|

Chrome Plating

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. A chrome plated part is called ''chrome'', or is said to have been ''chromed''. The chromium layer can be decorative, provide corrosion resistance, facilitate cleaning, and increase surface hardness. Sometimes a less expensive substitute for chrome, such as nickel, may be used for aesthetic purposes. Chromium compounds used in electroplating are toxic. In most countries, their disposal is tightly regulated. Some fume suppressants used to control the emission of airborne chromium from plating baths are also toxic, making disposal even more difficult. Process The preparation and chrome plating of a part typically includes some or all of these steps: * Surface preparation * Manual cleaning to remove dirt and surface impurities * Removal of remaining organic contaminants using emulsion cleaning, alkaline cleaning, anodic electrocleaning, or solvent cle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motorcycle Reflections Bw Edit

A motorcycle (motorbike, bike; uni (if one-wheeled); trike (if three-wheeled); quad (if four-wheeled)) is a lightweight private 1-to-2 passenger personal motor vehicle Steering, steered by a Motorcycle handlebar, handlebar from a saddle-style seat. Motorcycle designs vary greatly to suit a range of different purposes: Long-distance motorcycle riding, long-distance travel, Motorcycle commuting, commuting, cruising (driving), cruising, Motorcycle sport, sport (including Motorcycle racing, racing), and Off-roading, off-road riding. Motorcycling is riding a motorcycle and being involved in other related social activities such as joining a motorcycle club and attending motorcycle rally, motorcycle rallies. The 1885 Daimler Reitwagen made by Gottlieb Daimler and Wilhelm Maybach in Germany was the first internal combustion, petroleum-fueled motorcycle. In 1894, Hildebrand & Wolfmüller became the first series production motorcycle. Globally, motorcycles are comparable numerically t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nimonic

Nimonic is now a registered trademark of Special Metals Corporation that refers to a family of nickel-based high-temperature low creep superalloys. Nimonic alloys typically consist of more than 50% nickel and 20% chromium with additives such as titanium and aluminium. The main use is in gas turbine components and extremely high performance reciprocating internal combustion engines. The Nimonic family of alloys was first developed in the 1940s by research teams at the Wiggin Works in Hereford, England, in support of the development of the Whittle jet engine. Development Working at Inco- Mond's Wiggin facility at Birmingham in the United Kingdom, Leonard Bessemer Pfeil is credited with the development of Nimonic alloy 80 in 1941, and used in the Power Jets W.2B. Four years later, Nimonic alloy 80A followed, an alloy widely used in engine valves today. Progressively stronger alloys were subsequently developed: Nimonic alloy 90 (1945), Nimonic alloy 100 (1955), and Nimonic a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen Evolution Reaction

Hydrogen evolution reaction (HER) is a chemical reaction that yields H2. The conversion of protons to H2 requires reducing equivalents and usually a catalyst. In nature, HER is catalyzed by hydrogenase enzymes which rely on iron- and nickel-based catalysts. Commercial electrolyzers typically employ supported nickel-based catalysts. HER in electrolysis HER is a key reaction which occurs in the electrolysis of water for the production of hydrogen for both industrial energy applications, as well as small-scale laboratory research. Due to the abundance of water on Earth, hydrogen production poses a potentially scalable process for fuel generation. This is an alternative to steam methane reforming for hydrogen production, which has significant greenhouse gas emissions, and as such scientists are looking to improve and scale up electrolysis processes that have fewer emissions. Electrolysis mechanism In acidic conditions, the hydrogen evolution reaction follows the formula: : In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrode Potential

An electrode is an electrical conductor used to make contact with a nonmetallic part of a Electronic circuit, circuit (e.g. a semiconductor, an electrolyte, a vacuum or a gas). In electrochemical cells, electrodes are essential parts that can consist of a variety of materials (chemicals) depending on the type of cell. An electrode may be called either a cathode or anode according to the direction of the electric current, unrelated to the potential difference between electrodes. Michael Faraday coined the term "" in 1833; the word recalls the Greek ἤλεκτρον (, "amber") and ὁδός (, "path, way"). The Electrophorus, electrophore, invented by Johan Wilcke in 1762, was an early version of an electrode used to study static electricity. Anode and cathode in electrochemical cells Electrodes are an essential part of any Electric battery, battery. The first electrochemical battery was devised by Alessandro Volta and was aptly named the Voltaic cell. This battery consis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxidation

Redox ( , , reduction–oxidation or oxidation–reduction) is a type of chemical reaction in which the oxidation states of the reactants change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a decrease in the oxidation state. The oxidation and reduction processes occur simultaneously in the chemical reaction. There are two classes of redox reactions: * Electron-transfer – Only one (usually) electron flows from the atom, ion, or molecule being oxidized to the atom, ion, or molecule that is reduced. This type of redox reaction is often discussed in terms of redox couples and electrode potentials. * Atom transfer – An atom transfers from one substrate to another. For example, in the rusting of iron, the oxidation state of iron atoms increases as the iron converts to an oxide, and simultaneously, the oxidation state of oxygen decreases as it accepts electrons released by the iron. Although oxidati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

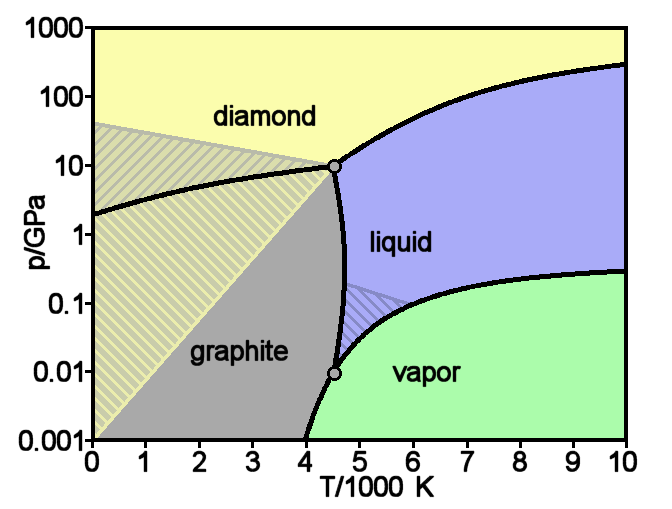

Graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on a large scale (1.3million metric tons per year in 2022) for uses in many critical industries including refractories (50%), lithium-ion batteries (18%), foundries (10%), and lubricants (5%), among others (17%). Graphite converts to diamond under extremely high pressure and temperature. Graphite's low cost, thermal and chemical inertness and characteristic conductivity of heat and electricity finds numerous applications in high energy and high temperature processes. Types and varieties Graphite can occur naturally or be produced synthetically. Natural graphite is obtained from naturally occurring geologic deposits and synthetic graphite is produced t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium Chloride

Chromium chloride may refer to: * Chromium(II) chloride, also known as chromous chloride * Chromium(III) chloride, also known as chromic chloride or chromium trichloride * Chromium(IV) chloride, unstable {{Short pages monitor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium(III) Sulfate

Chromium(III) sulfate usually refers to the inorganic compounds with the formula Cr2(SO4)3.x(H2O), where x can range from 0 to 18. Additionally, ill-defined but commercially important "basic chromium sulfates" are known. These salts are usually either violet or green solids that are soluble in water. It is commonly used in tanning leather. Chromium(III) sulfates Three chromium(III) sulfates are well characterized: *Anhydrous chromium(III) sulfate, Cr2(SO4)3, (CAS #10101-53-8) is a violet solid that dissolves in water upon addition of a reducing agent. *Hydrated chromium(III) sulfate, Cr2(SO4)3·18H2O, (CAS #13520-66-6) is a violet solid that readily dissolves in water to give the metal aquo complex, r(H2O)6sup>3+. The formula of this compound can be written more descriptively as r(H2O)6sub>2(SO4)3·6H2O. Six of the eighteen water molecules in this formula unit are water of crystallization. *Hydrated chromium(III) sulfate, Cr2(SO4)3·15(H2O), (CAS #10031-37-5) is a green solid th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throwing Power

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the redox, reduction of cations of that metal by means of a direct current, direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution (chemistry), solution of a salt (chemistry), salt whose cation is the metal to be coated, and the anode (positive electrode) is usually either a block of that metal, or of some inert electrical conductor, conductive material. The current is provided by an external power supply. Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion (mechanical), abrasion and corrosion, lubrication, lubricity, reflectivity, electrical conductivity, or appearance. It is used to build up thickness on undersized or worn-out parts and to manufacture metal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Current Density

In electromagnetism, current density is the amount of charge per unit time that flows through a unit area of a chosen cross section. The current density vector is defined as a vector whose magnitude is the electric current per cross-sectional area at a given point in space, its direction being that of the motion of the positive charges at this point. In SI base units, the electric current density is measured in amperes per square metre. Definition Assume that (SI unit: m2) is a small surface centered at a given point and orthogonal to the motion of the charges at . If (SI unit: A) is the electric current flowing through , then electric current density at is given by the limit: j = \lim_ \frac = \left.\frac \_, with surface remaining centered at and orthogonal to the motion of the charges during the limit process. The current density vector is the vector whose magnitude is the electric current density, and whose direction is the same as the motion of the positiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mill Scale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (, wüstite), iron(III) oxide (, hematite), and iron(II,III) oxide (, magnetite). Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are produced by passing red hot iron or steel billets through rolling mills. Mill scale is bluish-black in color. It is usually less than thick, and initially adheres to the steel surface and protects it from atmospheric corrosion provided no break occurs in this coating. Because it is electrochemically cathodic to steel, any break in the mill scale coating will cause accelerated corrosion of steel exposed at the break. Mill scale is thus a boon for a while, until its coating breaks due to handling of the steel product or due to any other mechanical cause. Mill scale becomes a nuisance when the steel is to be processed. Any paint applied over it is wasted, since it will come off ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromate Conversion Coating

Chromate conversion coating or alodine coating is a type of conversion coating used to passivate steel, aluminium, zinc, cadmium, copper, silver, titanium, magnesium, and tin alloys. The coating serves as a corrosion inhibitor, as a primer to improve the adherence of paints and adhesives, as a decorative finish, or to preserve electrical conductivity. It also provides some resistance to abrasion and light chemical attack (such as dirty fingers) on soft metals. Chromate conversion coatings are commonly applied to items such as screws, hardware and tools. They usually impart a distinctively iridescent, greenish-yellow color to otherwise white or gray metals. The coating has a complex composition including chromium salts, and a complex structure. The process is sometimes called alodine coating, a term used specifically in reference to the trademarked Alodine process of Henkel Surface Technologies. Process Chromate conversion coatings are usually applied by immersing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |