|

Bioreactor

A bioreactor is any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical reaction, chemical process is carried out which involves organisms or biochemistry, biochemically active chemical substance, substances derived from such organisms. This process can either be Aerobic organism, aerobic or Anaerobic organism, anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow Cell (biology), cells or Biological tissue, tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical engineering, biochemical/bioprocess engineering, bioprocess engineering. On the basis of mode of operation, a bioreactor may be classified as batch reactor, batch, fed-batch, fed batch or continuous reactor, continuous (e.g. a continuous s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Membrane Bioreactor

Membrane bioreactors are combinations of membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. These technologies are now widely used for municipal and industrial wastewater treatment.S. Judd, The MBR book (2006) Principles and applications of membrane bioreactors in water and wastewater treatment, Elsevier, Oxford The two basic membrane bioreactor configurations are the submerged membrane bioreactor and the side stream membrane bioreactor. In the submerged configuration, the membrane is located inside the biological reactor and submerged in the wastewater, while in a side stream membrane bioreactor, the membrane is located outside the reactor as an additional step after biological treatment. Overview Water scarcity has prompted efforts to reuse waste water once it has been properly treated, known as " water reclamation" (also called wastewater reuse, water reuse, or water recycling). Among the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bioreactor Principle

A bioreactor is any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical reaction, chemical process is carried out which involves organisms or biochemistry, biochemically active chemical substance, substances derived from such organisms. This process can either be Aerobic organism, aerobic or Anaerobic organism, anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow Cell (biology), cells or Biological tissue, tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical engineering, biochemical/bioprocess engineering, bioprocess engineering. On the basis of mode of operation, a bioreactor may be classified as batch reactor, batch, fed-batch, fed batch or continuous reactor, continuous (e.g. a continuous s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scale-down Bioreactor

A scale-down bioreactor is a miniature model designed to mimic or reproduce large-scale bio-processes or specific process steps on a smaller scale. These models play an important role during process development stage by fine-tuning the minute parameters and steps without the need for substantial investments in both materials and consumables. Vessel geometry like aspect ratios, impeller designs, and sparger placements should be nearly identical between the small and large scales. For this purpose computer fluid dynamics (CFD) are used as they can be employed to investigate the scalability of mixing processes from small-scale models to larger production scales. Scientists use outcome of these studies on scale down systems to derive and facilitate the transition from laboratory-scale studies to industrial large-scale conditions. Types of scale-down bioreactors Stirred tank bioreactors are systems further developed to two compartment systems to provide a fundamental structure for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

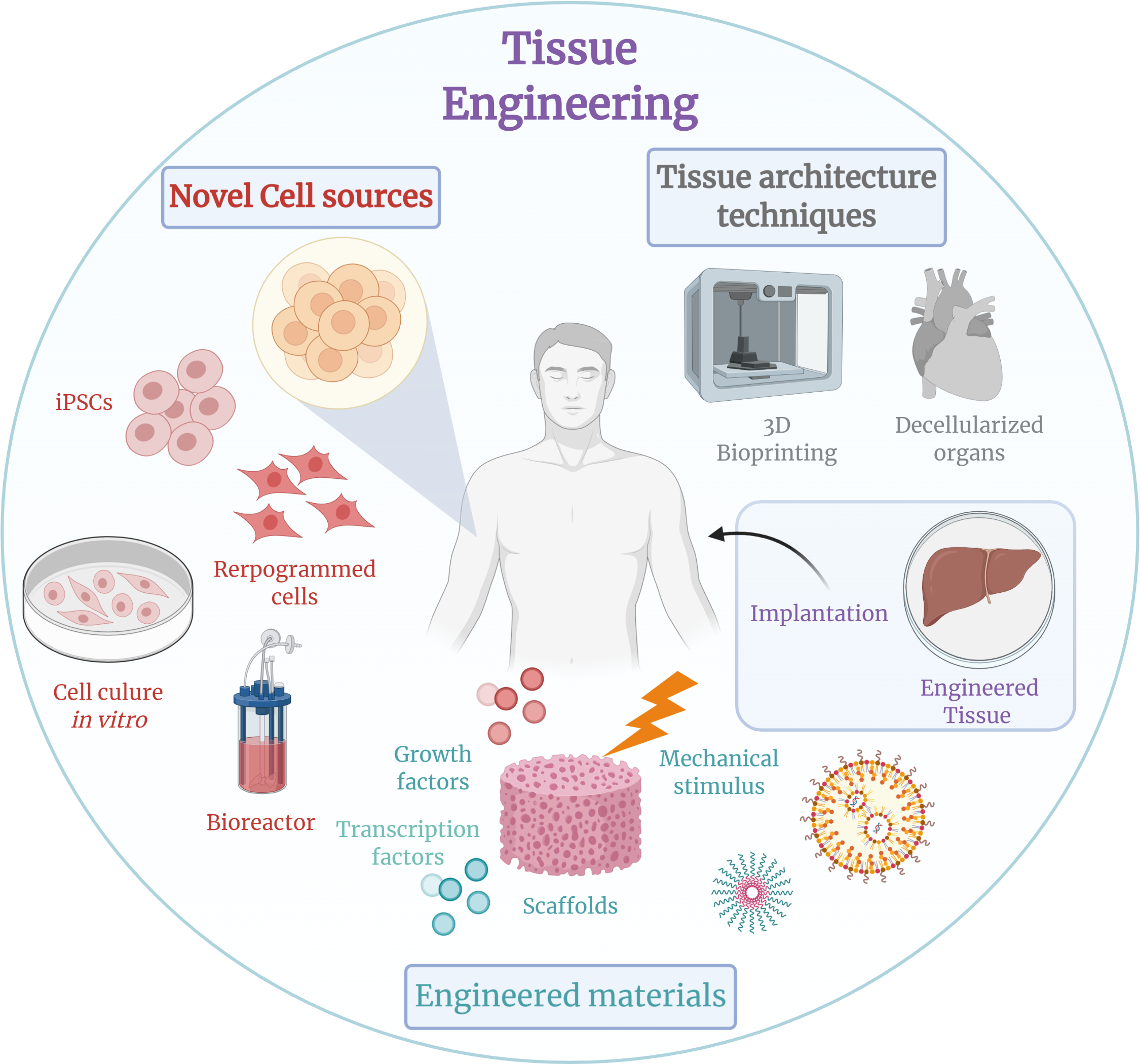

Tissue Engineering

Tissue engineering is a biomedical engineering discipline that uses a combination of cells, engineering, materials methods, and suitable biochemical and physicochemical factors to restore, maintain, improve, or replace different types of biological tissues. Tissue engineering often involves the use of cells placed on tissue scaffolds in the formation of new viable tissue for a medical purpose, but is not limited to applications involving cells and tissue scaffolds. While it was once categorized as a sub-field of biomaterials, having grown in scope and importance, it can be considered as a field of its own. While most definitions of tissue engineering cover a broad range of applications, in practice, the term is closely associated with applications that repair or replace portions of or whole tissues (i.e. organs, bone, cartilage, blood vessels, bladder, skin, muscle etc.). Often, the tissues involved require certain mechanical and structural properties for proper functioning. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemostat

A chemostat (from ''chem''ical environment is ''stat''ic) is a bioreactor to which fresh medium is continuously added, while culture liquid containing left over nutrients, metabolic end products and microorganisms is continuously removed at the same rate to keep the culture volume constant. By changing the rate with which medium is added to the bioreactor the specific growth rate of the microorganism can be easily controlled within limits. Operation Steady state One of the most important features of chemostats is that microorganisms can be grown in a physiological steady state under constant environmental conditions. In this steady state, growth occurs at a constant specific growth rate and all culture parameters remain constant (culture volume, dissolved oxygen concentration, nutrient and product concentrations, pH, cell density, etc.). In addition, environmental conditions can be controlled by the experimenter. Microorganisms growing in chemostats usually reach a steady sta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fed-batch

Fed-batch culture is, in the broadest sense, defined as an operational technique in biotechnological processes where one or more nutrients (substrates) are fed (supplied) to the bioreactor during cultivation and in which the product(s) remain in the bioreactor until the end of the run.Tsuneo Yamanè, Shoichi Shimizu: Fed-batch Techniques in Microbial Processes. Advances in Biochem Eng./Biotechnol 1984, 30:147-194. An alternative description of the method is that of a culture in which "a base medium supports initial cell culture and a feed medium is added to prevent nutrient depletion". It is also a type of semi-batch culture. In some cases, all the nutrients are fed into the bioreactor. The advantage of the fed-batch culture is that one can control concentration of fed-substrate in the culture liquid at arbitrarily desired levels (in many cases, at low levels). Generally speaking, fed-batch culture is superior to conventional batch culture when controlling concentrations of a n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Moving Bed Biofilm Reactor

Moving bed biofilm reactor (MBBR) is a type of wastewater treatment process that was first invented by Professor Hallvard Ødegaard at Norwegian University of Science and Technology in the late 1980s. The process takes place in an aeration tank with plastic carriers that a biofilm can grow on. The compact size and cheap wastewater treatment costs offers many advantages for the system. The main objective of using MBBR being water reuse and nutrient removal or recovery. In theory, wastewater will be no longer considered waste, it can be considered a resource. Background Overview Due to early issues with biofilm reactors, like hydraulic instability and uneven biofilm distribution, moving bed biofilm technology was developed. The MBBR system consists of an aeration tank (similar to an activated sludge tank) with special plastic carriers that provide a surface where a biofilm can grow. There is a wide variety of plastic carriers used in these systems. These carriers vary in surfac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cell Culture

Cell culture or tissue culture is the process by which cell (biology), cells are grown under controlled conditions, generally outside of their natural environment. After cells of interest have been Cell isolation, isolated from living tissue, they can subsequently be maintained under carefully controlled conditions. They need to be kept at body temperature (37 °C) in an incubator. These conditions vary for each cell type, but generally consist of a suitable vessel with a substrate or rich growth medium, medium that supplies the essential nutrients (amino acids, carbohydrates, vitamins, minerals), growth factors, hormones, and gases (Carbon dioxide, CO2, Oxygen, O2), and regulates the physio-chemical environment (Buffer solution, pH buffer, osmotic pressure, temperature). Most cells require a surface or an artificial substrate to form an adherent culture as a monolayer (one single-cell thick), whereas others can be grown free floating in a medium as a suspension culture. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Batch Reactor

A batch reactor is a chemical reactor in which a non-continuous reaction is conducted, i.e., one where the reactants, products and solvent do not flow in or out of the vessel during the reaction until the target reaction conversion is achieved. By extension, the expression is somehow inappropriately used for other batch fluid processing operations that do not involve a chemical reaction, such as solids dissolution, product mixing, batch distillation, crystallization, and liquid/liquid extraction. In such cases, however, they may not be referred to as reactors but rather with a term specific to the function they perform (such as crystallizer, bioreactor, etc.). Many batch processes are designed on the basis of a scale-up from the laboratory, particularly for the manufacture of specialty chemicals and pharmaceuticals. If this is the case, the process development will produce a ''recipe'' for the manufacturing process, which has many similarities to a recipe used in cookery. A typ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bioprocess Engineering

A bioprocess is a specific process that uses complete living cells or their components (e.g., bacteria, enzymes, chloroplasts) to obtain desired products. Transport of energy and mass is fundamental to many biological and environmental processes. Areas, from food processing (including brewing beer) to thermal design of buildings to biomedical devices, manufacture of monoclonal antibodies to pollution control, require knowledge of how energy and mass can be transported through materials (momentum, heat transfer, etc.). Cell bioprocessing Cell therapy bioprocessing is a discipline that bridges the fields of cell therapy and bioprocessing (i.e., biopharmaceutical manufacturing), and is a sub-field of bioprocess engineering. The goals of cell therapy bioprocessing are to establish reproducible and robust manufacturing processes for the production of therapeutic cells.Rowley, J.A. Developing Cell Therapy Biomanufacturing Processes, Chem Eng Progress, SBE Stem Cell Engineering Nov S ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Stripping

Air stripping is the transferring of volatile components of a liquid into an air stream. It is an environmental engineering technology used for the purification of groundwaters and wastewaters containing volatile compounds. Volatile compounds have relatively high vapor pressure and low aqueous solubility characterized by the compound's Henry's law coefficient, which is the ratio of the concentration in air that is in equilibrium with its concentration in water. Pollutants with relatively high Henry's Law coefficients can be economically stripped from water. These include BTEX compounds (benzene, toluene, ethylbenzene, and xylene found in gasoline), and solvents including trichloroethylene and tetrachloroethylene. Ammonia can also be stripped from wastewaters and liquid digestates (often requiring pH adjustment prior to stripping). Since Henry's law coefficient increases with temperature, stripping is easier at warmer temperatures. Air strippers Although any device that prom ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry's Law

In physical chemistry, Henry's law is a gas law that states that the amount of dissolved gas in a liquid is directly proportional at equilibrium to its partial pressure above the liquid. The proportionality factor is called Henry's law constant. It was formulated by the English chemist William Henry, who studied the topic in the early 19th century. In simple words, it states that the partial pressure of a gas in the vapour phase is directly proportional to the mole fraction of a gas in solution. An example where Henry's law is at play is the depth-dependent dissolution of oxygen and nitrogen in the blood of underwater divers that changes during decompression, going to decompression sickness. An everyday example is carbonated soft drinks, which contain dissolved carbon dioxide. Before opening, the gas above the drink in its container is almost pure carbon dioxide, at a pressure higher than atmospheric pressure. After the bottle is opened, this gas escapes, moving the partial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |