|

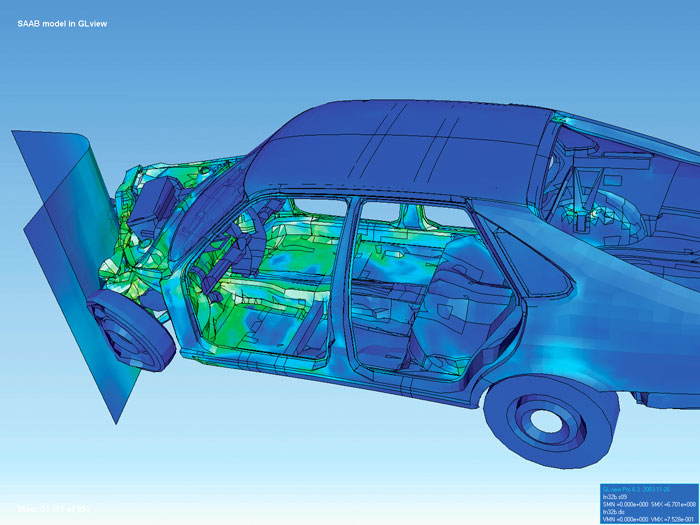

Assembly Modelling

Assembly modeling is a technology and method used by computer-aided design and product visualization computer software systems to handle multiple files that represent components within a product. The components within an assembly are represented as solid or surface models. Overview The designer generally has access to models that others are working on concurrently. For example, several people may be designing one machine that has many parts. New parts are added to an assembly model as they are created. Each designer has access to the assembly model, while a work in progress, and while working in their own parts. The design evolution is visible to everyone involved. Depending on the system, it might be necessary for the users to acquire the latest versions saved of each individual components to update the assembly. The individual data files describing the 3D geometry of individual components are assembled together through a number of sub-assembly levels to create an assembly desc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

100510 Ironcadv2011 Rendering

1 (one, unit, unity) is a number representing a single or the only entity. 1 is also a numerical digit and represents a single unit of counting or measurement. For example, a line segment of ''unit length'' is a line segment of length 1. In conventions of sign where zero is considered neither positive nor negative, 1 is the first and smallest positive integer. It is also sometimes considered the first of the infinite sequence of natural numbers, followed by 2, although by other definitions 1 is the second natural number, following 0. The fundamental mathematical property of 1 is to be a multiplicative identity, meaning that any number multiplied by 1 equals the same number. Most if not all properties of 1 can be deduced from this. In advanced mathematics, a multiplicative identity is often denoted 1, even if it is not a number. 1 is by convention not considered a prime number; this was not universally accepted until the mid-20th century. Additionally, 1 is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Visualization

Visualization or visualisation (see spelling differences) is any technique for creating images, diagrams, or animations to communicate a message. Visualization through visual imagery has been an effective way to communicate both abstract and concrete ideas since the dawn of humanity. Examples from history include cave paintings, Egyptian hieroglyphs, Greek geometry, and Leonardo da Vinci's revolutionary methods of technical drawing for engineering and scientific purposes. Visualization today has ever-expanding applications in science, education, engineering (e.g., product visualization), interactive multimedia, medicine, etc. Typical of a visualization application is the field of computer graphics. The invention of computer graphics (and 3D computer graphics) may be the most important development in visualization since the invention of central perspective in the Renaissance period. The development of animation also helped advance visualization. Overview The use of vis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid Modeling

Solid modeling (or solid modelling) is a consistent set of principles for mathematical and computer modeling of three-dimensional shapes '' (solids)''. Solid modeling is distinguished from related areas of geometric modeling and computer graphics, such as ''3D modeling'', by its emphasis on physical fidelity. Together, the principles of geometric and solid modeling form the foundation of 3D-computer-aided design and in general support the creation, exchange, visualization, animation, interrogation, and annotation of digital models of physical objects. Overview The use of solid modeling techniques allows for the automation process of several difficult engineering calculations that are carried out as a part of the design process. Simulation, planning, and verification of processes such as machining and assembly were one of the main catalysts for the development of solid modeling. More recently, the range of supported manufacturing applications has been greatly expanded to inc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Freeform Surface Modeling

Freeform surface modelling is a technique for engineering freeform surfaces with a CAD or CAID system. The technology has encompassed two main fields. Either creating aesthetic surfaces (class A surfaces) that also perform a function; for example, car bodies and consumer product outer forms, or technical surfaces for components such as gas turbine blades and other fluid dynamic engineering components. CAD software packages use two basic methods for the creation of surfaces. The first begins with construction curves ( splines) from which the 3D surface is then swept (section along guide rail) or meshed (lofted) through. The second method is direct creation of the surface with manipulation of the surface poles/control points. From these initially created surfaces, other surfaces are constructed using either derived methods such as offset or angled extensions from surfaces; or via bridging and blending between groups of surfaces. Surfaces Freeform surface, or freeform sur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifecycle

In industry, Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprises. History The inspiration for the burgeoning business process now known as PLM came from American Motors Corporation (AMC). The automaker was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François Castaing, Vice President for Product Engineering and Development. Lacking the "massive budgets of General Motors, Ford, and foreign competitors … AMC placed R&D emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps)." After introducing its compact Jeep Cherokee (XJ), the vehicle t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Constraint (computer-aided Design)

A constraint in computer-aided design (CAD) software is a limitation or restriction imposed by a designer or an engineer upon geometric properties of an entity of a design model that maintains its structure as the model is manipulated. These properties can include relative length, angle, orientation, size, shift, and displacement. The plural form ''constraints'' refers to demarcations of geometrical characteristics between two or more entities or solid modeling bodies; these delimiters are definitive for properties of theoretical physical position and motion, or displacement in parametric design. The exact terminology, however, may vary depending on a CAD program vendor. Constraints are widely employed in CAD software for solid modeling, computer-aided architectural design such as building information modeling, computer-aided engineering, assembly modeling, and other CAD subfields. Constraints are usually used for the creation of 3D assemblies and multibody systems. A constr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifecycle

In industry, Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprises. History The inspiration for the burgeoning business process now known as PLM came from American Motors Corporation (AMC). The automaker was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François Castaing, Vice President for Product Engineering and Development. Lacking the "massive budgets of General Motors, Ford, and foreign competitors … AMC placed R&D emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps)." After introducing its compact Jeep Cherokee (XJ), the vehicle t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

JT (visualization Format)

JT (Jupiter Tessellation) is an openly-published ISO-standardized 3D CAD data exchange format used for product visualization, collaboration, digital mockups, and other purposes. It was developed by Siemens. It can contain any combination of approximate (faceted) data, boundary representation surfaces ( NURBS), Product and Manufacturing Information (PMI), and Metadata (textual attributes) either exported from the native CAD system or inserted by a product data management (PDM) system. The JT format contains a scene graph representation of an assembly, nested sub-assemblies of parts with CAD specific node and attributes data. Facet information (triangles) is stored by using geometry compression techniques. Visual attributes of 3D scene and model like lights, textures, and/or materials are supported. Product and Manufacturing Information (PMI), Precise Part definitions (BRep), additional metadata, and a variety of representation configurations are supported. The JT format is des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |