|

Metal Lathe

In machining, a metal lathe or metalworking lathe is a large class of lathes designed for precisely machining relatively hard materials. They were originally designed to machine metals; however, with the advent of plastics and other materials, and with their inherent versatility, they are used in a wide range of applications, and a broad range of materials. In machining jargon, where the larger context is already understood, they are usually simply called ''lathes'', or else referred to by more-specific subtype names ('' toolroom lathe'', '' turret lathe'', etc.). These rigid machine tools remove material from a rotating workpiece via the (typically linear) movements of various cutting tools, such as tool bits and drill bits. Metal lathes can vary greatly, but the most common design is known as the universal lathe or parallel lathe. Construction The design of lathes can vary greatly depending on the intended application; however, basic features are common to most types. These m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

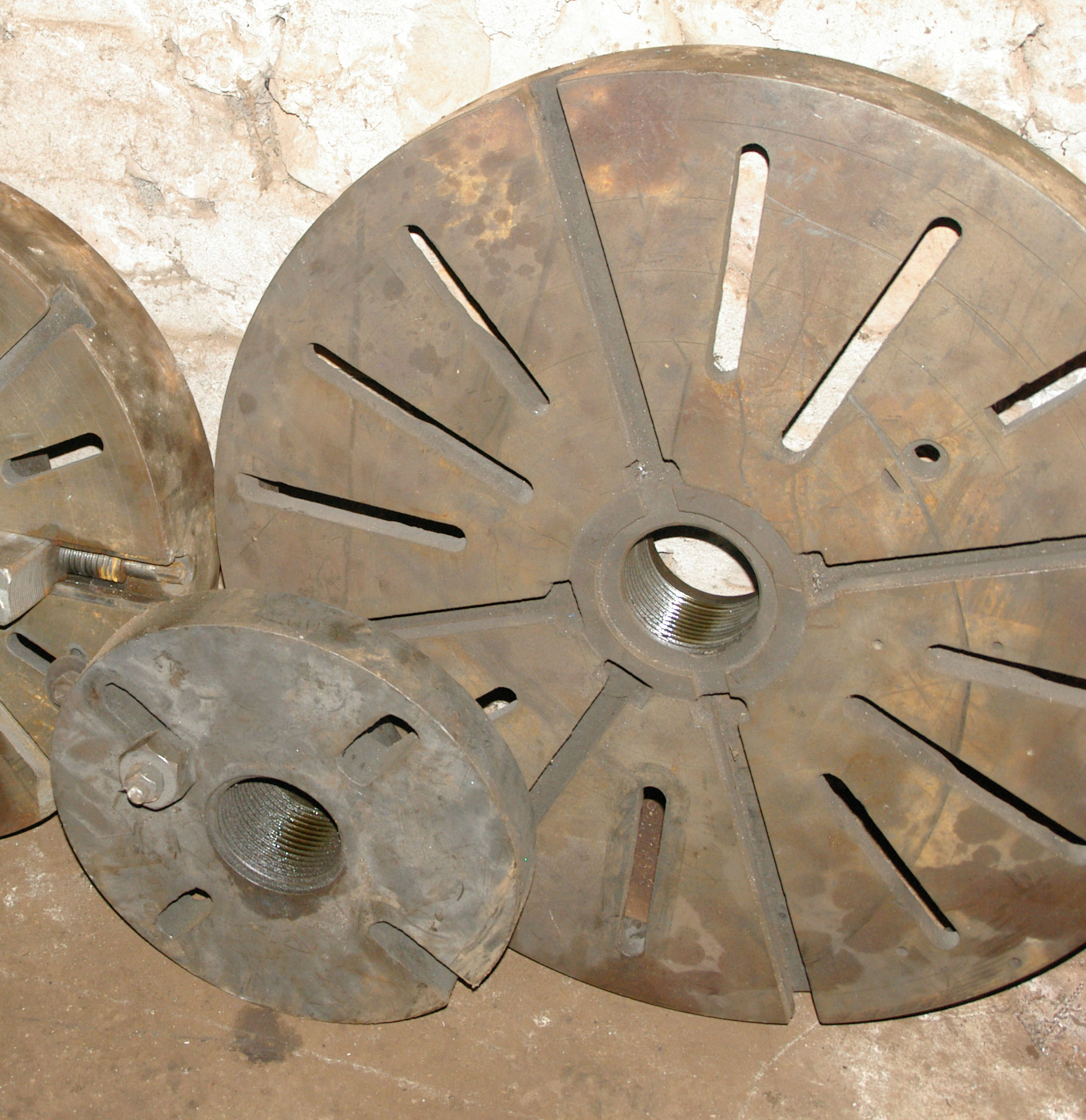

Lathe Faceplate

A lathe faceplate is a basic workholding accessory for a wood or metal turning lathe. It is a circular metal (usually cast iron) plate which fixes to the end of the lathe spindle (tool), spindle. The workpiece is then clamped to the faceplate, typically using t-slot nuts in slots in the faceplate, or less commonly threaded holes in the faceplate itself. The faceplate may be attached to the lathe in several ways: the two most common are a thread and a precision cone arrangement, and threaded studs and a circular recess fitting a flange on the end of the spindle. Increasingly common is the cam lock (latch), camlock arrangement, in which shaped studs and cams replace threaded studs for rapid exchanging of the faceplate with other accessories, such as Chuck (engineering)#Three-jaw, three or four jaw chucks. The faceplate was the ancestor of lathe chucks, an arrangement of three or more adjustable 'dogs' bolted to the faceplate providing a primitive chuck arrangement. The smaller pla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Taps And Dies

In the context of threading, taps and dies are the two classes of tools used to create screw threads. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called '' chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Worm Gear

A worm drive is a gear train, gear arrangement in which a worm (which is a gear in the form of a Screw thread, screw) meshes with a worm wheel (which is similar in appearance to a spur gear). Its main purpose is to translate the motion of two perpendicular axes or to translate circular motion to linear motion (example: band type hose clamp).The two machine element, elements are also called the worm screw and worm gear. The terminology is often confused by imprecise use of the term ''worm gear'' to refer to the worm, the worm wheel, or the worm drive as a unit. The worm drive or "endless screw" was invented by either Archytas of Tarentum, Apollonius of Perga, or Archimedes, the last one being the most probable author.Witold Rybczynski, ''One Good Turn (Rybczynski book), One good turn : a natural history of the screwdriver and the screw''. London, 2000. Page 139. The worm drive later appeared in the Indian subcontinent, for use in roller cotton gins, during the Delhi Sultanate in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Screw

A screw is an externally helical threaded fastener capable of being tightened or released by a twisting force (torque) to the screw head, head. The most common uses of screws are to hold objects together and there are many forms for a variety of materials. Screws might be inserted into holes in assembled parts or a screw may form its own thread. The #Differentiation between bolt and screw, difference between a screw and a bolt is that the latter is designed to be tightened or released by torquing a Nut (hardware), nut. The screw head on one end has a slot or other feature that commonly requires a tool to transfer the twisting force. Common tools for driving screws include screwdrivers, wrenches, coins and hex keys. The head is usually larger than the body, which provides a ''bearing surface'' and keeps the screw from being driven deeper than its length; an exception being the ''set screw'' (aka grub screw). The cylindrical portion of the screw from the underside of the head t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Norton Gearbox

Norton may refer to: Places Norton, meaning 'north settlement' in Old English, is a common place name. Places named Norton include: Canada * Rural Municipality of Norton No. 69, Saskatchewan * Norton Parish, New Brunswick ** Norton, New Brunswick, a village United Kingdom England * Norton, Runcorn, Cheshire, a district * Norton, South Hams, a location in Devon * Norton, Torridge, a location in Devon *Norton, County Durham, an area of Stockton-on-Tees * Norton, East Sussex, a location * Norton, Gloucestershire, a civil parish * Norton, Hampshire, a hamlet near Sutton Scotney * Norton, Herefordshire, a civil parish near Bromyard * Norton, Hertfordshire, a village * Norton, Isle of Wight, a location *Norton, Buckland and Stone, Kent, a civil parish * Norton, Northamptonshire, a village * Norton, Nottinghamshire, a village * Norton, Culmington, a location in Shropshire * Norton, Stockton, Shropshire, a location in Shropshire * Norton, Wroxeter and Uppington, a location in Shropshire * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Driveshaft

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power, torque, and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. As torque carriers, drive shafts are subject to torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, while avoiding too much additional weight as that would in turn increase their inertia. To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, or rag joints, and sometimes a splined joint or prismatic joint. History The term ''driveshaft'' first appeared during the mid-19th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Leadscrew

A leadscrew (or lead screw), also known as a power screw or translation screw,Bhandari, p. 202. is a screw used as a linkage in a machine, to translate turning motion into linear motion. Because of the large area of sliding contact between their male and female members, screw threads have larger frictional energy losses compared to other linkages. They are not typically used to carry high power, but more for intermittent use in low power actuator and positioner mechanisms. Leadscrews are commonly used in linear actuators, machine slides (such as in machine tools), vises, presses, and jacks.Shigley, p. 400. Leadscrews are a common component in electric linear actuators. Leadscrews are manufactured in the same way as other thread forms: they may be rolled, cut, or ground. A lead screw is sometimes used with a split nut (also called half nut) which allows the nut to be disengaged from the threads and moved axially, independently of the screw's rotation, when needed (suc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Rack And Pinion

rack and pinion is a type of linear actuator that comprises a circular gear (the '' pinion'') engaging a linear gear (the ''rack''). Together, they convert between rotational motion and linear motion: rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. The rack and pinion mechanism is used in rack railways, where the pinion mounted on a locomotive or a railroad car engages a rack usually placed between the rails, and helps to move the train up a steep gradient. It is also used in arbor presses and drill presses, where the pinion is connected to a lever and displaces a vertical rack (the ram). In pipelines and other industrial piping systems, a rack displaced by a linear actuator turns a pinion to open or close a valve. Stairlifts, lock gates, electric gates, and the mechanical steering mechanism of cars are other notable applications. The term "rack and pinion" may be used also when the rac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Way (machine Tool Element)

A way (sometimes known as a slideway, guideway, or bedway) is a type of linear bearing, specifically a linear plain bearing, in a machine tool. It facilitates precise linear motion along a given axis. A way is ground, scraped, or (less often) molded to be very flat, and ways often come in pairs to ensure a flat plane for the carriage or sliding element (slide) to move along smoothly. Ways are usually lubricated with way oil (a kind of machine oil specially made to adhere to the ways while vertical). Ways have been used since the 19th century and are a critical part of manufacturing processes, especially those requiring low tolerances such as machining. They have been made of various materials over the years, ranging from wood to cast iron, and nowadays including plastic alloys and special polymer materials. They are crafted with painstaking precision, usually being scraped into near total flatness with hand tools. This flatness is required to both provide good results in the ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Tailstock

Tailstock used for drilling A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine. It is usually used to apply support to the longitudinal rotary axis of a workpiece being machined. A lathe center is mounted in the tailstock, and inserted against the sides of a hole in the center of the workpiece. A Tailstock is particularly useful when the workpiece is relatively long and slender. Failing to use a tailstock can cause "chatter," where the workpiece bends excessively while being cut. This bending can also cause finished parts to exhibit an unintended taper where the unsupported end of the part is larger in diameter compared to the end supported by the headstock. It is also used on a lathe to hold drilling or reaming tools for machining a hole in the work piece. Unlike drilling with a drill press or a milling machine, the tool is stationary while the workp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Pulley

Sheave without a rope A pulley is a wheel on an axle or shaft enabling a taut cable or belt passing over the wheel to move and change direction, or transfer power between itself and a shaft. A pulley may have a groove or grooves between flanges around its circumference to locate the cable or belt. The drive element of a pulley system can be a rope, cable, belt, or chain. History The earliest evidence of pulleys dates back to Ancient Egypt in the Twelfth Dynasty (1991–1802 BC) and Mesopotamia in the early 2nd millennium BC. In Roman Egypt, Hero of Alexandria (c. 10–70 AD) identified the pulley as one of six simple machines used to lift weights. Pulleys are assembled to form a block and tackle in order to provide mechanical advantage to apply large forces. Pulleys are also assembled as part of belt and chain drives in order to transmit power from one rotating shaft to another. Plutarch's ''Parallel Lives'' recounts a scene where Archimedes proved the effectiveness ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |