|

Depanelization

Depaneling or depanelization is a process step in high-volume electronics assembly production. In order to increase the throughput of printed circuit board (PCB) manufacturing and surface-mount technology, surface mount (SMT) lines, PCBs are often arranged in a process called PCB panelization, panelization so that they consist of many smaller individual PCBs that will be used in the final product. This PCB cluster is called a panel or multiblock. The large panel is broken up or "depaneled" as a certain step in the process - depending on the product, it may happen right after surface-mount technology, SMT process, after in-circuit test (ICT), after soldering of through-hole elements, or even right before the final assembly of the PCB assembly (PCBA) into the enclosure. Risks When selecting a depaneling technique, it is important to be mindful of the risks, including: * Mechanical strain: depaneling can be a violent operation and may bend the PCB causing some components to fracture, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

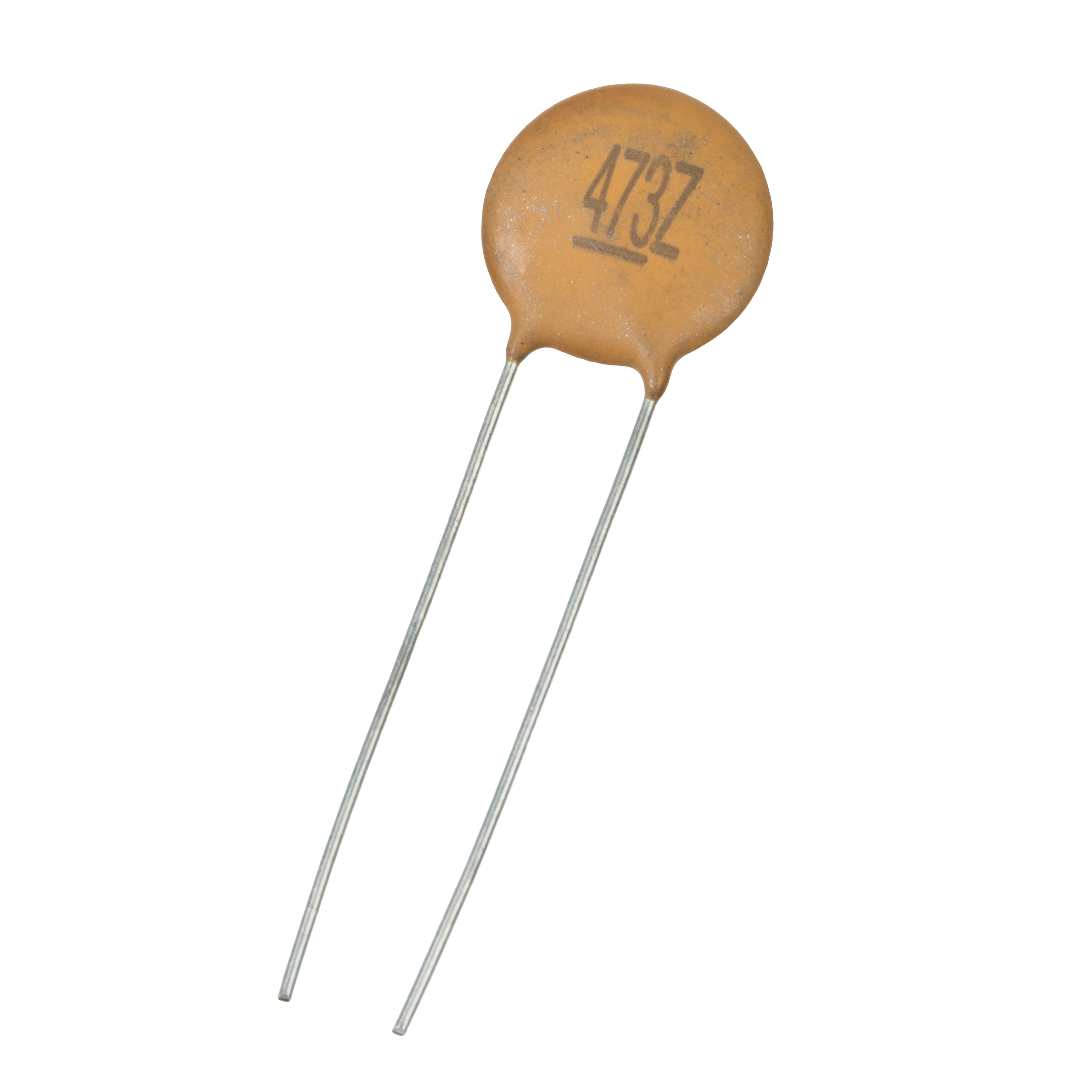

Capacitor Flex Cracking

A ceramic capacitor is a fixed-value capacitor where the ceramic material acts as the dielectric. It is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes. The composition of the ceramic material defines the electrical behavior and therefore applications. Ceramic capacitors are divided into two application classes: * Class 1 ceramic capacitors offer high stability and low losses for resonant circuit applications. * Class 2 ceramic capacitors offer high volumetric efficiency for buffer, by-pass, and coupling applications. Ceramic capacitors, especially multilayer ceramic capacitors (MLCCs), are the most produced and used capacitors in electronic equipment that incorporate approximately one trillion (1012) pieces per year.Download Ceramic capacitors of special shapes and styles are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB), also called printed wiring board (PWB), is a Lamination, laminated sandwich structure of electrical conduction, conductive and Insulator (electricity), insulating layers, each with a pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper laminated onto or between sheet layers of a non-conductive substrate. PCBs are used to connect or Electrical wiring, "wire" Electronic component, components to one another in an electronic circuit. Electrical components may be fixed to conductive pads on the outer layers, generally by soldering, which both electrically connects and mechanically fastens the components to the board. Another manufacturing process adds Via (electronics), vias, metal-lined drilled holes that enable electrical interconnections between conductive layers, to boards with more than a single side. Printed circuit boards are used in nearly all e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Punch (tool)

A punch is a tool used to indent or create a hole through a hard surface. They usually consist of a hard metal rod with a narrow tip at one end and a broad flat "butt" at the other. When used, the narrower end is pointed against a target surface and the broad end is struck with a hammer or mallet, causing the blunt force of the blow to be transmitted through the rod body and focused more sharply onto a small area. Typically, woodworkers use a ball-peen hammer to strike a punch. Use Punches are used to drive fasteners such as nails and dowels, making a hole, or forming an indentation or impression of the tip on a work piece. Decorative punches may also be used to create a pattern or even form an image. Pin Metal pins and similar connectors are driven in or out of holes using a pin punch. For removal, first use a starter punch to loosen the pin, then use a pin punch to finish. Center A ''center punch'' is used to mark the center of a point. It is usually used t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene Terephthalate

Polyethylene terephthalate (or poly(ethylene terephthalate), PET, PETE, or the obsolete PETP or PET-P), is the most common thermoplastic polymer resin of the polyester family and is used in synthetic fibre, fibres for clothing, packaging, containers for liquids and foods, and thermoforming for manufacturing, and in combination with glass fibre for engineering resins. In 2016, annual production of PET was 56 million tons. The biggest application is in fibres (in excess of 60%), with bottle production accounting for about 30% of global demand. In the context of textile applications, PET is referred to by its common name, polyester, whereas the acronym ''PET'' is generally used in relation to packaging. PET used in non-fiber applications (i.e. for packaging) makes up about 6% of world polymer production by mass. Accounting for the >60% fraction of polyethylene terephthalate produced for use as polyester fibers, PET is the fourth-most-produced polymer after polyethylene (PE), polypr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene, and has numerous applications because it is chemically inert. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a corporate spin-off, spin-off from DuPont (1802–2017), DuPont, which originally invented the compound in 1938. Polytetrafluoroethylene is a fluorocarbon solid, as it is a high-molecular-weight polymer consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances Wetting, wet PTFE, as fluorocarbons exhibit only small London dispersion forces due to the low polarizability, electric polarizability of fluorine. PTFE has one of the lowest Friction#Coefficient of friction, coefficients of friction of any solid. Polytetrafluoroethylene is used as a non-stick coating for Cookware and bakeware, pans and other Cookware and bakeware, cookware. It is Chemically inert, non-reactive, partly because of the strength of car ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

FR-4

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (''self-extinguishing''). "FR" stands for "flame retardant", and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968. FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrica ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

UV Laser

Ultraviolet radiation, also known as simply UV, is electromagnetic radiation of wavelengths of 10–400 nanometers, shorter than that of visible light, but longer than X-rays. UV radiation is present in sunlight and constitutes about 10% of the total electromagnetic radiation output from the Sun. It is also produced by electric arcs, Cherenkov radiation, and specialized lights, such as mercury-vapor lamps, tanning lamps, and black lights. The photons of ultraviolet have greater energy than those of visible light, from about 3.1 to 12 electron volts, around the minimum energy required to ionize atoms. Although long-wavelength ultraviolet is not considered an ionizing radiation because its photons lack sufficient energy, it can induce chemical reactions and cause many substances to glow or fluoresce. Many practical applications, including chemical and biological effects, are derived from the way that UV radiation can interact with organic molecules. These intera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrostatic Discharge

Electrostatic discharge (ESD) is a sudden and momentary flow of electric current between two differently-charged objects when brought close together or when the dielectric between them breaks down, often creating a visible electric spark, spark associated with the static electricity between the objects. ESD can create spectacular electric sparks (lightning, with the accompanying sound of thunder, is an example of a large-scale ESD event), but also less dramatic forms, which may be neither seen nor heard, yet still be large enough to cause damage to sensitive electronic devices. Electric sparks require a field strength above approximately 4 million V/m in air, as notably occurs in lightning strikes. Other forms of ESD include corona discharge from sharp electrodes, brush discharge from blunt electrodes, etc. ESD can cause harmful effects of importance in industry, including explosions in gas, fuel vapor and coal dust, as well as failure of solid state electronics components such as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Router

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle (tool), spindle may be driven by an electric motor or by a pneumatic motor. It routs (hollows out) an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinet making, cabinetry. They may be handheld or affixed to Router table (woodworking), router tables. Some woodworkers consider the router one of the most versatile power tools. There is also a traditional hand tool known as a router plane, a form of plane (tool), hand plane with a broad base and a narrow blade projecting well beyond the base plate. CNC wood routers add the advantages of Numerical control, computer numerical control (CNC). The laminate trimmer is a smaller, lighter version of the router. Although it is designed for trimming Lamination, laminates, it can also be used for smaller general routing work. Rotary tools can also be used similarly to routers with t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Jet Cutter

A water jet cutter, also known as a water jet or waterjet, is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance. The term abrasive jet refers specifically to the use of a mixture of water and an abrasive to cut hard materials such as metal, stone or glass, while the terms pure waterjet and water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber. Waterjet cutting is often used during the fabrication of machine parts. It is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods; examples of such materials include plastic and aluminium. Waterjet cutting is used in various industries, including mining and aerospace, for cutting, shaping, and reamer, reaming. History Waterjet While using high-pressure water for erosion dates bac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface-mount Technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred to as a surface-mount device (SMD). In industry, this approach has largely replaced through-hole technology construction method of fitting components, in large part because SMT allows for increased manufacturing automation which reduces cost and improves quality. It also allows for more components to fit on a given area of substrate. Both technologies can be used on the same board, with the through-hole technology often used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |