|

Vickers Scale

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell scale, Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe a material's ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). The hardness number can be converted into units of pascal (unit), pascals, but should not be confused with pressure, which uses the same units. The hardness number is determined by the load over the surface area ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standard Gravity

The standard acceleration of gravity or standard acceleration of free fall, often called simply standard gravity and denoted by or , is the nominal gravitational acceleration of an object in a vacuum near the surface of the Earth. It is a constant defined by standard as . This value was established by the third General Conference on Weights and Measures (1901, CR 70) and used to define the standard weight of an object as the product of its mass and this nominal acceleration. The acceleration of a body near the surface of the Earth is due to the combined effects of gravity and centrifugal acceleration from the rotation of the Earth (but the latter is small enough to be negligible for most purposes); the total (the apparent gravity) is about 0.5% greater at the poles than at the Equator. Although the symbol is sometimes used for standard gravity, (without a suffix) can also mean the local acceleration due to local gravity and centrifugal acceleration, which varies depending on on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness Comparison

A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels. Hardness comparison table {, class="wikitable" ! Brinell HB (10 mm Ball, 3000 kg load)!!Vickers Vickers was a British engineering company that existed from 1828 until 1999. It was formed in Sheffield as a steel foundry by Edward Vickers and his father-in-law, and soon became famous for casting church bells. The company went public in 18 ... HV (5 kg)!! Rockwell C HRC (120 degree cone 150 kg)!!Rockwell B HRB (1/16" ball 100 kg)!! Leeb HLDH.Pollok, „Umwertung der Skalen“ (“Conversion of Scales”), Qualität und Zuverlässigkeit, Ausgabe 4/2008. , - , 800, , -, , 72, , -, , 856 , - , 780, , 1220, , 71, , -, , 850 , - , 760, , 1210, , 70, , -, , 843 , - , 745, , 1114, , 68 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leeb Rebound Hardness Test

The Leeb Rebound Hardness Test (LRHT) invented by Swiss company Proceq SA is one of the four most used methods for testing metal hardness. This portable method is mainly used for testing sufficiently large workpieces (mainly above 1 kg). It measures the coefficient of restitution. It is a form of nondestructive testing. History The Equotip (later on also called simultaneously as Leeb method) rebound hardness test method was developed in the year 1975 by Leeb and Brandestini at Proceq SA to provide a portable hardness test for metals. It was developed as an alternative to the unwieldy and sometimes intricate traditional hardness measuring equipment. The first Leeb rebound product on the market was named “Equotip”, a phrase that still is used synonymously with “Leeb rebound” due to the wide circulation of the “Equotip” product. Traditional hardness measurements, ''e.g.'', those of Rockwell, Vickers, and Brinell, are stationary, requiring fixed workstations in seg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

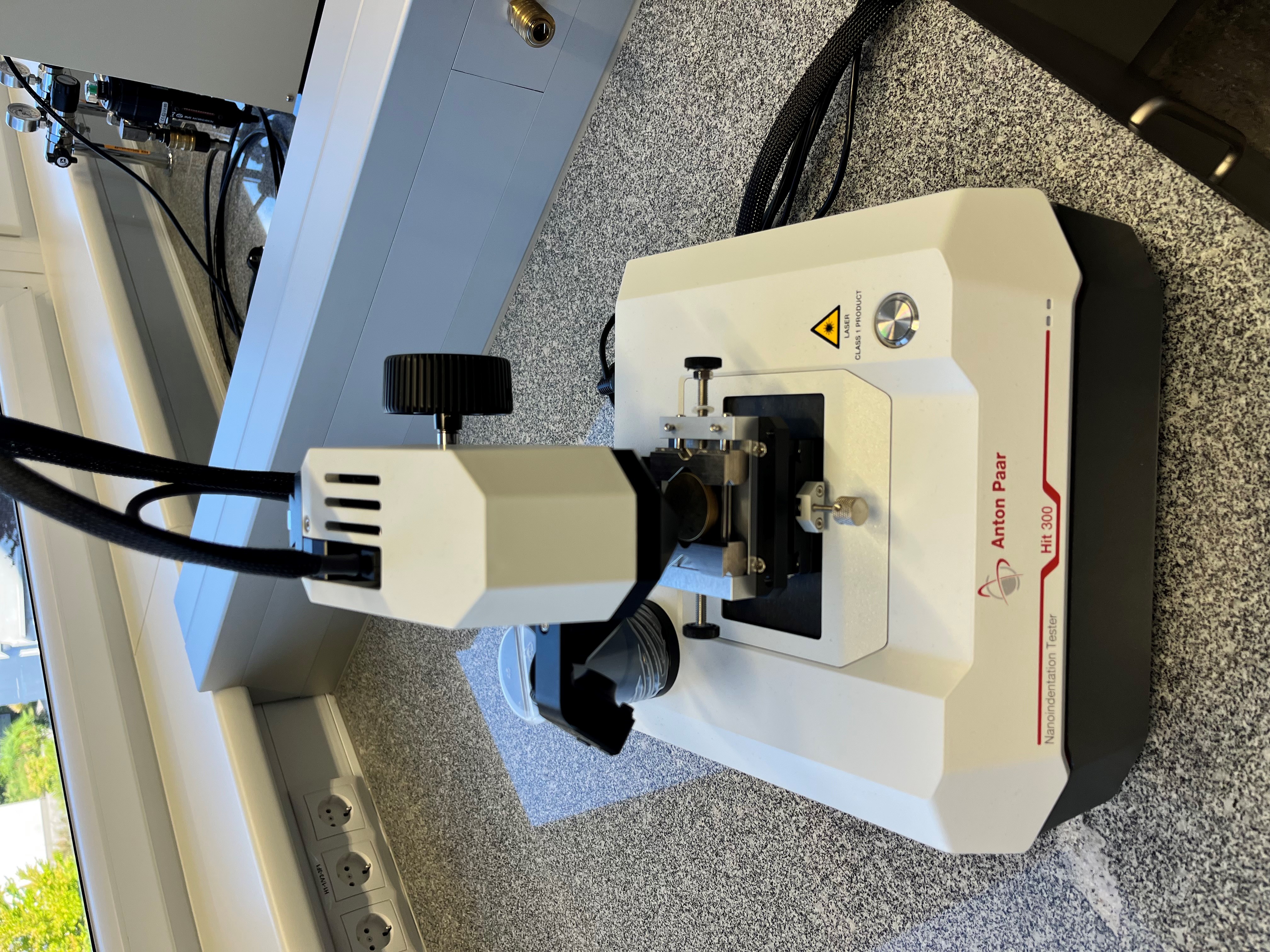

Indentation Hardness

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale. When testing metals, indentation hardness correlates roughly linearly with tensile strength, but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers. Material hardness Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile Strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate tensile strength is close to the yield point, whereas in ductile materials, the ultimate tensile strength can be higher. The ultimate tensile strength is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve is the ultimate tensile strength and has units of stress. The equivalent point for the case of compression, instead of tension, is called the compressive strength. Tensile strengths are rarely of any consequence in the design of ductile members, but they are important with brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood. Definition The ultimate tensile strength ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Meyer Hardness Test

The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, H, is defined as the maximum load, P_\text divided by the projected area of the indent, A_\text. :H=\frac . This is a more fundamental measurement of hardness than other hardness tests which are based on the surface area of an indentation. The principle behind the test is that the mean pressure required to test the material is the measurement of the hardness of the material. Units of megapascals (MPa) are frequently used for reporting Meyer hardness, but any unit of pressure can be used.. The test was originally defined for spherical indenters, but can be applied to any indenter shape. It is often the definition used in nanoindentation testing. An advantage of the Meyer test is that it is less sensitive to the applied load, especially compared to the Brinell hardness test. For cold worked materials the Meyer hardness is relatively constant and independent of load, whereas for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kilograms-force

The kilogram-force (kgf or kgF), or kilopond (kp, from ), is a non-standard gravitational metric unit of force. It is not accepted for use with the International System of Units (SI) and is deprecated for most uses. The kilogram-force is equal to the magnitude of the force exerted on one kilogram of mass in a gravitational field (standard gravity, a conventional value approximating the average magnitude of gravity on Earth). That is, it is the weight of a kilogram under standard gravity. One kilogram-force is defined as .NISTbr>''Guide for the Use of the International System of Units (SI)''Special Publication 811, (1995) page 51 Similarly, a gram-force is , and a milligram-force is . History The gram-force and kilogram-force were never well-defined units until the CGPM adopted a ''standard acceleration of gravity'' of 9.80665 m/s2 for this purpose in 1901, though they had been used in low-precision measurements of force before that time. Even then, the proposal to define ki ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Indentation Size Effect

The indentation size effect (ISE) is the observation that hardness tends to increase as the indent size decreases at small scales. When an indent (any small mark, but usually made with a special tool) is created during material testing, the hardness of the material is not constant. At the small scale, materials will actually be harder than at the macro-scale. For the conventional indentation size effect, the smaller the indentation, the larger the difference in hardness. The effect has been seen through nanoindentation and microindentation measurements at varying depths. Dislocations increase material hardness by increasing flow stress through dislocation blocking mechanisms. Materials contain statistically stored dislocations (SSD) which are created by homogeneous strain and are dependent upon the material and processing conditions. Geometrically necessary dislocations (GND) on the other hand are formed, in addition to the dislocations statistically present, to maintain continu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Instron

Illinois Tool Works Inc. (ITW) is an American ''Fortune'' 500 company that produces engineered fasteners and components, equipment and consumable systems, and specialty products. It was founded in 1912 by Byron L. Smith and has built its growth on a "small-wins strategy" based on decentralization, simplicity, customer-focused innovation, and acquisitions. , ITW employed 44,000 employees in 51 countries and held 20,900 granted and pending patent applications worldwide. The company is based in Glenview, Illinois, a suburb of Chicago. ITW subsidiaries ITW comprises a number of subsidiaries. Notable brands include Hobart, Miller Electric, Paslode, Foster Refrigerator, Brooks Instrument, and Permatex adhesives. In August 2018, U.S. Tax Court Judge Albert G. Lauber determined that ITW owed no tax on over $356 million in repatriated funds from its foreign subsidiaries because the transactions had been sufficiently structured as debt. Illegal exports The United States Department ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

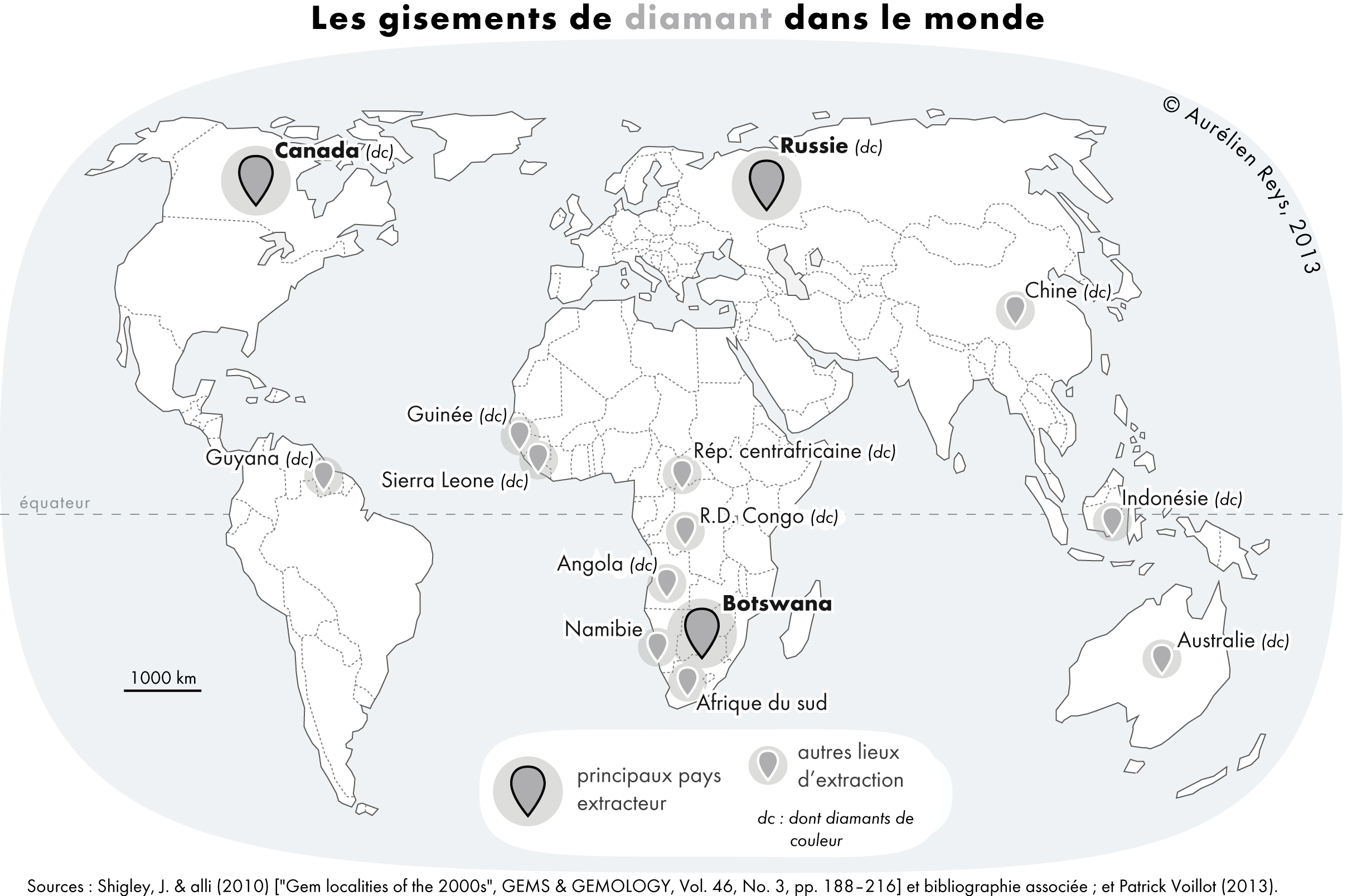

Diamond

Diamond is a Allotropes of carbon, solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Diamond is tasteless, odourless, strong, brittle solid, colourless in pure form, a poor conductor of electricity, and insoluble in water. Another solid form of carbon known as graphite is the Chemical stability, chemically stable form of carbon at Standard temperature and pressure, room temperature and pressure, but diamond is metastable and converts to it at a negligible rate under those conditions. Diamond has the highest Scratch hardness, hardness and thermal conductivity of any natural material, properties that are used in major industrial applications such as cutting and polishing tools. Because the arrangement of atoms in diamond is extremely rigid, few types of impurity can contaminate it (two exceptions are boron and nitrogen). Small numbers of lattice defect, defects or impurities (about one per million of lattice atoms) can color ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Martensite

Martensite is a very hard form of steel crystalline structure. It is named after German metallurgist Adolf Martens. By analogy the term can also refer to any crystal structure that is formed by diffusionless transformation. Properties Martensite is formed in carbon steels by the rapid cooling ( quenching) of the austenite form of iron at such a high rate that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to form cementite (Fe3C). Austenite is gamma-phase iron (γ-Fe), a solid solution of iron and alloying elements. As a result of the quenching, the face-centered cubic austenite transforms to a highly strained body-centered tetragonal form called martensite that is supersaturated with carbon. The shear deformations that result produce a large number of dislocations, which is a primary strengthening mechanism of steels. The highest hardness of a pearlitic steel is 400 Brinell, whereas martensite can achieve 700&n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |