|

Magnetic Pulse Welding

Magnetic pulse welding (MPW) is a solid state welding process that uses magnetic forces to weld two workpieces together. The welding mechanism is most similar to that of explosion welding. Magnetic pulse welding started in the early 1970s, when the automotive industry began to use solid state welding. The primary advantage of using magnetic pulse welding is that the formation of brittle intermetallic phases is avoided, allowing the joining of metals which cannot be effectively joined by fusion welding. Additionally, the process is nearly instantaneous and does not require shielding gas or other welding consumables. Process Magnetic pulse welding is based on a very short electromagnetic pulse (<100 μs), which is obtained by a fast discharge of capacitors through low inductance switches into a coil. The pulsed current with a very high amplitude and frequency (500 kA and 15 kHz) produces a high-density magnetic field, which creates an eddy current in one of the work ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frequency

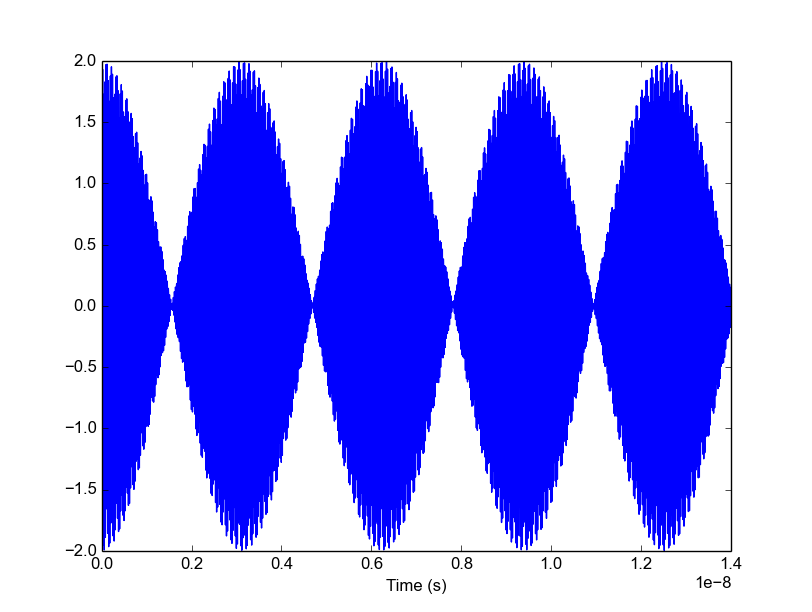

Frequency is the number of occurrences of a repeating event per unit of time. Frequency is an important parameter used in science and engineering to specify the rate of oscillatory and vibratory phenomena, such as mechanical vibrations, audio signals (sound), radio waves, and light. The interval of time between events is called the period. It is the reciprocal of the frequency. For example, if a heart beats at a frequency of 120 times per minute (2 hertz), its period is one half of a second. Special definitions of frequency are used in certain contexts, such as the angular frequency in rotational or cyclical properties, when the rate of angular progress is measured. Spatial frequency is defined for properties that vary or cccur repeatedly in geometry or space. The unit of measurement of frequency in the International System of Units (SI) is the hertz, having the symbol Hz. Definitions and units For cyclical phenomena such as oscillations, waves, or for examp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photon Doppler Velocimetry

Photon Doppler velocimetry (PDV) is a one-dimensional Fourier transform analysis of a heterodyne laser interferometry, used in the shock physics community to measure velocities in dynamic experiments with high temporal precision. PDV was developed at Lawrence Livermore National Laboratory by Oliver Strand. In recent years PDV has achieved popularity in the shock physics community as an adjunct or replacement for velocity interferometer system for any reflector (VISAR), another time-resolved velocity interferometry system. Modern data acquisition technology and off-the-shelf optical telecommunications devices now enable the assembly of PDV systems within reasonable budgets. Theory The fundamental mechanism of PDV is the interference pattern created by two electromagnetic waves with a small difference in frequency. Since most PDV systems are constructed with available telecommunications equipment, a standard laser source for a PDV system is centered at 1550 nm (or 193.4 T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dynamic Recrystallization

Dynamic recrystallization (DRX) is a type of recrystallization process, found within the fields of metallurgy and geology. In dynamic recrystallization, as opposed to static recrystallization, the nucleation and growth of new grains occurs during deformation rather than afterwards as part of a separate heat treatment. The reduction of grain size increases the risk of grain boundary sliding at elevated temperatures, while also decreasing dislocation mobility within the material. The new grains are less strained, causing a decrease in the hardening of a material. Dynamic recrystallization allows for new grain sizes and orientation, which can prevent crack propagation. Rather than strain causing the material to fracture, strain can initiate the growth of a new grain, consuming atoms from neighboring pre-existing grains. After dynamic recrystallization, the ductility of the material increases. In a stress–strain curve, the onset of dynamic recrystallization can be recognized by a d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Twinning

Crystal twinning occurs when two or more adjacent crystals of the same mineral are oriented so that they share some of the same crystal lattice points in a symmetrical manner. The result is an intergrowth of two separate crystals that are tightly bonded to each other. The surface along which the lattice points are shared in twinned crystals is called a composition surface or twin plane. Crystallographers classify twinned crystals by a number of twin laws, which are specific to the crystal structure. The type of twinning can be a diagnostic tool in mineral identification. There are three main types of twinning. The first is growth twinning which can occur both in very large and very small particles. The second is transformation twinning, where there is a change in the crystal structure. The third is deformation twinning, in which twinning develops in a crystal in response to a shear stress, and is an important mechanism for permanent shape changes in a crystal. Definition T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slip Bands

Slip bands or stretcher-strain marks are localized bands of plastic deformation in metals experiencing stresses. Formation of slip bands indicates a concentrated unidirectional Slip (materials science), slip on certain planes causing a stress concentration. Typically, slip bands induce surface steps (e.g., roughness due persistent slip bands during Fatigue (material), fatigue) and a stress concentration which can be a crack nucleation site. Slip bands extend until impinged by a Grain boundary, boundary, and the generated stress from dislocations pile-up against that boundary will either stop or transmit the operating slip depending on its (mis)orientation. Formation of slip bands under cyclic conditions is addressed as Slip bands#Persistent slip bands, persistent slip bands (PSBs) where formation under monotonic condition is addressed as dislocation planar arrays (or simply slip-bands, see Slip bands#Slip bands in the absence of cyclic loading, ''Slip bands in the absence of cyclic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or Slip (materials science), slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plasticity (physics), Plastic deformation of a material occurs by the creation and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Deformation

In engineering, deformation (the change in size or shape of an object) may be ''elastic'' or ''plastic''. If the deformation is negligible, the object is said to be ''rigid''. Main concepts Occurrence of deformation in engineering applications is based on the following background concepts: * ''Displacements'' are any change in position of a point on the object, including whole-body translations and rotations ( rigid transformations). * ''Deformation'' are changes in the relative position between internals points on the object, excluding rigid transformations, causing the body to change shape or size. * ''Strain'' is the ''relative'' ''internal'' deformation, the dimensionless change in shape of an infinitesimal cube of material relative to a reference configuration. Mechanical strains are caused by mechanical stress, ''see stress-strain curve''. The relationship between stress and strain is generally linear and reversible up until the yield point and the deformation is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lorentz Force

In electromagnetism, the Lorentz force is the force exerted on a charged particle by electric and magnetic fields. It determines how charged particles move in electromagnetic environments and underlies many physical phenomena, from the operation of electric motors and particle accelerators to the behavior of plasmas. The Lorentz force has two components. The electric force acts in the direction of the electric field for positive charges and opposite to it for negative charges, tending to accelerate the particle in a straight line. The magnetic force is perpendicular to both the particle's velocity and the magnetic field, and it causes the particle to move along a curved trajectory, often circular or helical in form, depending on the directions of the fields. Variations on the force law describe the magnetic force on a current-carrying wire (sometimes called Laplace force), and the electromotive force in a wire loop moving through a magnetic field, as described by Faraday's la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Amplitude

The amplitude of a periodic variable is a measure of its change in a single period (such as time or spatial period). The amplitude of a non-periodic signal is its magnitude compared with a reference value. There are various definitions of amplitude (see below), which are all functions of the magnitude of the differences between the variable's extreme values. In older texts, the phase of a periodic function is sometimes called the amplitude. Definitions Peak amplitude and semi-amplitude For symmetric periodic waves, like sine waves or triangle waves, ''peak amplitude'' and ''semi amplitude'' are the same. Peak amplitude In audio system measurements, telecommunications and others where the measurand is a signal that swings above and below a reference value but is not sinusoidal, peak amplitude is often used. If the reference is zero, this is the maximum absolute value of the signal; if the reference is a mean value ( DC component), the peak amplitude is the maximum ab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |