|

Jet Engine Compressors

As the name suggests, gas turbine engine compressors provide the compression part of the gas turbine engine thermodynamic cycle. There are three basic categories of gas turbine engine compressor: axial compressor, centrifugal compressor and mixed flow compressor. A fourth, unusual, type is the free-piston gas generator, which combines the functions of compressor and combustion chamber in one unit. Axial compressor Most high-compression jet engine use axial compressors for their high efficiency. In the axial compressor the air flows parallel to the axis of rotation. Axial compressor are made to be multi-staged. A stage consists of a row of rotating blades called the rotor, which are connected to the central shaft and a row of stationary or fixed blades called stator. In axial flow compressor, the air flows from stage to stage. The role of the rotor blades is the accelerate the incoming air for increasing the kinetic energy of the air. Then the fluid is decelerated across the stat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine Gaz Animee

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating electrical power when combined with a generator.Munson, Bruce Roy, T. H. Okiishi, and Wade W. Huebsch. "Turbomachines." Fundamentals of Fluid Mechanics. 6th ed. Hoboken, NJ: J. Wiley & Sons, 2009. Print. A turbine is a turbomachine with at least one moving part called a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades so that they move and impart rotational energy to the rotor. Early turbine examples are windmills and waterwheels. Gas, steam, and water turbines have a casing around the blades that contains and controls the working fluid. Credit for invention of the steam turbine is given both to Anglo-Irish engineer Sir Charles Parsons (1854–1931) for invention of the reaction turbine, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Turbine Engine

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part (known as the gas generator or core) and are, in the direction of flow: * a rotating gas compressor * a combustor * a compressor-driving turbine. Additional components have to be added to the gas generator to suit its application. Common to all is an air inlet but with different configurations to suit the requirements of marine use, land use or flight at speeds varying from stationary to supersonic. A propelling nozzle is added to produce thrust for flight. An extra turbine is added to drive a propeller (turboprop) or ducted fan (turbofan) to reduce fuel consumption (by increasing propulsive efficiency) at subsonic flight speeds. An extra turbine is also required to drive a helicopter rotor or land-vehicle transmission (turboshaft), marine propeller or electrical generator (power turbine). Greater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermodynamic Cycle

A thermodynamic cycle consists of a linked sequence of thermodynamic processes that involve transfer of heat and work into and out of the system, while varying pressure, temperature, and other state variables within the system, and that eventually returns the system to its initial state. In the process of passing through a cycle, the working fluid (system) may convert heat from a warm source into useful work, and dispose of the remaining heat to a cold sink, thereby acting as a heat engine. Conversely, the cycle may be reversed and use work to move heat from a cold source and transfer it to a warm sink thereby acting as a heat pump. If at every point in the cycle the system is in thermodynamic equilibrium, the cycle is reversible. Whether carried out reversible or irreversibly, the net entropy change of the system is zero, as entropy is a state function. During a closed cycle, the system returns to its original thermodynamic state of temperature and pressure. Process quanti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Axial Compressor

An axial compressor is a gas compressor that can continuously pressurize gases. It is a rotating, airfoil-based compressor in which the gas or working fluid principally flows parallel to the axis of rotation, or axially. This differs from other rotating compressors such as centrifugal compressor, axi-centrifugal compressors and mixed-flow compressors where the fluid flow will include a "radial component" through the compressor. The energy level of the fluid increases as it flows through the compressor due to the action of the rotor blades which exert a torque on the fluid. The stationary blades slow the fluid, converting the circumferential component of flow into pressure. Compressors are typically driven by an electric motor or a steam or a gas turbine. Axial flow compressors produce a continuous flow of compressed gas, and have the benefits of high efficiency and large mass flow rate, particularly in relation to their size and cross-section. They do, however, require sever ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centrifugal Compressor

Centrifugal compressors, sometimes called impeller compressors or radial compressors, are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. They achieve pressure rise by adding energy to the continuous flow of fluid through the rotor/impeller. The following equation shows this specific energy input. A substantial portion of this energy is kinetic which is converted to increased potential energy/static pressure by slowing the flow through a diffuser. The static pressure rise in the impeller may roughly equal the rise in the diffuser. Equation-0.1 : H = \left( \left( R \right)_2 - \left( R \right)_1 \right) :where the control volume nomenclature (illustrated in Figure-0.4) is: ::* subscript, is the impeller inlet location, station1 ::* subscript, is the impeller discharge/exit location, station2 ::* is the energy input per unit mass, units=(LP/m) ::* is the impeller's rotation speed, units=(radians/t) ::* is the radius of specified location, units=(L) ::* is v ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mixed Flow Compressor

A mixed flow compressor, or diagonal compressor, combines axial and radial components to produce a diagonal airflow compressor stage. The exit mean radius is greater than at the inlet, like a centrifugal design, but the flow tends to exit in an axial rather than radial direction. This eliminates the need for a relatively large diameter exit diffuser associated with centrifugal compressors. The impeller can be machined from solid using NC machines, in much the same way as that of a centrifugal design. Diagonal compressors were widely experimented during and just after World War II, but did not see much service use. A diagonal-flow compressor is featured since 2001 in the Pratt & Whitney Canada PW600 series turbofan engines used in the Phenom 100, Eclipse 500, Cessna Citation Mustang and other very light jet aircraft. See also * Gas compressor A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Free-piston

A free-piston engine is a linear, 'crankless' internal combustion engine, in which the piston motion is not controlled by a crankshaft but determined by the interaction of forces from the combustion chamber gases, a rebound device (e.g., a piston in a closed cylinder) and a load device (e.g. a gas compressor or a linear alternator). The purpose of all such piston engines is to generate power. In the free-piston engine, this power is not delivered to a crankshaft but is instead extracted through either exhaust gas pressure driving a turbine, through driving a linear load such as an air compressor for pneumatic power, or by incorporating a linear alternator directly into the pistons to produce electrical power. The basic configuration of free-piston engines is commonly known as single piston, dual piston or opposed pistons, referring to the number of combustion cylinders. The free-piston engine is usually restricted to the two-stroke operating principle, since a power stroke is req ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

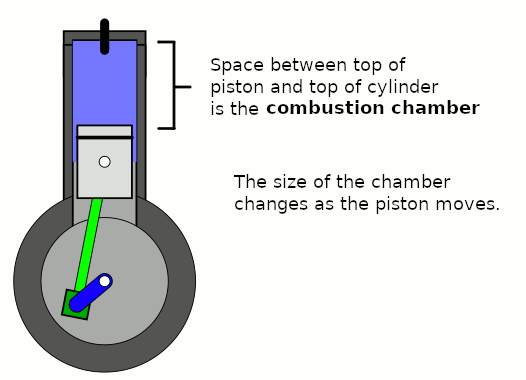

Combustion Chamber

A combustion chamber is part of an internal combustion engine in which the fuel/air mix is burned. For steam engines, the term has also been used for an extension of the firebox which is used to allow a more complete combustion process. Internal combustion engines In an internal combustion engine, the pressure caused by the burning air/fuel mixture applies direct force to part of the engine (e.g. for a piston engine, the force is applied to the top of the piston), which converts the gas pressure into mechanical energy (often in the form of a rotating output shaft). This contrasts an external combustion engine, where the combustion takes place in a separate part of the engine to where the gas pressure is converted into mechanical energy. Spark-ignition engines In spark ignition engines, such as petrol (gasoline) engines, the combustion chamber is usually located in the cylinder head. The engines are often designed such that the bottom of combustion chamber is roughly in l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolls Royce Goblin II Numbered Cutaway

Roll or Rolls may refer to: Movement about the longitudinal axis * Roll angle (or roll rotation), one of the 3 angular degrees of freedom of any stiff body (for example a vehicle), describing motion about the longitudinal axis ** Roll (aviation), one of the aircraft principal axes of rotation of an aircraft (angle of tilt to the left or right measured from the longitudinal axis) ** Roll (ship motion), one of the ship motions' principal axes of rotation of a ship (angle of tilt to the port or starboard measured from the longitudinal axis) * Rolling ''manoeuvre'', a manoeuvre of any stiff body (for example a vehicle) around its roll axis: ** Roll, an aerobatic maneuver with an airplane, usually referring to an aileron roll, but sometimes instead a barrel roll, rudder roll or slow roll ** Kayak roll, a maneuver used to right a capsized kayak ** Roll program, an aerodynamic maneuver performed in a rocket launch * Roll rate (or roll velocity), the angular speed at which an aircraft c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressor Map

A compressor map is a chart which shows the performance of a turbomachinery compressor. This type of compressor is used in gas turbine engines, for supercharging reciprocating engines and for industrial processes, where it is known as a dynamic compressor. A map is created from compressor rig test results or predicted by a special computer program. Alternatively the map of a similar compressor can be suitably scaled. This article is an overview of compressor maps and their different applications and also has detailed explanations of maps for a fan and intermediate and high-pressure compressors from a three-shaft aero-engine as specific examples. Compressor maps are an integral part of predicting the performance of gas turbine and turbocharged engines, both at design and off-design conditions. They also serve a critical purpose in selecting the correct compressors for industrial processes. Fans and turbines also have operating maps, although the latter are significantly different i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

RB199

The Turbo-Union RB199 is a turbofan jet engine designed and built in the early 1970s by Turbo-Union, a joint venture between Rolls-Royce, MTU and Aeritalia. The only production application was the Panavia Tornado. Design and development The RB199 originated with a requirement, in 1969, to power a new European multirole combat aircraft(MRCA) called the Panavia MRCA. The engine requirements to meet the Panavia MRCA specification were significant advances over current engines in thrust-to-weight ratio, fuel consumption and size. The final selection of the engine for the MRCA was made between a new European collaboration, Turbo Union, with the RB199, and Pratt & Whitney who proposed the JTF16. The Panavia MRCA would later be called the Panavia Tornado. Advanced engine studies at Bristol Siddeley had already been done to support the BAC/Dassault AFVG and were based on the Pegasus two-spool arrangement. At Rolls-Royce, where the three spool RB211 engine was in development, 3 s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |