|

Tube Bending

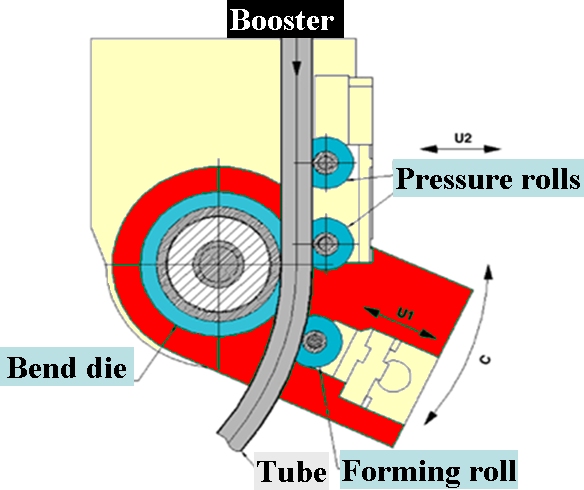

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a die. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry. Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubrican ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending Model 2

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roll Cage

A roll cage is a specially engineered and constructed frame built in (or sometimes around, in which case it is known as an exo cage) the passenger compartment of a vehicle to protect its occupants from being injured or killed in an accident, particularly in the event of a rollover. Designs There are many different roll cage designs depending on the application. Hence, various racing organizations have differing specifications and regulations, although most of these organizations harmonize their rules with those of the FIA. Roll cages help to stiffen the chassis, which is desirable in racing applications. Racing cages are typically either bolt-in or welded-in, with the former being more straightforward and cheaper to fit while the latter is stronger and more substantial. A roll bar is a single bar behind the driver that provides moderate rollover protection. Due to the lack of a protective top, some modern convertibles utilize a strong windscreen frame acting as a roll ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabrication (metal)

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product. Large fab shops employ a multitude of value-added processes, including welding, cutting, forming and machining. As with other manufacturing processes, both human labor and automation are commonly used. A fabricated product may be called a ''fabrication'', and shops specializing in this type of work are called ''fab shops''. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication. Processes *''Cutting'' is done by sawing, shear (sheet metal), shearing, or Chisel, chiselling (all with hand t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Springback Compensation

'Spring back compensation is used in metal forming to ensure that the final shape assumed by a piece of metal after being removed from a forming tool is the shape desired. Typically, when metal is being formed at room temperature, it will undergo both plastic and elastic deformation. After the metal workpiece is removed from the tool or deformation implement, the elastic deformation will be released and only the plastic deformation will remain; thus, the workpiece will "spring back" to a position between its original position and the position into which it was formed. Usually, spring back compensation is realized by over-bending the material by an amount corresponding to the magnitude of the spring back. When bending metal, spring back compensation is done by pushing the workpiece further into the die. For other sheet metal forming operations like drawing, it entails deforming the sheet metal past the planned shape of the part so that when the part's elastic deformation is released ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake (sheet Metal Bending)

A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. It is also known as a bending machine or bending brake or in Britain as a sheet metal folder or just a folder. Description The brake consists of a flat surface onto which the material is placed, and a clamping bar which will come down and hold the material firmly during the bend. This clamping action may be manual, automatic or operated using a foot pedal. The front, gate-like, plate of the machine is hinged and may be lifted, forcing the material extended over a straight edge to bend to follow the plate. The bends can be to any angle up to a practical limit of about 120 degrees, somewhat more in the case of a bar folder. If the area to be bent is narrow enough, a sharper bend (e.g., for a hem) can be made by inserting the bend under the clamping bar and lowering it. Box-and-p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending Machine (manufacturing)

A bending machine is a forming machine tool (DIN 8586). Its purpose is to assemble a bend on a workpiece. A bend is manufactured by using a bending tool during a linear or rotating move. The detailed classification can be done with the help of the kinematics.M. Weck, p. 112 CNC bending Numerical control, CNC bending machines are developed for high flexibility and low setup times. Those machines are able to bend single pieces as well as small batches with the same precision and efficiency as series-produced parts in an economical way. Universal bending machines – modular construction Universal bending machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools. The basic machine consists of a CNC-operated side stop, a work bench, and software for programming and operating. Its modular construction offers an affordable entry into the bending technology, because ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external Structural load, load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a Beam (structure), beam. For example, a closet rod Deflection (engineering), sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a wikt:shell, shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Pipe

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of the following: *Cylinder head and exhaust manifold *A turbocharger to increase engine power. *A catalytic converter to reduce air pollution. *A muffler (North America) / silencer (UK/India), to reduce noise. Design criteria An exhaust pipe must be carefully designed to carry toxic and noxious gases away from the users of the machine. Indoor generators and furnaces can quickly fill an enclosed space with poisonous exhaust gases such as hydrocarbons, carbon monoxide and nitrogen oxides, if they are not properly vented to the outdoors. Also, the gases from most machines are scorching; the pipe must be heat-resistant and not pass through or near anything that can burn or be damag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tube Bending

Tube bending is any metal forming processes used to permanently form pipes or tubing. Tube bending may be form-bound or use freeform-bending procedures, and it may use heat supported or cold forming procedures. Form bound bending procedures like “press bending” or “rotary draw bending” are used to form the work piece into the shape of a die. Straight tube stock can be formed using a bending machine to create a variety of single or multiple bends and to shape the piece into the desired form. These processes can be used to form complex shapes out of different types of ductile metal tubing. Freeform-bending processes, like three-roll-pushbending, shape the workpiece kinematically, thus the bending contour is not dependent on the tool geometry. Generally, round stock is used in tube bending. However, square and rectangular tubes and pipes may also be bent to meet job specifications. Other factors involved in the bending process are the wall thickness, tooling and lubrican ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Three Roll Push Bending Process

3 (three) is a number, numeral and digit. It is the natural number following 2 and preceding 4, and is the smallest odd prime number and the only prime preceding a square number. It has religious and cultural significance in many societies. Evolution of the Arabic digit The use of three lines to denote the number 3 occurred in many writing systems, including some (like Roman and Chinese numerals) that are still in use. That was also the original representation of 3 in the Brahmic (Indian) numerical notation, its earliest forms aligned vertically. However, during the Gupta Empire the sign was modified by the addition of a curve on each line. The Nāgarī script rotated the lines clockwise, so they appeared horizontally, and ended each line with a short downward stroke on the right. In cursive script, the three strokes were eventually connected to form a glyph resembling a with an additional stroke at the bottom: ३. The Indian digits spread to the Caliphate in the 9th c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Handrail

A handrail is a rail that is designed to be grasped by the hand so as to provide safety or support. In Great Britain, Britain, handrails are referred to as banisters. Handrails are commonly used while ascending or descending stairways and escalators in order to prevent injurious falls, and to provide bodily support in bathrooms or similar areas. Handrails are typically supported by balusters or attached to walls. Similar items not covered in this article include grab bar, bathroom handrails—which help to prevent falls on slippery, wet floors—other grab bars, used, for instance, in galley (kitchen), ships' galleys, and barre (ballet), barres, which serve as training aids for ballet dancers. Guard rails and balustrades line drop-offs and other dangerous areas, keeping people and vehicles out. British specifications British Standard and British Standard Code of Practice are harmonized to European Normal (EN) series. Handrail height is set between . US specifications Dimens ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |