|

Injector

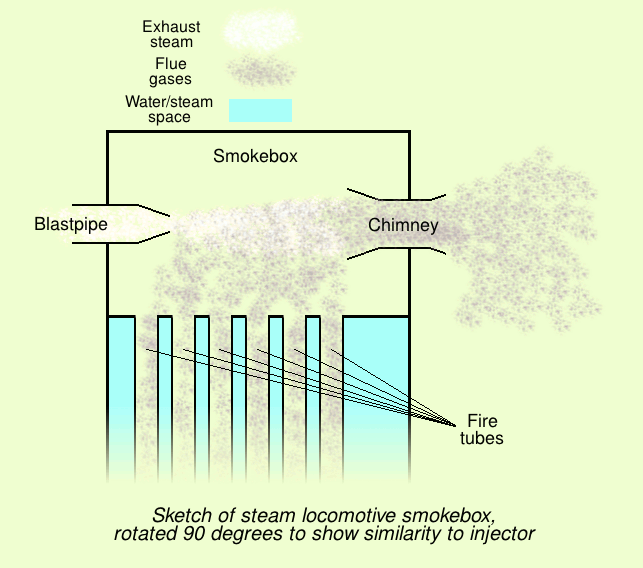

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is Entrainment (hydrodynamics), entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a ''water eductor'' or an ''aspirator''. An ''Vacuum ejector, ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc. The motive fluid may be a liquid, steam or any other gas. The entrained suction fluid may be a gas, a liquid, a slurry, or a dust-laden gas stream. Steam injector The steam injector is a common device used for delivering water to steam boilers, especially in steam locomotives. It is a typical application of the injector principle used to deliver cold boiler feedwater, water to a boiler against ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, Fuel oil, oil or, rarely, Wood fuel, wood) to heat water in the locomotive's Boiler (power generation), boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels. In most locomotives, the steam is admitted alternately to each end of its Steam locomotive components, cylinders in which pistons are mechanically connected to the locomotive's main wheels. Fuel and water supplies are usually carried with the locomotive, either on the locomotive itself or in a Tender (rail), tender coupled to it. #Variations, Variations in this general design include electrically powered boilers, turbines in place of pistons, and using steam generated externally. Steam locomotives were first developed in the United Kingdom of Great Britain an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

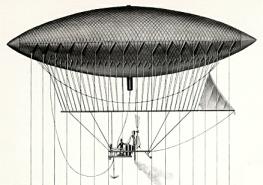

Henri Giffard

Baptiste Jules Henri Jacques Giffard (8 February 182514 April 1882) was a French engineer. In 1852 he invented the steam injector and the powered Giffard dirigible airship. Career Giffard was born in Paris in 1825. He invented the injector and the Giffard dirigible, an airship powered with a steam engine and weighing over . It was the world's first passenger-carrying airship (then known as a dirigible, from French). Both practical and steerable, the hydrogen-filled airship was equipped with a steam engine that drove a propeller. The engine was fitted with a downward-pointing funnel. The exhaust steam was mixed in with the combustion gases and it was hoped by these means to stop sparks rising up to the gas bag; he also installed a vertical rudder. On 24 September 1852, Giffard made the first powered and controlled flight travelling from Paris to Élancourt. The wind was too strong to allow him to make way against it, so he was unable to return to the start. However, he was ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum Ejector

A vacuum ejector, or simply ejector, or aspirator, is a type of vacuum pump, which produces vacuum by means of the Venturi effect. In an ejector, a working fluid (liquid or gaseous) flows through a jet nozzle into a tube that first narrows and then expands in cross-sectional area. The fluid leaving the jet is flowing at a high velocity which due to Bernoulli's principle results in it having low pressure, thus generating a vacuum. The outer tube then narrows into a mixing section where the high velocity working fluid mixes with the fluid that is drawn in by the vacuum, imparting enough velocity for it to be ejected, the tube then typically expands in order to decrease the velocity of the ejected stream, allowing the pressure to smoothly increase to the external pressure. The strength of the vacuum produced depends on the velocity and shape of the fluid jet and the shape of the constriction and mixing sections, but if a liquid is used as the working fluid, the strength of the va ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Venturi Effect

The Venturi effect is the reduction in fluid pressure that results when a moving fluid speeds up as it flows from one section of a pipe to a smaller section. The Venturi effect is named after its discoverer, the Italian physicist Giovanni Battista Venturi, and was first published in 1797. The effect has various engineering applications, as the reduction in pressure inside the constriction can be used both for measuring the fluid flow and for moving other fluids (e.g. in a vacuum ejector). Background In inviscid fluid dynamics, an incompressible fluid's velocity must ''increase'' as it passes through a constriction in accord with the principle of mass continuity, while its static pressure must ''decrease'' in accord with the principle of conservation of mechanical energy (Bernoulli's principle) or according to the Euler equations. Thus, any gain in kinetic energy a fluid may attain by its increased velocity through a constriction is balanced by a drop in pressure because ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharp, Stewart And Company

Sharp, Stewart and Company was a steam locomotive manufacturer, originally based in Manchester, England. The company was established in 1843 following the dissolution of Sharp, Roberts & Co.. In 1888, it relocated to Glasgow, Scotland, where it later amalgamated with two other Glasgow-based locomotive manufacturers to form the North British Locomotive Company. Early days Iron merchant Thomas Sharp and mechanical engineer Richard Roberts first formed a partnership, Sharp, Roberts & Co. (about which, see also company section in article on Roberts), to manufacture textile machinery and machine tools. They opened the Atlas Works in Manchester in 1828. They had built a few stationary steam engines, and in 1833 built a locomotive, ''Experiment'' for the Liverpool and Manchester Railway. It was a four-wheeled 2-2-0 with vertical cylinders over the leading wheels. After a number of modifications, three similar locomotives (Britannia, Manchester, and ''Hibernia'') were built in 1834 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermodynamic Process

Classical thermodynamics considers three main kinds of thermodynamic processes: (1) changes in a system, (2) cycles in a system, and (3) flow processes. (1) A Thermodynamic process is a process in which the thermodynamic state of a system is changed. A change in a system is defined by a passage from an initial to a final state of thermodynamic equilibrium. In classical thermodynamics, the actual course of the process is not the primary concern, and often is ignored. A state of thermodynamic equilibrium endures unchangingly unless it is interrupted by a thermodynamic operation that initiates a thermodynamic process. The equilibrium states are each respectively fully specified by a suitable set of thermodynamic state variables, that depend only on the current state of the system, not on the path taken by the processes that produce the state. In general, during the actual course of a thermodynamic process, the system may pass through physical states which are not describable as th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rankine Cycle

The Rankine cycle is an idealized thermodynamic cycle describing the process by which certain heat engines, such as steam turbines or reciprocating steam engines, allow mechanical work to be extracted from a fluid as it moves between a heat source and heat sink. The Rankine cycle is named after William John Macquorn Rankine, a Scottish polymath professor at Glasgow University. Heat energy is supplied to the system via a boiler where the working fluid (typically water) is converted to a high-pressure gaseous state (steam) in order to turn a turbine. After passing over the turbine the fluid is allowed to condense back into a liquid state as waste heat energy is rejected before being returned to boiler, completing the cycle. Friction losses throughout the system are often neglected for the purpose of simplifying calculations as such losses are usually much less significant than thermodynamic losses, especially in larger systems. Description The Rankine cycle closely describes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work (thermodynamics)

Thermodynamic work is one of the principal kinds of process by which a thermodynamic system can interact with and transfer energy to its surroundings. This results in externally measurable macroscopic forces on the system's surroundings, which can cause mechanical work, to lift a weight, for example,Kittel, C. Kroemer, H. (1980). ''Thermal Physics'', second edition, W.H. Freeman, San Francisco, or cause changes in electromagnetic,Guggenheim, E.A. (1985). ''Thermodynamics. An Advanced Treatment for Chemists and Physicists'', seventh edition, North Holland, Amsterdam, .Jackson, J.D. (1975). ''Classical Electrodynamics'', second edition, John Wiley and Sons, New York, .Konopinski, E.J. (1981). ''Electromagnetic Fields and Relativistic Particles'', McGraw-Hill, New York, . or gravitationalNorth, G.R., Erukhimova, T.L. (2009). ''Atmospheric Thermodynamics. Elementary Physics and Chemistry'', Cambridge University Press, Cambridge (UK), . variables. Also, the surroundings can perform t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Enthalpy Of Vaporization

In thermodynamics, the enthalpy of vaporization (symbol ), also known as the (latent) heat of vaporization or heat of evaporation, is the amount of energy (enthalpy) that must be added to a liquid substance to transform a quantity of that substance into a gas. The enthalpy of vaporization is a function of the pressure and temperature at which the transformation (vaporization or evaporation) takes place. The enthalpy of vaporization is often quoted for the normal boiling temperature of the substance. Although tabulated values are usually corrected to 298 K, that correction is often smaller than the uncertainty in the measured value. The heat of vaporization is temperature-dependent, though a constant heat of vaporization can be assumed for small temperature ranges and for reduced temperature . The heat of vaporization diminishes with increasing temperature and it vanishes completely at a certain point called the critical temperature (). Above the critical temperature, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler Feed Injector Diagram

A boiler is a closed pressure vessel, vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including Boiler (water heating), water heating, central heating, boiler (power generation), boiler-based power generation, cooking, and sanitation. Heat sources In a fossil fuel power plant using a steam cycle for power generation, the primary heat source will be combustion of Pulverized coal-fired boiler, coal, oil, or natural gas. In some cases byproduct fuel such as the carbon monoxide rich offgasses of a coke battery can be burned to heat a boiler; biofuels such as bagasse, where economically available, can also be used. In a nuclear power plant, boilers called Steam generator (nuclear power), steam generators are heated by the heat produced by nuclear fission. Where a large volume of hot gas is available from some process, a heat recovery steam gener ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |