|

Ultrasonic Thickness Measurement

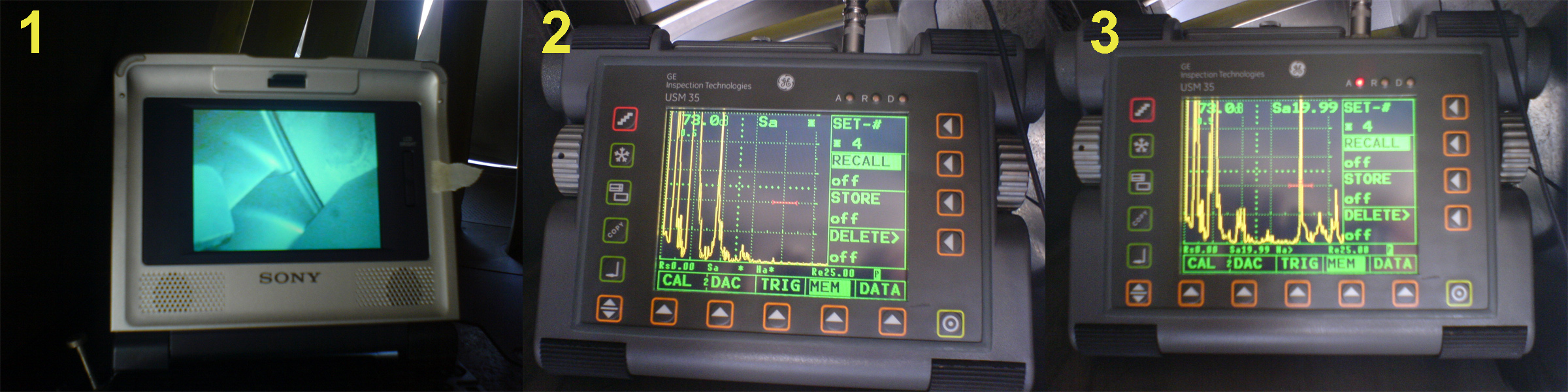

In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is typically performed with an ultrasonic thickness gauge. Ultrasonic waves have been observed to travel through metals at a constant speed characteristic to a given alloy with minor variations due to other factors like temperature. Thus, given this information, called celerity, one can calculate the length of the path traversed by the wave using this formula: l_m = c t / 2 where l_m is the thickness of the sample c is the velocity of sound in the given sample t is the traverse time The formula features division by two because usually the instrumentation emits and records the ultrasound wave on the same side of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Testing

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors. History The first efforts to use ultrasonic testing to detect flaws in solid material occurred in the 1930s.''Nondestructive F ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nondestructive Testing

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical im ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Thickness Gauge

In the field of ultrasonic testing, industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing Nondestructive testing, non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is typically performed with an ultrasonic thickness gauge. Ultrasonic waves have been observed to travel through metals at a constant speed characteristic to a given alloy with minor variations due to other factors like temperature. Thus, given this information, called celerity, one can calculate the length of the path traversed by the wave using this formula: l_m = c t / 2 where l_m is the thickness of the sample c is the velocity of sound in the given sample t is the traverse time The formula features division by two because usually the instrumentation emits and records th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piezoelectric

Piezoelectricity (, ) is the electric charge that accumulates in certain solid materials—such as crystals, certain ceramics, and biological matter such as bone, DNA, and various proteins—in response to applied Stress (mechanics), mechanical stress. The word ''piezoelectricity'' means electricity resulting from pressure and latent heat. It is derived from the Greek language, Greek word ; ''piezein'', which means to squeeze or press, and ''ēlektron'', which means amber, an ancient source of electric charge. The piezoelectric effect results from the linear electromechanical interaction between the mechanical and electrical states in crystalline materials with no Centrosymmetry, inversion symmetry. The piezoelectric effect is a reversible process (thermodynamics), reversible process: List of piezoelectric materials, materials exhibiting the piezoelectric effect also exhibit the reverse piezoelectric effect, the internal generation of a mechanical strain resulting from an appli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electromagnetic Acoustic Transducer

Electromagnetic acoustic transducer (EMAT) is a transducer for non-contact acoustic wave generation and reception in conducting materials. Its effect is based on electromagnetic mechanisms, which do not need direct coupling with the surface of the material. Due to this couplant-free feature, EMATs are particularly useful in harsh, i.e., hot, cold, clean, or dry environments. EMATs are suitable to generate all kinds of waves in metallic and/or magnetostrictive materials. Depending on the design and orientation of coils and magnets, shear horizontal (SH) bulk wave mode (norm-beam or angle-beam), surface wave, plate waves such as SH and Lamb waves, and all sorts of other bulk and guided-wave modes can be excited. After decades of research and development, EMAT has found its applications in many industries such as primary metal manufacturing and processing, automotive, railroad, pipeline, boiler and pressure vessel industries, in which they are typically used for nondestructive testing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Thickness Gauge

In the field of ultrasonic testing, industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing Nondestructive testing, non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is typically performed with an ultrasonic thickness gauge. Ultrasonic waves have been observed to travel through metals at a constant speed characteristic to a given alloy with minor variations due to other factors like temperature. Thus, given this information, called celerity, one can calculate the length of the path traversed by the wave using this formula: l_m = c t / 2 where l_m is the thickness of the sample c is the velocity of sound in the given sample t is the traverse time The formula features division by two because usually the instrumentation emits and records th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Measuring Instrument

A measuring instrument is a device to measure a physical quantity. In the physical sciences, quality assurance, and engineering, measurement is the activity of obtaining and comparing physical quantities of real-world objects and events. Established standard objects and events are used as units, and the process of measurement gives a number relating the item under study and the referenced unit of measurement. Measuring instruments, and formal test methods which define the instrument's use, are the means by which these relations of numbers are obtained. All measuring instruments are subject to varying degrees of instrument error and measurement uncertainty. These instruments may range from simple objects such as rulers and stopwatches to electron microscopes and particle accelerators. Virtual instrumentation is widely used in the development of modern measuring instruments. Time In the past, a common time measuring instrument was the sundial. Today, the usual measuring instrum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrasonic Testing

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors. History The first efforts to use ultrasonic testing to detect flaws in solid material occurred in the 1930s.''Nondestructive F ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transducer

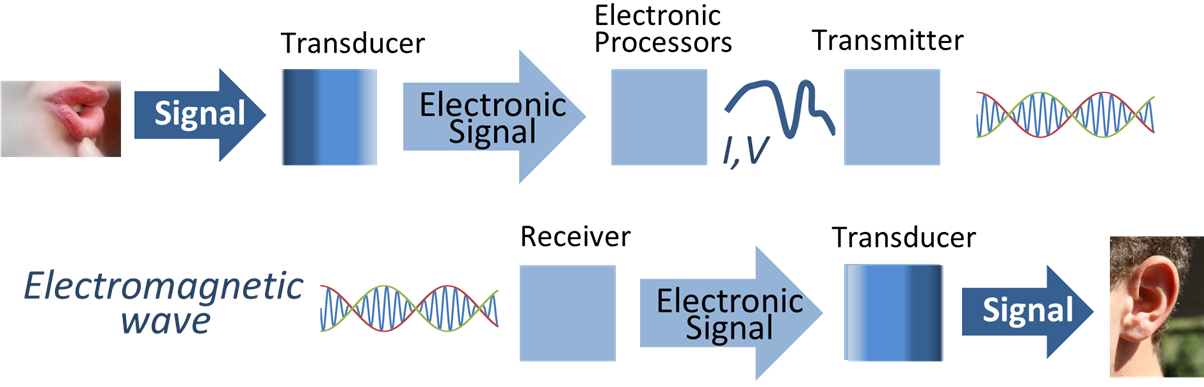

A transducer is a device that converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another. Transducers are often employed at the boundaries of automation, measurement, and control systems, where electrical signals are converted to and from other physical quantities (energy, force, torque, light, motion, position, etc.). The process of converting one form of energy to another is known as transduction. Types * Mechanical transducers, so-called as they convert physical quantities into mechanical outputs or vice versa; * Electrical transducers however convert physical quantities into electrical outputs or signals. Examples of these are: ** a thermocouple that changes temperature differences into a small voltage; ** a linear variable differential transformer (LVDT), used to measure displacement (position) changes by means of electrical signals. Sensors, actuators and transceivers Transducers can be categorized by wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Werner Sobek

Werner Sobek (born May 16, 1953) is a German architect and structural engineer. Life Werner Sobek was born 1953 in Aalen, Germany. From 1974 to 1980, he studied structural engineering and architecture at the University of Stuttgart. From 1980 to 1986, he was post-graduate fellow in the research project 'Wide-Span Lightweight Structures' at the University of Stuttgart and finished his PhD 1987 in structural engineering. In 1983, Sobek won the Fazlur Khan International Fellowship from the SOM Foundation. In 1991, he became a professor at the Leibniz University Hannover (successor to Bernd Tokarz) and director of the Institute for Structural Design and Building Methods. In 1992 he founded his own company Werner Sobek which now has offices in Stuttgart, Frankfurt, London, Moscow, New York, and Dubai. The company has over 200 employees and works with all types of structures and materials. Its core areas of expertise are lightweight construction, high-rise construction, façade des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propylene Glycol

Propylene glycol (IUPAC nomenclature, IUPAC name: propane-1,2-diol) is a viscous, colorless liquid, which is nearly odorless but possesses a faintly sweet taste. Its chemical formula is CH3CH(OH)CH2OH. Containing two Alcohol (chemistry), alcohol groups, it is classed as a diol. It is miscible with a broad range of solvents, including water, acetone, and chloroform. In general, glycols are non-irritating and have very low Volatility (chemistry), volatility. It is produced on a large scale primarily for the production of polymers. In the European Union, it has E-number E1520 for food applications. For cosmetics and pharmacology, the number is E490. Propylene glycol is also present in propylene glycol alginate, which is known as E405. Propylene glycol is a compound which is Generally recognized as safe, GRAS (generally recognized as safe) by the US Food and Drug Administration under 21 CFR x184.1666, and is also approved by the FDA for certain uses as an indirect food additive. Pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Classification Society

A ship classification society or ship classification organisation is a non-governmental organization that establishes and maintains technical standards for the construction and operation of ships and offshore structures. Classification societies certify that the construction of a vessel comply with relevant standards and carry out regular surveys in service to ensure continuing compliance with the standards. Currently, more than 50 organizations describe their activities as including marine classification, twelve of which are members of the International Association of Classification Societies. A classification certificate issued by a classification society recognised by the proposed ship register is required for a ship's owner to be able to register the ship and to obtain marine insurance on the ship, and may be required to be produced before a ship's entry into some ports or waterways, and may be of interest to charterers and potential buyers. To avoid liability, classification ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |