|

List Of Blade Materials

A variety of blade materials can be used to make the blade of a knife or other simple edged hand tool or weapon, such as a sickle, hatchet, or sword. The most common blade materials are carbon steel, stainless steel, tool steel, and alloy steel. Less common materials in blades include cobalt and titanium alloys, Ceramic knife, ceramic, obsidian, and plastic. The hardness of steel is usually stated as a number on the Rockwell scale#Scales and values, Rockwell C scale (HRC). The Rockwell scale is a hardness scale based on the resistance to indentation a material has. This differs from other scales such as the Mohs scale (scratch resistance testing), which is used in mineralogy. As hardness increases, the blade becomes more capable of taking and holding an edge but is more difficult to sharpen and increasingly more Brittleness, brittle (commonly called less "tough"). Lamination, Laminating harder steel between softer steel is an expensive process, though it gives the benefits of both ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

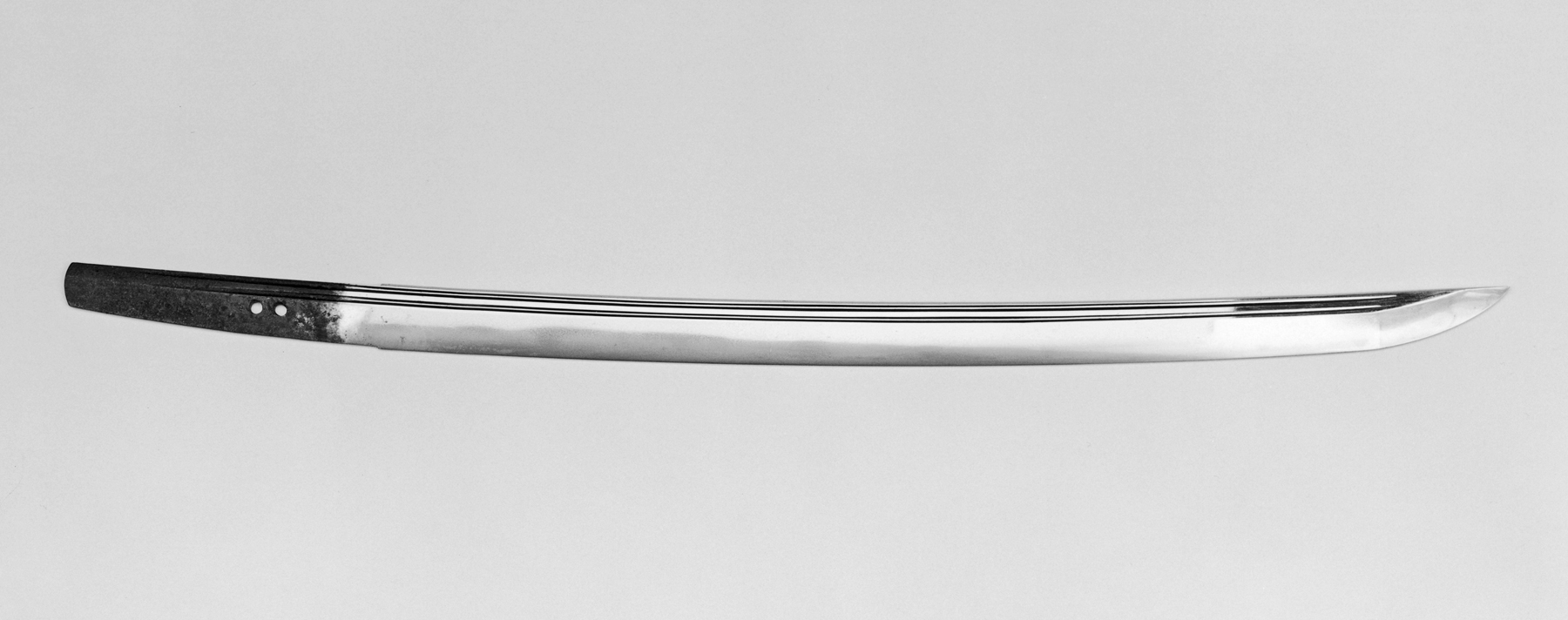

Blade

A blade is the Sharpness (cutting), sharp, cutting portion of a tool, weapon, or machine, specifically designed to puncture, chop, slice, or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are intended to cut. This includes early examples made from flaked stones like flint or obsidian, evolving through the ages into metal forms like copper, bronze, and iron, and culminating in modern versions made from steel or ceramics. Serving as one of humanity's oldest tools, blades continue to have wide-ranging applications, including in combat, cooking, and various other everyday and specialized tasks. Blades function by concentrating force at the cutting edge. Design variations, such as serrated edges found on bread knives and saws, serve to enhance this force concentration, adapting blades for specific functions and materials. Blades thus hold a significant place both historically and in contemporary society, reflecting an evolution i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mohs Scale

The Mohs scale ( ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material. The scale was introduced in 1812 by the German geologist and mineralogist Friedrich Mohs, in his book (English: Attempt at an elementary method for the natural-historical determination and recognition of fossils); it is one of several definitions of hardness in materials science, some of which are more quantitative. The method of comparing hardness by observing which minerals can scratch others is of great antiquity, having been mentioned by Theophrastus in his treatise ''On Stones'', , followed by Pliny the Elder in his '' Naturalis Historia'', . The Mohs scale is useful for identification of minerals in the field, but is not an accurate predictor of how well materials endure in an industrial setting. Reference minerals The Mohs scale of mineral hardness is based on the ab ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Phill Hartsfield

Phill Hartsfield (August 16, 1931 – May 20, 2010) was a Southern California sword and knifemaker based in Garden Grove who is noted for popularizing the chisel ground blade in the western world. Hartsfield's designs have influenced other knifemakers, primarily Ernest Emerson. Early life Hartsfield joined the US Navy at age17 and served as a sonar technician. After serving four years, he was discharged and worked as a television repairman. After six months of working for a repair shop, Hartsfield opened his own repairshop at the age of 22 while making knives part-time. In 1977, he closed his TV repair business and became a full-time knifemaker. Knife making Hartsfield's blades are Japanese-influenced, each one was hand ground from various kinds of tool steel, including 01 and A2. They are differentially edge hardened to RC 60-61 on the Rockwell scale with the remainder of the blade hardened to 58-59 on the scale to allow for flex during the cut. This strength prote ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cutting Tool

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force. Implements commonly used for cutting are the knife and saw, or in medicine and science the scalpel and microtome. However, any sufficiently sharp object is capable of cutting if it has a hardness sufficiently larger than the object being cut, and if it is applied with sufficient force. Even liquids can be used to cut things when applied with sufficient force (see water jet cutter). Cutting is a compressive and shearing phenomenon, and occurs only when the total stress generated by the cutting implement exceeds the ultimate strength of the material of the object being cut. The simplest applicable equation is: :\text = or \tau=\frac The stress generated by a cutting implement is directly proportional to the force with which it is applied, and inversely proportional to the area of contact. Hence, the smaller the area (i.e., the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging. Tool steels have a carbon content between 0.4% and 1.5%. The presence of carbides in their matrix plays the dominant role in the qualities of tool steel. The four major alloying elements that form carbides in tool steel are: tungsten, chromium, vanadium and molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high-temperature performance of steel (slower is better, making for a heat-resistant steel). Proper heat treatme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

41xx Steel

41xx steel is a family of SAE steel grades, as specified by the Society of Automotive Engineers (SAE). Alloying elements include chromium and molybdenum, and as a result these materials are often informally referred to as chromoly steel (common variant stylings include ''chrome-moly'', ''cro-moly'', ''CrMo'', ''CRMO'', ''CR-MOLY'', and similar). They have an excellent strength to weight ratio and are considerably stronger and harder than standard 1020 steel, but are not easily welded, requiring thermal treatment both before and after welding to avoid cold cracking. While these grades of steel do contain chromium, it is not in great enough quantities to provide the corrosion resistance found in stainless steel. Examples of applications for 4130, 4140, and 4145 include structural tubing, bicycle frames, gas bottles for transportation of pressurized gases, firearm parts, clutch and flywheel components, and roll cages. 4150 stands out as being one of the steels accepte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Middle Ages

In the history of Europe, the Middle Ages or medieval period lasted approximately from the 5th to the late 15th centuries, similarly to the post-classical period of global history. It began with the fall of the Western Roman Empire and transitioned into the Renaissance and the Age of Discovery. The Middle Ages is the middle period of the three traditional divisions of Western history: classical antiquity, the medieval period, and the modern period. The medieval period is itself subdivided into the Early, High, and Late Middle Ages. Population decline, counterurbanisation, the collapse of centralised authority, invasions, and mass migrations of tribes, which had begun in late antiquity, continued into the Early Middle Ages. The large-scale movements of the Migration Period, including various Germanic peoples, formed new kingdoms in what remained of the Western Roman Empire. In the 7th century, North Africa and the Middle East—once part of the Byzantine Empire� ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dalian Hanwei Metal

Hanwei (Dalian Hanwei Metal Co. Ltd., Chinese: :wikt:漢, :wikt:威, :wikt:金屬, :wikt:製造, ) is a Chinese company manufacturing replica swords and other types of medieval arms and armor. The company was founded in 1990 by Chen Chao-Po (陈朝波, Chinese name#Western name, Western name Paul Chen, born 1955Dalian Hanwei Blade Center Co., Ltd. sell123.org (2014).了解汉威 (hanweimetal.com) /ref>). The company produces replicas or reconstructions of Japanese swords, Chinese swords and European swords, besides various types shorter-bladed daggers, Sidearm (weapon), sidearms or combat knife, combat knives, other his ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spring Steel

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon steel with a very high yield strength. This allows objects made of spring steel to return to their original shape despite significant deflection or twisting. Grades Many grades of steel can be hardened and tempered to increase elasticity and resist deformation; however, some steels are inherently more elastic than others: Applications * Applications include piano wire, spring clamps, antennas, springs (e. g. vehicle coil springs or leaf springs), and s-tines. * Spring steel is commonly used in the manufacture of swords with rounded edges for training or stage combat, as well as sharpened swords for collectors and live combat. * Spring steel is one of the most popular materials used in the fabrication of lockpicks due to its pliabilit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Damascus Steel

Damascus steel (Arabic: فولاذ دمشقي) refers to the high-carbon crucible steel of the blades of historical swords forged using the wootz process in the Near East, characterized by distinctive patterns of banding and mottling reminiscent of flowing water, sometimes in a "ladder" or "rose" pattern. "Damascus steel" developed a reputation for being tough, resistant to shattering, and capable of being honed to a sharp, resilient edge. The term "Damascus steel" traces its roots to the medieval city of Damascus, Syria, perhaps as an early example of branding. However, there is now a general agreement that many of the swords, or at least the steel ingots from which they were forged, were imported from elsewhere. Originally, they came from either Southern India, where the steel-making techniques used were first developed, or from Khorasan, Iran. The methods used to create medieval Damascus steel died out by the late 19th century. Modern steelmakers and metallurgists have stud ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

San Mai

, in the context of metal blade construction/metalwork, refers to a knife, blade or sword that has the hard steel hagane forming the blade's edge, and the iron/stainless forming a jacket on both sides. It is also the term used to refer to the technique used to create these blades. Origin, use of the term, and history "San mai" roughly translates as three flat things, in Japanese (San=three Mai=unit counter for flat objects). The term, and its root honsanmai, has been used to describe that construction method for many hundreds of years, from around 1300 A.D. It refers to when three layers of steel are used. The center is hard, and the sides are typically softer. As san mai is a generic term for a technique, the term can't be trademarked. Outside in the specific context of blade construction technique, the term, in general use in Japan, refers to three flat things (e.g. three tickets, or three pieces of paper), mai 枚, being the counter unit term for flat objects in Japanese. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |