|

Mechanisation

Mechanization (or mechanisation) is the process of changing from working largely or exclusively by hand or with animals to doing that work with machinery. In an early engineering text, a machine is defined as follows: In every fields, mechanization includes the use of hand tools. In modern usage, such as in engineering or economics, mechanization implies machinery more complex than hand tools and would not include simple devices such as an ungeared horse or donkey mill. Devices that cause speed changes or changes to or from reciprocating to rotary motion, using means such as gears, pulleys or sheaves and belts, shafts, cams and cranks, usually are considered machines. After electrification, when most small machinery was no longer hand powered, mechanization was synonymous with motorized machines. Extension of mechanization of the production process is termed as automation and it is controlled by a Feedback, closed loop system in which feedback is provided by the sensors ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution, sometimes divided into the First Industrial Revolution and Second Industrial Revolution, was a transitional period of the global economy toward more widespread, efficient and stable manufacturing processes, succeeding the Second Agricultural Revolution. Beginning in Kingdom of Great Britain, Great Britain around 1760, the Industrial Revolution had spread to continental Europe and the United States by about 1840. This transition included going from craft production, hand production methods to machines; new Chemical industry, chemical manufacturing and Puddling (metallurgy), iron production processes; the increasing use of Hydropower, water power and Steam engine, steam power; the development of machine tools; and rise of the mechanisation, mechanised factory system. Output greatly increased, and the result was an unprecedented rise in population and population growth. The textile industry was the first to use modern production methods, and textiles b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine

A machine is a physical system that uses power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecules, such as molecular machines. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems. Renaissance natural philosophers identified six simple machines which were the elementary devices that put a load into motion, and calculated the ratio of output force to input force, known today as mechanical advantage. Modern machines are complex systems that consist of structural elements, mechanisms and contr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sawmill

A sawmill (saw mill, saw-mill) or lumber mill is a facility where logging, logs are cut into lumber. Modern sawmills use a motorized saw to cut logs lengthwise to make long pieces, and crosswise to length depending on standard or custom sizes (dimensional lumber). The Portable sawmill, "portable" sawmill is simple to operate. The log lies flat on a steel bed, and the motorized saw cuts the log horizontally along the length of the bed, by the operator manually pushing the saw. The most basic kind of sawmill consists of a chainsaw and a customized jig ("Alaskan sawmill"), with similar horizontal operation. Before the invention of the sawmill, boards were made in various manual labour, manual ways, either wood splitting, rived (split) and plane (tool), planed, hewing, hewn, or more often hand sawn by two men with a whipsaw, one above and another in a saw pit below. The earliest known mechanical mill is the Hierapolis sawmill, a Roman water-powered stone mill at Hierapolis, Asia M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Seed Drill

file:7263 Canterbury Agricultural College farm.jpg, Filling a feed-box of a seed drill, Lincoln University (New Zealand), Canterbury Agricultural College farm, 1948 A seed drill is a device used in agriculture that sowing, sows seeds for crops by positioning them in the soil and burying them to a specific depth while being dragged by a tractor. This ensures that seeds will be distributed evenly. The seed drill sows the seeds at the proper seeding rate and depth, ensuring that the seeds are covered by soil. This saves them from being eaten by birds and animals, or being dried up due to exposure to the sun. With seed drill machines, seeds are distributed in rows; this allows plants to get sufficient sunlight and nutrients from the soil. Before the introduction of the seed drill, most seeds were planted by hand broadcast seeding, broadcasting, an imprecise and wasteful process with a poor distribution of seeds and low productivity. The use of a seed drill can improve the ratio of cr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuous Production

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production. Continuous usually means operating 24 hours per day, seven days per week with infrequent maintenance shutdowns, such as semi-annual or annual. Some chemical plants can operate for more than one to two years without a shutdown. Blast furnaces can run from four to ten years without stopping. Common processes Some common continuous processes are the following: * Oil refining *Chemicals *Synthetic fibers * Fertilizers * Pulp and paper * Blast furnace (iron) *Metal smelting *Power stations * Natural gas processing *Sanitary waste water treat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

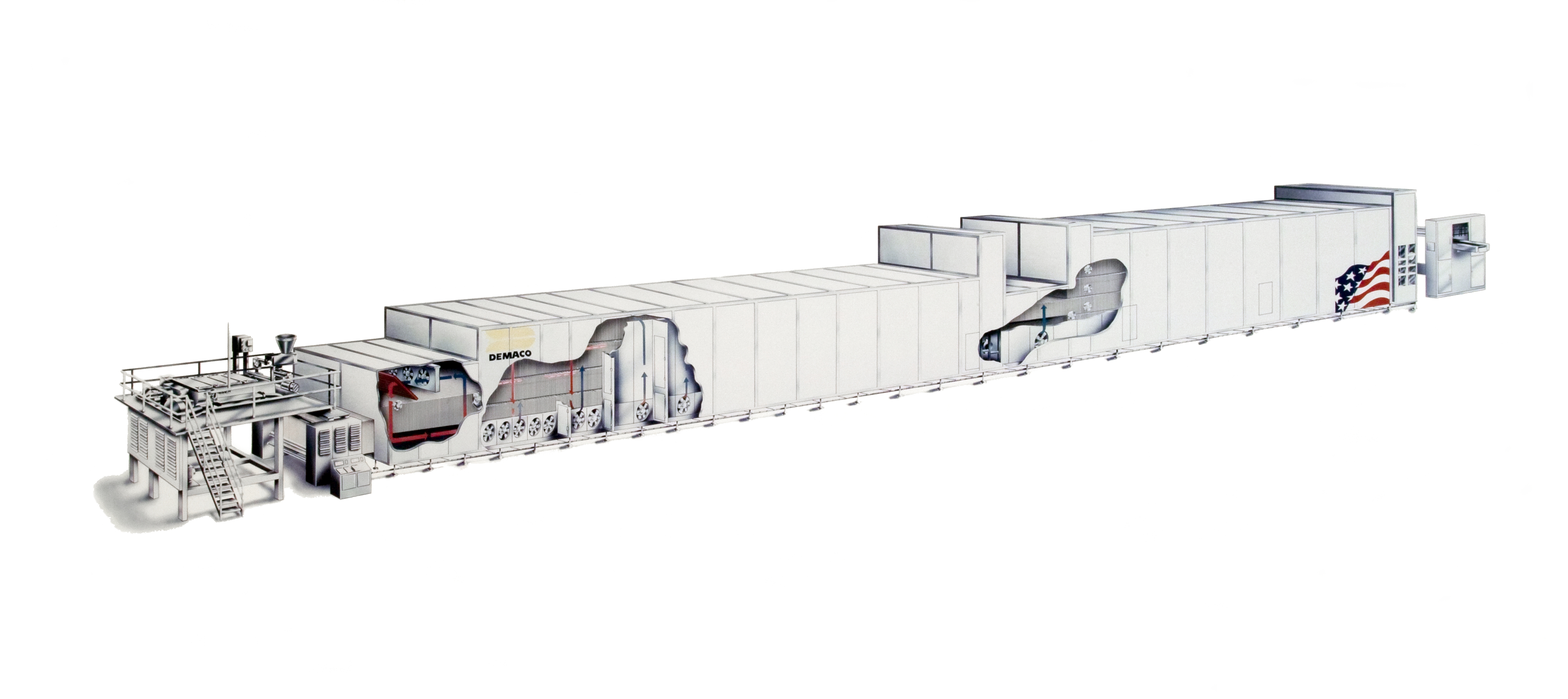

Paper Machine

A paper machine (or paper-making machine) is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web. The basic process is an industrialised version of the historical process of hand paper-making, which could not satisfy the demands of developing modern society for large quantities of a printing and writing substrate. The first modern paper machine was invented by Louis-Nicolas Robert in France in 1799, and an improved version patented in Britain by Henry and Sealy Fourdrinier in 1806. The same process is used to produce paperboard on a paperboard machine. Process sections Paper machines usually have at lea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, Boring (manufacturing), boring, grinding (abrasive cutting), grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "wikt:freehand#Adjective, freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users. While all machine tools are "machines that help people to make things", not a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Frame

The water frame is a spinning frame that is powered by a water-wheel. History Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread, which was first used in 1765. The Arkwright water frame was able to spin 96 threads at a time, which was an easier and faster method than ever before. The design was partly based on a spinning machine built for Thomas Highs by clockmaker John Kay, who was hired by Arkwright. Being run on water power, it produced stronger and harder yarn than the "spinning jenny", and propelled the adoption of the modern factory system. Another water-powered frame for the production of textiles was developed in 1760 in the early industrialized town of Elberfeld, Prussia (now in Wuppertal, Germany), by German bleach plant owner Johann Heinrich Bockmühl. The name ''water frame'' is derived from the use of a water wheel to drive a number of spinning frames. The water wheel provided more power to the spin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

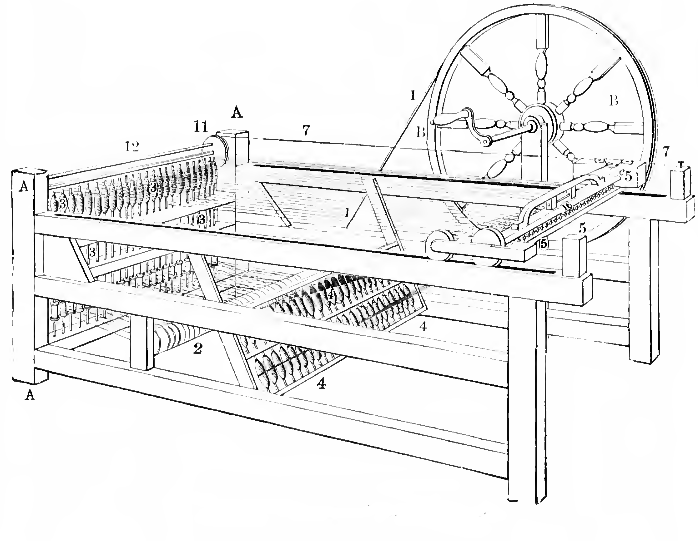

Spinning Jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialisation of textile manufacturing during the early Industrial Revolution. It was invented in 1764–1765 by James Hargreaves in Stan Hill, Oswaldtwistle, Lancashire in England. The device reduced the amount of work needed to produce cloth, with a worker able to work eight or more spools at once. This grew to 120 as technology advanced. The yarn produced by the jenny was not very strong until Richard Arkwright invented the water-powered water frame. The spinning jenny helped to start the factory system of cotton manufacturing. History The spinning jenny was invented by James Hargreaves. He was born in Oswaldtwistle, near Blackburn, around 1720. Blackburn was a town with a population of about 5,000, known for the production of "Blackburn greys," cloths of linen warp and cotton weft initially imported from India. They were usually sent to London to be printed. A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Smeaton

John Smeaton (8 June 1724 – 28 October 1792) was an English civil engineer responsible for the design of bridges, canals, harbours and lighthouses. He was also a capable mechanical engineer and an eminent scholar, who introduced various scientific method, scientific methodologies into engineering.Morris, Andrew M.A. (2021). "English engineer John Smeaton's experimental method(s)". Studies in History and Philosophy of Science, 89, 283-294, url=https://doi.org/10.1016/j.shpsa.2021.07.004 Smeaton was the first self-proclaimed "civil engineer", and is often regarded as the "father of civil engineering".Denny, Mark (2007). "Ingenium: Five Machines That Changed the World". p. 34. JHU Press. He pioneered the use of hydraulic lime in concrete, using pebbles and powdered brick as aggregate. Smeaton was associated with the Lunar Society. Law and physics Smeaton was born in Austhorpe, Leeds, England. After studying at Leeds Grammar School he joined his father's law firm, but left t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Newcomen Steam Engine

The atmospheric engine was invented by Thomas Newcomen in 1712, and is sometimes referred to as the Newcomen fire engine (see below) or Newcomen engine. The engine was operated by condensing steam being drawn into the cylinder, thereby creating a partial vacuum which allowed atmospheric pressure to push the piston into the cylinder. It is significant as the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mining, mines. Hundreds were constructed during the 18th century. James Watt's Watt steam engine, later engine design was an improved version of the Newcomen engine that roughly doubled fuel efficiency. Many atmospheric engines were converted to the Watt design. As a result, Watt is today better known than Newcomen in relation to the origin of the steam engine. Precursors Prior to Newcomen a number of small steam devices of various sorts had been made, but most were es ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |