Process simulation on:

[Wikipedia]

[Google]

[Amazon]

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: chemical plants,

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: chemical plants,

Efforts are made to develop new and improved models for the calculation of properties. This includes for example the description of

* thermophysical properties like

Efforts are made to develop new and improved models for the calculation of properties. This includes for example the description of

* thermophysical properties like

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: chemical plants,

Process simulation is used for the design, development, analysis, and optimization of technical processes such as: chemical plants, chemical process

In a scientific sense, a chemical process is a method or means of somehow changing one or more chemicals or chemical compounds. Such a chemical process can occur by itself or be caused by an outside force, and involves a chemical reaction of some ...

es, environmental systems, power station

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

Many ...

s, complex manufacturing operations, biological processes, and similar technical functions.

Main principle

Process simulation is a model-based representation ofchemical

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., w ...

, physical, biological, and other technical processes and unit operation

In chemical engineering and related fields, a unit operation is a basic step in a process. Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomeriza ...

s in software. Basic prerequisites for the model are chemical and physical properties of pure components and mixtures, of reactions, and of mathematical models which, in combination, allow the calculation of process properties by the software.

Process simulation software describes processes in flow diagram

Flow diagram is a collective term for a diagram representing a flow or set of dynamic relationships in a system. The term flow diagram is also used as a synonym for flowchart, and sometimes as a counterpart of the flowchart.Harris. (1999, p. 156 ...

s where unit operation

In chemical engineering and related fields, a unit operation is a basic step in a process. Unit operations involve a physical change or chemical transformation such as separation, crystallization, evaporation, filtration, polymerization, isomeriza ...

s are positioned and connected by product or educt streams. The software solves the mass

Mass is an intrinsic property of a body. It was traditionally believed to be related to the quantity of matter in a physical body, until the discovery of the atom and particle physics. It was found that different atoms and different eleme ...

and energy balance Energy balance may refer to:

* Earth's energy balance, the relationship between incoming solar radiation, outgoing radiation of all types, and global temperature change.

* Energy accounting, a system used within industry, where measuring and anal ...

to find a stable operating point on specified parameters. The goal of a process simulation is to find optimal conditions for a process. This is essentially an optimization

Mathematical optimization (alternatively spelled ''optimisation'') or mathematical programming is the selection of a best element, with regard to some criterion, from some set of available alternatives. It is generally divided into two subfi ...

problem which has to be solved in an iterative process.

In the example above the feed stream to the column is defined in terms of its chemical and physical properties. This includes the composition of individual molecular species in the stream; the overall mass flowrate; the streams pressure and temperature. For hydrocarbon systems the Vapor-Liquid Equilibrium Ratios (K-Values) or models that are used to define them are specified by the user. The properties of the column are defined such as the inlet pressure and the number of theoretical plates. The duty of the reboiler and overhead condenser are calculated by the model to achieve a specified composition or other parameter of the bottom and/or top product. The simulation calculates the chemical and physical properties of the product streams, each is assigned a unique number which is used in the mass and energy diagram.

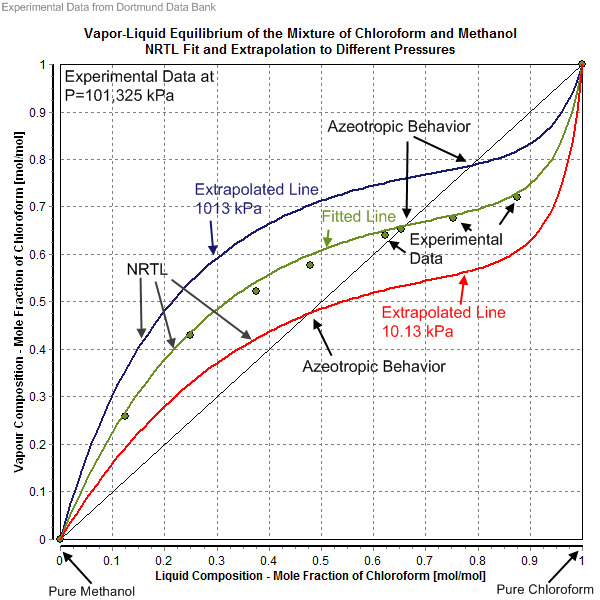

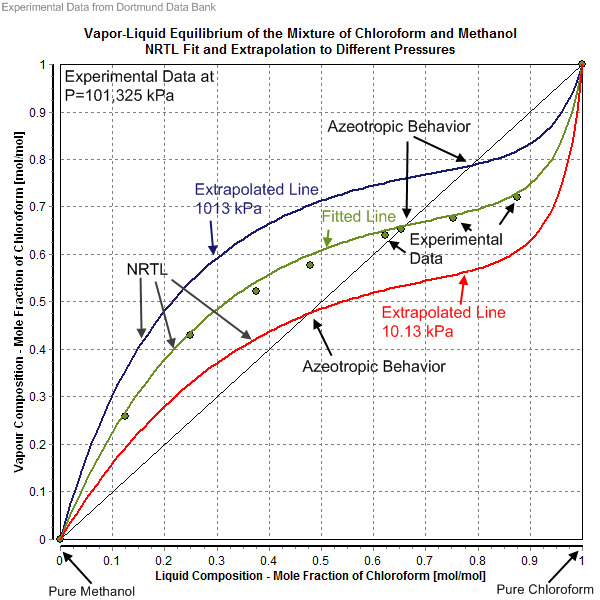

Process simulation uses models which introduce approximations and assumptions but allow the description of a property over a wide range of temperatures and pressures which might not be covered by available real data. Models also allow interpolation and extrapolation

In mathematics, extrapolation is a type of estimation, beyond the original observation range, of the value of a variable on the basis of its relationship with another variable. It is similar to interpolation, which produces estimates between know ...

- within certain limits - and enable the search for conditions outside the range of known properties.

Modelling

The development of models for a better representation of real processes is the core of the further development of the simulation software. Model development is done through the principles of chemical engineering but also control engineering and for the improvement of mathematical simulation techniques. Process simulation is therefore a field where practitioners from chemistry,physics

Physics is the natural science that studies matter, its fundamental constituents, its motion and behavior through space and time, and the related entities of energy and force. "Physical science is that department of knowledge which r ...

, computer science

Computer science is the study of computation, automation, and information. Computer science spans theoretical disciplines (such as algorithms, theory of computation, information theory, and automation) to practical disciplines (includi ...

, mathematics, and engineering

Engineering is the use of scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad range of more speciali ...

work together.

Efforts are made to develop new and improved models for the calculation of properties. This includes for example the description of

* thermophysical properties like

Efforts are made to develop new and improved models for the calculation of properties. This includes for example the description of

* thermophysical properties like vapor pressure

Vapor pressure (or vapour pressure in English-speaking countries other than the US; see spelling differences) or equilibrium vapor pressure is defined as the pressure exerted by a vapor in thermodynamic equilibrium with its condensed phas ...

s, viscosities, caloric data, etc. of pure components and mixtures

* properties of different apparatus like reactors, distillation columns, pumps, etc.

* chemical reactions and kinetics

* environmental and safety-related data

There are two main types of models:

# Simple equations and correlations where parameters are fitted to experimental data.

# Predictive methods where properties are estimated.

The equations and correlations are normally preferred because they describe the property (almost) exactly. To obtain reliable parameters it is necessary to have experimental data which are usually obtained from factual data banks or, if no data are publicly available, from measurements.

Using predictive methods is more cost effective than experimental work and also than data from data banks. Despite this advantage predicted properties are normally only used in early stages of the process development to find first approximate solutions and to exclude false pathways because these estimation methods normally introduce higher errors than correlations obtained from real data.

Process simulation has encouraged the development of mathematical models in the fields of numerics and the solving of complex problems.

History

The history of process simulation is related to the development of thecomputer science

Computer science is the study of computation, automation, and information. Computer science spans theoretical disciplines (such as algorithms, theory of computation, information theory, and automation) to practical disciplines (includi ...

and of computer hardware and programming languages. Early implementations of partial aspects of chemical processes were introduced in the 1970s when suitable hardware and software (here mainly the programming languages FORTRAN and C) became available. The modelling of chemical properties began much earlier, notably the cubic equation of state

In physics, chemistry, and thermodynamics, an equation of state is a thermodynamic equation relating state variables, which describe the state of matter under a given set of physical conditions, such as pressure, volume, temperature, or intern ...

s and the Antoine equation

The Antoine equation is a class of semi-empirical correlations describing the relation between vapor pressure and temperature for pure substances. The Antoine equation is derived from the Clausius–Clapeyron relation. The equation was presente ...

were precursory developments of the 19th century.

Steady state and dynamic process simulation

Initially process simulation was used to simulatesteady state

In systems theory, a system or a process is in a steady state if the variables (called state variables) which define the behavior of the system or the process are unchanging in time. In continuous time, this means that for those properties ''p' ...

processes. Steady-state models perform a mass and energy balance of a steady state process (a process in an equilibrium state) independent of time.

Dynamic simulation is an extension of steady-state process simulation whereby time-dependence is built into the models via derivative terms i.e. accumulation of mass and energy. The advent of dynamic simulation means that the time-dependent description, prediction and control of real processes in real time has become possible. This includes the description of starting up and shutting down a plant, changes of conditions during a reaction, holdups, thermal changes and more.

Dynamic simulations require increased calculation time and are mathematically more complex than a steady state simulation. It can be seen as a multiple repeated steady state simulation (based on a fixed time step) with constantly changing parameters.

Dynamic simulation can be used in both an online and offline fashion. The online case being model predictive control, where the real-time simulation results are used to predict the changes that would occur for a control input change, and the control parameters are optimised based on the results. Offline process simulation can be used in the design, troubleshooting and optimisation of process plant as well as the conduction of case studies to assess the impacts of process modifications. Dynamic simulation is also used for operator training.

See also

*Advanced Simulation Library

Advanced Simulation Library (ASL) is free and open-source hardware-accelerated multiphysics simulation platform. It enables users to write customized numerical solvers in C++ and deploy them on a variety of massively parallel architecture ...

{{cite web, url=http://asl.org.il/benchmarks/physical_vapor_deposition/ , title=ASL: Physical Vapor Deposition Simulation

* Computer simulation

* List of chemical process simulators

* Software Process simulation

References