious to oxidation making it well suited for service in extreme environments. Waspaloy has useful strength at temperatures up to 760-870°C (1400-1600°F), and good oxidation resistance in gas turbine engine atmospheres up to 870°C (1600°F). The creep rupture strength of Waspaloy is superior to that of Alloy 718 at temperatures above 620-650°C (1150-1200°F). Shor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel

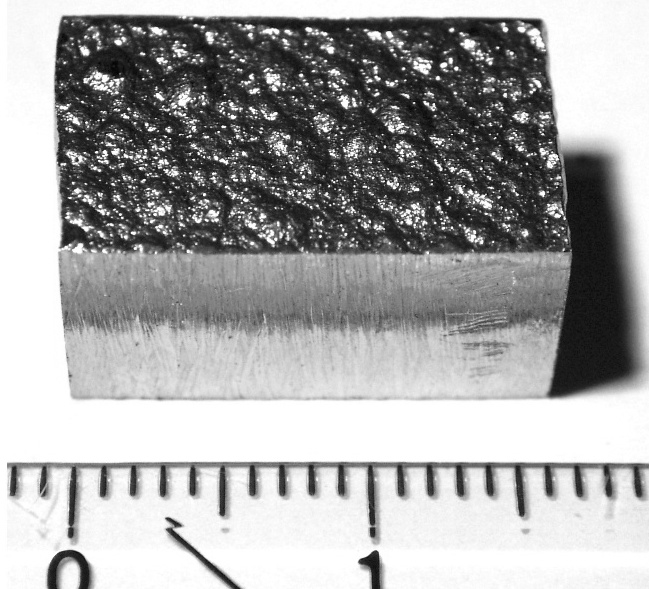

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or Mechanical load, mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivation (chemistry), passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminum and steel would succumb to creep (deformation), creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.Inconel alloy 718 , Special Metals Corporation Inconel all ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hastelloy

Haynes International, Inc., a subsidiary of Acerinox headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, Laporte, Indiana, and Mountain Home, North Carolina. The Kokomo facility specializes in flat products, the Arcadia facility in tubular products, and the Mountain Home facility in wire products. In fiscal year 2018, the company's revenues were derived from the aerospace (52.1%), chemical processing (18.2%), industrial gas turbine (12.0%) and other (12.3%) industries. The company's alloys are primarily marketed under the Hastelloy and the Haynes brands. They are based on nickel, but also include cobalt, chromium, molybdenum, tungsten, iron, silicon, manganese, carbon, aluminum, and/or titanium. History The company was founded by Elwood Haynes in 1912 in Kokomo, Indiana, as Haynes Stellite Works. The same year Haynes was awarded t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cobalt

Cobalt is a chemical element; it has Symbol (chemistry), symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, somewhat brittle, gray metal. Cobalt-based blue pigments (cobalt blue) have been used since antiquity for jewelry and paints, and to impart a distinctive blue tint to glass. The color was long thought to be due to the metal bismuth. Miners had long used the name ''kobold ore'' (German language, German for ''goblin ore'') for some of the blue pigment-producing minerals. They were so named because they were poor in known metals and gave off poisonous arsenic-containing fumes when smelted. In 1735, such ores were found to be reducible to a new metal (the first discovered since ancient times), which was ultimately named for the ''kobold''. Today, some cobalt is produced sp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molybdenum

Molybdenum is a chemical element; it has Symbol (chemistry), symbol Mo (from Neo-Latin ''molybdaenum'') and atomic number 42. The name derived from Ancient Greek ', meaning lead, since its ores were confused with lead ores. Molybdenum minerals have been known throughout history, but the element was discovered (in the sense of differentiating it as a new entity from the mineral salts of other metals) in 1778 by Carl Wilhelm Scheele. The metal was first isolated in 1781 by Peter Jacob Hjelm. Molybdenum does not occur naturally as a Native metal, free metal on Earth; in its minerals, it is found only in oxidation state, oxidized states. The free element, a silvery metal with a grey cast, has the List of elements by melting point, sixth-highest melting point of any element. It readily forms hard, stable carbides in alloys, and for this reason most of the world production of the element (about 80%) is used in steel alloys, including high-strength alloys and superalloys. Most molybdenum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's outer and inner core. It is the fourth most abundant element in the Earth's crust, being mainly deposited by meteorites in its metallic state. Extracting usable metal from iron ores requires kilns or furnaces capable of reaching , about 500 °C (900 °F) higher than that required to smelt copper. Humans started to master that process in Eurasia during the 2nd millennium BC and the use of iron tools and weapons began to displace copper alloys – in some regions, only around 1200 BC. That event is considered the transition from the Bronze Age to the Iron Age. In the modern world, iron alloys, such as steel, stainless steel, cast iron and special steels, are by far the most common industrial metals, due to their mechan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |