|

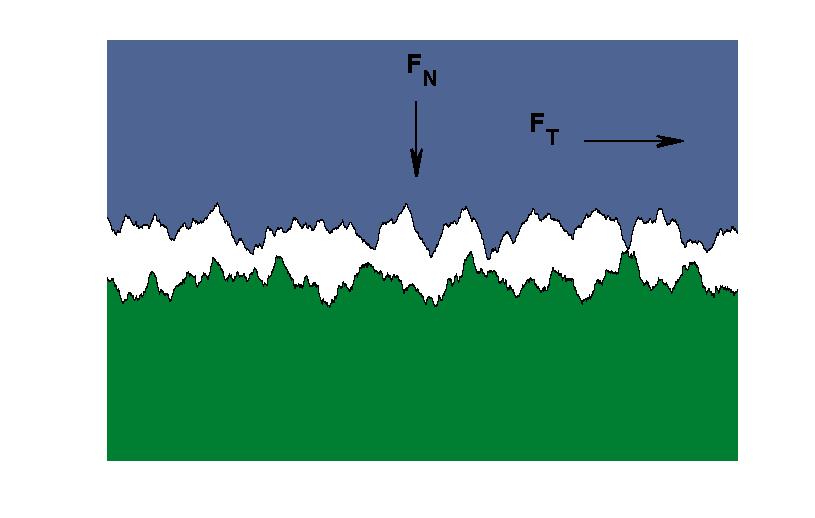

Contact Mechanics

Contact mechanics is the study of the Deformation (mechanics), deformation of solids that touch each other at one or more points. A central distinction in contact mechanics is between Stress (mechanics), stresses acting perpendicular to the contacting bodies' surfaces (known as normal stress) and frictional stresses acting Tangential and normal components, tangentially between the surfaces (shear stress). Normal contact mechanics or frictionless contact mechanics focuses on normal stresses caused by applied normal forces and by the adhesion present on surfaces in close contact, even if they are clean and dry. ''Frictional contact mechanics'' emphasizes the effect of friction forces. Contact mechanics is part of mechanical engineering. The physical and mathematical formulation of the subject is built upon the mechanics of materials and continuum mechanics and focuses on computations involving Elasticity (physics), elastic, viscoelasticity, viscoelastic, and Plastic Deformation, p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kontakt Spannungsoptik

Kontakt may refer to: * ''Kontakt'' (film), a 2005 Macedonian film directed by Sergej Stanojkovski * ''Kontakt'' (magazine), a Norwegian political magazine (1947–1954) * Kontakt (software), a music sampler * Kontakt-series explosive reactive armour ** Kontakt-1 ** Kontakt-5 See also * Contact (other) Contact may refer to: Interaction Physical interaction * Contact (geology), a common geological feature * Contact lens or contact, a lens placed on the eye * Contact sport, a sport in which players make contact with other players or objects * C ... * * * '' Kontakte'' (1958–60), electronic music by Karlheinz Stockhausen * Contakt * Kontact {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Deformation

In engineering, deformation (the change in size or shape of an object) may be ''elastic'' or ''plastic''. If the deformation is negligible, the object is said to be ''rigid''. Main concepts Occurrence of deformation in engineering applications is based on the following background concepts: * ''Displacements'' are any change in position of a point on the object, including whole-body translations and rotations ( rigid transformations). * ''Deformation'' are changes in the relative position between internals points on the object, excluding rigid transformations, causing the body to change shape or size. * ''Strain'' is the ''relative'' ''internal'' deformation, the dimensionless change in shape of an infinitesimal cube of material relative to a reference configuration. Mechanical strains are caused by mechanical stress, ''see stress-strain curve''. The relationship between stress and strain is generally linear and reversible up until the yield point and the deformation is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasket

Some seals and gaskets A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly. Gaskets allow for "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. Gaskets are commonly produced by cutting from sheet materials. Given the potential cost and safety implications of faulty or leaking gaskets, it is critical that the correct gasket material is selected to fit the needs of the application. Gaskets for specific applications, such as high pressure steam systems, may contain asbestos. However, due to health hazards associated with asbestos exposure, non-asbestos gasket materials are used when practical. It is usually desirable that the gasket be made from a material that is to some de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linkage (mechanical)

A mechanical linkage is an assembly of systems connected so as to manage forces and Motion, movement. The movement of a body, or link, is studied using geometry so the link is considered to be Rigid body, rigid. The connections between links are modeled as providing ideal movement, pure rotation or Sliding (motion), sliding for example, and are called joints. A linkage modeled as a network of rigid links and ideal joints is called a kinematic chain. Linkages may be constructed from open chains, closed chains, or a combination of open and closed chains. Each link in a chain is connected by a joint to one or more other links. Thus, a kinematic chain can be modeled as a graph in which the links are paths and the joints are vertices, which is called a linkage graph. The movement of an ideal joint is generally associated with a subgroup of the group of Euclidean geometry, Euclidean displacements. The number of parameters in the subgroup is called the degree of freedom (mecha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal Combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (reciprocating engine, piston engine), turbine blades (gas turbine), a Wankel engine, rotor (Wankel engine), or a propulsive nozzle, nozzle (jet engine). This force moves the component over a distance. This process transforms chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. The first commercially successful internal combustion engines were invented in the mid-19th century. The first modern internal combustion engine, the Otto engine, was designed in 1876 by the German engineer Nicolaus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A ball bearing A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or the directions of the loads (forces) applied to the parts. The term "bearing" is derived from the verb " to bear"; a bearing being a machine element that allows one part to bear (i.e., to support) another. The simplest bearings are bearing surfaces, cut or formed into a part, with varying degrees of control over the form, size, roughness, and location of the surface. Other bearings are separate devices installed into a machine or mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tire

A tire (North American English) or tyre (Commonwealth English) is a ring-shaped component that surrounds a Rim (wheel), wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide Traction (engineering), traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, providing a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, designed to match the vehicle's weight and the bearing on the surface that it rolls over by exerting a pressure that will avoid deforming the surface. The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric, and wire, along with carbon black and other chemical compounds. They consist of a tire tread, tread and a body. The tread provides Traction (engineering), traction while the body provides containment for a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brake

A brake is a machine, mechanical device that inhibits motion by absorbing energy from a moving system. It is used for Acceleration, slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction. Background Most brakes commonly use friction between two surfaces pressed together to convert the kinetic energy of the moving object into heat, though other methods of energy conversion may be employed. For example, regenerative braking converts much of the energy to electrical energy, which may be stored for later use. Other methods convert kinetic energy into potential energy in such stored forms as Compressed air energy storage, pressurized air or pressurized oil. Eddy current brakes use magnetic fields to convert kinetic energy into electric current in the brake disc, fin, or rail, which is converted into heat. Still other braking methods even transform kinetic energy into different forms, for example by transferring the en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coupling

A coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power. The primary purpose of couplings is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement or both. In a more general context, a coupling can also be a mechanical device that serves to connect the ends of adjacent parts or objects. Couplings do not normally allow disconnection of shafts during operation, however there are torque-limiting couplings which can slip or disconnect when some torque limit is exceeded. Selection, installation and maintenance of couplings can lead to reduced maintenance time and maintenance cost. Uses Shaft couplings are used in machinery for several purposes. A primary function is to transfer power from one end to another end (ex: motor transfer power to pump through coupling). Other common uses: * To alter the vibration characteristics of rotating units * To connect the driving and the driven ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

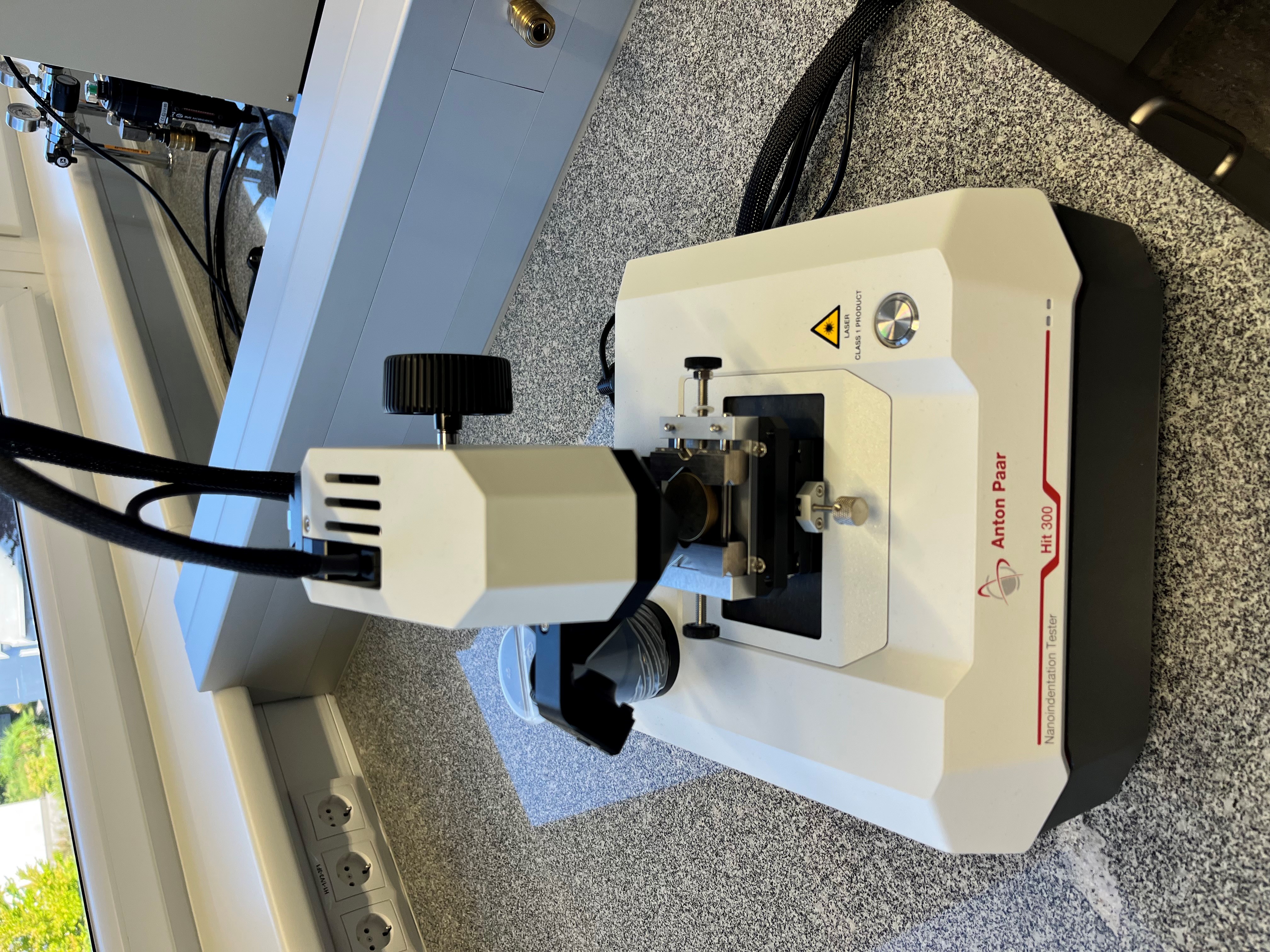

Indentation Hardness

Indentation hardness tests are used in mechanical engineering to determine the hardness of a material to deformation. Several such tests exist, wherein the examined material is indented until an impression is formed; these tests can be performed on a macroscopic or microscopic scale. When testing metals, indentation hardness correlates roughly linearly with tensile strength, but it is an imperfect correlation often limited to small ranges of strength and hardness for each indentation geometry. This relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers. Material hardness Different techniques are used to quantify material characteristics at smaller scales. Measuring mechanical properties for materials, for instance, of thin films, cannot be done using conventional uniaxial tensile testing. As a result, techniques testing material "hardness" by indenting a mater ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Resistance

Electrical contact resistance (ECR, or simply contact resistance) is resistance to the flow of electric current caused by incomplete contact of the surfaces through which the current is flowing, and by films or oxide layers on the contacting surfaces. It occurs at electrical connections such as switches, connectors, breakers, contacts, and measurement probes. Contact resistance values are typically small (in the microohm to milliohm range). Contact resistance can cause significant voltage drops and heating in circuits with high current. Because contact resistance adds to the intrinsic resistance of the conductors, it can cause significant measurement errors when exact resistance values are needed. Contact resistance may vary with temperature. It may also vary with time (most often decreasing) in a process known as resistance creep. Electrical contact resistance is also called ''interface resistance'', ''transitional resistance'', or the ''correction term''. ''Parasitic resist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Normal Contact Stiffness

Normal contact stiffness is a physical quantity related to the generalized force displacement behavior of rough surfaces in contact with a rigid body or a second similar rough surface. Specifically it is the amount of force per unit displacement required to compress an elastic object in the contact region. Rough surfaces can be considered as consisting of large numbers of asperities. As two solid bodies of the same material approach one another, the asperities interact, and they transition from conditions of non-contact to homogeneous bulk behaviour, with changes in the contact area. The varying values of stiffness and true contact area at an interface during this transition are dependent on the conditions of applied pressure and are of importance for the study of systems involving the physical interactions of multiple bodies including granular matter, electrode contacts, and thermal contact In heat transfer and thermodynamics, a thermodynamic system A thermodynamic system ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |