|

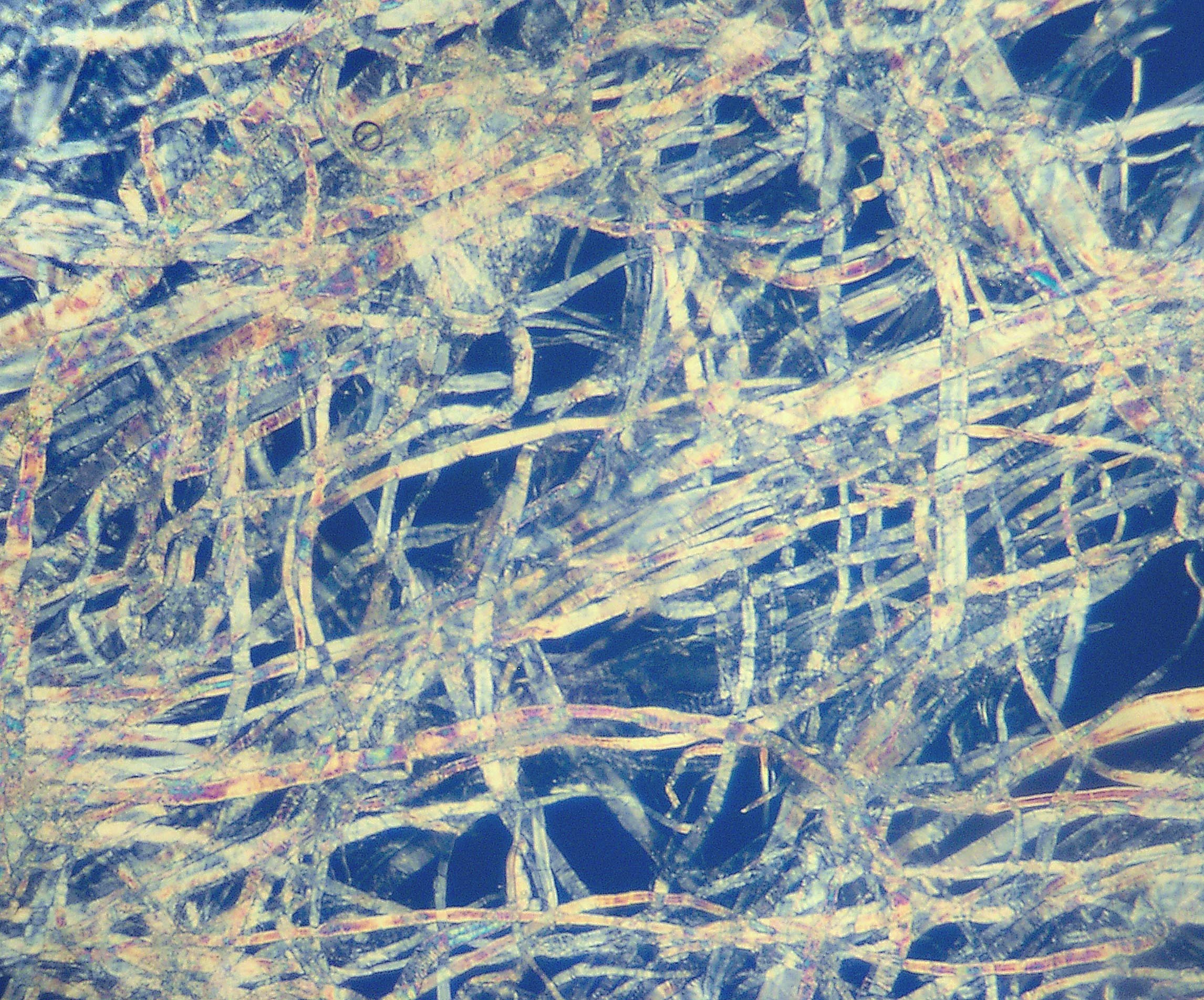

Mechanical Pulping

Mechanical pulping is the process in which wood is separated or defibrated mechanically into pulp for the paper industry. Mechanical pulping processes use wood in the form of logs or chips that are mechanically processes, by grinding stones (from logs) or in refiners (from chips), to separate the fibers. Industrial mechanical pulping started in the 1840s with groundwood pulping, producing the pulp from grinding. This made wood fibers the main raw material in paper, instead of textile fibers. Later the chemical pulping processes started dominating for many paper types. Today the groundwood pulping mills are few, but the mechanical pulping processes employing refiners are still important in the Pulp and paper industry. The mechanical pulps are primarily used in newspaper and magazine paper and the chemimechanical pulps for cardboard and soft paper. Mechanical pulps in the paper industry Mechanical pulp is very different from the pulp produced in the chemical processes (the sulfite ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulp And Paper Industry

The pulp and paper industry comprises companies that use wood, specifically pulpwood, as raw material and produce pulp, paper, paperboard, and other cellulose-based products. Manufacturing process In the manufacturing process, pulp is introduced into a paper machine where it is shaped into a paper web and water is extracted through pressing and drying stages. Pressing involves removing water from the sheet by applying force. This process employs a specialized type of felt, distinct from traditional felt, to absorb the water. In contrast, hand-made paper uses a blotter sheet for this purpose. Drying involves eliminating water from the paper sheets through air or heat. Historically, this was achieved by hanging the sheets to dry, similar to laundry. In modern papermaking, various heated drying mechanisms are employed, with the steam-heated can dryer being the most prevalent on paper machines. History Papermaking as a craft is ancient, and for centuries it used various fibers, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Paper Recycling

The recycling of paper is the process by which waste paper is turned into new paper products. It has several important benefits: It saves waste paper from occupying the homes of people and producing methane as it breaks down. Because paper fibre contains carbon (originally absorbed by the tree from which it was produced), recycling keeps the carbon locked up for longer and out of the atmosphere. Around two-thirds of all paper products in the US are now recovered and recycled, although it does not all become new paper. After repeated processing the fibres become too short for the production of new paper, which is why virgin fibre (from sustainably farmed trees) is frequently added to the pulp recipe. Three categories of paper can be used as feedstocks for making ''recycled paper'': mill broke, pre-consumer waste, and post-consumer waste. ''Mill broke'' is paper trimmings and other paper scraps from the manufacture of paper, and is recycled in a paper mill. ''Pre-consumer waste' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bleaching Of Wood Pulp

Bleaching of wood pulp is the chemical processing of wood pulp to lighten its color and whiten the pulp. The primary product of wood pulp is paper, for which whiteness (similar to, but distinct from brightness) is an important characteristic. These processes and chemistry are also applicable to the bleaching of non-wood pulps, such as those made from bamboo or kenaf. Paper brightness Brightness is the amount of incident light reflected from paper under specified conditions, usually reported as the percentage of light reflected, so a higher number means a brighter or whiter paper. In the US, the TAPPI T 452 or T 525 standards are used. The international community uses ISO standards. The table shows how the two systems rate high-brightness papers, but there is no simple way to convert between the two systems because the test methods are so different. The ISO rating is higher and can be over 100. This is because contemporary white paper incorporates fluorescent whiten ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

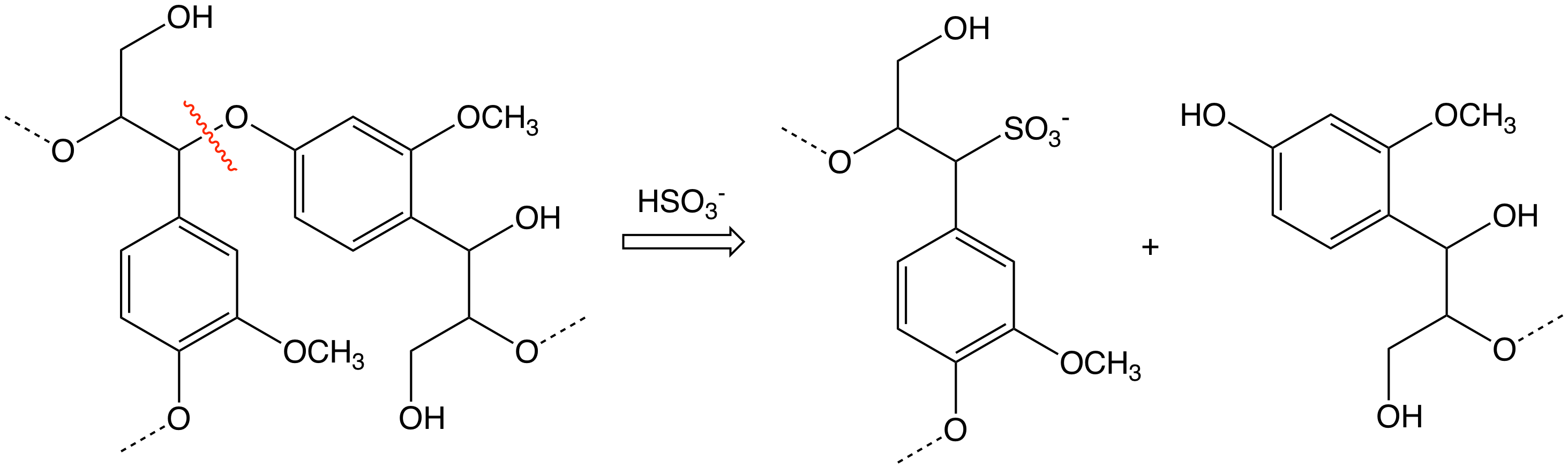

Sulfite Process

The sulfite process produces wood pulp that is almost pure cellulose fibers by treating wood chips with solutions of sulfite and bisulfite ions. These chemicals cleave the bonds between the cellulose and lignin components of the lignocellulose. A variety of sulfite/bisulfite salts are used, including sodium (Na+), calcium (Ca2+), potassium (K+), magnesium (Mg2+), and ammonium (NH4+). The lignin is converted to lignosulfonates, which are soluble and can be separated from the cellulose fibers. For the production of cellulose, the sulfite process competes with the Kraft process which produces stronger fibers and is less environmentally costly. History The use of wood to make pulp for paper began with the development of mechanical pulping in the 1840s by Charles Fenerty in Nova ScotiaBurger, Peter 'Charles Fenerty and his Paper Invention''. Toronto: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulp (paper)

Pulp is a fibrous Lignocellulosic biomass, lignocellulosic material prepared by chemically, semi-chemically, or mechanically isolating the cellulose fiber, cellulosic fibers of wood, fiber crops, Paper recycling, waste paper, or cotton paper, rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other Pulp and paper industry, paper products. History Before the widely acknowledged invention of papermaking by Cai Lun in China around AD 105, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of Bark (botany), bark or Bast fibre, bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bleached Chemi-ThermoMechanical Pulp

Bleached Chemi-ThermoMechanical Pulp (BCTMP) is a pulp product used by the paper industry as a less-expensive alternative for Northern Bleached Softwood Kraft (NBSK). BCTMP was first produced by Millar Western in 1988 in its Whitecourt Mill, and was initially used in lower grade paper applications. The product is attractive to producers because it needed less capital to construct the production facilities. It also provides higher yields than other processes, which lowers the total cost of production. In addition, BCTMP provides higher bulk, opacity, and stiffness in the final product, and the process is more environmentally friendly Environment friendly processes, or environmental-friendly processes (also referred to as eco-friendly, nature-friendly, and green), are sustainability and marketing terms referring to goods and services, laws, guidelines and policies that c .... See also * Northern bleached softwood kraft * Southern bleached softwood kraft References { ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

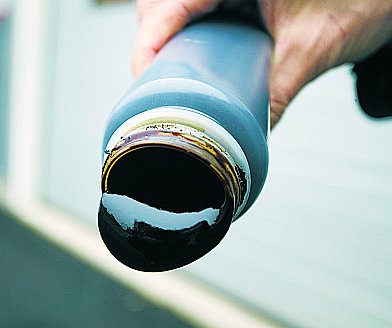

Black Liquor

In industrial chemistry, black liquor is the by-product from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers. The equivalent material in the sulfite process is usually called brown liquor, but the terms red liquor, thick liquor and sulfite liquor are also used. Composition Approximately seven tonnes of black liquor are produced in the manufacture of one tonne of pulp. The black liquor is an aqueous suspension of lignin residues, hemicellulose, and the inorganic chemicals used in the process. The black liquor comprises 15% solids by weight of which two thirds are organic chemicals and the remainder are inorganic. Normally the organics in black liquor are 40-45% soaps, 35-45% lignin and 10-15% other organics. The organic matter in the black liquor is made up of water/alkali soluble degradation components from the wood. Lignin is degraded to shorter fragments with sulphur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tissue Paper

Tissue paper, or simply tissue, is a lightweight paper or light crêpe paper. Tissue can be made from recycled pulp (paper), paper pulp on a paper machine. Tissue paper is very versatile, and different kinds are made to best serve these purposes, which are hygienic tissue paper, facial tissues, paper towels, as packing material, among other (sometimes creative) uses. The use of tissue paper is common in developed nations, around 21 million tonnes in North America and 6 million in Europe, and is growing due to urbanization. As a result, the industry has often been scrutinized for deforestation. However, more companies are presently using more recycled fibres in tissue paper. Properties The key properties of tissues are absorbency, basis weight, thickness, bulk (specific volume), brightness, stretch, appearance and comfort. Production Tissue paper is produced on a Fourdrinier machine, paper machine that has a single large steam heated drying cylinder (Yankee dryer) fitted with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sodium Dithionite

Sodium dithionite (also known as sodium hydrosulfite) is a white crystalline powder with a sulfurous odor. Although it is stable in dry air, it decomposes in hot water and in acid solutions. Structure left, 220px, Packing of sodium dithionite ions in a crystal, showing the saw-horse geometry of the dianion. Color code: red = O, yellow = S. The structure has been examined by Raman spectroscopy and X-ray crystallography. The dithionite dianion has C symmetry, with almost eclipsed with a 16° O-S-S-O torsional angle. In the dihydrated form (), the dithionite anion has gauche 56° O-S-S-O torsional angle. A weak S-S bond is indicated by the S-S distance of 239 pm, which is elongated by ca. 30 pm relative to a typical S-S bond. Because this bond is fragile, the dithionite anion dissociates in solution into the O2sup>− radicals, as has been confirmed by EPR spectroscopy. It is also observed that 35S undergoes rapid exchange between S2O42− and SO2 in neutral or acidic solu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Umeå Stadsarkiv-1967-lastning Av Våtmassa

Umeå ( , , , locally ; ; ; ; ) is a city in northeast Sweden. It is the seat of Umeå Municipality and the capital of Västerbotten County. Situated on the Ume River, Umeå is the largest Urban areas in Sweden, locality in Norrland and the thirteenth largest in Sweden, with a wider municipal population of 132,235 inhabitants in the beginning of 2023. When Umeå University was established in 1965, growth accelerated, and the amount of housing has doubled in 30 years from 1980 to 2010. , Umeå was gaining around 1,000 inhabitants per year and the municipality plans for having 200,000 inhabitants by 2050. The projection of municipality size in 2050 has, however, been questioned as an overestimation in an independent study. Umeå is a college town, university town and centre of education, technical and medical research in northern Sweden. The two universities located in the city, Umeå University and one of the 3 main branches of Swedish University of Agricultural Sciences, SLU, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen Peroxide

Hydrogen peroxide is a chemical compound with the formula . In its pure form, it is a very pale blue liquid that is slightly more viscosity, viscous than Properties of water, water. It is used as an oxidizer, bleaching agent, and antiseptic, usually as a dilute solution (3%–6% by weight) in water for consumer use and in higher concentrations for industrial use. Concentrated hydrogen peroxide, or "high-test peroxide", decomposes explosively when heated and has been used as both a monopropellant and an oxidizer in rocketry. Hydrogen peroxide is a reactive oxygen species and the simplest peroxide, a compound having an oxygen–oxygen single bond. It decomposes slowly into water and elemental oxygen when exposed to light, and rapidly in the presence of organic or reactive compounds. It is typically stored with a Stabilizer (chemistry), stabilizer in a weakly acidic solution in an opaque bottle. Hydrogen peroxide is found in biological systems including the human body. Enzymes that u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lignin

Lignin is a class of complex organic polymers that form key structural materials in the support tissues of most plants. Lignins are particularly important in the formation of cell walls, especially in wood and bark, because they lend rigidity and do not rot easily. Chemically, lignins are polymers made by cross-linking phenolic precursors. History Lignin was first mentioned in 1813 by the Swiss botanist A. P. de Candolle, who described it as a fibrous, tasteless material, insoluble in water and alcohol but soluble in weak alkaline solutions, and which can be precipitated from solution using acid. He named the substance "lignine", which is derived from the Latin word '' lignum'', meaning wood. It is one of the most abundant organic polymers on Earth, exceeded only by cellulose and chitin. Lignin constitutes 30% of terrestrial non-fossil organic carbon on Earth, and 20 to 35% of the dry mass of wood. Lignin is present in red algae, which suggest that the common ancestor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |