|

Reflux

Reflux is a technique involving the condensation of vapors and the return of this condensate to the system from which it originated. It is used in industrial and laboratory distillations. It is also used in chemistry to supply energy to Chemical reaction, reactions over a long period of time. Reflux in industrial distillation The term ''reflux'' is very widely used in industries that utilize large-scale Fractionating column, distillation columns and Fractional distillation, fractionators such as oil refinery, petroleum refineries, petrochemical and chemical plants, and natural gas processing plants. In that context, reflux refers to the portion of the overhead liquid product from a distillation column or fractionator that is returned to the upper part of the column as shown in the schematic diagram of a typical industrial distillation column. Inside the column, the downflowing reflux liquid provides cooling and condensation of the upflowing vapors thereby increasing the effi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuous Distillation

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously (without interruption) fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling (or evaporation) and condensation. The process produces at least two output fractions. These fractions include at least one '' volatile'' distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a ''bottoms'' (or ''residuum'') fraction, which is the least volatile residue that has not been separately captured as a condensed vapor. An alternative to continuous distillation is batch distillation, where the mixture is added to the unit at the start of the distillation, distillate fractions are taken out sequentially in time (one after another) during the distillation, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fractional Distillation

Fractional distillation is the separation of a mixture into its component parts, or fractions. Chemical compounds are separated by heating them to a temperature at which one or more fractions of the mixture will vaporize. It uses distillation to fractionate. Generally the component parts have boiling points that differ by less than 25 °C (45 °F) from each other under a pressure of one atmosphere. If the difference in boiling points is greater than 25 °C, a simple distillation is typically used. A crude oil distillation unit uses fractional distillation in the process of refining crude oil. History The fractional distillation of organic substances played an important role in the 9th-century works attributed to the Islamic alchemist Jabir ibn Hayyan, as for example in the ('The Book of Seventy'), translated into Latin by Gerard of Cremona (c. 1114–1187) under the title . The Jabirian experiments with fractional distillation of animal and vegetable subs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Condenser (laboratory)

In chemistry, a condenser is laboratory apparatus used to condense vaporsthat is, turn them into liquidsby cooling them down. Condensers are routinely used in laboratory operations such as distillation, reflux, and extraction. In distillation, a mixture is heated until the more volatile components boil off, the vapors are condensed, and collected in a separate container. In reflux, a reaction involving volatile liquids is carried out at their boiling point, to speed it up; and the vapors that inevitably come off are condensed and returned to the reaction vessel. In Soxhlet extraction, a hot solvent is infused onto some powdered material, such as ground seeds, to leach out some poorly soluble component; the solvent is then automatically distilled out of the resulting solution, condensed, and infused again. Many different types of condensers have been developed for different applications and processing volumes. The simplest and oldest condenser is just a long tube through which t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Round Bottom Flask

Round-bottom flasks (also called round-bottomed flasks or RB flasks) are types of Laboratory flask, flasks having spherical bottoms used as laboratory glassware, mostly for chemistry, chemical or biochemistry, biochemical work. They are typically made of glass for chemical Chemically inert, inertness; and in modern days, they are usually made of heat-resistant borosilicate glass. There is at least one tubular section known as the ''neck'' with an opening at the tip. Two- or three-necked flasks are common as well. Round bottom flasks come in many sizes, from 5 mL to 20 L, with the sizes usually inscribed on the glass. In pilot plants even larger flasks are encountered. The ends of the necks are usually conical ground glass joints. These are standardized, and can accept any similarly-sized tapered (male) fittings. Ground glass joint, 24/40 is common for 250 mL or larger flasks, while smaller sizes such as 14/20 or 19/22 are used for smaller flasks. Because of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distillation

Distillation, also classical distillation, is the process of separating the component substances of a liquid mixture of two or more chemically discrete substances; the separation process is realized by way of the selective boiling of the mixture and the condensation of the vapors in a still. Distillation can operate over a wide range of pressures from 0.14 bar (e.g., ethylbenzene/ styrene) to nearly 21 bar (e.g., propylene/propane) and is capable of separating feeds with high volumetric flowrates and various components that cover a range of relative volatilities from only 1.17 ( o-xylene/ m-xylene) to 81.2 (water/ ethylene glycol). Distillation provides a convenient and time-tested solution to separate a diversity of chemicals in a continuous manner with high purity. However, distillation has an enormous environmental footprint, resulting in the consumption of approximately 25% of all industrial energy use. The key issue is that distillation operates based on phase changes, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fractionating Column

A fractionating column or fractional column is equipment used in the distillation of liquid mixtures to separate the mixture into its component parts, or fractions, based on their differences in volatility. Fractionating columns are used in small-scale laboratory distillations as well as large-scale industrial distillations. Laboratory fractionating columns A laboratory fractionating column is a piece of glassware used to separate vaporized mixtures of liquid compounds with close volatility. Most commonly used is either a Vigreux column or a straight column packed with glass beads or metal pieces such as Raschig rings. Fractionating columns help to separate the mixture by allowing the mixed vapors to cool, condense, and vaporize again in accordance with Raoult's law. With each condensation-vaporization cycle, the vapors are enriched in a certain component. A larger surface area allows more cycles, improving separation. This is the rationale for a Vigreux column or a packed fr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heating Mantle

A heating mantle, or isomantle, is a piece of laboratory equipment used to apply heat to containers, as an alternative to other forms of heated bath. In contrast to other heating devices, such as hotplates or Bunsen burners, glassware containers may be placed in direct contact with the heating mantle without substantially increasing the risk of the glassware shattering, because the heating element of a heating mantle is insulated from the container so as to prevent excessive temperature gradients. Heating mantles may have various forms. In a common arrangement, electric wires are embedded within a strip of fabric that can be wrapped around a flask. The current supplied to the device, and hence the temperature achieved, is regulated by a rheostat. This type of heating mantle is quite useful for maintaining an intended temperature within a separatory funnel, for example, after the contents of a reaction have been removed from a primary heat source. Another variety of heati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Plate

A hot plate or hotplate is a heated flat surface on a stove or electric cooker on which food may be cooked, either built into an electric cooker or kitchen stove, or portable, plugged into an electric outlet. Hot plates can also be used as a heat source in laboratories. Description A hot plate or hotplate is a heated flat surface on a stove or electric cooker on which food may be cooked. It comprises a heated top which is flat and usually circular, and may be made of metal, ceramic, or heat-resistant glass, with resistive wire forming a heating element fitted underneath and a thermostat to control the temperature. An electric current is passed through the wire, heating it; the thermostat controls the temperature the top reaches. A hotplate may be a portable self-contained tabletop small appliance cooktop, or incorporated into an electric cooker or kitchen stove. Portable hot plates are often used for food preparation, generally in locations where a full kitchen stove would no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand Bath

A sand bath is a common piece of laboratory equipment made from a container filled with heated sand. It is used to evenly heat another container, most often during a chemical reaction. A sand bath is most commonly used in conjunction with a hot plate or heating mantle. A beaker is filled with sand or metal pellets (called shot) and is placed on the plate or mantle. The reaction vessel is then partially covered by sand or pellets. The sand or shot then conducts the heat from the plate to all sides of the reaction vessel. This technique allows a reaction vessel to be heated throughout with minimal stirring, as opposed to heating the bottom of the vessel and waiting for convection to heat the remainder, cutting down on both the duration of the reaction and the possibility of side reactions that may occur at higher temperatures. A variation on this theme is the water bath in which the sand is replaced with water. It can be used to keep a reaction vessel at the temperature o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Bath

An oil bath is a type of heated bath used in a laboratory, most commonly used to heat up chemical reactions. It is a container of oil that is heated by a hot plate or (in rare cases) a Bunsen burner. Use These baths are commonly used to heat Chemical reaction, reaction mixtures more evenly than would be possible with a hot plate alone, as the entire outside of the reaction flask is heated. Generally, silicone oil is used in modern oil baths, although mineral oil, cottonseed oil and even phosphoric acid have been used in the past. Hazards Overheating the oil bath can result in a fire hazard, especially if mineral oil is being used. Generally, the maximum safe operating temperature of a mineral oil bath is approximately , the oil's flash point. Mineral oil cannot be used above due to the compound's boiling point. If higher temperatures are needed, a silicone oil or a sand bath may be used instead. Silicone oil baths are effective in the 25 °C (77 °F) - 230 °C (446 °F) range ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

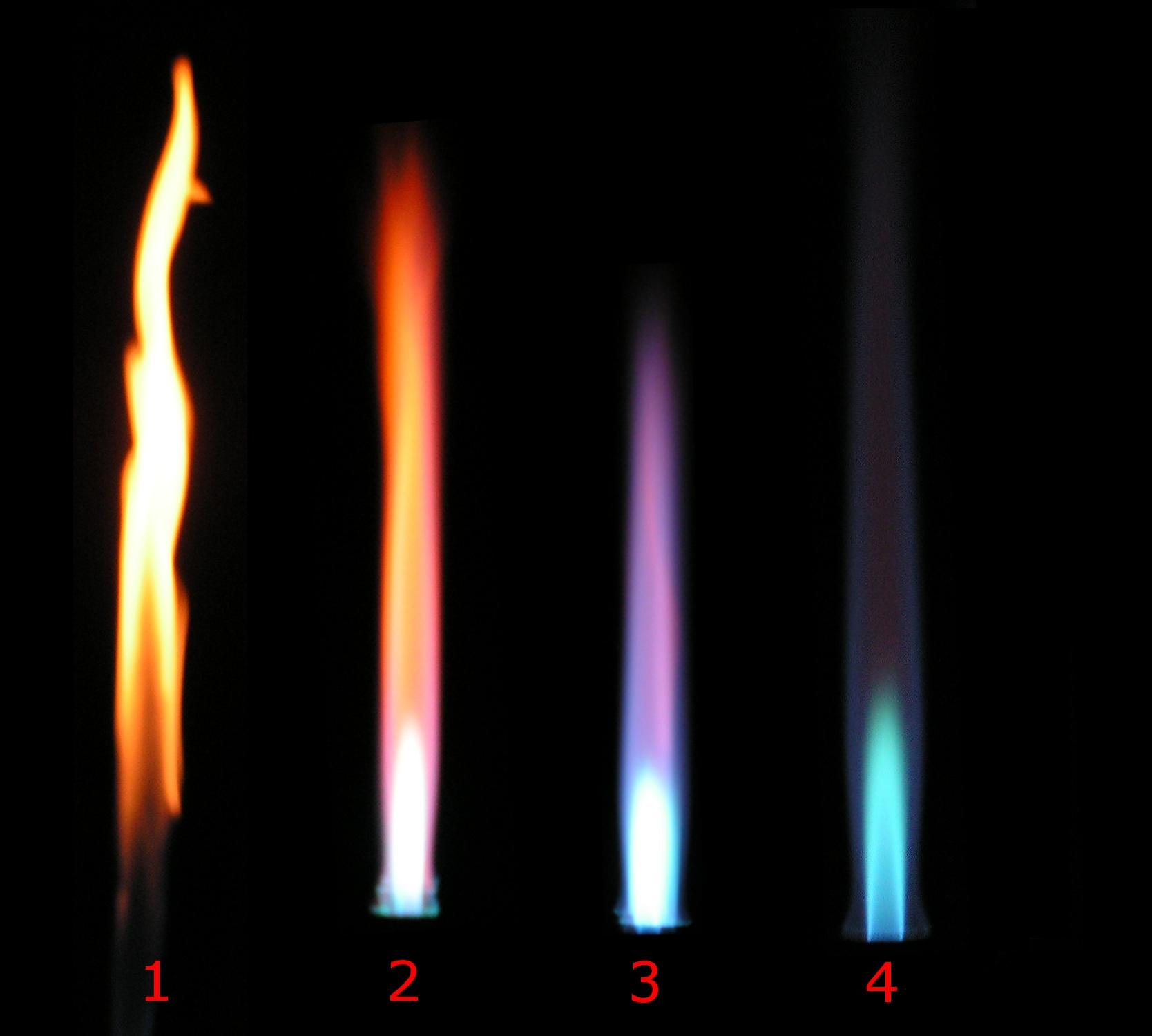

Bunsen Burner

A Bunsen burner, named after Robert Bunsen, is a kind of ambient air gas burner used as laboratory equipment; it produces a single open gas flame, and is used for heating, sterilization, and combustion. The gas can be natural gas (which is mainly methane) or a liquefied petroleum gas, such as propane, butane, a mixture or, as Bunsen himself used, coal gas. Combustion temperature achieved depends in part on the adiabatic flame temperature of the chosen fuel mixture. History In 1852, the University of Heidelberg hired Bunsen and promised him a new laboratory building. The city of Heidelberg had begun to install coal-gas street lighting, and the university laid gas lines to the new laboratory. The designers of the building intended to use the gas not just for lighting, but also as fuel for burners for laboratory operations. For any burner lamp, it was desirable to maximize the temperature of its flame, and minimize its luminosity (which represented lost heating energy). Bunsen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |