|

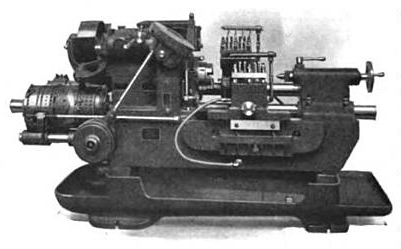

Automatic Lathe

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non- CNC types. The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implicit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fay Automatic Lathe

The Fay automatic lathe was an automatic lathe tailored to cutting workpieces that were mounted on centers (tools with pointed ends to accurately position a center-drilled workpiece about an axis, either directly or by using a mandrel). It could also do chucking work. (feeding of unformed blanks or pieces of stock from a magazine to be automatically gripped by the machine for turning). Examples of workpieces included automotive steering knuckles and transmission gears, and such work done on mandrels as flanges, disks, and hubs. The machine tool was developed by F.C. Fay of Philadelphia and improved by Otto A. Schaum. It was originally manufactured by the Fay & Scott Machine Shop. James Hartness acquired manufacturing rights on behalf of the Jones & Lamson Machine Company. and manufactured an improved version, developed under the management of Ralph Flanders.. In 1937 Roe, writing for the American Society of Mechanical Engineers, framed the importance of the Fay automatic lathe t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Churchill Machine Tool Company

Sir Winston Leonard Spencer Churchill (30 November 187424 January 1965) was a British statesman, soldier, and writer who served as Prime Minister of the United Kingdom twice, from 1940 to 1945 during the Second World War, and again from 1951 to 1955. Apart from two years between 1922 and 1924, he was a Member of Parliament (MP) from 1900 to 1964 and represented a total of five constituencies. Ideologically an economic liberal and imperialist, he was for most of his career a member of the Conservative Party, which he led from 1940 to 1955. He was a member of the Liberal Party from 1904 to 1924. Of mixed English and American parentage, Churchill was born in Oxfordshire to a wealthy, aristocratic family. He joined the British Army in 1895 and saw action in British India, the Anglo-Sudan War, and the Second Boer War, gaining fame as a war correspondent and writing books about his campaigns. Elected a Conservative MP in 1900, he defected to the Liberals in 1904. In H. H. A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bullard Machine Tool Company

The Bullard Machine Tool Company was a large American machine tool builder. It specialized in vertical boring mills and was largely responsible for the development of the modern form of that class of machine tools.pp. 183-185/ref> The firm was founded in 1894 by Edward Payson Bullard Sr. (born April 18, 1841 in Uxbridge, Massachusetts, USA; died December 22, 1906 in Bridgeport, Connecticut, USApp. 113-114/ref>). He received formative experience at the Colt armory and Pratt & Whitney, which were influential development centers for generations of toolmakers.p. 174/ref> Bullard Sr is believed to have developed the first small boring machine designed to do the accurate work previously performed on the faceplate of a lathe.p. 184/ref> Roe (1916) says that "Up to that time boring machines were relied on only for large and rough work." Bullard Sr.'s son, Edward Payson Bullard Jr. (1872–1953), continued the family machine tool business and brought the turret principle to the ve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Tool

A pneumatic tool, air tool, air-powered tool or pneumatic-powered tool is a type of power tool, driven by compressed air supplied by an air compressor. Pneumatic tools can also be driven by compressed carbon dioxide () stored in small cylinders allowing for portability. Most pneumatic tools convert the compressed air to work using a pneumatic motor. Compared to electric power tool equivalents, pneumatic tools are safer to run and maintain, without risk of sparks, short-circuiting or electrocution, and have a higher power to weight ratio, allowing a smaller, lighter tool to accomplish the same task. Furthermore, they are less likely to self-destruct in case the tool is jammed or overloaded. General grade pneumatic tools with a short life span are commonly less expensive and considered “disposable tools” in tooling industries, while industrial grade pneumatic tools with long life span are more expensive. In general, pneumatic tools are cheaper than the equivalent electric-po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spindle (tool)

In machine tools, a spindle is a rotating axis of the machine, which often has a shaft at its heart. The shaft itself is called a spindle, but also, in shop-floor practice, the word often is used metonymically to refer to the entire rotary unit, including not only the shaft itself, but its bearings and anything attached to it ( chuck, etc.). A machine tool may have several spindles, such as the headstock and tailstock spindles on a bench lathe. The main spindle is usually the biggest one. References to "the spindle" without further qualification imply the main spindle. Some machine tools that specialize in high-volume mass production have a group of 4, 6, or even more main spindles. These are called multispindle machines. For example, gang drills and many screw machines are multispindle machines. Although a bench lathe has more than one spindle (counting the tailstock), it is not called a multispindle machine; it has one main spindle. Examples of spindles include * On a la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brown & Sharpe

Brown & Sharpe is a division of Hexagon AB, a Swedish multinational corporation focused mainly on metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool builders and was a leading manufacturer of instruments for machinists (such as micrometers and indicators). Its reputation and influence were such that its name is often considered to be inseparably paired with certain industrial standards that it helped establish, including: * The American wire gauge (AWG) standards for wire; * The Brown & Sharpe taper in machine tool spindle tapers; and * The Brown & Sharpe worm threadform for worm gears. Since being acquired by Hexagon Metrology in 2001, Brown and Sharpe has concentrated exclusively on metrology equipment. History Founding (1833) and early years Brown & Sharpe was founded in 1833 on South Main Street in Providence, Rhode Island by David Brown and his son Joseph R. Brown. The el ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Retronym

A retronym is a newer name for an existing thing that helps differentiate the original form/version from a more recent one. It is thus a word or phrase created to avoid confusion between older and newer types, whereas previously (before there were more than one type) no clarification was required. Advances in technology are often responsible for the coinage of retronyms. For example, the term "acoustic guitar" was coined with the advent of electric guitars; analog watches were renamed to distinguish them from digital watches once the latter were invented; and "push bike" was created to distinguish from motorbikes and motorized bicycles; finally "feature phones" were also coined behind smartphones. Etymology The term ''retronym'', a neologism composed of the combining forms '' retro-'' (from Latin ''retro'', "before") + '' -nym'' (from Greek '' ónoma'', "name"), was coined by Frank Mankiewicz in 1980 and popularized by William Safire in ''The New York Times Magazine''. In 2000 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turret Lathe

The turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the ''turret'', which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between (such as installing or uninstalling tools) or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via digitally-directed servomechanisms for computer numerical control lathes. The name derives from the way early turrets took the general form of a flattened cylindrical block mounted to the lathe's cross-slide, capable of rotating about the vertical axis and with toolholders pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw-cutting Lathe

A screw-cutting lathe is a machine (specifically, a lathe) capable of cutting very accurate screw threads via single-point screw-cutting, which is the process of guiding the linear motion of the tool bit in a precisely known ratio to the rotating motion of the workpiece. This is accomplished by gearing the leadscrew (which drives the tool bit's movement) to the spindle with a certain gear ratio for each thread pitch. Every degree of spindle rotation is matched by a certain distance of linear tool travel, depending on the desired thread pitch (English or metric, fine or coarse, etc.). The name "screw-cutting lathe" carries a taxonomic qualification on its use—it is a term of historical classification rather than one of current commercial machine tool terminology. Early lathes, many centuries ago, were not adapted to screw-cutting. Later, from the Late Middle Ages until the early nineteenth century, some lathes were distinguishable as "screw-cutting lathes" because of the scre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a ''straight'' thread and the latter called a ''tapered'' thread. A screw thread is the essential feature of the screw as a simple machine and also as a threaded fastener. The mechanical advantage of a screw thread depends on its ''lead'', which is the linear distance the screw travels in one revolution. In most applications, the lead of a screw thread is chosen so that friction is sufficient to prevent linear motion being converted to rotary, that is so the screw does not slip even when linear force is applied, as long as no external rotational force is present. This characteristic is essential to the vast majority of its uses. The tightening of a fastener's screw thread is comparable to driving a wedge into a gap until it sticks fast ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fasten materials by the engagement of the screw thread with a similar ''female thread'' (internal thread) in a matching part. Screws are often self-threading (also known as self-tapping) where the thread cuts into the material when the screw is turned, creating an internal thread that helps pull fastened materials together and prevents pull-out. There are many screws for a variety of materials; materials commonly fastened by screws include wood, sheet metal, and plastic. Explanation A screw is a combination of simple machines: it is, in essence, an inclined plane wrapped around a central shaft, but the inclined plane (thread) also comes to a sharp edge around the outside, which acts as a wedge as it pushes into the fastened material, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |