|

Polymer Engineering

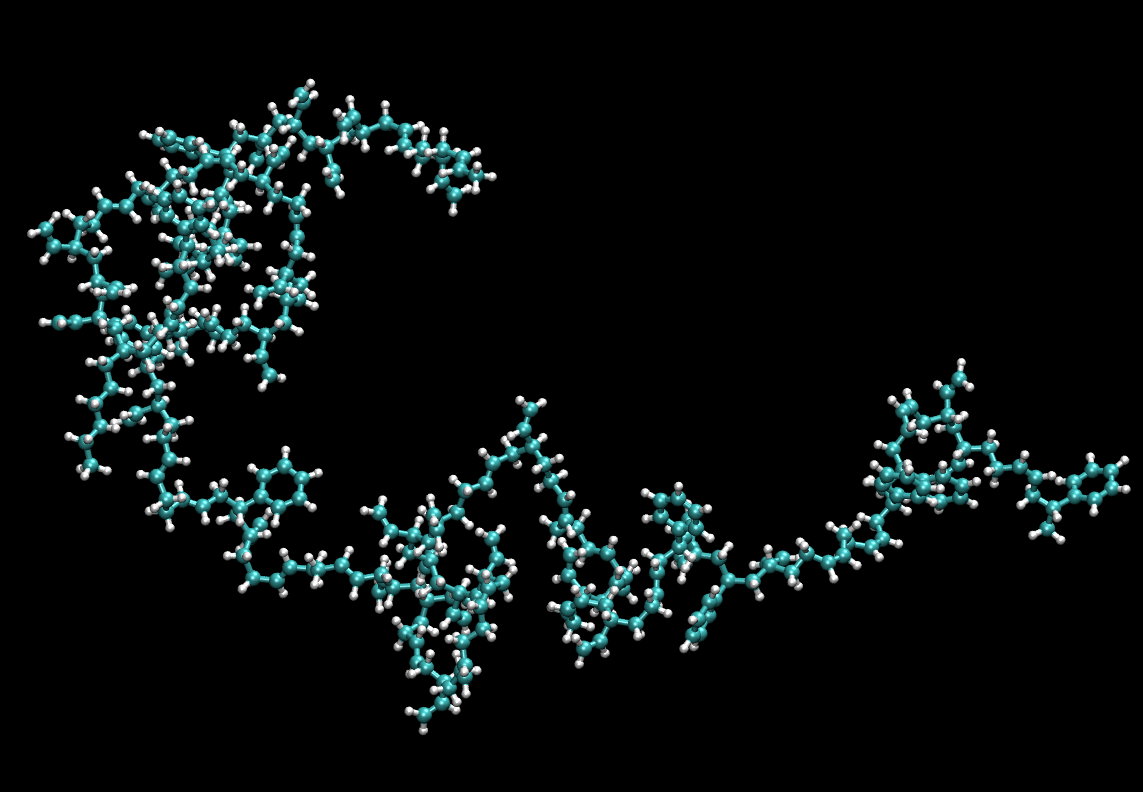

Polymer engineering is generally an engineering field that designs, analyses, and modifies polymer materials. Polymer engineering covers aspects of the petrochemical industry, polymerization, structure and characterization of polymers, properties of polymers, compounding and processing of polymers and description of major polymers, structure property relations and applications. History The word “polymer” was introduced by the Swedish chemist J. J. Berzelius. He considered, for example, benzene (C6H6) to be a polymer of ethyne (C2H2). Later, this definition underwent a subtle modification. The history of human use of polymers has been long since the mid-19th century, when it entered the chemical modification of natural polymers. In 1839, Charles Goodyear found a critical advance in the research of rubber vulcanization, which has turned natural rubber into a practical engineering material. In 1870, J. W. Hyatt uses camphor to plasticize nitrocellulose to make nitrocellulose ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engineering

Engineering is the practice of using natural science, mathematics, and the engineering design process to Problem solving#Engineering, solve problems within technology, increase efficiency and productivity, and improve Systems engineering, systems. Modern engineering comprises many subfields which include designing and improving infrastructure, machinery, vehicles, electronics, Materials engineering, materials, and energy systems. The Academic discipline, discipline of engineering encompasses a broad range of more Academic specialization, specialized fields of engineering, each with a more specific emphasis for applications of applied mathematics, mathematics and applied science, science. See glossary of engineering. The word '':wikt:engineering, engineering'' is derived from the Latin . Definition The American Engineers' Council for Professional Development (the predecessor of the Accreditation Board for Engineering and Technology aka ABET) has defined "engineering" as: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nylon

Nylon is a family of synthetic polymers characterised by amide linkages, typically connecting aliphatic or Polyamide#Classification, semi-aromatic groups. Nylons are generally brownish in color and can possess a soft texture, with some varieties exhibiting a silk-like appearance. As Thermoplastic, thermoplastics, nylons can be melt-processed into fibres, Thin film, films, and diverse shapes. The properties of nylons are often modified by blending with a variety of additives. Numerous types of nylon are available. One family, designated nylon-XY, is derived from diamines and dicarboxylic acids of carbon chain lengths X and Y, respectively. An important example is nylon-6,6 (). Another family, designated nylon-Z, is derived from amino acid, aminocarboxylic acids with carbon chain length Z. An example is nylon-[6]. Nylon polymers have extensive commercial applications, including uses in textiles and fibres (such as apparel, flooring and rubber reinforcement), molded components fo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phenolic Resin

Phenol formaldehyde resins (PF), also called phenolic resins or phenoplasts, are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. Used as the basis for Bakelite, PFs were the first commercial synthetic resins. They have been widely used for the production of molded products including billiard balls, laboratory countertops, and as coatings and adhesives. They were at one time the primary material used for the production of circuit boards but have been largely replaced with epoxy resins and fiberglass cloth, as with fire-resistant FR-4 circuit board materials. There are two main production methods. One reacts phenol and formaldehyde directly to produce a thermosetting network polymer, while the other restricts the formaldehyde to produce a prepolymer known as novolac which can be moulded and then cured with the addition of more formaldehyde and heat.A. Gardziella, L.A. Pilato, A. Knop, Phenolic Resins: Chemistry, Applications, Standard ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermosetting Polymer

In materials science, a thermosetting polymer, often called a thermoset, is a polymer that is obtained by irreversibly hardening (" curing") a soft solid or viscous liquid prepolymer (resin). Curing is induced by heat or suitable radiation and may be promoted by high pressure or mixing with a catalyst. Heat is not necessarily applied externally, and is often generated by the reaction of the resin with a curing agent (''catalyst'', '' hardener''). Curing results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network. The starting material for making thermosets is usually malleable or liquid prior to curing, and is often designed to be molded into the final shape. It may also be used as an adhesive. Once hardened, a thermoset cannot be melted for reshaping, in contrast to thermoplastic polymers which are commonly produced and distributed in the form of pellets, and shaped into the final product form ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Styrene-butadiene

Styrene-butadiene or styrene-butadiene rubber (SBR) describe families of synthetic rubbers derived from styrene and butadiene (the version developed by Goodyear is called Neolite). These materials have good abrasion resistance and good aging stability when protected by additives. In 2012, more than 5.4 million tonnes of SBR were processed worldwide. About 50% of car tires are made from various types of SBR. The styrene/butadiene ratio influences the properties of the polymer: with high styrene content, the rubbers are harder and less rubbery. SBR is not to be confused with the thermoplastic elastomer, styrene-butadiene block copolymer, although being derived from the same monomers. Types SBR is derived from two monomers, styrene and butadiene. The mixture of these two monomers is polymerized by two processes: from solution (S-SBR) or as an emulsion (E-SBR). E-SBR is more widely used. Emulsion polymerization E-SBR produced by emulsion polymerization is initiated by f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polybutadiene

Polybutadiene utadiene rubber, BRis a synthetic rubber. It offers high elasticity, high resistance to wear, good strength even without fillers, and excellent abrasion resistance when filled and vulcanized. "Polybutadiene" is a collective name for homopolymers formed from the polymerization of the monomer 1,3-butadiene. The IUPAC refers to polybutadiene as "poly(buta-1,3-diene)". Historically, an early generation of synthetic polybutadiene rubber produced in Germany by Bayer using sodium as a catalyst was known as "Buna rubber". Polybutadiene is typically crosslinked with sulphur, however, it has also been shown that it can be UV cured when bis-benzophenone additives are incorporated into the formulation. Polybutadiene rubber (BR) accounted for about 28% of total global consumption of synthetic rubbers in 2020, whereas styrene-butadiene rubber (SBR) was by far the most important grade (S-SBR 12%, E-SBR 27% of the entire synthetic rubber market). It is mainly used in the manuf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polychloroprene

Neoprene (also polychloroprene) is a family of synthetic rubbers that are produced by polymerization of chloroprene.Werner Obrecht, Jean-Pierre Lambert, Michael Happ, Christiane Oppenheimer-Stix, John Dunn and Ralf Krüger "Rubber, 4. Emulsion Rubbers" in Ullmann's Encyclopedia of Industrial Chemistry, 2012, Wiley-VCH, Weinheim. Neoprene exhibits good chemical stability and maintains flexibility over a wide temperature range. Neoprene is sold either as solid rubber or in latex form and is used in a wide variety of commercial applications, such as laptop sleeves, orthopaedic braces (wrist, knee, etc.), electrical insulation, medical gloves, liquid and sheet-applied elastomeric membranes or flashings, and automotive fan belts. Production Neoprene is produced by free-radical polymerization of chloroprene. In commercial production, this polymer is prepared by free radical emulsion polymerization. Polymerization is initiated using potassium persulfate. Bifunctional nucleophiles, me ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitrile Rubber

Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene. Trade names include Perbunan, Nipol, Krynac and Europrene. This rubber is unusual in being resistant to oil, fuel, and other chemicals. NBR is used in the automotive and aeronautical industry to make fuel and oil handling hoses, seals, grommets, and self-sealing fuel tanks. It is also used in the food service, medical, and nuclear industries to make protective gloves. NBR's stability at temperatures from makes it an ideal material for aeronautical applications. Nitrile butadiene is also used to produce moulded goods, footwear, adhesives, sealants, sponges, expanded foams, and floor mats. Its Resilience_(materials_science), resilience makes NBR a useful material for disposable lab, cleaning, and examination gloves. Nitrile rubber is more resistant than natural rubber to oils and acids, and has superior streng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Natural Rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Hevea brasiliensis, Pará rubber tree (''Hevea brasiliensis'') or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called "tapping". Manufacturers refine this latex into the rubber that is ready for commercial processing. Natural rubber is used extensively in many applications and products, either alone or in combination with other materials. In most of its useful forms, it has a large stretch ratio and high resilience and also is buoyant and water-proof. Industrial demand for rubber-like materials began to out ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tyres

A tire (North American English) or tyre (Commonwealth English) is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, providing a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, designed to match the vehicle's weight and the bearing on the surface that it rolls over by exerting a pressure that will avoid deforming the surface. The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric, and wire, along with carbon black and other chemical compounds. They consist of a tread and a body. The tread provides traction while the body provides containment for a quantity of compressed air. Before rubber was developed, tires were ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermoplastic Elastomer

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers (TPR), are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. While most elastomers are thermosets, thermoplastic elastomers are not, in contrast making them relatively easy to use in manufacturing, for example, by injection moulding. Thermoplastic elastomers show advantages typical of both rubbery materials and plastic materials. The benefit of using thermoplastic elastomers is the ability to stretch to moderate elongations and return to its near original shape creating a longer life and better physical range than other materials. The principal difference between thermoset elastomers and thermoplastic elastomers is the type of cross-linking bond in their structures. In fact, crosslinking is a critical structural factor which imparts high elastic properties. Types There are six g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastomer

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus (E) and high failure strain compared with other materials. The term, a portmanteau of ''elastic polymer'', is often used interchangeably with ''rubber'', although the latter is preferred when referring to vulcanisates. Each of the monomers which link to form the polymer is usually a compound of several elements among carbon, hydrogen, oxygen and silicon. Elastomers are amorphous polymers maintained above their glass transition temperature, so that considerable molecular reconformation is feasible without breaking of covalent bonds. Rubber-like solids with elastic properties are called elastomers. Polymer chains are held together in these materials by relatively weak intermolecular bonds, which permit the polymers to stretch in response to macroscopic stresses. Elastomers are usually thermosets (requiring vulcanization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |