Return connecting rod engine on:

[Wikipedia]

[Google]

[Amazon]

A return connecting rod, return piston rod or (in marine parlance) double piston rod engine or back-acting engine is a particular layout for a

A return connecting rod, return piston rod or (in marine parlance) double piston rod engine or back-acting engine is a particular layout for a

'Table' and 'steeple' engines are vertical stationary engines with return connecting rods.

'Table' and 'steeple' engines are vertical stationary engines with return connecting rods.

The first

The first

The trunk engine was largely replaced by the ''double piston-rod'' engine. This was a return connecting rod engine, with the crankshaft between the crosshead and cylinder. Four piston rods were used to pass around the crankshaft, both above and below, and also to each side of the crank, as the crank throw was wider than the vertical spacing of the piston rods. As most of these engines were parallel compounds, two piston rods would be taken from each of the HP and LP pistons. In some engines, double rods were used from the large LP cylinder and a single rod from the HP cylinder, with a yoke to pass around the crankshaft. Double piston rods could also be used from a simple engine, but these required an overhung gudgeon pin on the crosshead, so tended to be limited to smaller engines. An advantage of the double piston rod engine over the trunk was that both ends of the connecting rod were accessible for maintenance. One factor learned from naval use of horizontal cylinders was that, despite previous fears, there was little additional wear owing to the piston's weight resting on the cylinder.

An Admiralty committee of 1858 recommended strongly that older engine designs be abandoned in favour of rationalisation on only three designs: the single piston rod engine (the most recognisable type today), the trunk engine and the double piston rod.

A later variant of the trunk engine re-visited the return connecting rod layout as the vibrating lever or half-trunk engine. This was a paired engine with two short-stroke trunk engines facing outwards. Their connecting rods from the pistons led to upright 'vibrating levers' that could rock back and forth. These levers rotated a short axle shaft with further levers on it that in turn drove another pair of connecting rods and a shared central crankshaft. These complex engines were the invention of the Swedish-American engineer

The trunk engine was largely replaced by the ''double piston-rod'' engine. This was a return connecting rod engine, with the crankshaft between the crosshead and cylinder. Four piston rods were used to pass around the crankshaft, both above and below, and also to each side of the crank, as the crank throw was wider than the vertical spacing of the piston rods. As most of these engines were parallel compounds, two piston rods would be taken from each of the HP and LP pistons. In some engines, double rods were used from the large LP cylinder and a single rod from the HP cylinder, with a yoke to pass around the crankshaft. Double piston rods could also be used from a simple engine, but these required an overhung gudgeon pin on the crosshead, so tended to be limited to smaller engines. An advantage of the double piston rod engine over the trunk was that both ends of the connecting rod were accessible for maintenance. One factor learned from naval use of horizontal cylinders was that, despite previous fears, there was little additional wear owing to the piston's weight resting on the cylinder.

An Admiralty committee of 1858 recommended strongly that older engine designs be abandoned in favour of rationalisation on only three designs: the single piston rod engine (the most recognisable type today), the trunk engine and the double piston rod.

A later variant of the trunk engine re-visited the return connecting rod layout as the vibrating lever or half-trunk engine. This was a paired engine with two short-stroke trunk engines facing outwards. Their connecting rods from the pistons led to upright 'vibrating levers' that could rock back and forth. These levers rotated a short axle shaft with further levers on it that in turn drove another pair of connecting rods and a shared central crankshaft. These complex engines were the invention of the Swedish-American engineer

A blowing engine is a large

A blowing engine is a large

A return connecting rod, return piston rod or (in marine parlance) double piston rod engine or back-acting engine is a particular layout for a

A return connecting rod, return piston rod or (in marine parlance) double piston rod engine or back-acting engine is a particular layout for a steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be ...

.

The key attribute of this layout is that the piston rod

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels.

Internal combustion engines, and in particular all current automobile engin ...

emerges from the cylinder to the crosshead

In mechanical engineering, a crosshead is a mechanical joint used as part of the slider-crank linkages of long reciprocating engines (either internal combustion or steam) and reciprocating compressors to eliminate sideways force on the piston ...

, but the connecting rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crank ...

then reverses direction and goes ''backwards'' to the crankshaft

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecti ...

. This layout is compact, but has mechanical disadvantages. Return connecting rod engines were thus rarely used.

The return connecting rod layout has two possible forms:

* The cylinder is between the crosshead and the crankshaft. This requires long connecting rods. To avoid unbalanced forces on the crosshead, these rods are usually paired and run either side of the cylinder.

* The crankshaft is between the crosshead and cylinder. This requires a paired piston rod or yoke, so as to pass around the crankshaft.

Both horizontal and vertical arrangements have used the return connecting rod layout. Vertical return connecting rod engines used the original 'vertical' layout, with the cylinder facing upwards to the crosshead.

Table and Steeple engines

'Table' and 'steeple' engines are vertical stationary engines with return connecting rods.

'Table' and 'steeple' engines are vertical stationary engines with return connecting rods.

Table engines

Table engine

A table engine is a variety of stationary steam engine where the cylinder is placed on top of a table-shaped base, the legs of which stand on the baseplate which locates the crankshaft bearings. The piston rod protrudes from the top of the cylinder ...

s place the cylinder above and between the crankshaft and the crosshead. They saw widespread manufacture by Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were an ...

from around 1805 and were used to supply power to small engineering workshops. They were especially popular for driving lineshaft

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to e ...

ing, as they could operate at a higher speed than beam engines.

Like the smaller grasshopper beam engine

Grasshopper beam engines are beam engines that are pivoted at one end, rather than in the centre.

Usually the connecting rod to the crankshaft is placed ''between'' the piston and the beam's pivot. That is, they use a second-class lever, rather t ...

s, an advantage for Maudslay's table engines was that they could be made in factories as a complete unit. This included their large cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuri ...

baseplate or table. Unlike horizontal engines and house-built beam engines, they did not require the construction of a large and carefully aligned masonry foundation at the engine's site. Engines could also be made in advance and sold 'off the shelf'. Although this had cost savings, it was mostly beneficial because it was ''quicker'' than commissioning the building of an engine and engine house to go with it.

Steeple engines

Steeple engine

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their ...

s place the crankshaft above the cylinder, between it and the crosshead. They use paired piston rods, two or even four, from the piston to the crosshead, to avoid the crankshaft. Another pattern used a triangular yoke on the single piston rod, allowing the crankshaft to pass through it.

Steeple engines were mostly used as marine engines. Some American paddlewheel riverboats had especially large steeples that towered over their deckhouse.

The term 'steeple engine' was also used later to refer to inverted-vertical tandem-compound engines, owing to their great height. These were not return connecting rod engines.

Locomotives

Trevithick Trevithick ( ) is a Cornish surname, and may refer to:

* Francis Trevithick (1812–1877), one of the first locomotive engineers of the London and North Western Railway

* Jonathan Trevethick (1864–1939), New Zealand politician

* Paul Trevithic ...

's first high-pressure engines from 1801 onwards, including his locomotives, used the return connecting rod layout in both horizontal and vertical arrangements. The cylinders were embedded within the boiler, to avoid heat loss, and the short boiler also formed the frame of the engine. This made the return connecting rod a natural layout, with the crankshaft at the opposite end of the boiler from the crosshead. The paired connecting rods were relatively simple components, even though two were required. As they also allowed the crankshaft to use two simple overhung cranks on the ends of the shaft, rather than a complex forged

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which it ...

crankshaft with an internal crank, this was also a valuable simplification.

Other early steam locomotives

Articles about steam locomotives (and locomotive types/classes) built before 1840. Of these, see info-box immediately below for the most well-known individual steam locomotives built before 1830 (listed by year).

{{early-steam-locos

Steam locom ...

such as Murray

Murray may refer to:

Businesses

* Murray (bicycle company), an American manufacturer of low-cost bicycles

* Murrays, an Australian bus company

* Murray International Trust, a Scottish investment trust

* D. & W. Murray Limited, an Australian who ...

's ''Salamanca'' (1812) and George Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was a British civil engineer and mechanical engineer. Renowned as the "Father of Railways", Stephenson was considered by the Victorians

In the history of the United Kingdom and the ...

's ''Blücher'' (1815) and ''Locomotion'' (1825) also used return connecting rod engines. These all had heavy vertical cylinders set in tandem within the boiler barrel, driving through transverse crossheads above the locomotive, supported by swinging links. The complexity of this motion led to it being named '' 'the knitting' '' by drivers. The swinging link was simpler than Watt

The watt (symbol: W) is the unit of power or radiant flux in the International System of Units (SI), equal to 1 joule per second or 1 kg⋅m2⋅s−3. It is used to quantify the rate of energy transfer. The watt is named after James ...

's earlier parallel motion and did not constrain the crosshead to move in such an accurate straight line. However the additional length of the connecting rods for a return connecting rod engine, relative to the piston stroke, made this angulation effect less serious. The ''Steam Elephant

''Steam Elephant'' was an early steam locomotive from North East England.

Historiography

An illustration of the locomotive first came to modern attention in 1931 and it was then generally assumed to be the work of George Stephenson. More rec ...

'' used a rudimentary set of slidebars to support the crosshead instead.

The use of a return connecting rod to a shaft beneath the boiler with overhung cranks also avoided the need for an internal crank. For Stephenson's designs, this crank axle would also have carried the locomotive's weight, not being merely a crankshaft, and so this avoided a particularly difficult piece of forging work.

One of the last locomotives to use return connecting rods was Ericsson

(lit. "Telephone Stock Company of LM Ericsson"), commonly known as Ericsson, is a Swedish multinational networking and telecommunications company headquartered in Stockholm. The company sells infrastructure, software, and services in inform ...

and Braithwaite

Braithwaite is a village in the northern Lake District, in Cumbria, England. Historically in Cumberland, it lies just to the west of Keswick and to the east of the Grisedale Pike ridge, in the Borough of Allerdale. It forms part of the ...

's ''Novelty'' at the Rainhill trials.

; Abandonment of return connecting rod designs

Hedley's ''Puffing Billy'', a contemporary of ''Blücher'', avoided the return connecting rod in favour of a grasshopper beam. The cylinders were now mounted side by side, but were still large, heavy and mounted as an integral part of the boiler. Although a beam engine

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newc ...

has a similar layout to a return connecting rod engine, in that the piston rod points in one direction and the connecting rod runs backwards from this, beam engines are not considered as return connecting rod engines. Stephenson's manager Hackworth's locomotive ''Royal George'' inverted the design to having the cylinders, still vertical, face downwards directly onto the crankshaft. By the time of Stephenson's ''Rocket'', particularly as the new fire-tube boiler

A fire-tube boiler is a type of boiler in which hot gases pass from a fire through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating ...

locomotives became lighter and faster, it was recognised that vertical cylinders caused hammer blow

In rail terminology, hammer blow or dynamic augment is a vertical force which alternately adds to and subtracts from the locomotive's weight on a wheel. It is transferred to the track by the driving wheels of many steam locomotives. It is an out-of ...

on the flimsy fishbelly rails of the time. ''Rocket'' was built with cylinders inclined at 45° but was soon rebuilt to place them near-horizontally. Since then, almost all steam locomotives have had their cylinders placed close to horizontal.

Marine steam engines

Paddle ships

The first

The first marine steam engine

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their ...

s drove paddlewheel

A paddle wheel is a form of waterwheel or impeller in which a number of paddles are set around the periphery of the wheel. It has several uses, of which some are:

* Very low-lift water pumping, such as flooding paddy fields at no more than about ...

s. Paddles require a relatively high axle, that often also forms the crankshaft. For stability the main weight of the engine, i.e. its cylinder, is mounted low down. Later engines drove single screw propellers. These now required a low-mounted drive, but still benefited from the stability effect of a low-set engine. Such early engines, constrained by the technology of the time, worked at low boiler pressures and slow piston speeds. Together with the short piston stroke constrained by lack of space for the engine, these early engines required large diameter pistons in order to develop enough power.

Crosshead engines

Crosshead, 'double crosshead' or 'square' engines were vertical engines analogous in layout to the table engine, with their cylinder above the crankshaft. The crosshead needed to be very wide, to allow the connecting rods to pass either side of the large cylinder, which in turn required a large supporting frame for the slidebars. They were popular for early American riverboats and their large wooden A frame crosshead supports were a distinctive feature. Larger engines became top-heavy and so the design was replaced by steeple orwalking beam

A marine steam engine is a steam engine that is used to power a ship or boat. This article deals mainly with marine steam engines of the reciprocating type, which were in use from the inception of the steamboat in the early 19th century to their ...

engines.

Steeple engines

European practice, particularly on theClyde Clyde may refer to:

People

* Clyde (given name)

* Clyde (surname)

Places

For townships see also Clyde Township

Australia

* Clyde, New South Wales

* Clyde, Victoria

* Clyde River, New South Wales

Canada

* Clyde, Alberta

* Clyde, Ontario, a tow ...

, favoured Napier's steeple engine instead of the square engine. These were more complicated to construct and used more ironwork, but they placed the cylinder beneath the crankshaft and so were more stable in a narrow hull. Neither form was popular for sea-going vessels.

Screw propulsion

In marine practice, the return connecting rod engine for screw propulsion was termed the ''back-acting''(US parlance) or ''double piston rod'' engine.Trunk engines

John Penn patented thetrunk engine

Trunk may refer to:

Biology

* Trunk (anatomy), synonym for torso

* Trunk (botany), a tree's central superstructure

* Trunk of corpus callosum, in neuroanatomy

* Elephant trunk, the proboscis of an elephant

Computing

* Trunk (software), in re ...

in 1848. This was a design to allow a particularly short engine (measured in the direction of its piston rod), that was also able to support a large diameter piston. They were mounted transversely, usually as two cylinder engines, and used for naval ships with relatively high installed power. A trunk engine achieves its short length by having a large diameter, hollow piston rod or 'trunk'. The gudgeon pin

In internal combustion engines, the gudgeon pin (UK, wrist pin or piston pin US) connects the piston to the connecting rod, and provides a bearing for the connecting rod to pivot upon as the piston moves.Nunney, Malcolm James (2007) "The Reciproc ...

of the connecting rod is mounted inside this trunk, allowing the overall length of the two man components, the piston rod and connecting rod, to be telescoped together. As the trunk must be large enough to allow for the angulation of the connecting rod as the crank rotates, this design is limited to large diameter engines. It was also found that as boiler pressure increased, the large diameter seal around the trunk was increasingly prone to leaking.

Double piston rod engines

The trunk engine was largely replaced by the ''double piston-rod'' engine. This was a return connecting rod engine, with the crankshaft between the crosshead and cylinder. Four piston rods were used to pass around the crankshaft, both above and below, and also to each side of the crank, as the crank throw was wider than the vertical spacing of the piston rods. As most of these engines were parallel compounds, two piston rods would be taken from each of the HP and LP pistons. In some engines, double rods were used from the large LP cylinder and a single rod from the HP cylinder, with a yoke to pass around the crankshaft. Double piston rods could also be used from a simple engine, but these required an overhung gudgeon pin on the crosshead, so tended to be limited to smaller engines. An advantage of the double piston rod engine over the trunk was that both ends of the connecting rod were accessible for maintenance. One factor learned from naval use of horizontal cylinders was that, despite previous fears, there was little additional wear owing to the piston's weight resting on the cylinder.

An Admiralty committee of 1858 recommended strongly that older engine designs be abandoned in favour of rationalisation on only three designs: the single piston rod engine (the most recognisable type today), the trunk engine and the double piston rod.

A later variant of the trunk engine re-visited the return connecting rod layout as the vibrating lever or half-trunk engine. This was a paired engine with two short-stroke trunk engines facing outwards. Their connecting rods from the pistons led to upright 'vibrating levers' that could rock back and forth. These levers rotated a short axle shaft with further levers on it that in turn drove another pair of connecting rods and a shared central crankshaft. These complex engines were the invention of the Swedish-American engineer

The trunk engine was largely replaced by the ''double piston-rod'' engine. This was a return connecting rod engine, with the crankshaft between the crosshead and cylinder. Four piston rods were used to pass around the crankshaft, both above and below, and also to each side of the crank, as the crank throw was wider than the vertical spacing of the piston rods. As most of these engines were parallel compounds, two piston rods would be taken from each of the HP and LP pistons. In some engines, double rods were used from the large LP cylinder and a single rod from the HP cylinder, with a yoke to pass around the crankshaft. Double piston rods could also be used from a simple engine, but these required an overhung gudgeon pin on the crosshead, so tended to be limited to smaller engines. An advantage of the double piston rod engine over the trunk was that both ends of the connecting rod were accessible for maintenance. One factor learned from naval use of horizontal cylinders was that, despite previous fears, there was little additional wear owing to the piston's weight resting on the cylinder.

An Admiralty committee of 1858 recommended strongly that older engine designs be abandoned in favour of rationalisation on only three designs: the single piston rod engine (the most recognisable type today), the trunk engine and the double piston rod.

A later variant of the trunk engine re-visited the return connecting rod layout as the vibrating lever or half-trunk engine. This was a paired engine with two short-stroke trunk engines facing outwards. Their connecting rods from the pistons led to upright 'vibrating levers' that could rock back and forth. These levers rotated a short axle shaft with further levers on it that in turn drove another pair of connecting rods and a shared central crankshaft. These complex engines were the invention of the Swedish-American engineer John Ericsson

John Ericsson (born Johan Ericsson; July 31, 1803 – March 8, 1889) was a Swedish-American inventor. He was active in England and the United States.

Ericsson collaborated on the design of the railroad steam locomotive ''Novelty'', which co ...

and were little used outside these two countries.

Maudslay's siamese engine

Other compact alternatives to the return connecting rod or trunk engines were Maudslay's siamese engine and the rare annular piston engine. Like the trunk engine, these placed the gudgeon pin within the length of the piston stroke by having a pair of pistons and a T-shaped crosshead that could relocate the gudgeon pin behind its usual position.Builders

*Humphrys, Tennant and Dykes

Humphrys, Tennant and Dykes (later named Humphrys, Tennant and Co.) was a British engineering company based in Deptford, London, England.

History

The company was founded in 1852 by Edward Humphrys, formerly chief engineer of Woolwich Dockyard, ...

(later named Humphrys, Tenant & Co)

* Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were an ...

* Penn

Directly coupled pumps and blowing engines

A blowing engine is a large

A blowing engine is a large stationary steam engine

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from Steam locomotive, locomotive engines used on Rail transport, railways, traction engines for heavy s ...

directly coupled to air pumping cylinders. They are used to provide the air blast for blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheri ...

s and other forms of smelter

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a c ...

. As the working cylinder and the driven load are both reciprocating pistons, they may be directly coupled by their piston rod. The connecting rod is only used to drive a flywheel whose inertia balances load through the cycle of the engine, not as an output shaft. These engines were some of the last new return connecting rod designs to be built.

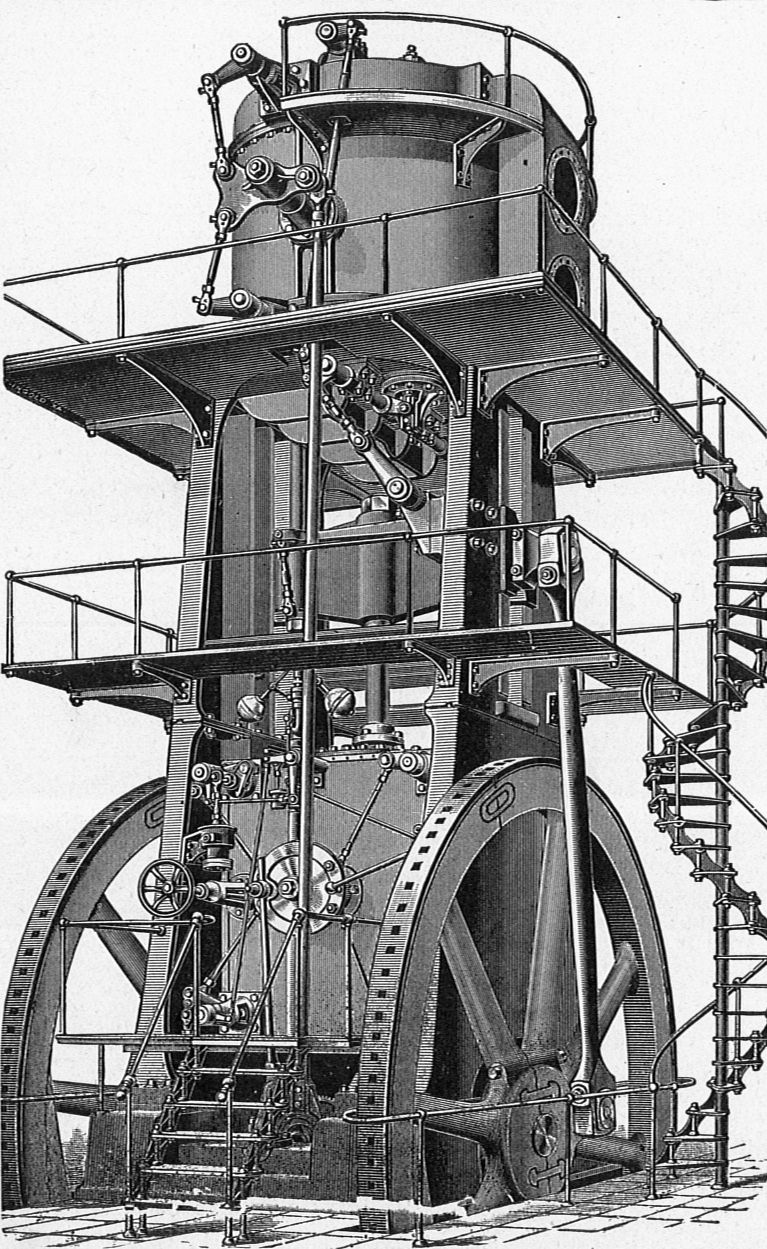

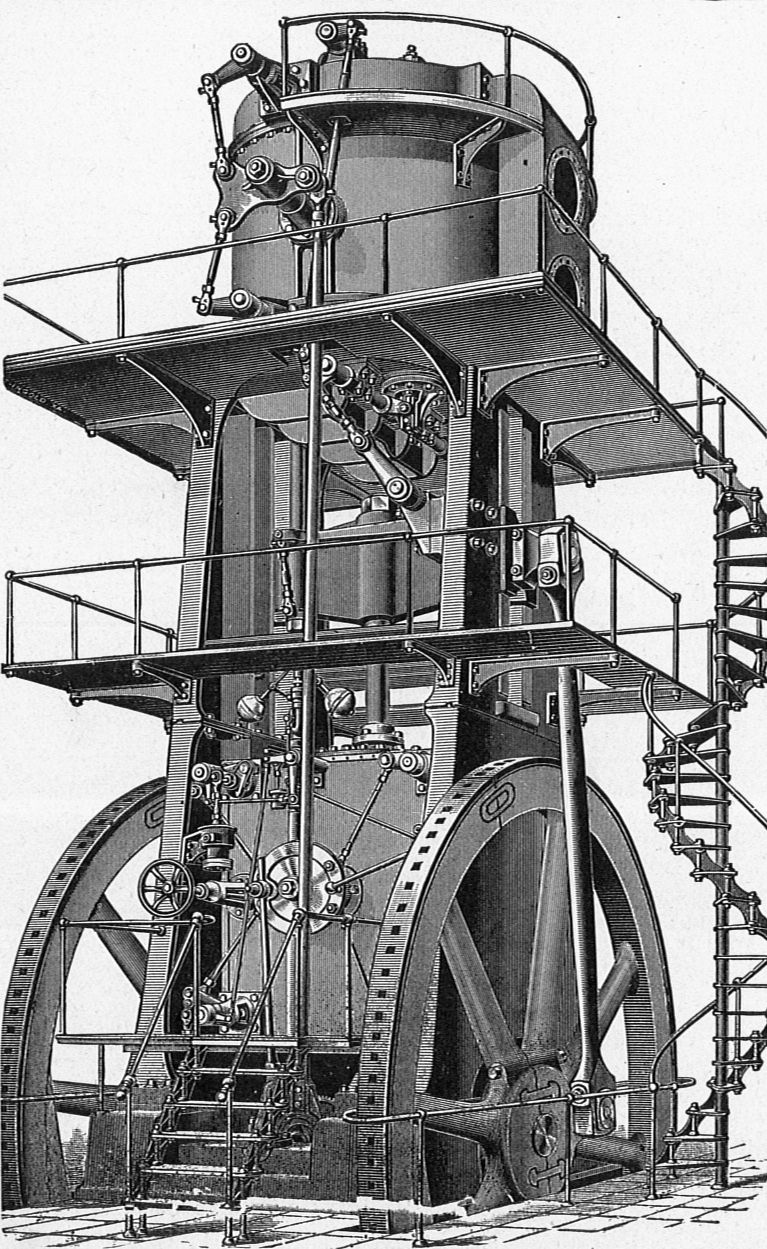

The large vertical blowing engine illustrated was built in the 1890s by E. P. Allis Co. of Milwaukee

Milwaukee ( ), officially the City of Milwaukee, is both the most populous and most densely populated city in the U.S. state of Wisconsin and the county seat of Milwaukee County. With a population of 577,222 at the 2020 census, Milwaukee i ...

(later to form part of Allis-Chalmers

Allis-Chalmers was a U.S. manufacturer of machinery for various industries. Its business lines included agricultural equipment, construction equipment, power generation and power transmission equipment, and machinery for use in industrial s ...

). The air pumping cylinder is above the steam power cylinder and crosshead. The main force of the piston is transmitted to the air cylinder by a purely reciprocating action and the flywheels are there merely to smooth the action of the engine. The flywheel shaft is mounted below the steam piston, the paired connecting rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crank ...

s driving downwards and backwards.

Similar pumping engines were also used in waterworks

Water supply is the provision of water by public utilities, commercial organisations, community endeavors or by individuals, usually via a system of pumps and pipes. Public water supply systems are crucial to properly functioning societies. Th ...

. Inverted vertical engines had their cylinder at the top and water ram pumps at their base, or in a borehole below them. A crankshaft and flywheels were provided in the space between these, for smoother running rather than rotary power output. These were driven from the lower (pump) yoke, by short return connecting rods. Two Worth McKenzie engines of this type; a triple-expansion engine on 1895 and a duplex simple of 1906 were installed at the Waterworks Museum, Hereford, Hereford

Hereford () is a cathedral city, civil parish and the county town of Herefordshire, England. It lies on the River Wye, approximately east of the border with Wales, south-west of Worcester, England, Worcester and north-west of Gloucester. ...

and are preserved in steam there.

Notes

References

{{steam engine configurations Steam engines by layout Steam engines