|

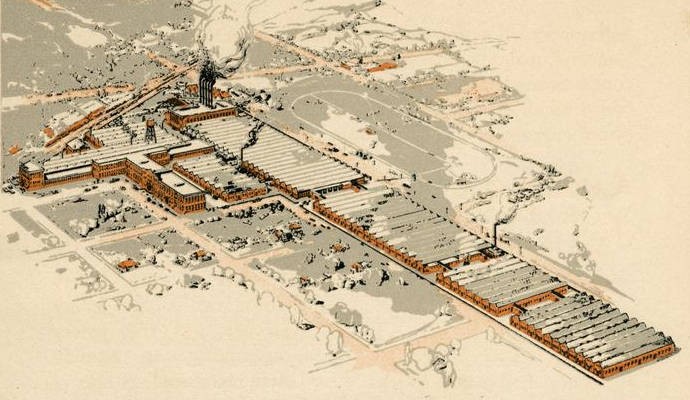

Stamping (metalworking)

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and Die (manufacturing), die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined. St ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Press Animation

Power may refer to: Common meanings * Power (physics), meaning "rate of doing work" ** Engine power, the power put out by an engine ** Electric power, a type of energy * Power (social and political), the ability to influence people or events Mathematics, science and technology Computing * IBM POWER (software), an IBM operating system enhancement package * IBM POWER architecture, a RISC instruction set architecture * Power ISA, a RISC instruction set architecture derived from PowerPC * IBM Power microprocessors, made by IBM, which implement those RISC architectures * Power.org, a predecessor to the OpenPOWER Foundation Mathematics * Exponentiation, "''x'' to the power of ''y''" * Power function * Power of a point * Statistical power Physics * Magnification, the factor by which an optical system enlarges an image * Optical power, the degree to which a lens converges or diverges light Social sciences and politics * Economic power, encompassing several concepts that economists use, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hemming (metalworking)

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials.. Hems are commonly used to reinforce an edge, hide burrs and rough edges, and improve appearance. Seams are commonly used in the food industry on canned goods, on amusement park An amusement park is a park that features various attractions, such as rides and games, and events for entertainment purposes. A theme park is a type of amusement park that bases its structures and attractions around a central theme, often fea ... cars, in metal roofing (with a roof seamer), and in the automotive industry. Process The process for both hemming and seaming are the same, except that the tonnage (amount of force exerted) requirement is greater for seaming. The process starts by bending the edge to an acute angle. A flattening die is then used to flatten th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Northwestern University

Northwestern University (NU) is a Private university, private research university in Evanston, Illinois, United States. Established in 1851 to serve the historic Northwest Territory, it is the oldest University charter, chartered university in Illinois. Chartered by the Illinois General Assembly in 1851, Northwestern was initially affiliated with the Methodist Episcopal Church but later became non-sectarian. By 1900, the university was the third-largest Higher education in the United States, university in the United States, after University of Michigan, Michigan and Harvard University, Harvard. Northwestern became a founding member of the Big Ten Conference in 1896 and joined the Association of American Universities in 1917. Northwestern is composed of eleven undergraduate, graduate, and professional schools in the fields of Kellogg School of Management, management, Pritzker School of Law, law, Medill School of Journalism, journalism, McCormick School of Engineering, enginee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Miniaturization

Miniaturization ( Br.Eng.: ''miniaturisation'') is the trend to manufacture ever-smaller mechanical, optical, and electronic products and devices. Examples include miniaturization of mobile phones, computers and vehicle engine downsizing. In electronics, the exponential scaling and miniaturization of silicon MOSFETs (MOS transistors) leads to the number of transistors on an integrated circuit chip doubling every two years, an observation known as Moore's law. This leads to MOS integrated circuits such as microprocessors and memory chips being built with increasing transistor density, faster performance, and lower power consumption, enabling the miniaturization of electronic devices. Electronic circuits The history of miniaturization is associated with the history of information technology based on the succession of switching devices, each smaller, faster, and cheaper than its predecessor. During the period referred to as the Second Industrial Revolution (), miniaturizati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a methods of production, method of manufacturing goods aimed primarily at reducing times within the Operations management#Production systems, production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to Supply and demand, demand by only supplying goods that have been ordered and focus on efficiency, productivity (with a commitment to continuous improvement), and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing Cycle time variation, cycle, flow, and Throughput (business), throughput times by further eliminating activities that do not add any Value (economics), value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Industry

The automotive industry comprises a wide range of company, companies and organizations involved in the design, Business development, development, manufacturing, marketing, selling, Maintenance, repairing, and Custom car, modification of motor vehicles. It is one of the world's largest industry (economics), industries by revenue (from 16% such as in France up to 40% in countries such as Slovakia). The word ''automotive'' comes from the Greek language, Greek ''autos'' (self), and Latin ''motivus'' (of motion), referring to any form of self-powered vehicle. This term, as proposed by Elmer Ambrose Sperry, Elmer Sperry (1860–1930), first came into use to describe automobiles in 1898. History The automotive industry began in the 1860s with hundreds of manufacturers pioneering the Brass Era car, horseless carriage. Early car manufacturing involved manual assembly by a human worker. The process evolved from engineers working on a stationary car to a conveyor belt system where the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Industry

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

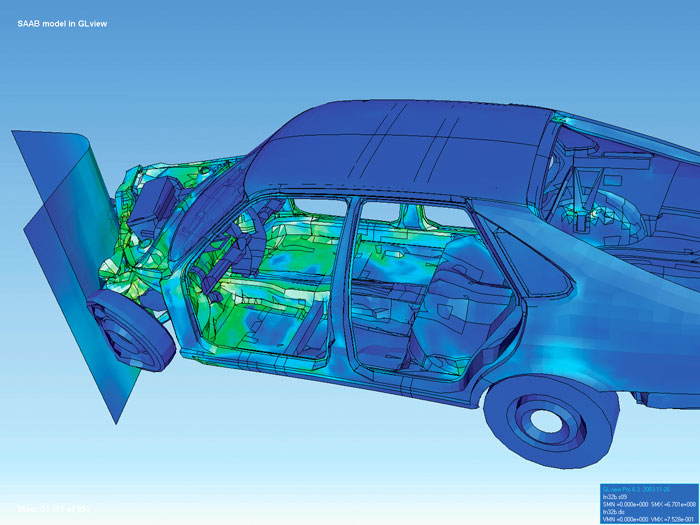

Finite Element Analysis

Finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical models, mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. Computers are usually used to perform the calculations required. With high-speed supercomputers, better solutions can be achieved and are often required to solve the largest and most complex problems. FEM is a general numerical analysis, numerical method for solving partial differential equations in two- or three-space variables (i.e., some boundary value problems). There are also studies about using FEM to solve high-dimensional problems. To solve a problem, FEM subdivides a large system into smaller, simpler parts called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the constructio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal Forming Simulation

Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies, processes and blanks prior to building try-out tooling. Finite element analysis (FEA) is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling. Sheet metal forming challenges Sheet metal forming, which is often referred to as stamping, is a process in which a piece of sheet metal, referred to as the blank, is formed by stretching between a punch and a die. The most painful and most frequent defects are wrinkles, thinning, springback and splits or cracks. Few methods are being used around the industry to cope with the main defects, based on the experience of the technicians. However, the correct process is the most vital, since it involves the correct geometry followed by number of steps to reach at final geometry. Which demands for specific experience or high ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

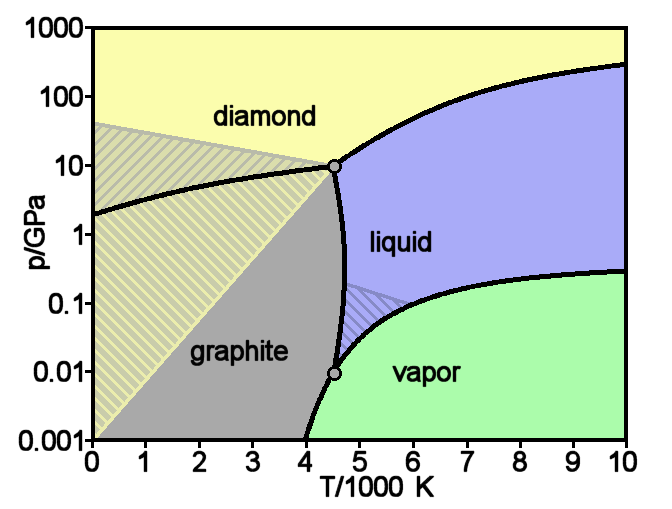

Graphite

Graphite () is a Crystallinity, crystalline allotrope (form) of the element carbon. It consists of many stacked Layered materials, layers of graphene, typically in excess of hundreds of layers. Graphite occurs naturally and is the most stable form of carbon under standard conditions. Synthetic and natural graphite are consumed on a large scale (1.3million metric tons per year in 2022) for uses in many critical industries including refractories (50%), lithium-ion batteries (18%), foundries (10%), and lubricants (5%), among others (17%). Graphite converts to diamond under extremely high pressure and temperature. Graphite's low cost, thermal and chemical inertness and characteristic conductivity of heat and electricity finds numerous applications in high energy and high temperature processes. Types and varieties Graphite can occur naturally or be produced synthetically. Natural graphite is obtained from naturally occurring geologic deposits and synthetic graphite is produced t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, transporting foreign particles, or heating or cooling the surfaces. The property of reducing friction is known as lubricity. In addition to industrial applications, lubricants are used for many other purposes. Other uses include cooking (oils and fats in use in frying pans and baking to prevent food sticking), to reduce rusting and friction in machinery, through the use of motor oil and Grease (lubricant), grease, bioapplications on humans (e.g., lubricants for Replacement joint, artificial joints), ultrasound examination, medical examination, and sexual intercourse. It is mainly used to reduce friction and to contribute to a better, more efficient functioning of a mechanism. History Lubricants have been in some use for thousands of year ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tribology

Tribology is the science and engineering of understanding friction, lubrication and wear phenomena for interacting surfaces in relative Motion (physics), motion. It is highly interdisciplinary, drawing on many academic fields, including physics, chemistry, materials science, mathematics, biology and engineering. The fundamental objects of study in tribology are tribosystems, which are physical systems of contacting surfaces. Subfields of tribology include biotribology, nanotribology and space tribology. It is also related to other areas such as the coupling of corrosion and tribology in tribocorrosion and the contact mechanics of how surfaces in contact deform. Approximately 20% of the total energy expenditure of the world is due to the impact of friction and wear in the transportation, manufacturing, power generation, and residential sectors. Etymology The word ''tribology'' derives from the Ancient Greek, Greek root τριβ- of the verb , ''wiktionary:tribo-, tribo'', "I rub" in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |