|

Test Equipment

Test equipment is a general term describing equipment used in many fields. Types of test equipment include: Electrical and electronic test equipment Electrical test equipment * Battery tester, used to test the state of an electric battery * Continuity tester, used to determine if an electrical path can be established between two points ** Cable tester, used to verify the electrical connections in a signal cable or other wired assembly ** Receptacle tester, used to verify that an AC wall outlet is wired properly **Test light A test light, test lamp, voltage tester, or mains tester is a piece of electronic test equipment used to determine the presence of electricity in a piece of equipment under test. A test light is simpler and less costly than a measuring instrumen ..., used to determine the presence or absence of an electric voltage * Hipot tester, used to verify electrical insulation in finished products carrying high electrical potential Electronic test equipment {{see also, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Battery Tester

A battery tester is an electronic device intended for testing the state of an electric Battery (electricity), battery, going from a simple device for testing the Battery charger#C-rate, charge actually present in the cells and/or its voltage output, to a more comprehensive testing of the battery's condition, namely its capacity for accumulating charge and any possible flaws affecting the battery's performance and security. Simple battery testers The most simple battery tester is a DC ammeter, that indicates the battery's Battery charger#C-rate, charge rate. DC voltmeters can be used to estimate the charge rate of a battery, provided that its nominal voltage is known. Integrated battery testers There are many types of integrated battery testers, each one corresponding to a specific condition testing procedure, according to the type of battery being tested, such as the “421” test for Lead-acid battery, lead-acid Automotive battery, vehicle batteries. Their common principle i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuity Tester

A continuity tester is an item of electronic test equipment, electrical test equipment used to determine if an electrical path can be established between two points; that is if an electrical circuit can be made. The circuit under test is completely de-energized prior to connecting the apparatus. Details The tester consists of an indicator in series with a source of electrical power - normally a battery (electricity), battery, terminating in two test leads. If a complete circuit is established between the test-leads, the indicator is activated. The indicator may be an electric light or a buzzer. This led to the term "buzzing out a circuit" (which means to test for continuity) Audible continuity buzzers or beepers are built into some models of multimeter, and the continuity setting is normally shared with the ohmmeter setting. A popular design has the tester combined with a standard flashlight. A phone connector (audio), phone connector or jack plug in the rear of the unit permit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

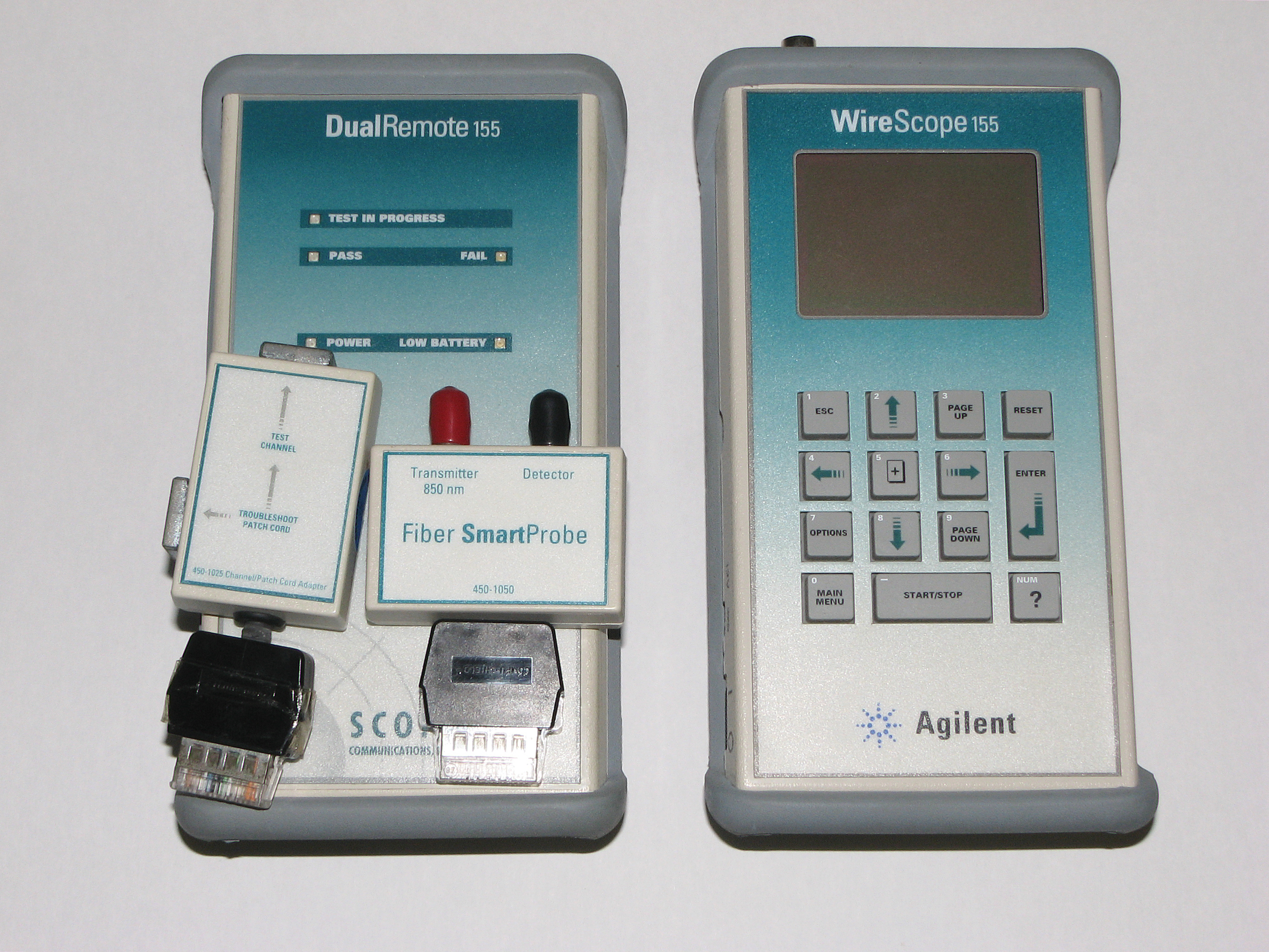

Cable Tester

A cable tester is an electronic device used to verify the electrical connections in a signal cable or other wired assembly. Basic cable testers are continuity testers that verify the existence of a conductive path between ends of the cable, and verify the correct wiring of connectors on the cable. More advanced cable testers can measure the signal transmission properties of the cable such as its resistance, signal attenuation, noise and interference.Terry William Ogletree, ''Upgrading and Repairing Networks'', Que Publishing 2004, , page 961 Basic tester Generally a basic cable tester is a battery operated portable instrument with a source of electric current, one or more voltage indicators, and possibly a switching or scanning arrangement to check each of several conductors sequentially. A cable tester may also have a microcontroller and a display to automate the testing process and show the testing results, especially for multiple-conductor cables. A cable tester may be conne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

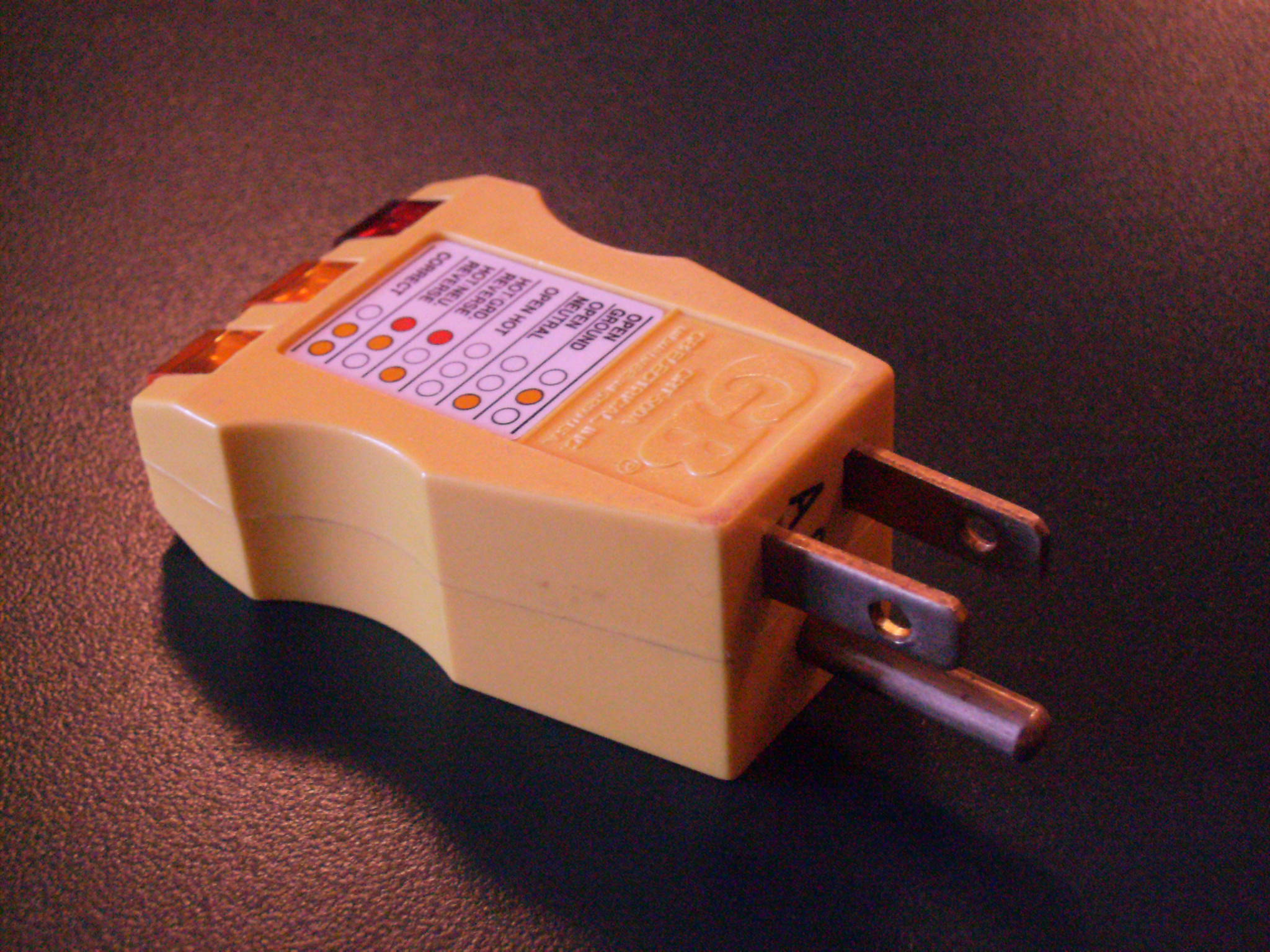

Receptacle Tester

An electrical outlet tester, receptacle tester, or socket tester is a small device containing a 3-prong power plug and three indicator lights, used for quickly detecting some types of incorrectly-wired electrical wall outlets or campsite supplies. Tests and limitations The outlet tester checks that each contact in the outlet appears to be connected to the correct wire in the building's electrical wiring. It can identify several common wiring errors, including swapped phase and neutral, and failure to connect ground. The tester confirms continuity and polarity of the electrical connections, but it does not verify current-carrying ability, electrical safety (which requires impedance testing), insulation breakdown voltage, or loop connection of ring mains. Simple three-light testers cannot detect some potentially serious house wiring errors, including neutral and ground interchanged at the receptacle. There may be a "bootleg ground", where the neutral and ground pins have been ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Test Light

A test light, test lamp, voltage tester, or mains tester is a piece of electronic test equipment used to determine the presence of electricity in a piece of equipment under test. A test light is simpler and less costly than a measuring instrument such as a multimeter, and often suffices for checking for the presence of voltage on a conductor. Properly designed test lights include features to protect the user from accidental electric shock. Non-contact test lights can detect voltage on insulated conductors. Two-contact test lights The test light is an electric lamp connected with one or two insulated wire leads.Terrel Croft, Wilford Summers ''American Electricians' Handbook, Eleventh Edition'', McGraw Hill, 1987 pages 1-56 through 1-57 Often, it takes the form of a screwdriver with the lamp connected between the tip of the screwdriver and a single lead that projects out the back of the screwdriver. By connecting the flying lead to an earth (ground) reference and touching the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hipot Tester

In electrical engineering, a dielectric withstand test (also pressure test, high potential test, hipot test, or insulation test) is an electrical safety test performed on a component or product to determine the effectiveness of its insulation. The test may be between mutually insulated sections of a part, or energized parts and ground. The test is a means to qualify a device's ability to operate safely during rated electrical conditions. If the current through a device under test is less than a specified limit at the required test potential and time duration, the device meets the dielectric withstand requirement. A dielectric withstand test may be done as a factory test on new equipment, or may be done on apparatus already in service as a routine maintenance test.Paul Gill (2009), ''Electrical Power Equipment Maintenance and Testing'', Second Edition, CRC Press, 1574446568, page 459 Voltage withstand testing is done with a high-voltage source and voltage and current meters. A s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

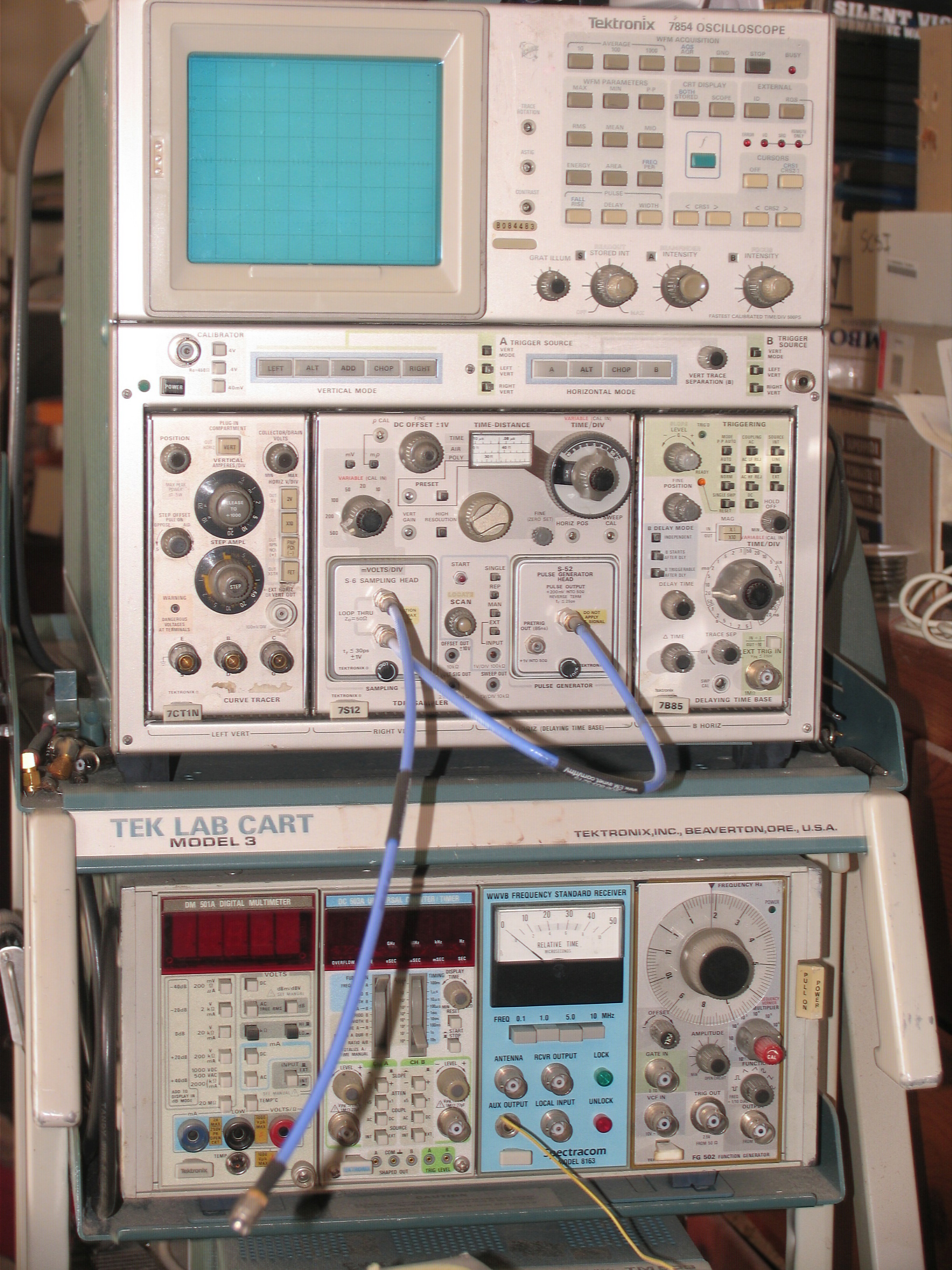

Electronic Test Equipment

Electronic test equipment is used to create signals and capture responses from electronic devices under test (DUTs). In this way, the proper operation of the DUT can be proven or faults in the device can be traced. Use of electronic test equipment is essential to any serious work on electronics systems. Practical electronics engineering and assembly requires the use of many different kinds of electronic test equipment ranging from the very simple and inexpensive (such as a test light consisting of just a light bulb and a test lead) to extremely complex and sophisticated such as automatic test equipment (ATE). ATE often includes many of these instruments in real and simulated forms. Generally, more advanced test gear is necessary when developing circuits and systems than is needed when doing production testing or when troubleshooting existing production units in the field. Types of test equipment Basic equipment The following items are used for basic measurement of voltages, c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automatic Test Equipment

Automatic test equipment or automated test equipment (ATE) is any apparatus that performs tests on a device, known as the device under test (DUT), equipment under test (EUT) or unit under test (UUT), using automation to quickly perform measurements and evaluate the test results. An ATE can be a simple computer-controlled Multimeter, digital multimeter, or a complicated system containing dozens of complex test instruments (real or simulated electronic test equipment) capable of automatically testing and diagnosing faults in sophisticated electronic packaged parts or on wafer testing, including system on chips and integrated circuits. ATE is widely used in the electronic manufacturing industry to test electronic components and systems after being fabricated. ATE is also used to test avionics and the electronic modules in automobiles. It is used in military applications like radar and wireless communication. In the semiconductor industry Semiconductor ATE, named for testing se ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Built-in Test Equipment

Built-in test equipment (BITE) for avionics primarily refers to passive fault management and diagnosis equipment built into airborne systems to support maintenance processes. Built-in test equipment includes multimeter A multimeter (also known as a multi-tester, volt-ohm-milliammeter, volt-ohmmeter or VOM, avometer or ampere-volt-ohmmeter) is a measuring instrument that can measure multiple electrical properties. A typical multimeter can measure voltage, elec ...s, oscilloscopes, discharge probes, and frequency generators that are provided as part of the system to enable testing and perform diagnostics. The acronym BIT is often used for this same function or, more specifically, in reference to the individual tests. BIT often includes: * The detection of the fault * The accommodation of the fault (how the system actively responds to the fault) * The annunciation or logging of the fault to warn of possible effects and/or aid in troubleshooting the faulty equipment. Functiona ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

On-board Diagnostics

On-board diagnostics (OBD) is a term referring to a vehicle's self-diagnostic and reporting capability. In the United States, this capability is a requirement to comply with United States vehicle emission standards, federal emissions standards to detect failures that may increase the vehicle tailpipe Air pollution, emissions to more than 150% of the standard to which it was originally certified. OBD systems give the vehicle owner or repair technician access to the status of the various vehicle sub-systems. The amount of diagnostic information available via OBD has varied widely since its introduction in the early 1980s versions of onboard vehicle computers. Early versions of OBD would simply illuminate a Tell-tale (automotive), tell-tale light if a problem was detected, but would not provide any information as to the nature of the problem. Modern OBD implementations use a standardized digital communications port to provide real-time data and Table of OBD-II Codes, diagnostic tro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transistor Tester

Transistor testers are instruments for testing the electrical behavior of transistors and solid-state diodes. Types of tester There are three types of transistor testers each performing a unique operation. * Quick-check in-circuit checker * Service type tester * Laboratory-standard tester In addition, Semiconductor curve tracer, curve tracers are reliable indicators of transistor performance. Circuit Tester A circuit tester is used to check whether a transistor which has previously been performing properly in a circuit is still operational. The transistor's ability to "amplify" is taken as a rough index of its performance. This type of tester indicates to a technician whether the transistor is dead or still operative. The advantage of this tester is that the transistor does not have to be removed from the circuit. Service type transistor testers These devices usually perform three types of checks: *Forward-current gain, or beta of transistor. *Base-to-collector leakage curr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adhesion Tester

In the paint and coating industries, paint adhesion testing is often used to determine if the paint or coating will adhere properly to the substrates to which they are applied. Several tests measure the resistance of paints and coatings from substrates: cross-cut test, scrape adhesion, pull-off test, and others. Scrape Adhesion Test The scrape adhesion test measures the determination of the adhesion of organic coatings when applied to smooth, flat panel surfaces. It is helpful in giving relative ratings for a number of coated panels showing significant differences in adhesion. The tested materials are applied uniformly to flat panels, mainly some sort of sheet metal. When the materials have dried, the adhesion is determined by pressing panels under a rounded stylus loaded with increasing weight until the coating is removed from the substrate surface. Pull-off test The adhesion of a coating or several coated samples of any paint product is measured by assessing the minimum t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |