|

Woodchips

Woodchips are small- to medium-sized pieces of wood formed by cutting or chipping larger pieces of wood such as trees, branches, logging residues, Tree stump, stumps, roots, and wood waste. Woodchips may be used as a biomass solid fuel and are raw material for producing wood pulp. They may also be used as an organic mulch in gardening, landscaping, and ecosystem restoration; in bioreactors for denitrification; and as a substrate for mushroom cultivation. The process of making woodchips is called wood chipping and is done using a Woodchipper, wood chipper. The types of woodchips formed following chipping is dependent on the type of wood chipper used and the material from which they are made. Woodchip varieties include: forest chips (from forested areas), wood residue chips (from untreated wood residues, recycled wood and off-cuts), sawing residue chips (from sawmill residues), and short rotation forestry chips (from energy crops). Raw materials The raw materials of woodchips ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood Pulp

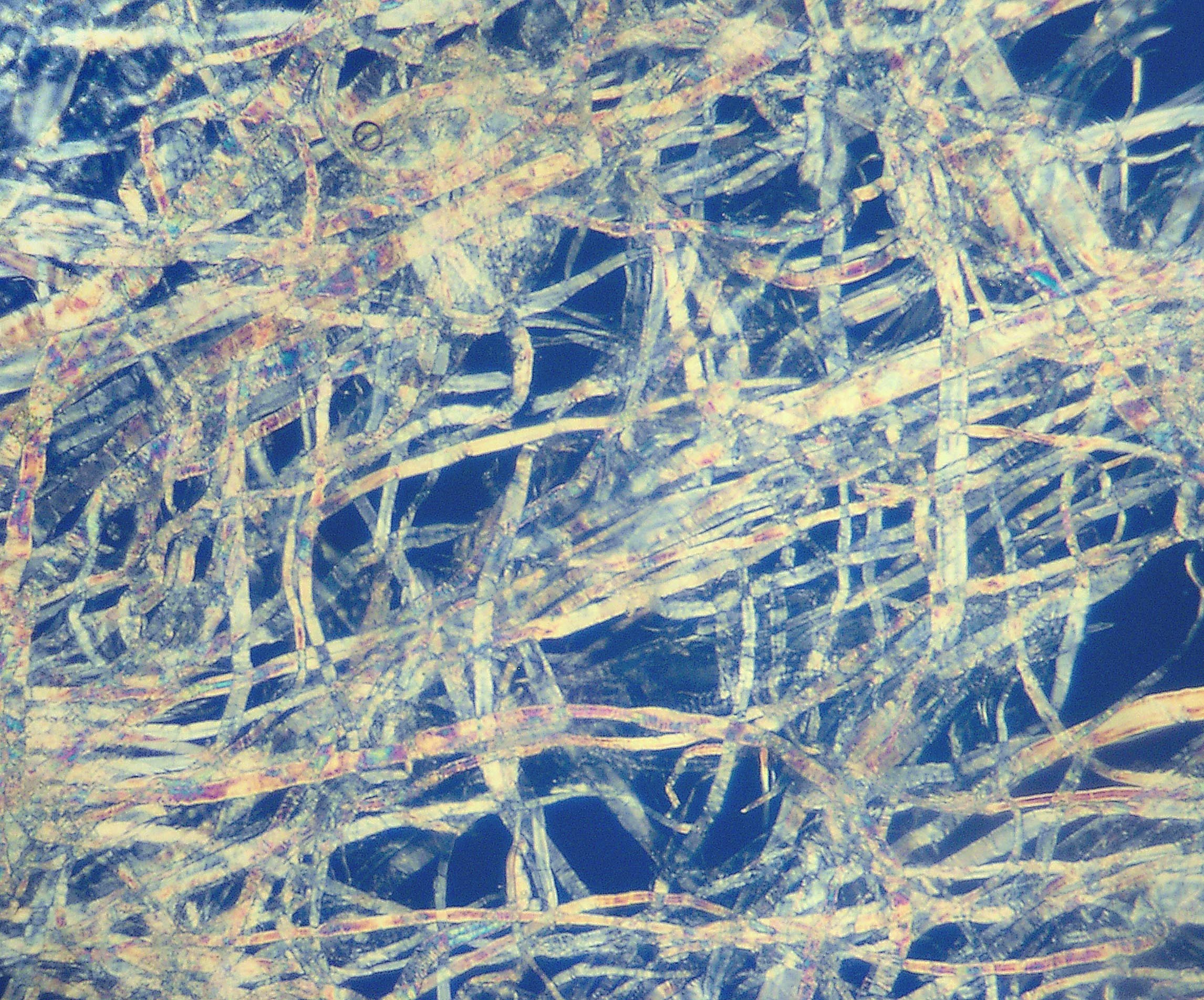

Pulp is a fibrous Lignocellulosic biomass, lignocellulosic material prepared by chemically, semi-chemically, or mechanically isolating the cellulose fiber, cellulosic fibers of wood, fiber crops, Paper recycling, waste paper, or cotton paper, rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other Pulp and paper industry, paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around AD 105, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of Bark (botany), bark or Bast fibre, bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulp Mill

A pulp mill is a manufacturing facility that converts wood chips or other plant fiber sources into a thick fiber board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical, or fully chemical methods ( kraft and sulfite processes). The finished product may be either bleached or non-bleached, depending on the customer requirements. Wood and other plant materials used to make pulp contain three main components (apart from water): cellulose fibres (desired for papermaking), lignin (a three-dimensional polymer that binds the cellulose fibres together) and hemicelluloses, (shorter branched carbohydrate polymers). The aim of pulping is to break down the bulk structure of the fiber source, be it chips, stems or other plant parts, into the constituent fibers. Chemical pulping achieves this by degrading the lignin and hemicellulose into small, water-soluble molecules that can be washed away from the cellulose fibers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodchip

Woodchip may refer to: * Woodchips, a medium-sized solid material ** Woodchipper A tree chipper or woodchipper is a machine used for reducing wood (generally tree limbs or trunks) into smaller woodchips. They are often portable, being mounted on wheels on frames suitable for towing behind a truck or van. Power is general ..., a machine * Ingrain wallpaper, in home decoration {{Disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mulch

A mulch is a layer of material applied to the surface of soil. Reasons for applying mulch include conservation of soil moisture, improving soil fertility, fertility and health of the soil, reducing Weed control, weed growth, and enhancing the visual appeal of the area. A mulch is usually, but not exclusively, organic in nature. It may be permanent (e.g. plastic sheeting) or temporary (e.g. barkdust, bark chips). It may be applied to bare soil or around existing plants. Mulches of manure and compost will be incorporated naturally into the soil by the activity of worms and other organisms. The process is used both in commercial crop production and in gardening, and when applied correctly, can improve soil productivity. Living mulches include moss lawnsMoss Myths/ref> and other ground covers. Uses Many materials are used as mulches, which are used to retain soil moisture, regulate soil temperature, suppress weed growth, and for aesthetics. They are applied to the soil surface, ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Denitrification

Denitrification is a microbially facilitated process where nitrate (NO3−) is reduced and ultimately produces molecular nitrogen (N2) through a series of intermediate gaseous nitrogen oxide products. Facultative anaerobic bacteria perform denitrification as a type of respiration that reduces oxidized forms of nitrogen in response to the oxidation of an electron donor such as organic matter. The preferred nitrogen electron acceptors in order of most to least thermodynamically favorable include nitrate (NO3−), nitrite (NO2−), nitric oxide (NO), nitrous oxide (N2O) finally resulting in the production of dinitrogen (N2) completing the nitrogen cycle. Denitrifying microbes require a very low oxygen concentration of less than 10%, as well as organic C for energy. Since denitrification can remove NO3−, reducing its leaching to groundwater, it can be strategically used to treat sewage or animal residues of high nitrogen content. Denitrification can leak N2O, which is an ozone-d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulpwood

Pulpwood can be defined as timber that is ground and processed into a fibrous pulp. It is a versatile natural resource commonly used for Papermaking, paper-making but also made into low-grade wood and used for chips, energy, pellets, and engineered products. Pulpwood can be derived from most types of trees. Categorizing trees into hardwood and softwood is the easiest way to characterize types of paper produced from pulpwood. Hardwoods are raw material that are preferred for Pulp (paper), pulp used in printing papers. It has small dimensions in its fibres, which can be useful for small-scale uniformity, opacity, and surface smoothness, all important for printing paper. Softwoods are the preferred raw material for strong papers, due to the length and slimness of the fibres. Low-density softwoods, such as firs with thin-walled fibres are preferred for papers with high demands for bonding-related strength characteristics. Some of these characteristics include tensile, burst, and surf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sawmill

A sawmill (saw mill, saw-mill) or lumber mill is a facility where logging, logs are cut into lumber. Modern sawmills use a motorized saw to cut logs lengthwise to make long pieces, and crosswise to length depending on standard or custom sizes (dimensional lumber). The Portable sawmill, "portable" sawmill is simple to operate. The log lies flat on a steel bed, and the motorized saw cuts the log horizontally along the length of the bed, by the operator manually pushing the saw. The most basic kind of sawmill consists of a chainsaw and a customized jig ("Alaskan sawmill"), with similar horizontal operation. Before the invention of the sawmill, boards were made in various manual labour, manual ways, either wood splitting, rived (split) and plane (tool), planed, hewing, hewn, or more often hand sawn by two men with a whipsaw, one above and another in a saw pit below. The earliest known mechanical mill is the Hierapolis sawmill, a Roman water-powered stone mill at Hierapolis, Asia M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device that uses the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical Inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical veloc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chute (gravity)

A chute is a vertical or inclined plane, channel, or passage through which objects are moved by means of gravity. Landform A chute, also known as a race, flume, cat, or river canyon, is a steep-sided passage through which water flows rapidly. Akin to these, man-made chutes, such as the timber slide and log flume, were used in the logging industry to facilitate the downstream transportation of timber along rivers. These are no longer in common use. Man-made chutes may also be a feature of spillways on some dams. Some types of water supply and irrigation systems are gravity fed, hence chutes. These include aqueducts, puquios, and acequias. Building chutes Chutes are in common use in tall buildings to allow fast and efficient transport of items and materials from the upper floors to a central location on one of the lower floors, especially the basement. Chutes may be of a round, square or rectangular cross-section at the top and/or the bottom. * Laundry chutes in hotels are pl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conveyor Belt

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to a belt conveyor). A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley, while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more. Overview Conveyors are durable and reliable components used in automated distribution and warehousing, as well as manufacturing and production facilities. In combination with computer-controlled pallet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |