Shell and tube heat exchanger on:

[Wikipedia]

[Google]

[Amazon]

A shell and tube heat exchanger is a class of

A shell and tube heat exchanger is a class of

In nuclear power plants called

In nuclear power plants called  Surface condensers in power plants are often 1-pass straight-tube heat exchangers (see surface condenser for diagram). Two and four pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler.

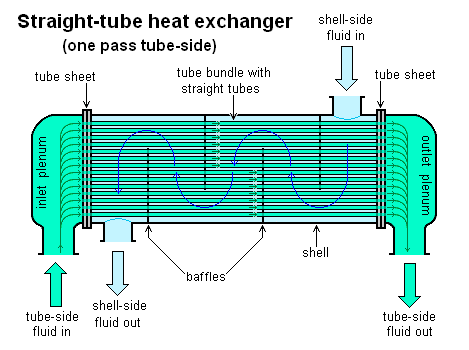

Surface condensers in power plants are often 1-pass straight-tube heat exchangers (see surface condenser for diagram). Two and four pass designs are common because the fluid can enter and exit on the same side. This makes construction much simpler.

There are often baffles directing flow through the shell side so the fluid does not take a short cut through the shell side leaving ineffective low flow volumes. These are generally attached to the tube bundle rather than the shell in order that the bundle is still removable for maintenance.

Countercurrent heat exchangers are most efficient because they allow the highest

There are often baffles directing flow through the shell side so the fluid does not take a short cut through the shell side leaving ineffective low flow volumes. These are generally attached to the tube bundle rather than the shell in order that the bundle is still removable for maintenance.

Countercurrent heat exchangers are most efficient because they allow the highest

Shell-and-Tube Heat Exchangers Construction DetailsBasics of Shell and Tube Exchanger DesignBasics of Industrial Heat TransferSpecifying a Liquid_Liquid Heat ExchangerShell and tube heat exchanger calculator for shellside

Heat exchangers

A shell and tube heat exchanger is a class of

A shell and tube heat exchanger is a class of heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ...

designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size o ...

) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

Theory and application

Two fluids, of different starting temperatures, flow through the heat exchanger. One flows through the tubes (the tube side) and the other flows outside the tubes but inside the shell (the shell side). Heat is transferred from one fluid to the other through the tube walls, either from tube side to shell side or vice versa. The fluids can be eitherliquid

A liquid is a nearly incompressible fluid that conforms to the shape of its container but retains a (nearly) constant volume independent of pressure. As such, it is one of the four fundamental states of matter (the others being solid, gas, ...

s or gases on either the shell or the tube side. In order to transfer heat efficiently, a large heat transfer

Heat transfer is a discipline of thermal engineering that concerns the generation, use, conversion, and exchange of thermal energy ( heat) between physical systems. Heat transfer is classified into various mechanisms, such as thermal conducti ...

area should be used, leading to the use of many tubes. In this way, waste heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utilit ...

can be put to use. This is an efficient way to conserve energy.

Heat exchangers with only one phase (liquid or gas) on each side can be called one-phase or single-phase heat exchangers. Two-phase heat exchangers can be used to heat a liquid to boil it into a gas (vapor), sometimes called boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central ...

s, or to cool the vapors and condense it into a liquid (called condensers), with the phase change usually occurring on the shell side. Boilers in steam engine locomotive

A locomotive or engine is a rail transport vehicle that provides the motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, motor coach, railcar or power car; the ...

s are typically large, usually cylindrically-shaped shell-and-tube heat exchangers. In large power plant

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Many ...

s with steam-driven turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating ...

s, shell-and-tube surface condensers are used to condense the exhaust steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporizatio ...

exiting the turbine into condensate water

Water (chemical formula ) is an inorganic, transparent, tasteless, odorless, and nearly colorless chemical substance, which is the main constituent of Earth's hydrosphere and the fluids of all known living organisms (in which it acts as ...

which is recycled back to be turned into steam in the steam generator.

They are also used in liquid-cooled chiller

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression, adsorption refrigeration, or absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another p ...

s for transferring heat between the refrigerant

A refrigerant is a working fluid used in the refrigeration cycle of air conditioning systems and heat pumps where in most cases they undergo a repeated phase transition from a liquid to a gas and back again. Refrigerants are heavily regulated ...

and the water in both the evaporator

An evaporator is a device used to turn the liquid form of a chemical substance, such as water, into a vapor.

Uses

Air conditioning and refrigeration

Some air conditioners and refrigerators use a compressed liquid with a low boiling point, su ...

and condenser, and in air-cooled chillers for only the evaporator.

Shell and tube heat exchanger design

There can be many variations on the shell and tube design. Typically, the ends of each tube are connected to plenums (sometimes called water boxes) through holes in tubesheets. The tubes may be straight or bent in the shape of a U, called U-tubes.pressurized water reactor

A pressurized water reactor (PWR) is a type of light-water nuclear reactor. PWRs constitute the large majority of the world's nuclear power plants (with notable exceptions being the UK, Japan and Canada). In a PWR, the primary coolant (water) i ...

s, large heat exchangers called steam generators are two-phase, shell-and-tube heat exchangers which typically have U-tubes. They are used to boil water recycled from a surface condenser into steam to drive a turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating ...

to produce power. Most shell-and-tube heat exchangers are either 1, 2, or 4 pass designs on the tube side. This refers to the number of times the fluid in the tubes passes through the fluid in the shell. In a single pass heat exchanger, the fluid goes in one end of each tube and out the other.

log mean temperature difference

The logarithmic mean temperature difference (also known as log mean temperature difference, LMTD) is used to determine the temperature driving force for heat transfer in flow systems, most notably in heat exchangers. The LMTD is a logarithmic aver ...

between the hot and cold streams. Many companies however do not use two pass heat exchangers with a u-tube because they can break easily in addition to being more expensive to build. Often multiple heat exchangers can be used to simulate the countercurrent flow

Countercurrent exchange is a mechanism occurring in nature and mimicked in industry and engineering, in which there is a crossover of some property, usually heat or some chemical, between two flowing bodies flowing in opposite directions to each ...

of a single large exchanger.

Selection of tube material

To be able to transfer heat well, the tube material should have goodthermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

. Because heat is transferred from a hot to a cold side through the tubes, there is a temperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measured with a thermometer.

Thermometers are calibrated in various temperature scales that historically have relied o ...

difference through the width of the tubes. Because of the tendency of the tube material to thermally expand differently at various temperatures, thermal stresses occur during operation. This is in addition to any stress

Stress may refer to:

Science and medicine

* Stress (biology), an organism's response to a stressor such as an environmental condition

* Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase ...

from high pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country a ...

s from the fluids themselves. The tube material also should be compatible with both the shell and tube side fluids for long periods under the operating conditions (temperatures

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measured with a thermometer.

Thermometers are calibrated in various temperature scales that historically have relied on ...

, pressures, pH, etc.) to minimize deterioration such as corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

. All of these requirements call for careful selection of strong, thermally-conductive, corrosion-resistant, high quality tube materials, typically metal

A metal (from ancient Greek, Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electrical resistivity and conductivity, e ...

s, including aluminium

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

, copper alloy

Copper alloys are metal alloys that have copper as their principal component. They have high resistance against corrosion. The best known traditional types are bronze, where tin is a significant addition, and brass, using zinc instead. Both of t ...

, stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's r ...

, carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, coba ...

, non-ferrous copper alloy, Inconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys.

Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected ...

, nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

, Hastelloy

Haynes International, Inc., headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, and Mountain Home ...

and titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

. Fluoropolymers

A fluoropolymer is a fluorocarbon-based polymer with multiple carbon–fluorine bonds. It is characterized by a high resistance to solvents, acids, and bases. The best known fluoropolymer is polytetrafluoroethylene under the brand name "Teflon, ...

such as Perfluoroalkoxy alkane (PFA) and Fluorinated ethylene propylene

Fluorinated ethylene propylene (FEP) is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the polytetrafluoroethylene (PTFE) resins in that it is melt-processable using conventional injection molding and screw extrusion t ...

(FEP) are also used to produce the tubing material due to their high resistance to extreme temperatures. Poor choice of tube material could result in a leak

A leak is a way (usually an opening) for fluid to escape a container or fluid-containing system, such as a tank or a ship's hull, through which the contents of the container can escape or outside matter can enter the container. Leaks are usually ...

through a tube between the shell and tube sides causing fluid cross-contamination and possibly loss of pressure.

Applications and uses

The simple design of a shell and tube heat exchanger makes it an ideal cooling solution for a wide variety of applications. One of the most common applications is the cooling of hydraulic fluid and oil in engines, transmissions andhydraulic power pack

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counter ...

s. With the right choice of materials they can also be used to cool or heat other mediums, such as swimming pool water or charge air. There are many advantages to shell and tube technology over plates

* One of the big advantages of using a shell and tube heat exchanger is that they are often easy to service, particularly with models where a floating tube bundle is available.(where the tube plates are not welded to the outer shell).

* The cylindrical design of the housing is extremely resistant to pressure and allows all ranges of pressure applications

Overpressure protection

In shell and tube heat exchangers there is a potential for a tube to rupture and for high pressure (HP) fluid to enter and over-pressurise the low pressure (LP) side of the heat exchanger. The usual configuration of exchangers is for the HP fluid to be in the tubes and for LP water, cooling or heating media to be on the shell side. There is a risk that a tube rupture could compromise the integrity of the shell and the release flammable gas or liquid, with a risk to people and financial loss. The shell of an exchanger must be protected against over-pressure by rupture discs or relief valves. The opening time of protection devices has been found to be critical for exchanger protection. Such devices are fitted directly on the shell of the exchanger and discharge into a relief system.Design and construction standards

* Standards of the Tubular Exchanger Manufacturers Association (TEMA), 10th edition, 2019 * EN 13445-3 "Unfired Pressure Vessels - Part 3: Design", Section 13 (2012) *ASME Boiler and Pressure Vessel Code

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

, Section VIII, Division 1, Part UHX

See also

*Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centr ...

or Reboiler

*EJMA The Expansion Joint Manufacturers Association is an organization of a metal bellows expansion joint manufacturers. It was founded in 1955 to create and maintain a set of standards for quality expansion joint design and manufacturing. The EJMA stan ...

* Fired heater

*Fouling

Fouling is the accumulation of unwanted material on solid surfaces. The fouling materials can consist of either living organisms ( biofouling) or a non-living substance (inorganic or organic). Fouling is usually distinguished from other sur ...

or scaling

Scaling may refer to:

Science and technology

Mathematics and physics

* Scaling (geometry), a linear transformation that enlarges or diminishes objects

* Scale invariance, a feature of objects or laws that do not change if scales of length, energ ...

*Heat exchanger

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct conta ...

* NTU method as an alternative to finding the LMTD

* Plate and frame heat exchanger

* Plate fin heat exchanger

* Pressure vessel

*Surface condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid stat ...

References

External links

{{Commons category, Shell and tube heat exchangersShell-and-Tube Heat Exchangers Construction Details

Heat exchangers