|

Ductile Iron Pipe

Ductile iron pipe is pipe (material), pipe made of ductile iron, ductile cast iron commonly used for potable water transmission and distribution.Moser, A. P. and Folkman, Steven L. (2008) ''Buried Pipe Design'' (3rd edition) McGraw-Hill, New Yorkp. 336-337 This type of pipe is a direct development of earlier cast iron pipe, which it has superseded. Description The ductility, ductile iron used to manufacture the pipe is characterized by the spheroidal or nodular nature of the graphite within the iron. Typically, the pipe is manufactured using Centrifugal casting (industrial), centrifugal casting in metal or resin lined moulds.Public Works April 15, 1995 Ductile iron mains; Water Supply and Treatment SECTION: Pg. pC34(4) Vol. V126 No. N5 Protective internal linings and external coatings are often applied to ductile iron pipes to inhibit corrosion: the standard internal lining is Cement-mortar lined ductile iron pipe, cement mortar and standard external coatings include bonded zinc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standards Australia

Standards Australia is a standards organisation established in 1922 and is recognised through a Memorandum of Understanding (MoU) with the Australian government as the primary non-government standards development body in Australia. It is a company limited by guarantee. As of 1998, it had 73 members representing groups interested in the development and application of technical standards and related products and services. The MoU recognises Standards Australia as Australia's representative on the International Organization for Standardization (ISO), the International Electrotechnical Commission (IEC) and the Pacific Area Standards Congress (PASC). Standards Australia develops internationally aligned Australian standards (AS) and participates in standards-related activities. Standards Australia and Standards New Zealand work together to develop joint standards (AS/NZS). Licensing of the sale of standards In 2003, Standards Australia sold its standards publication business and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cathodic Protection

Cathodic protection (CP; ) is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. A simple method of protection connects the metal to be protected to a more easily corroded " sacrificial metal" to act as the anode. The sacrificial metal then corrodes instead of the protected metal. For structures such as long pipelines, where passive galvanic cathodic protection is not adequate, an external DC electrical power source is used to provide sufficient current. Cathodic protection systems protect a wide range of metallic structures in various environments. Common applications are: steel water or fuel pipelines and steel storage tanks such as home water heaters; steel pier piles; ship and boat hulls; offshore oil platforms and onshore oil well casings; offshore wind farm foundations and metal reinforcement bars in concrete buildings and structures. Another common application is in galvanized steel, in which a sacrif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Research Council (Canada)

The National Research Council Canada (NRC; ) is the primary national agency of the Government of Canada dedicated to science and technology research and development. It is the largest federal research and development organization in Canada. The Minister of Innovation, Science and Industry, Minister of Innovation, Science, and Economic Development is responsible for the NRC. Mandate NRC is an Government agency, agency of the Government of Canada, and its mandate is set out in the ''National Research Council Act''. Under the Act, the NRC is responsible for: * Undertaking, assisting or promoting scientific and industrial research in fields of importance to Canada; * Providing vital scientific and technological services to the research and industrial communities; * Investigating standards and methods of measurement; * Working on the standardization and certification of scientific and technical apparatus, instruments and materials used or usable by Canadian industry; * Operating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pitting Corrosion

Pitting corrosion, or pitting, is a form of extremely localized corrosion that leads to the random creation of small holes in metal. The driving power for pitting corrosion is the depassivation of a small area, which becomes anodic (oxidation reaction) while an unknown but potentially vast area becomes cathodic (reduction reaction), leading to very localized galvanic corrosion. The corrosion penetrates the mass of the metal, with a limited diffusion of ions. Another term arises, pitting factor, which is defined as the ratio of the depth of the deepest pit (resulting due to corrosion) to the average penetration, which can be calculated based on the weight loss. Development and kinetics of pitting According to Frankel (1998) who performed a review on pitting corrosion, it develops in three successive steps: (or nucleation) by breakdown of the passive film protecting the metal surface from oxidation, (2) growth of metastable pits (growing up to the micron scale and then repassivat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Graphitization

Graphitization is a process of transforming a carbonaceous material, such as coal or the carbon in certain forms of iron alloys, into graphite. Process The graphitization process involves a restructuring of the molecular structure of the carbon material. In the initial state, these materials can have an amorphous structure or a crystalline structure different from graphite. Graphitization generally occurs at high temperatures (up to ), and can be accelerated by catalysts such as iron or nickel. When carbonaceous material is exposed to high temperatures for an extended period of time, the carbon atoms begin to rearrange and form layered crystal planes. In the structure of graphite, carbon atoms are arranged in flat hexagonal sheets that are stacked on top of each other. These crystal planes give graphite its characteristic flake structure, giving it specific properties such as good electrical and thermal conductivity, low friction and excellent lubrication. Interest Graphiti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasket Ring

Some seals and gaskets A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly. Gaskets allow for "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. Gaskets are commonly produced by cutting from sheet materials. Given the potential cost and safety implications of faulty or leaking gaskets, it is critical that the correct gasket material is selected to fit the needs of the application. Gaskets for specific applications, such as high pressure steam systems, may contain asbestos. However, due to health hazards associated with asbestos exposure, non-asbestos gasket materials are used when practical. It is usually desirable that the gasket be made from a material that is to some de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ammonium Chloride

Ammonium chloride is an inorganic chemical compound with the chemical formula , also written as . It is an ammonium salt of hydrogen chloride. It consists of ammonium cations and chloride anions . It is a white crystalline salt (chemistry), salt that is highly soluble in water. Solutions of ammonium chloride are mildly acidic. In its naturally occurring mineralogic form, it is known as salammoniac. The mineral is commonly formed on burning coal dumps from condensation of coal-derived gases. It is also found around some types of volcanic vents. It is mainly used as fertilizer and a flavouring agent in Salty liquorice, some types of liquorice. It is a product of the reaction of hydrochloric acid and ammonia. Production It is a product of the Solvay process used to produce sodium carbonate: :CO2 + 2 NH3 + 2 NaCl + H2O → 2 NH4Cl + Na2CO3 Not only is that method the principal one for the manufacture of ammonium chloride, but also it is used to minimize ammonia release in some ind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Industry

The water industry provides drinking water and wastewater services (including sewage treatment) to residential, commercial, and industrial sectors of the economy. Typically public utilities operate water supply networks. The water industry does not include manufacturers and suppliers of bottled water, which is part of the beverage production and belongs to the food sector. The water industry includes water engineering, operations, water and wastewater plant construction, equipment supply and specialist water treatment chemicals, among others. The water industry is at the service of other industries, e.g. of the food sector which produces beverages such as bottled water. Organizational structure There are a variety of organizational structures for the water industry, with countries usually having one dominant traditional structure, which usually changes only gradually over time. Ownership of water infrastructure and operations * local government - the most usual stru ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

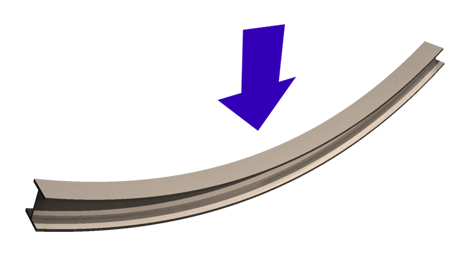

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external Structural load, load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a Beam (structure), beam. For example, a closet rod Deflection (engineering), sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a wikt:shell, shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Stress

Shear stress (often denoted by , Greek alphabet, Greek: tau) is the component of stress (physics), stress coplanar with a material cross section. It arises from the shear force, the component of force vector parallel to the material cross section. ''Normal stress'', on the other hand, arises from the force vector component perpendicular to the material cross section on which it acts. General shear stress The formula to calculate average shear stress or force per unit area is: \tau = ,where is the force applied and is the cross-sectional area. The area involved corresponds to the material face (geometry), face parallel to the applied force vector, i.e., with surface normal vector perpendicular to the force. Other forms Wall shear stress Wall shear stress expresses the retarding force (per unit area) from a wall in the layers of a fluid flowing next to the wall. It is defined as:\tau_w := \mu\left.\frac\_,where is the dynamic viscosity, is the flow velocity, and is the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compression (physical)

In mechanics, compression is the application of balanced inward ("pushing") forces to different points on a material or structure, that is, forces with no net sum or torque directed so as to reduce its size in one or more directions.Ferdinand Pierre Beer, Elwood Russell Johnston, John T. DeWolf (1992), "Mechanics of Materials". (Book) McGraw-Hill Professional, It is contrasted with tension or traction, the application of balanced outward ("pulling") forces; and with shearing forces, directed so as to displace layers of the material parallel to each other. The compressive strength of materials and structures is an important engineering consideration. In uniaxial compression, the forces are directed along one direction only, so that they act towards decreasing the object's length along that direction. The compressive forces may also be applied in multiple directions; for example inwards along the edges of a plate or all over the side surface of a cylinder, so as to reduce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |