Powder metallurgy on:

[Wikipedia]

[Google]

[Amazon]

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

Powder metallurgy is also used to make unique materials impossible to get from melting or forming in other ways. A very important product of this type is

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

Powder metallurgy is also used to make unique materials impossible to get from melting or forming in other ways. A very important product of this type is

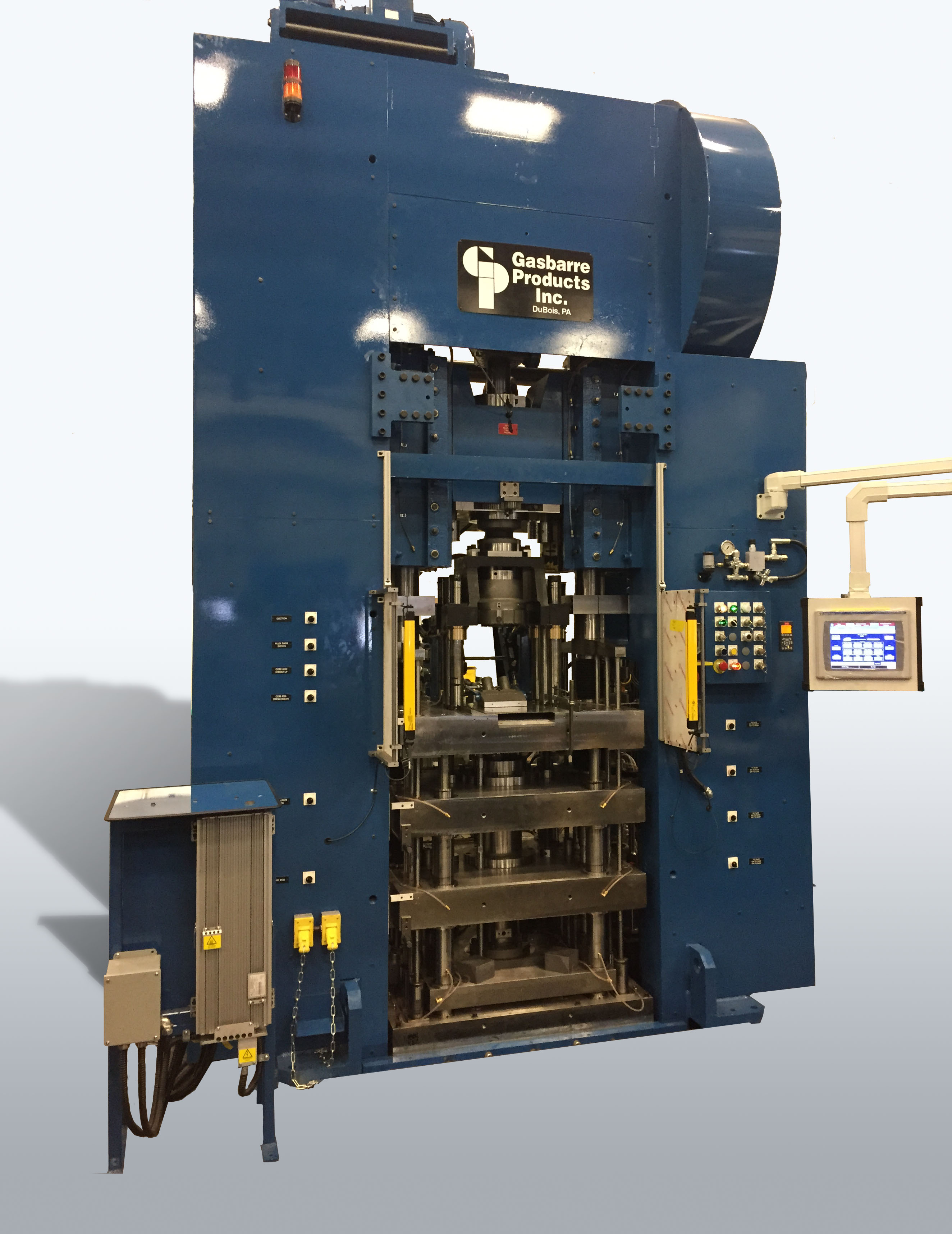

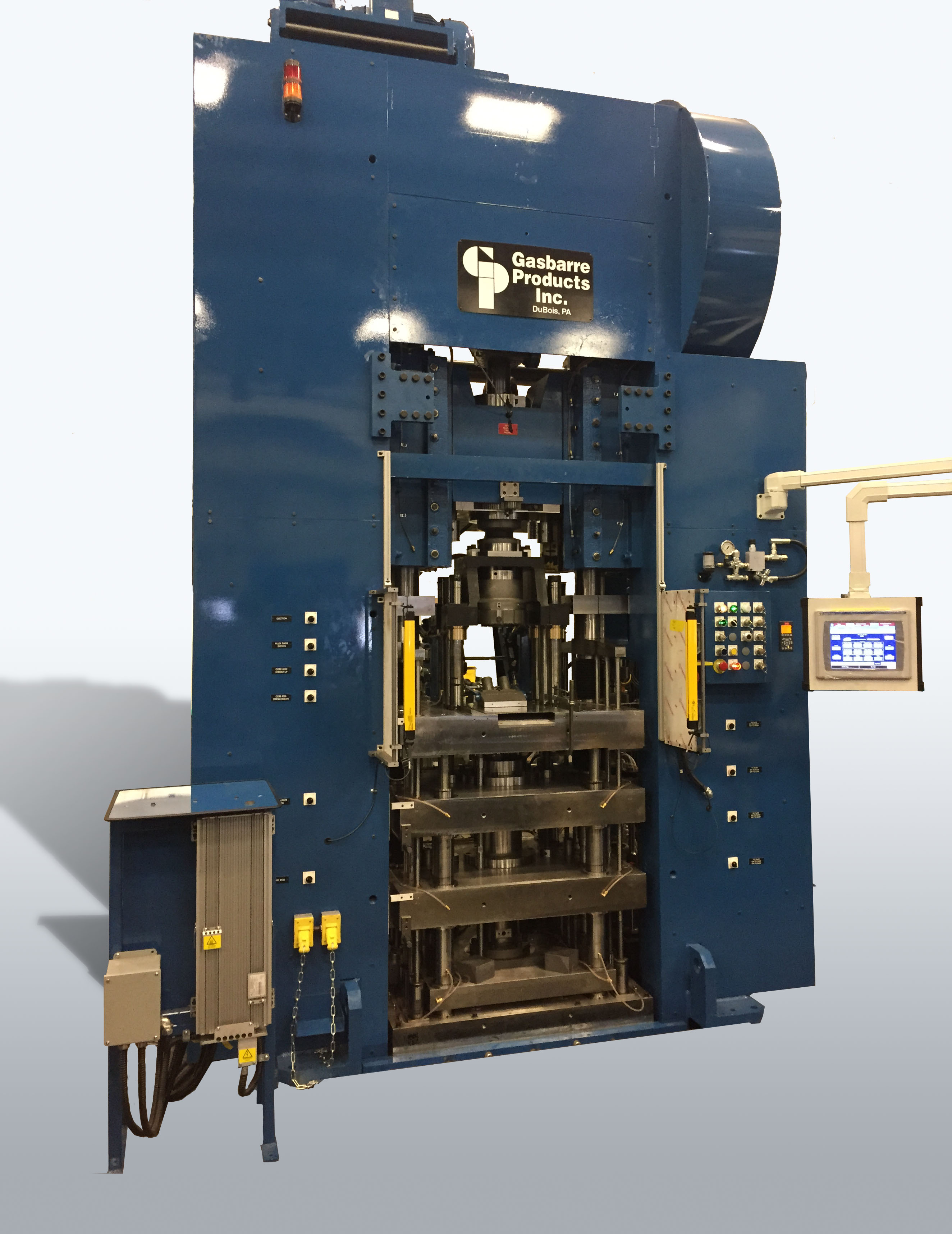

Powder compaction is the process of compacting metal powder in a die through the application of high pressures. Typically the tools are held in the vertical orientation with the punch tool forming the bottom of the cavity. The powder is then compacted into a shape and then ejected from the die cavity. In a number of these applications the parts may require very little additional work for their intended use; making for very cost efficient manufacturing.

The density of the compacted powder increases with the amount of pressure applied. Typical pressures range from 80 psi to 1000 psi (0.5 MPa to 7 MPa), pressures from 1000 psi to 1,000,000 psi have been obtained. Pressure of 10 t/in² to 50 t/in² (150 MPa to 700 MPa) are commonly used for metal powder compaction. To attain the same compression ratio across a component with more than one level or height, it is necessary to work with multiple lower punches. A cylindrical workpiece is made by single-level tooling. A more complex shape can be made by the common multiple-level tooling.

Production rates of 15 to 30 parts per minute are common.

There are four major classes of tool styles: single-action compaction, used for thin, flat components; opposed double-action with two punch motions, which accommodates thicker components; double-action with floating die; and double action withdrawal die. Double action classes give much better density distribution than single action. Tooling must be designed so that it will withstand the extreme pressure without deforming or bending. Tools must be made from materials that are polished and wear-resistant.

Better workpiece materials can be obtained by repressing and re-sintering.

Powder compaction is the process of compacting metal powder in a die through the application of high pressures. Typically the tools are held in the vertical orientation with the punch tool forming the bottom of the cavity. The powder is then compacted into a shape and then ejected from the die cavity. In a number of these applications the parts may require very little additional work for their intended use; making for very cost efficient manufacturing.

The density of the compacted powder increases with the amount of pressure applied. Typical pressures range from 80 psi to 1000 psi (0.5 MPa to 7 MPa), pressures from 1000 psi to 1,000,000 psi have been obtained. Pressure of 10 t/in² to 50 t/in² (150 MPa to 700 MPa) are commonly used for metal powder compaction. To attain the same compression ratio across a component with more than one level or height, it is necessary to work with multiple lower punches. A cylindrical workpiece is made by single-level tooling. A more complex shape can be made by the common multiple-level tooling.

Production rates of 15 to 30 parts per minute are common.

There are four major classes of tool styles: single-action compaction, used for thin, flat components; opposed double-action with two punch motions, which accommodates thicker components; double-action with floating die; and double action withdrawal die. Double action classes give much better density distribution than single action. Tooling must be designed so that it will withstand the extreme pressure without deforming or bending. Tools must be made from materials that are polished and wear-resistant.

Better workpiece materials can be obtained by repressing and re-sintering.

The dominant technology for the forming of products from powder materials, in terms of both tonnage quantities and numbers of parts produced, is die pressing. There are mechanical, servo-electrical and hydraulic presses available in the market, whereby the biggest powder throughput is processed by hydraulic presses.

This forming technology involves a production cycle comprising:

# Filling a die cavity with a known volume of the powder feedstock, delivered from a fill shoe.

# Compaction of the powder within the die with punches to form the compact. Generally, compaction pressure is applied through punches from both ends of the toolset in order to reduce the level of density gradient within the compact.

# Ejection of the compact from the die, using the lower punch(es) withdrawal from the die.

# Removal of the compact from the upper face of the die using the fill shoe in the fill stage of the next cycle, or an automation system or robot.

This cycle offers a readily automated and high production rate process.

The dominant technology for the forming of products from powder materials, in terms of both tonnage quantities and numbers of parts produced, is die pressing. There are mechanical, servo-electrical and hydraulic presses available in the market, whereby the biggest powder throughput is processed by hydraulic presses.

This forming technology involves a production cycle comprising:

# Filling a die cavity with a known volume of the powder feedstock, delivered from a fill shoe.

# Compaction of the powder within the die with punches to form the compact. Generally, compaction pressure is applied through punches from both ends of the toolset in order to reduce the level of density gradient within the compact.

# Ejection of the compact from the die, using the lower punch(es) withdrawal from the die.

# Removal of the compact from the upper face of the die using the fill shoe in the fill stage of the next cycle, or an automation system or robot.

This cycle offers a readily automated and high production rate process.

Rapid manufacturing technique developed at the KU Leuven, BelgiumSlow motion video images of metal atomization at

the Ames Laboratory *APMI International "The Global Professional Society for Powder Metallurg

a non-profit organization {{Authority control Metalworking Ceramic engineering

tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into ...

(WC). WC is used to cut and form other metals and is made from WC particles bonded with cobalt. It is very widely used in industry for tools of many types and globally ~50,000 tonne

The tonne ( or ; symbol: t) is a unit of mass equal to 1000 kilograms. It is a non-SI unit accepted for use with SI. It is also referred to as a metric ton to distinguish it from the non-metric units of the short ton ( United State ...

s/year (t/y) is made by PM. Other products include sintered filters, porous oil-impregnated bearings, electrical contacts and diamond tools.

Since the advent of industrial production–scale metal powder–based additive manufacturing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ...

(AM) in the 2010s, selective laser sintering and other metal AM processes are a new category of commercially important powder metallurgy applications.

Overview

The powder metallurgy press and sinter process generally consists of three basic steps: powder blending (pulverisation), die compaction, and sintering. Compaction is generally performed at room temperature, and the elevated-temperature process of sintering is usually conducted at atmospheric pressure and under carefully controlled atmosphere composition. Optional secondary processing such as coining or heat treatment often follows to obtain special properties or enhanced precision. One of the older such methods, and still one used to make around 1 Mt/y of structural components of iron-based alloys, is the process of blending fine (<180 microns) metal (normally iron) powders with additives such as a lubricant wax,carbon

Carbon () is a chemical element with the symbol C and atomic number 6. It is nonmetallic and tetravalent—its atom making four electrons available to form covalent chemical bonds. It belongs to group 14 of the periodic table. Carbon ma ...

, copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pink ...

, and/or nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow t ...

, pressing them into a die of the desired shape, and then heating the compressed material ("green part") in a controlled atmosphere to bond the material by sintering. This produces precise parts, normally very close to the die dimensions, but with 5–15% porosity, and thus sub-wrought steel properties. There are several other PM processes which have been developed over the last fifty years. These include:

* Powder forging: A "preform" made by the conventional "press and sinter" method is heated and then hot forged to full density, resulting in practically as-wrought properties.

* Hot isostatic pressing (HIP): Here the powder (normally gas atomized, spherical type) is filled into a mould, normally consisting of a metallic "can" of suitable shape. The can is vibrated, then evacuated and sealed. It is then placed in a hot isostatic press, where it is heated to a homologous temperature

Homologous temperature expresses the thermodynamic temperature of a material as a fraction of the thermodynamic temperature of its melting point (i.e. using the Kelvin scale):

T_H = \frac

For example, the homologous temperature of lead at room ...

of around 0.7, and subjected to an external gas pressure of ~100 MPa (1000 bar, 15,000 psi) for several hours. DeGarmo, pp. 469–470 This results in a shaped part of full density with as-wrought or better, properties. HIP was invented in the 1950-60s and entered tonnage production in the 1970-80s. In 2015, it was used to produce ~25,000 t/y of stainless and tool steels, as well as important parts of superalloys for jet engines.

* Metal injection moulding (MIM): Here the powder, normally very fine (<25 microns) and spherical, is mixed with plastic or wax binder to near the maximum solid loading, typically around 65vol%, and injection moulded to form a "green" part of complex geometry. This part is then heated or otherwise treated to remove the binder (debinding) to give a "brown" part. This part is then sintered, and shrinks by ~18% to give a complex and 95–99% dense finished part (surface roughness ~3 microns). Invented in the 1970s, production has increased since 2000 with an estimated global volume in 2014 of 12,000 t worth €1265 million.

* Electric current assisted sintering (ECAS) technologies rely on electric currents to densify powders, with the advantage of reducing production time dramatically (from 15 minutes of the slowest ECAS to a few microseconds of the fastest), not requiring a long furnace heat and allowing near theoretical densities but with the drawback of simple shapes. Powders employed in ECAS can avoid binders thanks to the possibility of direct sintering, without the need of pre-pressing and a green compact. Molds are designed for the final part shape since the powders densify while filling the cavity under an applied pressure thus avoiding the problem of shape variations caused by non isotropic sintering and distortions caused by gravity at high temperatures. The most common of these technologies is hot pressing, which has been under use for the production of the diamond tools employed in the construction industry. Spark plasma sintering Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique.

The main characteristic of SPS is that the pulsed or u ...

and electro sinter forging Electro sinter forging (ESF) is an industrial single electromagnetic pulse sintering technique to rapidly produce a wide range of small components in metals, alloys, intermetallics, semiconductors, and composites. ESF was invented by Alessandro Fa ...

are two modern, industrial commercial ECAS technologies.

* Additive manufacturing (AM) is a relatively novel family of techniques which use metal powders (among other materials, such as plastics) to make parts by laser sintering or melting. This is a process under rapid development , and whether to classify it as a PM process is perhaps uncertain at this stage. Processes include 3D printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ...

, selective laser sintering (SLS), selective laser melting (SLM), and electron beam melting (EBM).

History and capabilities

The history of powder metallurgy and the art of metal andceramic

A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, ...

sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

are intimately related to each other. Sintering involves the production of a hard solid metal or ceramic piece from a starting powder. The ancient Incas made jewelry and other artifacts from precious metal powders, though mass manufacturing of PM products did not begin until the mid or late 19th century. In these early manufacturing operations, iron was extracted by hand from metal sponge following reduction and was then reintroduced as a powder for final melting or sintering.

A much wider range of products can be obtained from powder processes than from direct alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductili ...

ing of fused materials. In melting operations the "phase rule

In thermodynamics, the phase rule is a general principle governing "pVT" systems, whose thermodynamic states are completely described by the variables pressure (), volume () and temperature (), in thermodynamic equilibrium. If is the number of d ...

" applies to all pure and combined elements and strictly dictates the distribution of liquid and solid phases which can exist for specific compositions. In addition, whole body melting of starting materials is required for alloying, thus imposing unwelcome chemical, thermal, and containment constraints on manufacturing. Unfortunately, the handling of aluminium/iron powders poses major problems. Other substances that are especially reactive with atmospheric oxygen, such as titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion i ...

, are sinterable in special atmospheres or with temporary coatings.

In powder metallurgy or ceramics it is possible to fabricate components which otherwise would decompose or disintegrate. All considerations of solid-liquid phase changes can be ignored, so powder processes are more flexible than casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejecte ...

, extrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile by pushing material through a die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex c ...

, or forging

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. The blows are delivered with a hammer (often a power hammer) or a die. Forging is often classified according to the temperature at which ...

techniques. Controllable characteristics of products prepared using various powder technologies include mechanical, magnetic, and other unconventional properties of such materials as porous solids, aggregates, and intermetallic compounds. Competitive characteristics of manufacturing processing (e.g. tool wear, complexity, or vendor options) also may be closely controlled.

Powder production techniques

Any fusible material can be atomized. Several techniques have been developed which permit large production rates of powdered particles, often with considerable control over the size ranges of the final grain population. Powders may be prepared by crushing, grinding, chemical reactions, or electrolytic deposition. The most commonly used powders are copper-base and iron-base materials. Powders of the elements titanium, vanadium, thorium, niobium, tantalum, calcium, and uranium have been produced by high-temperature reduction of the correspondingnitride

In chemistry, a nitride is an inorganic compound of nitrogen. The "nitride" anion, N3- ion, is very elusive but compounds of nitride are numerous, although rarely naturally occuring. Some nitrides have a find applications, such as wear-resistant ...

s and carbide

In chemistry, a carbide usually describes a compound composed of carbon and a metal. In metallurgy, carbiding or carburizing is the process for producing carbide coatings on a metal piece.

Interstitial / Metallic carbides

The carbides of t ...

s. Iron, nickel, uranium, and beryllium submicrometre powders are obtained by reducing metallic oxalate

Oxalate (IUPAC: ethanedioate) is an anion with the formula C2O42−. This dianion is colorless. It occurs naturally, including in some foods. It forms a variety of salts, for example sodium oxalate (Na2C2O4), and several esters such as dimethyl ...

s and formate

Formate (IUPAC name: methanoate) is the conjugate base of formic acid. Formate is an anion () or its derivatives such as ester of formic acid. The salts and esters are generally colorless.Werner Reutemann and Heinz Kieczka "Formic Acid" in ''Ull ...

s. Exceedingly fine particles also have been prepared by directing a stream of molten metal through a high-temperature plasma jet or flame

A flame (from Latin '' flamma'') is the visible, gaseous part of a fire. It is caused by a highly exothermic chemical reaction taking place in a thin zone. When flames are hot enough to have ionized gaseous components of sufficient density the ...

, atomizing the material. Various chemical and flame associated powdering processes are adopted in part to prevent serious degradation of particle surfaces by atmospheric oxygen.

In tonnage terms, the production of iron powders for PM structural part production dwarfs the production of all of the non-ferrous metal powders combined. Virtually all iron powders are produced by one of two processes: the sponge iron process or water atomization.

Sponge iron process

The longest established of these processes is the sponge iron process, the leading example of a family of processes involving solid state reduction of an oxide. In the process, selected magnetite (Fe3O4) ore is mixed with coke and lime and placed in a silicon carbide retort. The filled retort is then heated in a kiln, where the reduction process leaves an iron “cake” and a slag. In subsequent steps, the retort is emptied, the reduced iron sponge is separated from the slag and is crushed and annealed. The resultant powder is highly irregular in particle shape, therefore ensuring good “green strength Green strength, or handling strength, can be defined as the strength of a material as it is processed to form its final ultimate tensile strength. This strength is usually considerably lower than the final ultimate strength of a material. The term ...

” so that die-pressed compacts can be readily handled prior to sintering, and each particle contains internal pores (hence the term “sponge”) so that the good green strength is available at low compacted density levels.

Sponge iron provides the

feedstock for all iron-based self-lubricating bearings, and still accounts for around 30% of iron powder usage in PM structural parts.

Atomization

Atomization is accomplished by forcing a molten metal stream through an orifice at moderate pressures. A gas is introduced into the metal stream just before it leaves the nozzle, serving to create turbulence as the entrained gas expands (due to heating) and exits into a large collection volume exterior to the orifice. The collection volume is filled with gas to promote further turbulence of the molten metal jet. Air and powder streams are segregated using gravity orcyclonic separation

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone ...

. Most atomized powders are annealed, which helps reduce the oxide and carbon content. The water atomized particles are smaller, cleaner, and nonporous and have a greater breadth of size, which allows better compacting. The particles produced through this method are normally of spherical or pear shape. Usually, they also carry a layer of oxide over them.

There are three types of atomization:

* Liquid atomization

* Gas atomization

* Centrifugal atomization

Simple atomization techniques are available in which liquid metal is forced through an orifice at a sufficiently high velocity to ensure turbulent flow. The usual performance index used is the Reynolds number

In fluid mechanics, the Reynolds number () is a dimensionless quantity that helps predict fluid flow patterns in different situations by measuring the ratio between inertial and viscous forces. At low Reynolds numbers, flows tend to be dom ...

R = fvd/n, where f = fluid density, v = velocity of the exit stream, d = diameter of the opening, and n = absolute viscosity. At low R the liquid jet oscillates, but at higher velocities the stream becomes turbulent and breaks into droplets. Pumping energy is applied to droplet formation with very low efficiency (on the order of 1%) and control over the size distribution of the metal particles produced is rather poor. Other techniques such as nozzle vibration, nozzle asymmetry, multiple impinging streams, or molten-metal injection into ambient gas are all available to increase atomization efficiency, produce finer grains, and to narrow the particle size distribution. Unfortunately, it is difficult to eject metals through orifices smaller than a few millimeters in diameter, which in practice limits the minimum size of powder grains to approximately 10 μm. Atomization also produces a wide spectrum of particle sizes, necessitating downstream classification by screening and remelting a significant fraction of the grain boundary.

Centrifugal disintegration

Centrifugal disintegration of molten particles offers one way around these problems. Extensive experience is available with iron, steel, and aluminium. Metal to be powdered is formed into a rod which is introduced into a chamber through a rapidly rotating spindle. Opposite the spindle tip is an electrode from which an arc is established which heats the metal rod. As the tip material fuses, the rapid rod rotation throws off tiny melt droplets which solidify before hitting the chamber walls. A circulating gas sweeps particles from the chamber. Similar techniques could be employed in space or on the Moon. The chamber wall could be rotated to force new powders into remote collection vessels, DeGarmo, pp. 322–324 and the electrode could be replaced by a solar mirror focused at the end of the rod. An alternative approach capable of producing a very narrow distribution of grain sizes but with low throughput consists of a rapidly spinning bowl heated to well above the melting point of the material to be powdered. Liquid metal, introduced onto the surface of the basin near the center at flow rates adjusted to permit a thin metal film to skim evenly up the walls and over the edge, breaks into droplets, each approximately the thickness of the film.Other techniques

Another powder-production technique involves a thin jet of liquid metal intersected by high-speed streams of atomized water which break the jet into drops and cool the powder before it reaches the bottom of the bin. In subsequent operations the powder is dried. This is called water atomization. The advantage of water atomization is that metal solidifies faster than by gas atomization since the heat capacity of water is some magnitudes higher than gases. Since the solidification rate is inversely proportional to the particle size, smaller particles can be made using water atomization. The smaller the particles, the more homogeneous the micro structure will be. Notice that particles will have a more irregular shape and the particle size distribution will be wider. In addition, some surface contamination can occur by oxidation skin formation. Powder can be reduced by some kind of pre-consolidation treatment, such as annealing used for the manufacture of ceramic tools.Powder compaction

Powder compaction is the process of compacting metal powder in a die through the application of high pressures. Typically the tools are held in the vertical orientation with the punch tool forming the bottom of the cavity. The powder is then compacted into a shape and then ejected from the die cavity. In a number of these applications the parts may require very little additional work for their intended use; making for very cost efficient manufacturing.

The density of the compacted powder increases with the amount of pressure applied. Typical pressures range from 80 psi to 1000 psi (0.5 MPa to 7 MPa), pressures from 1000 psi to 1,000,000 psi have been obtained. Pressure of 10 t/in² to 50 t/in² (150 MPa to 700 MPa) are commonly used for metal powder compaction. To attain the same compression ratio across a component with more than one level or height, it is necessary to work with multiple lower punches. A cylindrical workpiece is made by single-level tooling. A more complex shape can be made by the common multiple-level tooling.

Production rates of 15 to 30 parts per minute are common.

There are four major classes of tool styles: single-action compaction, used for thin, flat components; opposed double-action with two punch motions, which accommodates thicker components; double-action with floating die; and double action withdrawal die. Double action classes give much better density distribution than single action. Tooling must be designed so that it will withstand the extreme pressure without deforming or bending. Tools must be made from materials that are polished and wear-resistant.

Better workpiece materials can be obtained by repressing and re-sintering.

Powder compaction is the process of compacting metal powder in a die through the application of high pressures. Typically the tools are held in the vertical orientation with the punch tool forming the bottom of the cavity. The powder is then compacted into a shape and then ejected from the die cavity. In a number of these applications the parts may require very little additional work for their intended use; making for very cost efficient manufacturing.

The density of the compacted powder increases with the amount of pressure applied. Typical pressures range from 80 psi to 1000 psi (0.5 MPa to 7 MPa), pressures from 1000 psi to 1,000,000 psi have been obtained. Pressure of 10 t/in² to 50 t/in² (150 MPa to 700 MPa) are commonly used for metal powder compaction. To attain the same compression ratio across a component with more than one level or height, it is necessary to work with multiple lower punches. A cylindrical workpiece is made by single-level tooling. A more complex shape can be made by the common multiple-level tooling.

Production rates of 15 to 30 parts per minute are common.

There are four major classes of tool styles: single-action compaction, used for thin, flat components; opposed double-action with two punch motions, which accommodates thicker components; double-action with floating die; and double action withdrawal die. Double action classes give much better density distribution than single action. Tooling must be designed so that it will withstand the extreme pressure without deforming or bending. Tools must be made from materials that are polished and wear-resistant.

Better workpiece materials can be obtained by repressing and re-sintering.

Die pressing

The dominant technology for the forming of products from powder materials, in terms of both tonnage quantities and numbers of parts produced, is die pressing. There are mechanical, servo-electrical and hydraulic presses available in the market, whereby the biggest powder throughput is processed by hydraulic presses.

This forming technology involves a production cycle comprising:

# Filling a die cavity with a known volume of the powder feedstock, delivered from a fill shoe.

# Compaction of the powder within the die with punches to form the compact. Generally, compaction pressure is applied through punches from both ends of the toolset in order to reduce the level of density gradient within the compact.

# Ejection of the compact from the die, using the lower punch(es) withdrawal from the die.

# Removal of the compact from the upper face of the die using the fill shoe in the fill stage of the next cycle, or an automation system or robot.

This cycle offers a readily automated and high production rate process.

The dominant technology for the forming of products from powder materials, in terms of both tonnage quantities and numbers of parts produced, is die pressing. There are mechanical, servo-electrical and hydraulic presses available in the market, whereby the biggest powder throughput is processed by hydraulic presses.

This forming technology involves a production cycle comprising:

# Filling a die cavity with a known volume of the powder feedstock, delivered from a fill shoe.

# Compaction of the powder within the die with punches to form the compact. Generally, compaction pressure is applied through punches from both ends of the toolset in order to reduce the level of density gradient within the compact.

# Ejection of the compact from the die, using the lower punch(es) withdrawal from the die.

# Removal of the compact from the upper face of the die using the fill shoe in the fill stage of the next cycle, or an automation system or robot.

This cycle offers a readily automated and high production rate process.

Design considerations

Probably the most basic consideration is being able to remove the part from the die after it is pressed, along with avoiding sharp corners in the design. Keeping the maximum surface area below and the height-to-diameter ratio below 7-to-1 is recommended. Along with having walls thicker than and keeping the adjacent wall thickness ratios below 2.5-to-1. One of the major advantages of this process is its ability to produce complex geometries. Parts with undercuts and threads require a secondary machining operation. Typical part sizes range from to . in area and from in length. However, it is possible to produce parts that are less than and larger than . in area and from a fraction of an inch (2.54 cm) to approximately in length.Isostatic pressing

In some pressing operations, such ashot isostatic pressing

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

The process can be used to p ...

(HIP) compact formation and sintering occur simultaneously. This procedure, together with explosion-driven compressive techniques is used extensively in the production of high-temperature and high-strength parts such as turbine disks for jet engines. In most applications of powder metallurgy the compact is hot-pressed, heated to a temperature above which the materials cannot remain work-hardened. Hot pressing lowers the pressures required to reduce porosity and speeds welding and grain deformation processes. It also permits better dimensional control of the product, lessens sensitivity to physical characteristics of starting materials, and allows powder to be compressed to higher densities than with cold pressing, resulting in higher strength. Negative aspects of hot pressing include shorter die life, slower throughput because of powder heating, and the frequent necessity for protective atmospheres during forming and cooling stages.

Isostatic powder compacting

Isostatic powder compacting is a mass-conserving shaping process. Fine metal particles are placed into a flexible mould and then high fluid pressure is applied to the mold, in contrast to the direct pressure applied by the die faces of a die pressing process. The resulting article is then sintered in a furnace which increases the strength of the part by bonding the metal particles. This manufacturing process produces very little scrap metal and can be used to make many different shapes. The tolerances that this process can achieve are very precise, ranging from +/- 0.008 inches (0.2 mm) for axial dimensions and +/- 0.020 inches (0.5 mm) for radial dimensions. This is the most efficient type of powder compacting (the following subcategories are also from this reference).Todd, Robert H., Allen, Dell K., Alting, Leo1994 ''Manufacturing Processes Reference Guide'', Industrial Press Inc., New York, This operation is generally only applicable on small production quantities, although the cost of a mold much lower than that of pressing dies it is generally not reusable and the production time is much longer. Compacting pressures range from to for most metals and approximately to for non-metals. The density of isostatic compacted parts is 5% to 10% higher than with other powder metallurgy processes.Equipment

There are many types of equipment used in isostatic powder compacting. There is the mold containing the part, which is flexible, a flexible outer pressure mold that contains and seals the mold, and the machine delivering the pressure. There are also devices to control the amount of pressure and how long the pressure is held. The machines need to apply pressures from for metals.Geometrical possibilities

Typical workpiece sizes range from to thick and to long. It is possible to compact workpieces that are between and thick and to long.Tool style

Isostatic tools are available in three styles, free mold (wet-bag), coarse mold (damp-bag) and fixed mold (dry-bag). The free mold style is the traditional style of isostatic compaction and is not generally used for high production work. In free mold tooling the mold is removed and filled outside the canister. Damp bag is where the mold is located in the canister, yet filled outside. In fixed mold tooling, the mold is contained within the canister, which facilitates automation of the process.Hot isostatic pressing

Hot isostatic pressing (HIP) compresses and sinters the part simultaneously by applying heat ranging from 900 °F (480 °C) to 2250 °F (1230 °C).Argon

Argon is a chemical element with the symbol Ar and atomic number 18. It is in group 18 of the periodic table and is a noble gas. Argon is the third-most abundant gas in Earth's atmosphere, at 0.934% (9340 ppmv). It is more than twice a ...

gas is the most common gas used in HIP because it is an inert gas, thus prevents chemical reactions during the operation.

Cold isostatic pressing

Cold isostatic pressing (CIP) uses fluid as a means of applying pressure to the mold at room temperature. After removal the part still needs to be sintered. It is helpful in distributing pressure uniformly over the compaction material contained in a rubber bag.Design considerations

Advantages over standard powder compaction are the possibility of thinner walls and larger workpieces. Height to diameter ratio has no limitation. No specific limitations exist in wall thickness variations, undercuts, reliefs, threads, and cross holes. No lubricants are need for isostatic powder compaction. The minimum wall thickness is 0.05 inches (1.27 mm) and the product can have a weight between 40 and 300 pounds (18 and 136 kg). There is 25 to 45% shrinkage of the powder after compacting.Sintering

After compaction, powdered materials are heated in a controlled atmosphere in a process known as sintering. During this process, the surfaces of the particles are bonded and desirable properties are achieved.Sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

of powder metals is a process in which particles under pressure chemically bond to themselves in order to form a coherent shape when exposed to a high temperature. The temperature in which the particles are sintered is most commonly below the melting point of the main component in the powder. If the temperature is above the melting point of a component in the powder metal part, the liquid of the melted particles fills the pores. This type of sintering is known as liquid-state sintering. A major challenge with sintering in general is knowing the effect of the process on the dimensions of the compact particles. This is especially difficult for tooling purposes in which specific dimensions may be needed. It is most common for the sintered part to shrink and become denser, but it can also expand or experience no net change.

The main driving force for solid state sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

is an excess of surface free energy. The process of solid-state sintering is complex and dependent on the material and furnace (temperature and gas) conditions. There are six main stages that sintering processes can be grouped in which may overlap with one another: 1 initial bonding among particles, 2) neck growth, 3) pore channel closure, 4) pore rounding, 5) densification or pore shrinkage, and 6) pore coarsening. The main mechanisms present in these stages are evaporation

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. High concentration of the evaporating substance in the surrounding gas significantly slows down evaporation, such as when h ...

, condensation

Condensation is the change of the state of matter from the gas phase into the liquid phase, and is the reverse of vaporization. The word most often refers to the water cycle. It can also be defined as the change in the state of water vapo ...

, grain boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional defects in the crystal structure, and tend to decrease the electrical and therma ...

, volume diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical ...

, and plastic deformation

In engineering, deformation refers to the change in size or shape of an object. ''Displacements'' are the ''absolute'' change in position of a point on the object. Deflection is the relative change in external displacements on an object. Strain ...

.

Most sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

furnaces contain three zones with three different properties that help to carry out the six steps above. The first zone, commonly coined the burn-off or purge stage, is designed to combust air, burn any contaminants such as lubricant or binders, and slowly raise the temperature of the compact materials. If the temperature of the compact parts is raised too quickly, the air in the pores will be at a very high internal pressure which could lead to expansion or fracture of the part. The second zone, known as the high-temperature stage, is used to produce solid-state diffusion and particle bonding. The material is seeking to lower its surface energy

In surface science, surface free energy (also interfacial free energy or surface energy) quantifies the disruption of intermolecular bonds that occurs when a surface is created. In solid-state physics, surfaces must be intrinsically less ener ...

and does so by moving toward the points of contact between particles. The contact points become larger and eventually a solid mass with small pores is created. The third zone, also called the cooling period, is used to cool down the parts while still in a controlled atmosphere. This is an important zone as it prevents oxidation from immediate contact with the air or a phenomenon known as rapid cooling. All of the three stages must be carried out in a controlled atmosphere containing no oxygen. Hydrogen, nitrogen, dissociated ammonia, and cracked hydrocarbons are common gases pumped into the furnace zones providing a reducing atmosphere, preventing oxide formation.

During this process, a number of characteristics are increased including the strength, ductility

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile str ...

, toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.thermal conductivity

The thermal conductivity of a material is a measure of its ability to conduct heat. It is commonly denoted by k, \lambda, or \kappa.

Heat transfer occurs at a lower rate in materials of low thermal conductivity than in materials of high thermal ...

of the material. If different elemental powders are compact and sintered, the material would form into alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductili ...

s and intermetallic phases.

As the pore sizes decrease, the density of the material will increase. As stated above, this shrinkage is a huge problem in making parts or tooling in which particular dimensions are required. The shrinkage of test materials is monitored and used to manipulate the furnace conditions or to oversize the compact materials in order to achieve the desired dimensions. Although, sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

does not deplete the compact part of porosity

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measur ...

. In general, powder metal parts contain five to twenty-five percent porosity after sintering.

To allow efficient stacking of product in the furnace during sintering and prevent parts sticking together, many manufacturers separate ware using ceramic powder separator sheets. These sheets are available in various materials such as alumina, zirconia, and magnesia. They are also available in fine, medium, and coarse particle sizes. By matching the material and particle size to the wares being sintered, surface damage and contamination can be reduced, while maximizing furnace loading per batch.

One recently developed technique for high-speed sintering involves passing high electric current through a powder to preferentially heat the asperities. Most of the energy serves to melt that portion of the compact where migration is desirable for densification; comparatively little energy is absorbed by the bulk materials and forming machinery. Naturally, this technique is not applicable to electrically insulating powders.

Continuous powder processing

The phrase "continuous process" should be used only to describe modes of manufacturing which could be extended indefinitely in time. Normally, however, the term refers to processes whose products are much longer in one physical dimension than in the other two. Compression, rolling, and extrusion are the most common examples. In a simple compression process, powder flows from a bin onto a two-walled channel and is repeatedly compressed vertically by a horizontally stationary punch. After stripping the compress from the conveyor, the compacted mass is introduced into a sintering furnace. An even easier approach is to spray powder onto a moving belt and sinter it without compression. However, good methods for stripping cold-pressed materials from moving belts are hard to find. One alternative that avoids the belt-stripping difficulty altogether is the manufacture of metal sheets using opposed hydraulic rams, although weakness lines across the sheet may arise during successive press operations. Powders can also be rolled to produce sheets. The powdered metal is fed into a two-high rolling mill, and is compacted into strip form at up to . The strip is then sintered and subjected to another rolling and further sintering. Rolling is commonly used to produce sheet metal for electrical and electronic components, as well ascoin

A coin is a small, flat (usually depending on the country or value), round piece of metal or plastic used primarily as a medium of exchange or legal tender. They are standardized in weight, and produced in large quantities at a mint in order ...

s. Considerable work also has been done on rolling multiple layers of different materials simultaneously into sheets.

Extrusion processes are of two general types. In one type, the powder is mixed with a binder or plasticizer

A plasticizer ( UK: plasticiser) is a substance that is added to a material to make it softer and more flexible, to increase its plasticity, to decrease its viscosity, and/or to decrease friction during its handling in manufacture.

Plasticiz ...

at room temperature; in the other, the powder is extruded at elevated temperatures without fortification. Extrusions with binders are used extensively in the preparation of tungsten-carbide composites. Tubes, complex sections, and spiral drill shapes are manufactured in extended lengths and diameters varying in the range . Hard metal wires of diameter have been drawn from powder stock. At the opposite extreme, large extrusions on a tonnage basis may be feasible.

For softer, easier to form metals such as aluminium and copper alloys continuous extrusion may also be performed using processes such as conform or continuous rotary extrusion. These processes use a rotating wheel with a groove around its circumference to drive the loose powder through a forming die. Through a combination of high pressure and a complex strain path the powder particles deform, generate a large amount of frictional heat and bond together to form a bulk solid. Theoretically fully continuous operation is possible as long as the powder can be fed into the process.

There appears to be no limitation to the variety of metals and alloys that can be extruded, provided the temperatures and pressures involved are within the capabilities of die materials. Extrusion lengths may range from 3 to 30 m and diameters from 0.2 to 1 m. Modern presses are largely automatic and operate at high speeds (on the order of m/s).

Shock (dynamic) consolidation

Shock consolidation, or dynamic consolidation, is an experimental technique of consolidating powders using high pressure shock waves. These are commonly produced by impacting the workpiece with an explosively accelerated plate. Despite being researched for a long time, the technique still has some problems in controlability and uniformity. However, it offers some valuable potential advantages. As an example, consolidation occurs so rapidly that metastable microstructures may be retained.Electric current assisted sintering

These techniques employ electric currents to drive or enhance sintering. Through a combination of electric currents and mechanical pressure powders sinter more rapidly thereby reducing the sintering time compared to conventional thermal solutions. The techniques can be divided into two main categories: resistance sintering, which incorporatesspark plasma sintering Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique.

The main characteristic of SPS is that the pulsed or u ...

and hot pressing; and electric discharge sintering, such as capacitor discharge sintering or its derivative, electro sinter forging Electro sinter forging (ESF) is an industrial single electromagnetic pulse sintering technique to rapidly produce a wide range of small components in metals, alloys, intermetallics, semiconductors, and composites. ESF was invented by Alessandro Fa ...

. Resistance sintering techniques are consolidation methods based on temperature, where heating of the mold and of the powders is accomplished through electric currents, usually with a characteristic processing time of 15 to 30 minutes. On the other hand, electric discharge sintering methods rely on high-density currents (from 0.1 to 1 kA/mm^2) to directly sinter electrically conductive powders, with a characteristic time between tens of microseconds to hundreds of milliseconds.

Special products

Many special products are possible with powder metallurgy technology. A nonexhaustive list includes Al2O3 whiskers coated with very thin oxide layers for improved refraction; iron compacts with Al2O3 coatings for improved high-temperature creep strength;light bulb

An electric light, lamp, or light bulb is an electrical component that produces light. It is the most common form of artificial lighting. Lamps usually have a base made of ceramic, metal, glass, or plastic, which secures the lamp in the soc ...

filaments made with powder technology; linings for friction brakes; metal glasses for high-strength films and ribbons; heat shield

In thermodynamics, heat is defined as the form of energy crossing the boundary of a thermodynamic system by virtue of a temperature difference across the boundary. A thermodynamic system does not ''contain'' heat. Nevertheless, the term is al ...

s for spacecraft reentry into Earth's atmosphere; electrical contacts for handling large current flows; magnet

A magnet is a material or object that produces a magnetic field. This magnetic field is invisible but is responsible for the most notable property of a magnet: a force that pulls on other ferromagnetic materials, such as iron, steel, nicke ...

s; microwave

Microwave is a form of electromagnetic radiation with wavelengths ranging from about one meter to one millimeter corresponding to frequencies between 300 MHz and 300 GHz respectively. Different sources define different frequency ra ...

ferrites; filters for gases; and bearings which can be infiltrated with lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, t ...

s.

Extremely thin films and tiny spheres exhibit high strength. One application of this observation is to coat brittle materials in whisker form with a submicrometre film of much softer metal (e.g. cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, p ...

-coated tungsten). The surface strain of the thin layer places the harder metal under compression, so that when the entire composite is sintered the rupture strength increases markedly. With this method, strengths on the order of 2.8 GPa versus 550 MPa have been observed for, respectively, coated (25% cobalt) and uncoated tungsten carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into ...

s.

Hazards

The special materials and processes used in powder metallurgy can pose hazards to life and property. The high surface-area-to-volume ratio of the powders can increase their chemical reactivity in biological exposures (for example, inhalation or ingestion), and increases the risk of dust explosions. Materials considered relatively benign in bulk can pose special toxicological risks when in a finely divided form. Inhalation of heavy metals can result in many health issues. Lead and cadmium are generally toxic, and cobalt can cause asthma and fibrosis in sensitive individuals.See also

*Electro sinter forging Electro sinter forging (ESF) is an industrial single electromagnetic pulse sintering technique to rapidly produce a wide range of small components in metals, alloys, intermetallics, semiconductors, and composites. ESF was invented by Alessandro Fa ...

* Mechanical powder press

* Selective laser melting

* Selective laser sintering

*Sintering

Clinker nodules produced by sintering

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction.

Sintering happens as part of a manufacturing ...

*Spark plasma sintering Spark plasma sintering (SPS), also known as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), or plasma pressure compaction (P2C) is a sintering technique.

The main characteristic of SPS is that the pulsed or u ...

* Spray forming

References

Cited sources

*Further reading

*An earlier version of this article was copied from Appendix 4C of ''Advanced Automation for Space Missions'', a NASA report in the public domain. * R. M. German, "Powder Metallurgy and Particulate Materials Processing," Metal Powder Industries Federation, Princeton, New Jersey, 2005. * F. Thummler and R.Oberacker "An Introduction to Powder Metallurgy" The institute of Materials, London 1993 * G. S. Upadhyaya, "Sintered Metallic and Ceramic Materials" John Wiley and Sons, West Sussex, England, 2000External links

Rapid manufacturing technique developed at the KU Leuven, Belgium

the Ames Laboratory *APMI International "The Global Professional Society for Powder Metallurg

a non-profit organization {{Authority control Metalworking Ceramic engineering

Metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the sc ...