Stress concentration on:

[Wikipedia]

[Google]

[Amazon]

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches.

The degree of concentration of a discontinuity under typically

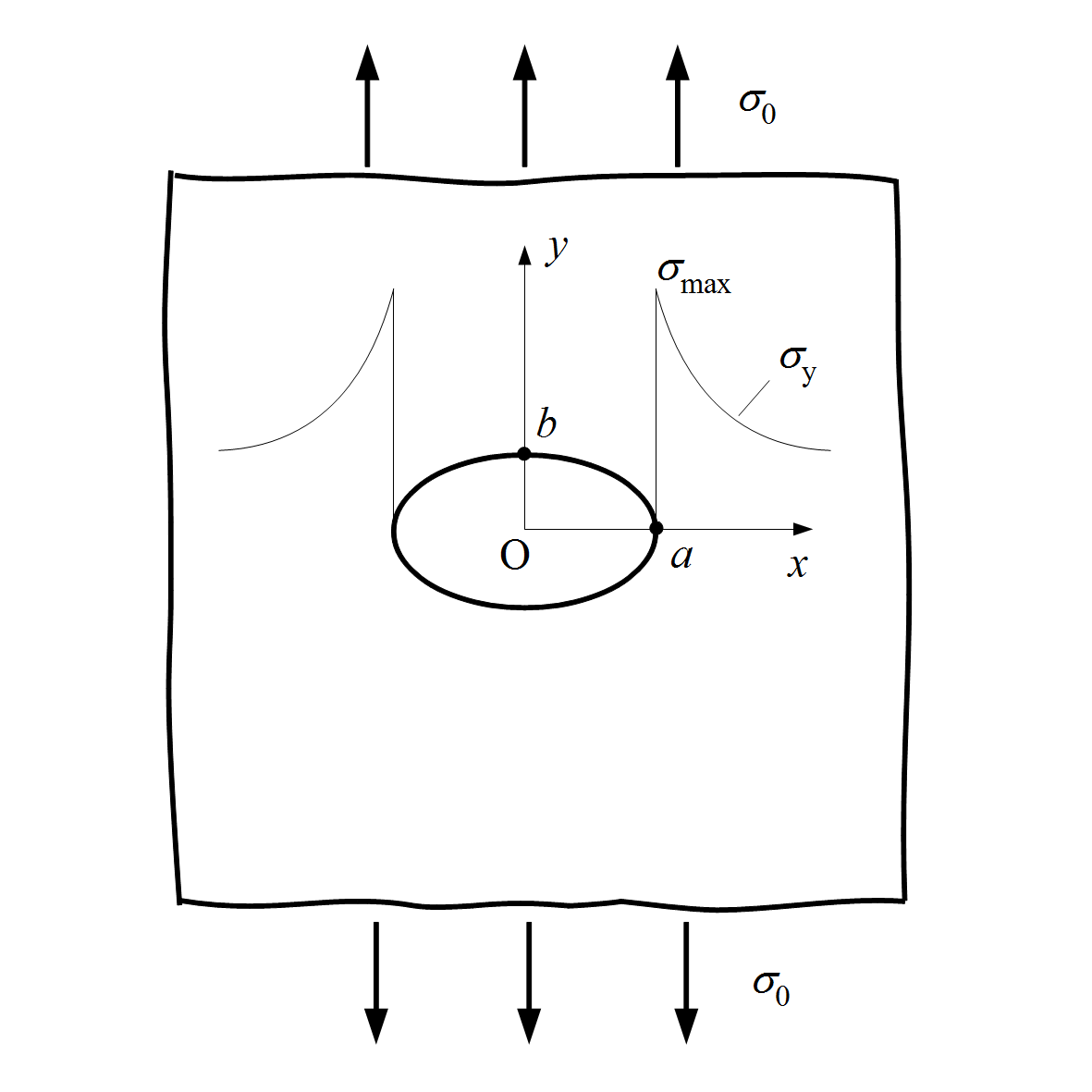

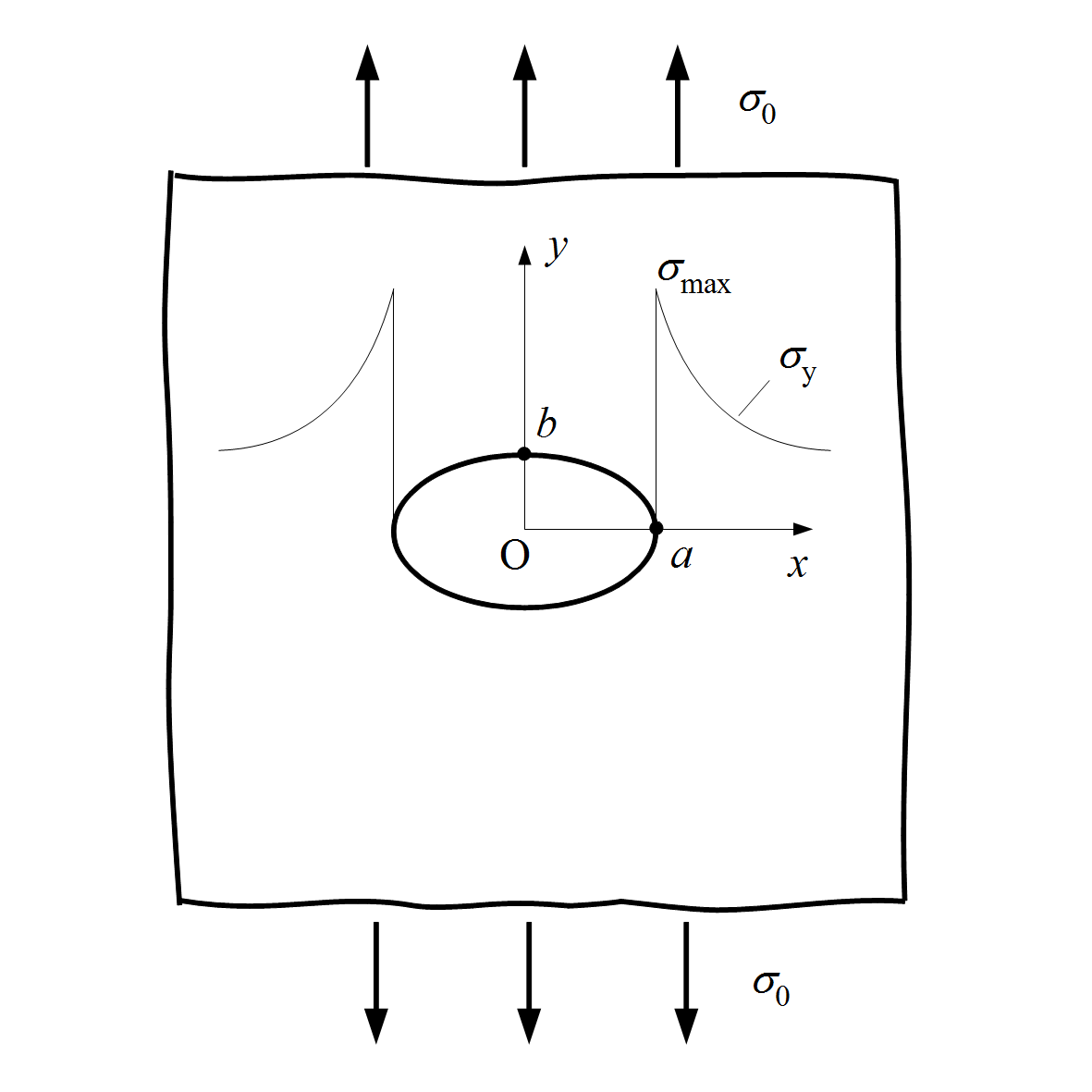

E. Kirsch derived the equations for the elastic stress distribution around a hole. The maximum stress felt near a hole or notch occurs in the area of lowest radius of curvature. In an elliptical hole of length and width , under a far-field stress , the stress at the ends of the major axes is given by Inglis' equation:

:

where is the radius of curvature of the elliptical hole. For circular holes in an infinite plate where , the stress concentration factor is .

As the radius of curvature approaches zero, such as at the tip of a sharp crack, the maximum stress approaches infinity and a stress concentration factor cannot therefore be used for a crack. Instead, the stress intensity factor which defines the scaling of the stress field around a crack tip, is used.

E. Kirsch derived the equations for the elastic stress distribution around a hole. The maximum stress felt near a hole or notch occurs in the area of lowest radius of curvature. In an elliptical hole of length and width , under a far-field stress , the stress at the ends of the major axes is given by Inglis' equation:

:

where is the radius of curvature of the elliptical hole. For circular holes in an infinite plate where , the stress concentration factor is .

As the radius of curvature approaches zero, such as at the tip of a sharp crack, the maximum stress approaches infinity and a stress concentration factor cannot therefore be used for a crack. Instead, the stress intensity factor which defines the scaling of the stress field around a crack tip, is used.

an improved solution Another method used to decrease the stress concentration is by adding a fillet to internal corners. This reduces the stress concentration and results in smoother flow of stress streamlines. In a threaded component, the force flow line is bent as it passes from shank portion to threaded portion; as a result, stress concentration takes place. To reduce this, a small undercut is made between the shank and threaded portions.

When Metal Lets Us Down

{{DEFAULTSORT:Stress Concentration Engineering concepts Elasticity (physics)

tensile

In physics, tension is described as the pulling force transmitted axially by the means of a string, a rope, chain, or similar object, or by each end of a rod, truss member, or similar three-dimensional object; tension might also be described a ...

loads can be expressed as a non-dimensional stress concentration factor , which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, . The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip.

For ductile materials, large loads can cause localised plastic deformation

In engineering, deformation refers to the change in size or shape of an object. ''Displacements'' are the ''absolute'' change in position of a point on the object. Deflection is the relative change in external displacements on an object. Strain ...

or yielding that will typically occur first at a stress concentration allowing a redistribution of stress and enabling the component to continue to carry load. Brittle materials will typically fail at the stress concentration. However, repeated low level loading may cause a fatigue crack to initiate and slowly grow at a stress concentration leading to the failure of even ductile materials. Fatigue cracks always start at stress raisers, so removing such defects increases the fatigue strength

The fatigue limit or endurance limit is the stress level below which an infinite number of loading cycles can be applied to a material without causing fatigue failure. Some metals such as ferrous alloys and titanium alloys have a distinct limit, ...

.

Description

Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. Geometric discontinuities cause an object to experience a localised increase in stress. Examples of shapes that cause stress concentrations are sharp internal corners, holes, and sudden changes in the cross-sectional area of the object as well as unintentional damage such as nicks, scratches and cracks. High local stresses can cause objects to fail more quickly, so engineers typically design the geometry to minimize stress concentrations. Material discontinuities, such as inclusions in metals, may also concentrate the stress. Inclusions on the surface of a component may be broken from machining during manufacture leading to microcracks that grow in service from cyclic loading. Internally, the failure of the interfaces around inclusions during loading may lead to static failure bymicrovoid coalescence

Microvoid coalescence (MVC) is a high energy microscopic fracture mechanism observed in the majority of metallic alloys and in some engineering plastics.

Fracture process

MVC proceeds in three stages: nucleation, growth, and coalescence of mic ...

.

Stress concentration factor

The ''stress concentration factor'', , is the ratio of the highest stress to a nominal stress of the gross cross-section and defined as : Note that the dimensionless stress concentration factor is a function of the geometry shape and independent of its size. These factors can be found in typical engineering reference materials. E. Kirsch derived the equations for the elastic stress distribution around a hole. The maximum stress felt near a hole or notch occurs in the area of lowest radius of curvature. In an elliptical hole of length and width , under a far-field stress , the stress at the ends of the major axes is given by Inglis' equation:

:

where is the radius of curvature of the elliptical hole. For circular holes in an infinite plate where , the stress concentration factor is .

As the radius of curvature approaches zero, such as at the tip of a sharp crack, the maximum stress approaches infinity and a stress concentration factor cannot therefore be used for a crack. Instead, the stress intensity factor which defines the scaling of the stress field around a crack tip, is used.

E. Kirsch derived the equations for the elastic stress distribution around a hole. The maximum stress felt near a hole or notch occurs in the area of lowest radius of curvature. In an elliptical hole of length and width , under a far-field stress , the stress at the ends of the major axes is given by Inglis' equation:

:

where is the radius of curvature of the elliptical hole. For circular holes in an infinite plate where , the stress concentration factor is .

As the radius of curvature approaches zero, such as at the tip of a sharp crack, the maximum stress approaches infinity and a stress concentration factor cannot therefore be used for a crack. Instead, the stress intensity factor which defines the scaling of the stress field around a crack tip, is used.

Methods for determining factors

There are experimental methods for measuring stress concentration factors including photoelastic stress analysis, thermoelastic stress analysis, brittle coatings orstrain gauge

A strain gauge (also spelled strain gage) is a device used to measure strain on an object. Invented by Edward E. Simmons and Arthur C. Ruge in 1938, the most common type of strain gauge consists of an insulating flexible backing which supports ...

s.

During the design phase, there are multiple approaches to estimating stress concentration factors. Several catalogs of stress concentration factors have been published. Perhaps most famous is ''Stress Concentration Design Factors'' by Peterson, first published in 1953. Finite element methods are commonly used in design today.

Limiting the effects of stress concentrations

Known as crack tip blunting, a counter-intuitive method of reducing one of the worst types of stress concentrations, a crack, is to drill a large hole at the end of the crack. The drilled hole, with its relatively large size, serves to increase the effective crack tip radius and thus reduce the stress concentration.stress at round-tip notchesan improved solution Another method used to decrease the stress concentration is by adding a fillet to internal corners. This reduces the stress concentration and results in smoother flow of stress streamlines. In a threaded component, the force flow line is bent as it passes from shank portion to threaded portion; as a result, stress concentration takes place. To reduce this, a small undercut is made between the shank and threaded portions.

Examples

* Thede Havilland Comet

The de Havilland DH.106 Comet was the world's first commercial jet airliner. Developed and manufactured by de Havilland in the United Kingdom, the Comet 1 prototype first flew in 1949. It featured an aerodynamically clean design with four d ...

aircraft

An aircraft is a vehicle that is able to flight, fly by gaining support from the Atmosphere of Earth, air. It counters the force of gravity by using either Buoyancy, static lift or by using the Lift (force), dynamic lift of an airfoil, or in ...

experienced a number of catastrophic failures that were eventually found to be due to fatigue cracks growing from the high stress concentration caused by the use of punched rivet holes around the automatic direction finder cutouts (sometimes referred to as windows). The square passenger windows were also found to have higher stress concentrations than expected and were redesigned.

* Brittle fractures at the corners of hatches in Liberty ships in cold and stressful conditions in winter storms in the Atlantic Ocean

The Atlantic Ocean is the second-largest of the world's five oceans, with an area of about . It covers approximately 20% of Earth's surface and about 29% of its water surface area. It is known to separate the " Old World" of Africa, Europe ...

.

* A focus point of stress on the margins of an implant, where metal meets bone, of an implanted orthosis

Orthotics ( el, Ορθός, translit=ortho, lit=to straighten, to align) is a medical specialty that focuses on the design and application of orthoses, or braces. An is "an externally applied device used to influence the structural and functi ...

is very likely to be the point of failure.

References

External links

When Metal Lets Us Down

{{DEFAULTSORT:Stress Concentration Engineering concepts Elasticity (physics)