|

Lathe Center

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. The primary use of a center is to ensure concentric work is produced; this allows the workpiece to be transferred between machining (or inspection) operations without any loss of accuracy. A part may be ''turned'' in a lathe, sent off for hardening and tempering and then ground ''between centers'' in a cylindrical grinder. The preservation of concentricity between the turning and grinding operations is crucial for quality work. When turning between centres, a steady can be used to support longer workpieces where the cutting forces would deflect the work excessively, reducing the finish and accuracy of the workpiece, or creating a hazardous situation. A center lathe has applications anywhere that a ''centered'' workpiece may be used; this is not ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tungsten Carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, cutting tools, chisels, abrasives, armor-piercing shells and jewelry. Tungsten carbide is approximately twice as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is double the density of steel—nearly midway between that of lead and gold. It is comparable with corundum (α-) in hardness and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond powder, wheels and compounds. Naming Historically referred to as Wolfram, ''Wolf Rahm'', wolframite ore was then later carburized and cemented with a binder creating a composite now called "tungsten carbide". Tungsten is Swedish for "heavy stone". Co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture wells at Kückhofen and Eythra. Examples of Bronze Age wood-carving include tree trunks worked into coffins from nor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

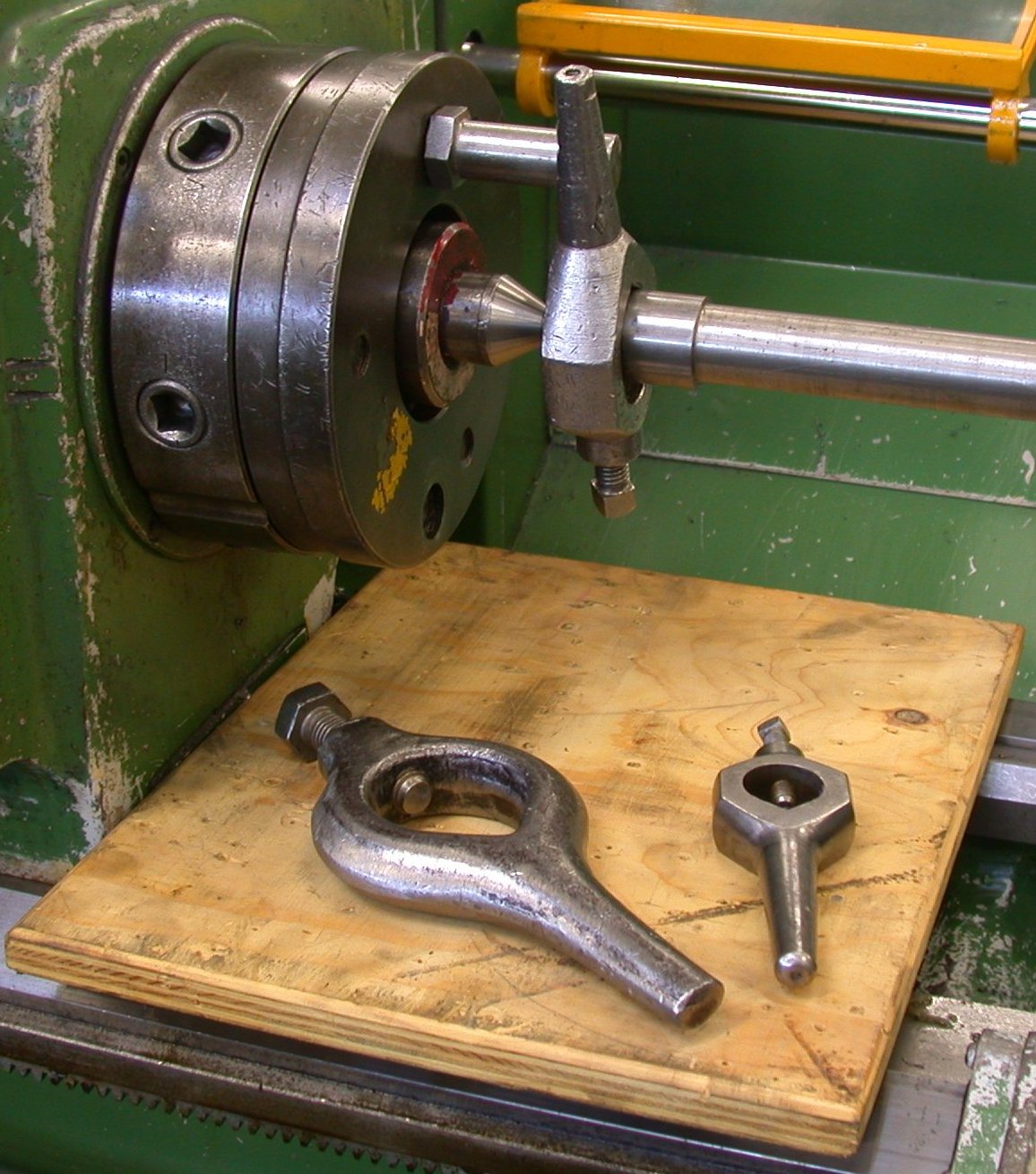

Lathe Carrier

A lathe dog is a mechanical device typically made of cast iron, steel or aluminum that transmits rotary motion from a faceplate to a workpiece mounted between centers in a lathe. The tail of the dog is rotated by a slot in a driving faceplate, a stud mounted on a faceplate, or sometimes a side of a chuck jaw. The workpiece passes through an aperture in the dog into which the work is secured by one or more setscrews or a clamp arrangement. The maximum cross sectional dimension of the workpiece is limited by the dimensions of the dog aperture. Lathe dogs are provided in ''straight tail'' or ''bent tail'' form, and may be ''single tail'' or ''double tail''. A lathe dog designed to hold square, rectangular or odd-shaped work and having a moveable portion secured typically by two cap screws is called a ''clamp dog''. Bent tail dogs are able to engage directly with a driving faceplate slot or a chuck jaw but can crowd work off centre if clearance is not present between the dog tail and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anchor

An anchor is a device, normally made of metal , used to secure a vessel to the bed of a body of water to prevent the craft from drifting due to wind or current. The word derives from Latin ''ancora'', which itself comes from the Greek ἄγκυρα (ankȳra). Anchors can either be temporary or permanent. Permanent anchors are used in the creation of a mooring, and are rarely moved; a specialist service is normally needed to move or maintain them. Vessels carry one or more temporary anchors, which may be of different designs and weights. A sea anchor is a drag device, not in contact with the seabed, used to minimise drift of a vessel relative to the water. A drogue is a drag device used to slow or help steer a vessel running before a storm in a following or overtaking sea, or when crossing a bar in a breaking sea.. Overview Anchors achieve holding power either by "hooking" into the seabed, or mass, or a combination of the two. Permanent moorings use large masse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

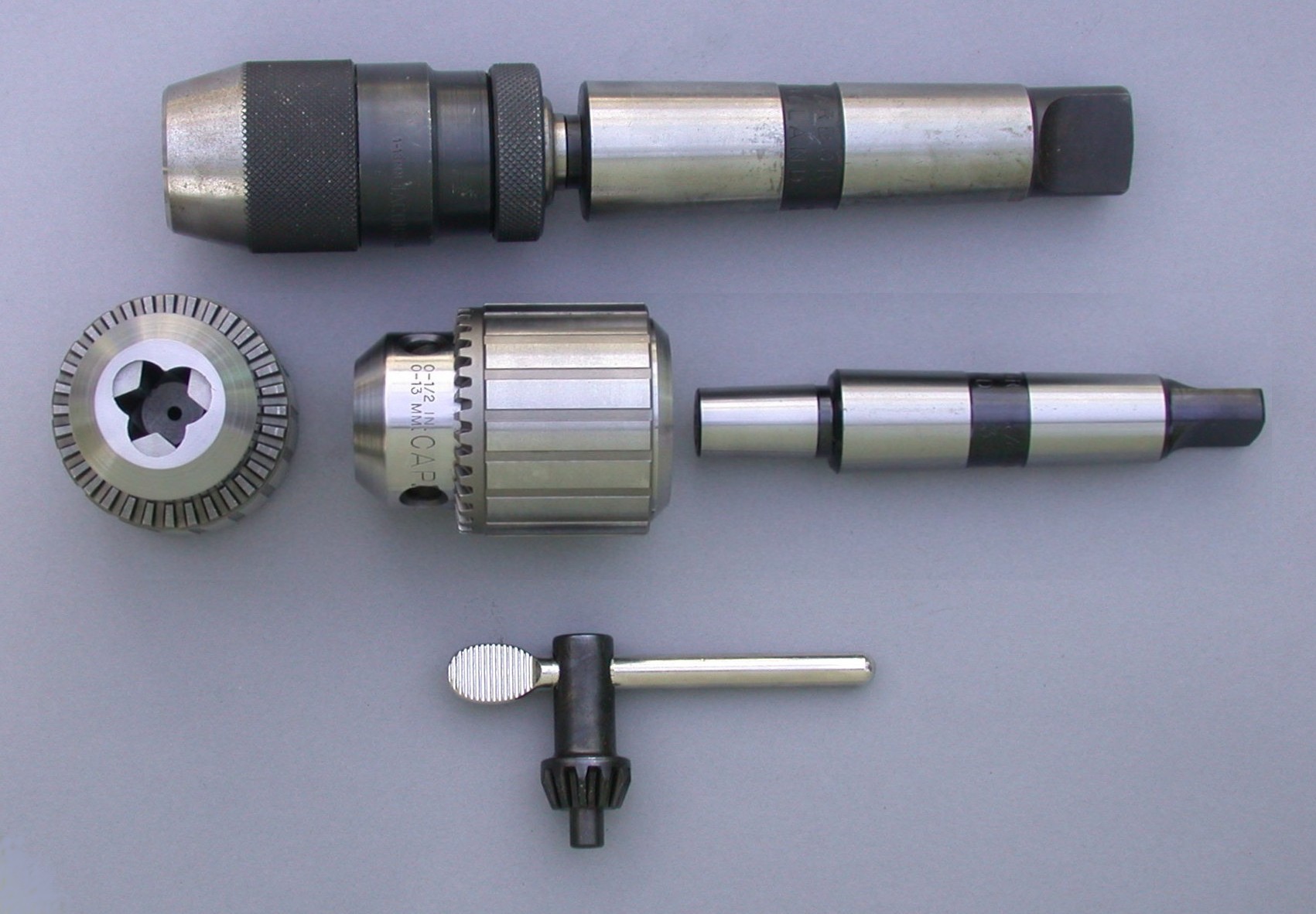

Chuck (engineering)

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws (sometimes called dogs) are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a chuck may use magnetism, vacuum, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may want to moun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction Welding

Friction welding (FRW) is a solid-state welding process that generates heat through mechanical friction between workpieces in relative motion to one another, with the addition of a lateral force called "upset" to plastically displace and fuse the materials. Because no melting occurs, friction welding is not a fusion welding process, but a solid-state welding technique more like forge welding. Friction welding is used with metals and thermoplastics in a wide variety of aviation and automotive applications. ISO norm of friction welding is EN ISO 15620:2019 there is information about basic terms and definitions and table of weldability of metals and alloys. History Some applications and patents connected with friction welding were dated back to the turn of the 20th century and rotary friction welding is the oldest of this methods. W. Richter patented the method of linear friction welding (LFW) process in 1924 in England and 1929 in Germany, however, the description of the process ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concentric

In geometry, two or more objects are said to be concentric, coaxal, or coaxial when they share the same center or axis. Circles, regular polygons and regular polyhedra, and spheres may be concentric to one another (sharing the same center point), as may cylinders (sharing the same central axis). Geometric properties In the Euclidean plane, two circles that are concentric necessarily have different radii from each other.. However, circles in three-dimensional space may be concentric, and have the same radius as each other, but nevertheless be different circles. For example, two different meridians of a terrestrial globe are concentric with each other and with the globe of the earth (approximated as a sphere). More generally, every two great circles on a sphere are concentric with each other and with the sphere. By Euler's theorem in geometry on the distance between the circumcenter and incenter of a triangle, two concentric circles (with that distance being zero) are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)