Plunger pump on:

[Wikipedia]

[Google]

[Amazon]

A plunger pump is a type of

A plunger pump is a type of

/ref>

A plunger pump is a type of

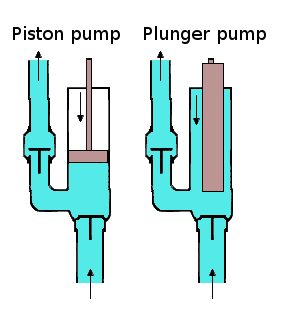

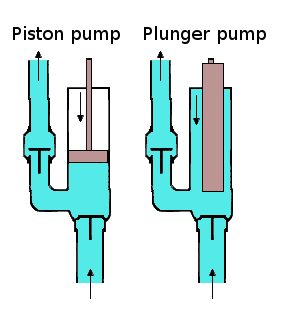

A plunger pump is a type of positive displacement pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they ...

where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. This makes them different from piston pumps and allows them to be used at higher pressures. This type of pump is often used to transfer municipal and industrial sewage.Plunger vs piston pumps/ref>

History

The invention of the plunger pump is attributed toSamuel Morland

Sir Samuel Morland, 1st Baronet (1625 – 30 December 1695), or Moreland, was an English academic, diplomat, spy, inventor and mathematician of the 17th century, a polymath credited with early developments in relation to computing, hydraulics a ...

based on a patent of 1675.

Operation

Piston pumps and plunger pumps are positive displacement pumps that use a plunger or piston to move media through a cylindrical chamber. The plunger or piston is actuated by asteam powered

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be tr ...

, pneumatic, hydraulic, or electric drive.

Rotary piston and plunger pumps use a crank mechanism to create a reciprocating motion

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth linear motion. It is found in a wide range of mechanisms, including reciprocating engines and pumps. The two opposite motions that comprise a single r ...

along an axis, which then builds pressure in a cylinder or working barrel to force gas or fluid through the pump. The pressure in the chamber actuates the valves at both the suction and discharge points. Plunger pumps are used in applications that could range from . Piston pumps are used in lower pressure applications. The volume of the fluid discharged is equal to the area of the plunger or piston, multiplied by its stroke length. The overall capacity of the piston pumps and plunger pumps can be calculated with the area of the piston or plunger, the stroke length, the number of pistons or plungers and the speed of the drive. The power needed from the drive is proportional to the pressure and capacity of the pump.

Seals are an integral part of piston pumps and plunger pumps to separate the power fluid from the medium that is being pumped. A stuffing box or packing is used to seal the joint between the vessel where the medium is transferred and the plunger or piston. A stuffing box may be composed of bushings, packing or seal rings, and a gland.

Plunger pumps' component materials are chosen for wear and contact with the type of medium. Component materials include bronze, brass, steel, stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's r ...

, iron, nickel alloy, or other material. For example, plunger pumps that function in general service or oil service applications often have an iron cylinder and plunger. The plunger, discharge valves, and suction valves come in contact with the transferred medium, and material choices are based on the fluid transferred. In power applications where continuous duty plunger pumps are needed, solid ceramic plungers may be used when in contact with water and oil, but may not be compatible for use with highly acidic media types.

See also

* Piston pumpReferences

* A History of Mechanical Inventions, Abbott Payson Usher, Courier Dover Publications, 1988, , 9780486255934 {{DEFAULTSORT:Plunger Pump Pumps