|

Electrospinning

Electrospinning is a fiber production method that uses Electrostatics, electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution spinning (polymers)#Dry spinning, dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the dr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospun Pcl

Electrospinning is a fiber production method that uses Electrostatics, electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution spinning (polymers)#Dry spinning, dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the dr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospun Fibre Drying

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the droplet is stretched; at a critical point a strea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospinning Image For Wikipedia

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the droplet is stretched; at a critical point a strea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospinning Diagram

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.Ziabicki, A. (1976) ''Fundamentals of fiber formation'', John Wiley and Sons, London, . The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product. Process When a sufficiently high voltage is applied to a liquid droplet, the body of the liquid becomes charged, and electrostatic repulsion counteracts the surface tension and the droplet is stretched; at a critical point a strea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alternating Current Electrospinning

Alternating current electrospinning is a fiber formation technique to produce micro- and nanofibers from polymer solutions under the dynamic drawing force of the electrostatic field with periodically changing polarity. The main benefit of alternating current electrospinning is that multiple times higher productivities are achievable compared to widely used direct current electrospinning setups. References {{reflist Nanotechnology Spinning ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinning (polymers)

Spinning is a manufacturing process for creating polymer fibers. It is a specialized form of extrusion that uses a spinneret to form multiple continuous filaments.. Melt Spinning If the polymer is a thermoplastic then it can undergo melt spinning. The molten polymer is extruded through a spinneret composed of capillaries where the resulting filament is solidified by cooling. Nylon, olefin, polyester, saran, and sulfar are produced via this process. Extrusion spinning Pellets or granules of the solid polymer are fed into an extruder. The pellets are compressed, heated and melted by an extrusion screw, then fed to a spinning pump and into the spinneret. Direct spinning The direct spinning process avoids the stage of solid polymer pellets. The polymer melt is produced from the raw materials, and then from the polymer finisher directly pumped to the spinning mill. Direct spinning is mainly applied during production of polyester fibers and filaments and is dedicated to high prod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Taylor Cone

A Taylor cone refers to the cone observed in electrospinning, electrospraying and hydrodynamic spray processes from which a jet of charged particles emanates above a threshold voltage. Aside from electrospray ionization in mass spectrometry, the Taylor cone is important in field-emission electric propulsion (FEEP) and colloid thrusters used in fine control and high efficiency (low power) thrust of spacecraft. History This cone was described by Sir Geoffrey Ingram Taylor in 1964 before electrospray was "discovered". This work followed on the work of Zeleny who photographed a cone-jet of glycerine in a strong electric field and the work of several others: Wilson and Taylor (1925), Nolan (1926) and Macky (1931). Taylor was primarily interested in the behavior of water droplets in strong electric fields, such as in thunderstorms. Formation When a small volume of electrically conductive liquid is exposed to an electric field, the shape of liquid starts to deform from the shape ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Electrospinning

Roller Electrospinning system a method for producing nanofibres was developed by Jirsak ''et al.''. This method is known under the name Nanospider from Elmarco Company in Liberec. Roller electrospinning is the unique method which has been used in industry to produce nanofibers continuously. Nanospider consists of rotating roller to spin fibers directly from the polymer solution. This roller spinning electrode partially immersed in the tank with the polymer solution. A grounded collector electrode is placed at the top of the spinner . A nonwoven backing material moves along the collector electrode which makes the production of the nanofibre layer a continuous process. Many Taylor cones are simultaneously formed on the surface of the rotating spinning electrode, which makes the technology highly productive. Parameters There are independent and dependent parameters for roller electrospinning. Independent Parameters :Solution parameters: concentration of polymer solution, molecular wei ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinneret (polymers)

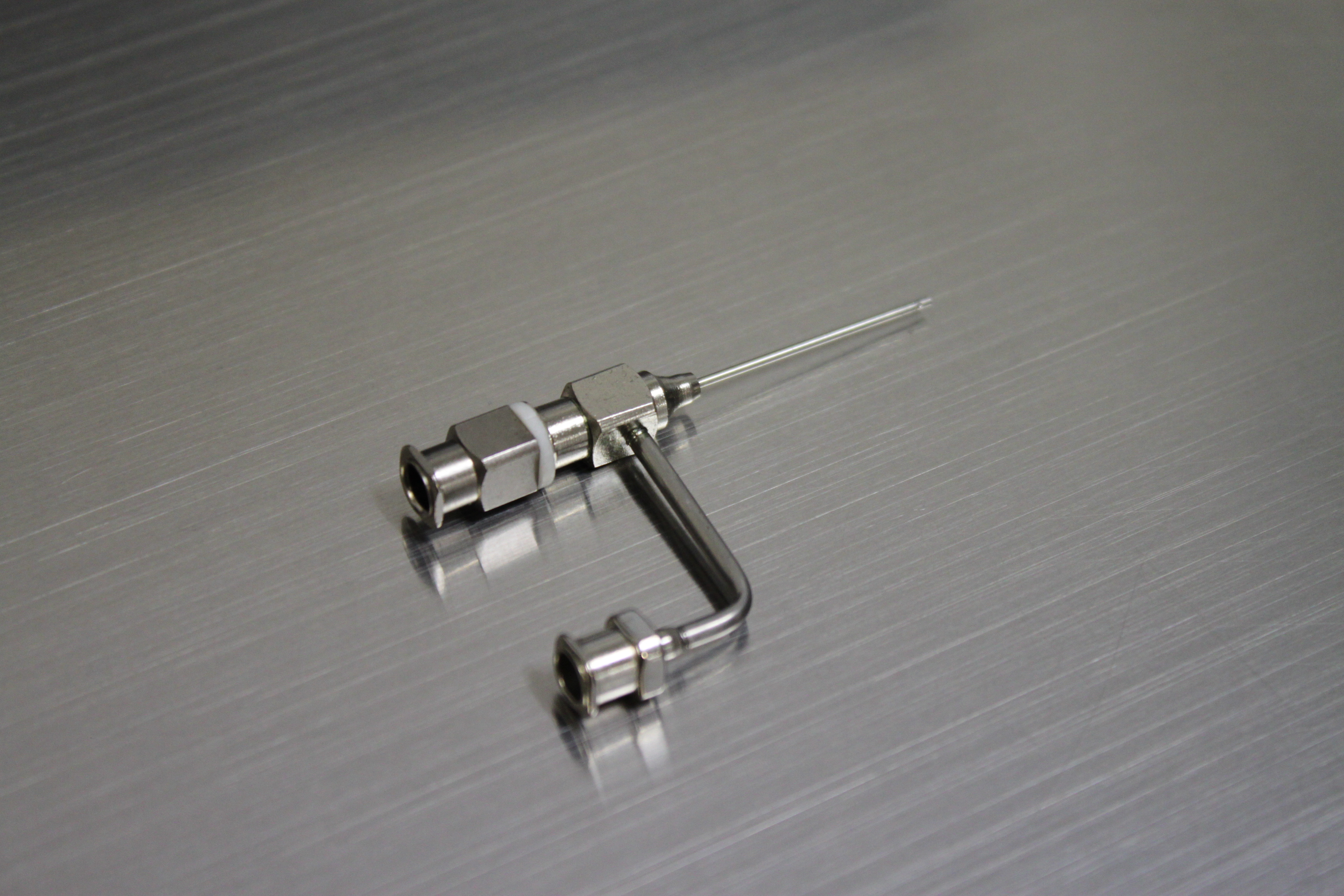

A spinneret is a device used to extrude a polymer solution or polymer melt to form fibers. Streams of viscous polymer exit via the spinneret into air or liquid leading to a phase inversion which allows the polymer to solidify. The individual polymer chains tend to align in the fiber because of viscous flow. This airstream liquid-to-fiber formation process is similar to the production process for cotton candy. The fiber production process is generally referred to as "spinning". Depending on the type of spinneret used, either solid or hollow fibers can be formed. Spinnerets are also used for electrospinning and electrospraying applications. They are sometimes called ''coaxial needles,'' or ''coaxial emitters.'' Spinnerets are usually made of metals with melting points too low to withstand the heating processes employed in industrial metallurgy, and thus are generally not used to form metallic fibers. See also * Electrospinning * Hollow fiber membrane * Spinning (polymers) * Te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinneret (polymers)

A spinneret is a device used to extrude a polymer solution or polymer melt to form fibers. Streams of viscous polymer exit via the spinneret into air or liquid leading to a phase inversion which allows the polymer to solidify. The individual polymer chains tend to align in the fiber because of viscous flow. This airstream liquid-to-fiber formation process is similar to the production process for cotton candy. The fiber production process is generally referred to as "spinning". Depending on the type of spinneret used, either solid or hollow fibers can be formed. Spinnerets are also used for electrospinning and electrospraying applications. They are sometimes called ''coaxial needles,'' or ''coaxial emitters.'' Spinnerets are usually made of metals with melting points too low to withstand the heating processes employed in industrial metallurgy, and thus are generally not used to form metallic fibers. See also * Electrospinning * Hollow fiber membrane * Spinning (polymers) * Te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrospray

The name electrospray is used for an apparatus that employs electricity to disperse a liquid or for the fine aerosol resulting from this process. High voltage is applied to a liquid supplied through an emitter (usually a glass or metallic capillary). Ideally the liquid reaching the emitter tip forms a Taylor cone, which emits a liquid jet through its apex. Varicose waves on the surface of the jet lead to the formation of small and highly charged liquid droplets, which are radially dispersed due to Coulomb repulsion. History In the late 16th century William GilbertGilbert, W. (1628) De Magnete, Magneticisque Corporibus, et de Magno Magnete Tellure (On the Magnet and Magnetic Bodies, and on That Great Magnet the Earth), London, Peter Short set out to describe the behaviour of magnetic and electrostatic phenomena. He observed that, in the presence of a charged piece of amber, a drop of water deformed into a cone. This effect is clearly related to electrosprays, even though Gilber ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Syringe Driver

A syringe driver, also known as a syringe pump, is a small infusion pump, used to gradually administer small amounts of fluid (with or without medication) to a patient or for use in chemical and biomedical research. Some syringe drivers can both infuse and withdraw solutions. Uses Syringe drivers can be used for electrospinning, electrospraying, microdialysis, microfluidics, dispensing/dilution, tissue perfusion, and fluid circulation. Intravenous therapy Syringe drivers are useful for delivering intravenous (IV) therapies over several minutes. They infuse solutions at a constant rate. In the case of a medication which should be slowly pushed in over the course of several minutes, this device saves staff time and reduces medical errors. It is useful for patients who cannot take medicines orally (such as those with difficulty swallowing), and for medications too harmful to be taken orally. Palliative care Syringe drivers are particularly useful in palliative care, to c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |