|

List Of Welding Processes

This is a list of welding processes, separated into their respective categories. The associated ''N reference numbers'' (second column) are specified in ISO 4063 (in the European Union published as ''EN ISO 4063''). Numbers in parentheses are obsolete and were removed from the current (1998) version of ISO 4063. The AWS reference codes of the American Welding Society are commonly used in North America."Welding Inspection Handbook", 3rd edition, American Welding Society, , Miami, FL, pp. 10-11 (2000) Arc welding ''Overview article: arc welding'' Oxyfuel gas welding ''Overview article: Oxy-fuel welding and cutting'' Resistance welding ''Overview article: electric resistance welding'' Solid-state welding Other types of welding Notes and references *Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. . *Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland: Lincoln Electric. . ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Welding Society

The American Welding Society (AWS) was founded in 1919 as a non-profit organization to advance the science, technology and application of welding and allied joining and cutting processes, including brazing, soldering and thermal spraying. Headquartered in Doral, Florida, and led by a volunteer organization of officers and directors, AWS serves over 73,000 members worldwide and is composed of 22 Districts with 250 Sections and student chapters. History The roots of the American Welding Society stretch back to World War I, when the sudden demands of swiftly producing military equipment brought about the need for standardization of the manufacturing industry. An evolving metal joining process, welding, suddenly became very necessary to enhance the war effort. To ensure that industry took advantage of this technology, President Woodrow Wilson called upon a Harvard professor, Comfort A. Adams, to chair the Welding Committee of the Emergency Fleet Corp. Welding performed well in th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Gas Welding

Principle of burn cutting Oxy-fuel welding (commonly called oxyacetylene welding, oxy welding, or gas welding in the United States) and oxy-fuel cutting are processes that use fuel gases (or liquid fuels such as gasoline or petrol, diesel, biodiesel, kerosene, etc) and oxygen to weld or cut metals. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903. Pure oxygen, instead of air, is used to increase the flame temperature to allow localized melting of the workpiece material (e.g. steel) in a room environment. A common propane/air flame burns at about , a propane/oxygen flame burns at about , an oxyhydrogen flame burns at and an acetylene/oxygen flame burns at about . During the early 20th century, before the development and availability of coated arc welding electrodes in the late 1920s that were capable of making sound welds in steel, oxy-acetylene welding was the only process capable of making welds of exceptionally ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forge Welding

Forge welding (FOW), also called fire welding, is a solid-state welding process that joins two pieces of metal by heating them to a high temperature and then hammering them together. It may also consist of heating and forcing the metals together with presses or other means, creating enough pressure to cause plastic deformation at the weld surfaces. The process, although challenging, has been a method of joining metals used since ancient times and is a staple of traditional blacksmithing. Forge welding is versatile, being able to join a host of similar and dissimilar metals. With the invention of electrical welding and gas welding methods during the Industrial Revolution, manual forge-welding has been largely replaced, although automated forge-welding is a common manufacturing process. Introduction Forge welding is a process of joining metals by heating them beyond a certain threshold and forcing them together with enough pressure to cause deformation of the weld surfaces, creating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnetic Pulse Welding

Magnetic pulse welding (MPW) is a solid state welding process that uses magnetic forces to weld two workpieces together. The welding mechanism is most similar to that of explosion welding. Magnetic pulse welding started in the early 1970s, when the automotive industry began to use solid state welding. The primary advantage of using magnetic pulse welding is that the formation of brittle intermetallic phases is avoided, allowing the joining of metals which cannot be effectively joined by fusion welding. Additionally, the process is nearly instantaneous and does not require shielding gas or other welding consumables. Process Magnetic pulse welding is based on a very short electromagnetic pulse (<100 μs), which is obtained by a fast discharge of capacitors through low inductance switches into a coil. The pulsed current with a very high amplitude and frequency (500 kA and 15 kHz) produces a high-density magnetic field, which creates an eddy current in one of the work ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Explosion Welding

Explosion welding (EXW) is a solid state (solid-phase) process where welding is accomplished by accelerating one of the components at extremely high velocity through the use of chemical explosives. This process is often used to clad carbon steel or aluminium plate with a thin layer of a harder or more corrosion-resistant material (e.g., stainless steel, nickel alloy, titanium, or zirconium). Due to the nature of this process, producible geometries are very limited. Typical geometries produced include plates, tubing and tube sheets. Development Unlike other forms of welding such as arc welding (which was developed in the late 19th century), explosion welding was developed relatively recently, in the decades after World War II. Its origins, however, go back to World War I, when it was observed that pieces of shrapnel sticking to armor plating were not only embedding themselves, but were actually being welded to the metal. Since the extreme heat involved in other forms of weldin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffusion Welding

Diffusion bonding or diffusion welding is a solid-state welding technique used in metalworking, capable of joining similar and dissimilar metals. It operates on the principle of solid-state diffusion, wherein the atoms of two solid, metallic surfaces intersperse themselves over time. This is typically accomplished at an elevated temperature, approximately 50-75% of the absolute melting temperature of the materials. A weak bond can also be achieved at room temperature. Diffusion bonding is usually implemented by applying high pressure, in conjunction with necessarily high temperature, to the materials to be welded; the technique is most commonly used to weld "sandwiches" of alternating layers of thin metal foil, and metal wires or filaments. Currently, the diffusion bonding method is widely used in the joining of high-strength and refractory metals within the aerospace and nuclear industries. History The act of diffusion welding is centuries old. This can be found in the form of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Welding

Cold welding or contact welding is a solid-state welding process in which joining takes place without fusion or heating at the interface of the two parts to be welded. Unlike in fusion welding, no liquid or molten phase is present in the joint. Cold welding was first recognized as a general materials phenomenon in the 1940s. It was then discovered that two clean, flat surfaces of similar metal would strongly adhere if brought into contact while in a vacuum . Micro and nano-scale cold welding has shown potential in nanofabrication processes. Applications include wire stock and electrical connections (such as insulation-displacement connectors and wire wrap connections). In space Mechanical problems in early satellites were sometimes attributed to cold welding. In 2009 the European Space Agency published a peer reviewed paper detailing why cold welding is a significant issue that spacecraft designers need to carefully consider. The paper also cites a documented exampl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

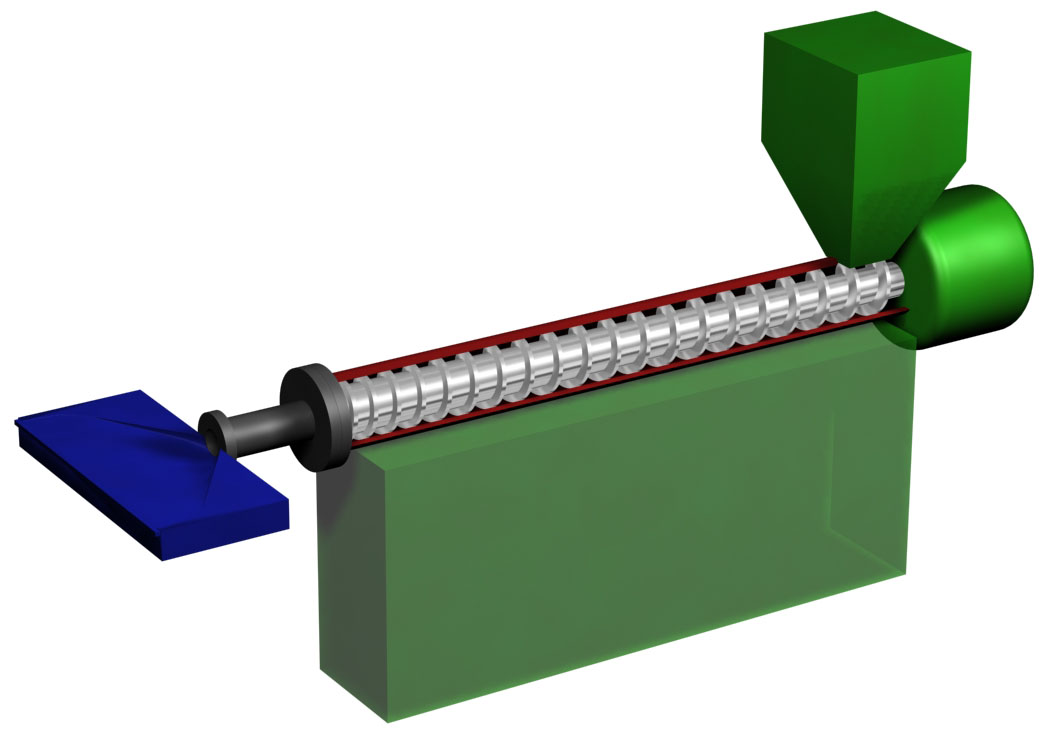

Coextrusion Welding

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted by the mechanical energy generated by turning screws and by heaters arranged along the barrel. The molten polymer is then forced into a die, which shapes the polymer into a shape that hardens during cooling. History The first precursors to the modern extruder were developed in the early 19th century. In 1820, Thomas Hancock invented a rubber "masticator" designed to reclaim processed rubber scraps, and in 1836 Edwin Chaffee developed a two-roller machine to mix additives into rubber. The first thermoplastic extru ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Upset Welding

Upset welding (UW)/resistance butt welding is a welding technique that produces coalescence simultaneously over the entire area of abutting surfaces or progressively along a joint, by the heat obtained from resistance to electric current through the area where those surfaces are in contact. Pressure is applied before heating is started and is maintained throughout the heating period. The equipment used for upset welding is very similar to that used for flash welding. It can be used only if the parts to be welded are equal in cross-sectional area. The abutting surfaces must be very carefully prepared to provide for proper heating. The difference from flash welding is that the parts are clamped in the welding machine and force is applied bringing them tightly together. High-amperage current is then passed through the joint, which heats the abutting surfaces. When they have been heated to a suitable forging temperature an upsetting force is applied and the current is stopped. The hi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flash Welding

Flash welding is a type of resistance welding that does not use any filler metals. The pieces of metal to be welded are set apart at a predetermined distance based on material thickness, material composition, and desired Material properties, properties of the finished weld. Electrical current, Current is applied to the metal, and the gap between the two pieces creates Electrical resistance and conductance, resistance and produces the Electric arc, arc required to melt the metal. Once the pieces of metal reach the proper temperature, they are pressed together, effectively forge welding them together. Parameters According to a study published in Materials and Design, several parameters affect the final product. Flash time is the time that the Electric arc, arc is present. Upset time is the amount of time that the two pieces are pressed together. Flash time needs to be long enough to sufficiently heat the metal before it is pressed together. However, if it is too long, too much of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

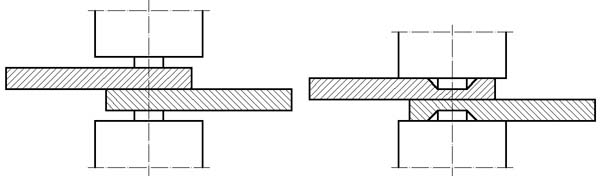

Projection Welding

Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude and duration of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drum (container)

A drum (also called a barrel) is a cylindrical shipping container used for shipping bulk cargo. Drums can be made of steel, dense paperboard (commonly called a fiber drum), or plastic, and are generally used for the transportation and storage of liquids and powders. Drums are often stackable, and have dimensions designed for efficient warehouse and logistics use. This type of packaging is frequently certified for transporting dangerous goods. Proper shipment requires the drum to comply with all applicable regulations. Steel drums Steel drums are ubiquitous industrial shipping containers. They are manufactured from sheets of cold rolled steel formed into a tube and welded along the side seam. Stainless steel, nickel, and special alloys are occasionally used. The bottom head is permanently attached by the manufacturer. Two primary options are available for the top head: * Open head drum, removable head drum: Top head is attached after filling with a closing ring and bolted lo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |