|

Collet

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool (such as a drill), but collets have other mechanical applications. An external collet is a sleeve with a cylindrical inner surface and a conical outer surface. The collet can be squeezed against a matching taper such that its inner surface contracts to a slightly smaller diameter, squeezing the tool or workpiece to hold it securely. Most often the collet is made of spring steel, with one or more kerf cuts along its length to allow it to expand and contract. This type of collet holds the external surface of the tool or workpiece being clamped. This is the most usual type of collet chuck. An external collet clamps against the internal surface or bore of a hollow cylinder. The collet's taper is int ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chuck (engineering)

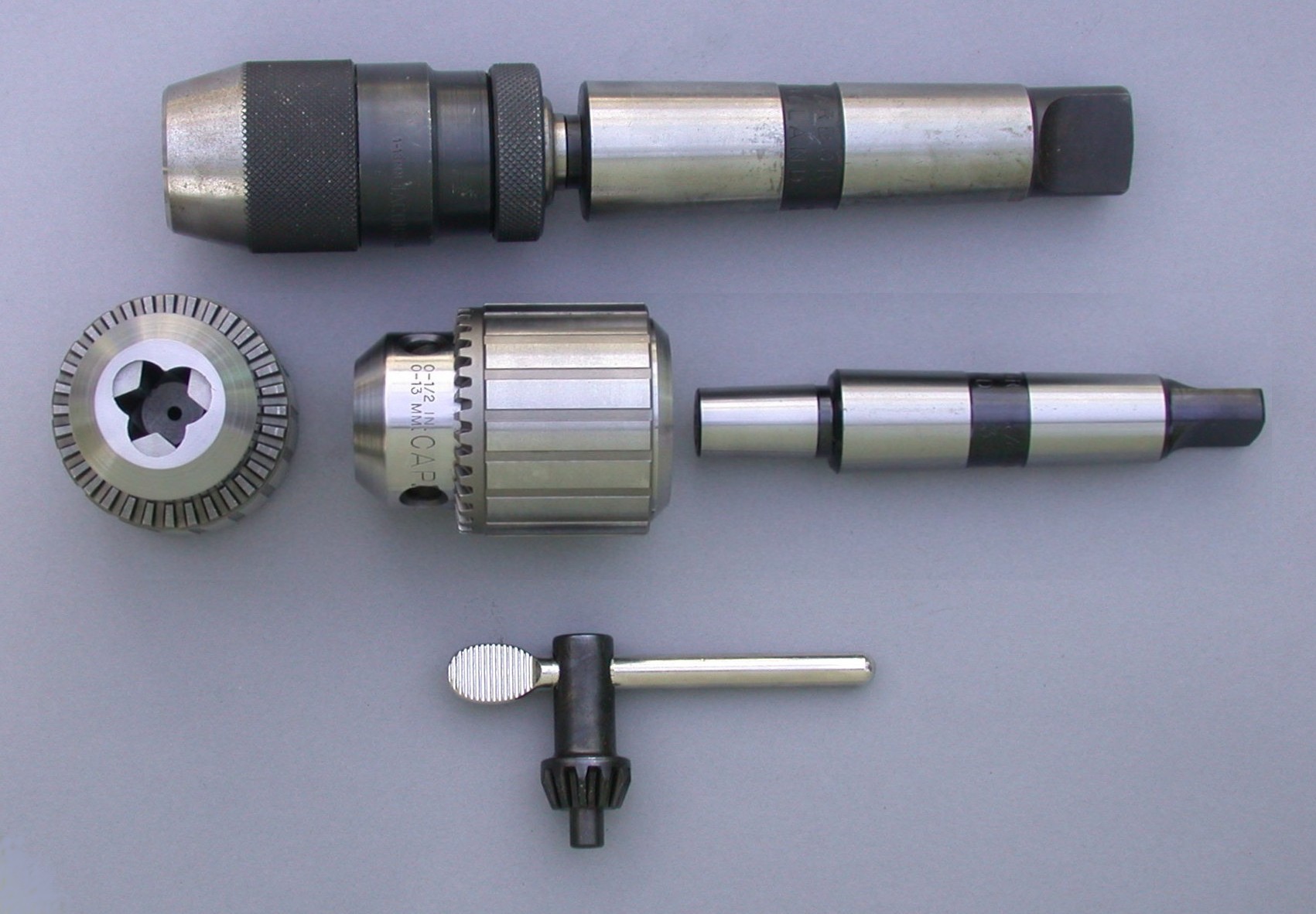

A chuck is a specialized type of clamp (tool), clamp used to hold an object with rotational symmetry, radial symmetry, especially a cylinder (geometry), cylinder. In a drill, a Milling (machining), mill and a transmission (mechanics), transmission, a chuck holds the rotating tool bit, tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws are typically arranged in a radially symmetrical pattern like the points of a star (polygon), star. Jawed chucks may require a Wrench#Other types of keys, wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scroll Chuck

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a chuck may use magnetism, vacuum, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece and grip it when squeeze ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chuck (engineering)

A chuck is a specialized type of clamp (tool), clamp used to hold an object with rotational symmetry, radial symmetry, especially a cylinder (geometry), cylinder. In a drill, a Milling (machining), mill and a transmission (mechanics), transmission, a chuck holds the rotating tool bit, tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws are typically arranged in a radially symmetrical pattern like the points of a star (polygon), star. Jawed chucks may require a Wrench#Other types of keys, wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Independent-jaw Chuck

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a chuck may use magnetism, vacuum, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece and grip it when squeeze ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. Usually the term "turning" is reserved for the generation of ''external'' surfaces by this cutting action, whereas this same essential cutting action when applied to ''internal'' surfaces (holes, of one kind or another) is called " boring". Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset. Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other type ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bridgeport Machines, Inc

Bridgeport is the most populous city in the U.S. state of Connecticut and the fifth-most populous city in New England, with a population of 148,654 in 2020. Located in eastern Fairfield County at the mouth of the Pequonnock River on Long Island Sound, it is a port city from Manhattan and from The Bronx. It borders the towns of Trumbull to the north, Fairfield to the west, and Stratford to the east. Bridgeport and other towns in Fairfield County make up the Greater Bridgeport Planning Region, as well as the Bridgeport–Stamford–Norwalk–Danbury metropolitan statistical area, the second largest metropolitan area in Connecticut. The Bridgeport–Stamford–Norwalk–Danbury metropolis forms part of the New York metropolitan area. Inhabited by the Paugussett Native American tribe until English settlement in the 1600s, Bridgeport was incorporated in 1821 as a town, and as a city in 1836. Showman P. T. Barnum was a resident of the city and served as the town's mayor (1871 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

External Thread Pull Collet Action

{{disambig ...

External may refer to: * Externality, in economics, the cost or benefit that affects a party who did not choose to incur that cost or benefit * Externals, a fictional group of X-Men antagonists See also * *Internal (other) Internal may refer to: *Internality as a concept in behavioural economics *Neijia, internal styles of Chinese martial arts *Neigong or "internal skills", a type of exercise in meditation associated with Daoism * ''Internal'' (album) by Safia, 2016 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

A mandrel, mandril, or arbor is a tapered tool against which material can be forged, pressed, stretched or shaped (e.g., a ring mandrel - also called a triblet - used by jewellers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an opposing thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically flanged or tapered mandrels), but may also be gripped in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |