Platform chassis on:

[Wikipedia]

[Google]

[Amazon]

A platform chassis is a form of

The platform chassis, and the large number of available VW Beetles, encouraged the use of the Beetle platform as a donor car for building

The platform chassis, and the large number of available VW Beetles, encouraged the use of the Beetle platform as a donor car for building

Modern developments of chassis materials, bodyshells materials and design, and also changes in

Modern developments of chassis materials, bodyshells materials and design, and also changes in

A punt chassis is similar to the platform chassis, but in addition to the lower platform there are also deep raised sides. These give vertical stiffness, without requiring added stiffeners.

Punt chassis have often been used with armoured vehicles. The armoured outer bodyshell forms a robust

A punt chassis is similar to the platform chassis, but in addition to the lower platform there are also deep raised sides. These give vertical stiffness, without requiring added stiffeners.

Punt chassis have often been used with armoured vehicles. The armoured outer bodyshell forms a robust

vehicle frame

A vehicle frame, also historically known as its ''chassis'', is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism.

Until the 1930s, virtually every car had a ...

/ automobile chassis, constructed as a flat plate or platform, sometimes integrating a backbone or frame-structure with a vehicle's floor-pan.

Design

A platform chassis is a separate chassis for a car or small vehicle. It is distinguished from other forms of chassis by being arranged as largely a single flat steel sheet, usually with additional box section stiffeners. Platform chassis developed after the ladder chassis or cruciform chassis designs in the 1930s, once car bodies began to be pressed from large steel sheets, rather than the chassis assembled fromrolled

Rolling is a Motion (physics)#Types of motion, type of motion that combines rotation (commonly, of an Axial symmetry, axially symmetric object) and Translation (geometry), translation of that object with respect to a surface (either one or the ot ...

channel sections. As a semi-monocoque

The term semi-monocoque or semimonocoque refers to a stressed shell structure that is similar to a true monocoque, but which derives at least some of its strength from conventional reinforcement. Semi-monocoque construction is used for, among ot ...

they are still a form of body-on-frame construction, rather than a monocoque

Monocoque ( ), also called structural skin, is a structural system in which loads are supported by an object's external skin, in a manner similar to an egg shell. The word ''monocoque'' is a French term for "single shell".

First used for boats, ...

or unibody

A vehicle frame, also historically known as its '' chassis'', is the main supporting structure of a motor vehicle to which all other components are attached, comparable to the skeleton of an organism.

Until the 1930s, virtually every car ha ...

where the bodyshell and chassis are integrated into one component. Although both body and platform chassis are each made from similar pressed steel panels welded together, they were often bolted as the final two units and so may still be separable after construction.

Achieving sufficient rigidity is difficult with a pure platform and so they are usually extended vertically with some form of box or tube section. This can be either a perimeter frame (e.g. Renault 4

The Renault 4, also known as the 4L (pronounced "Quatrelle" in French), is a small economy car produced by the French automaker Renault between 1961 and 1994. Although the Renault 4 was marketed as a short station wagon, its minimal rear overhang ...

) or a central spine (e.g. VW Beetle). Longitudinal rigidity is more critical than transverse rigidity and so this stiffening is mostly as front to back girders, rather than crosswise. The diaphragm sheet is usually pressed into shallow stiffening ridges as well, but these are mostly to stop drumming noise and are too minor to provide major structural strength.

Platforms are usually the full width of the car, but shorter and only span the length between the wheels. Suspension attachments for the wheels and the weight of the engine and transmission are carried on additional subframe

A subframe is a structural component of a vehicle, such as an automobile or an aircraft, that uses a discrete, separate structure within a larger body-on-frame or unit body to carry certain components, such as the engine, drivetrain, or suspen ...

s beyond this. These subframes may be formed of box section tubes welded on to the chassis, deep-drawn box sections formed from sheet, or as separate subframes that are bolted in place.

Platform chassis have been used for both rear-wheel drive (Beetle) and front-wheel drive (Renault) layouts. However they keep the engine at the driven end, with a transaxle

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

Engine and drive at the s ...

, rather than using the propeller shaft

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power and torque and rotation, usually used to connect ...

of the Hotchkiss layout of front-engine, rear-drive that was universal with chassis designs beforehand. This avoided transmitting the propeller shaft torque through the platform. Where a propeller shaft has been used, these have been for rare examples with four-wheel drive

Four-wheel drive, also called 4×4 ("four by four") or 4WD, refers to a two-axled vehicle drivetrain capable of providing torque to all of its wheels simultaneously. It may be full-time or on-demand, and is typically linked via a transfer cas ...

.

Attaching the suspension to a platform chassis requires independent suspension and encourages the use of suspension features such as torsion bars or trailing arms. As the chassis is in a single plane, it would be difficult to use a solid axle, without raising the entire platform above the axle line. It is also difficult to arrange spring attachments for springs such as half-elliptic springs requiring distance fore and aft of the axle line, or for coil spring or strut suspensions needing an attachment point raised vertically above the platform. Instead, springs such as torsion bars are used. Whether these are transverse or longitudinal, they lie in the horizontal plane of the platform and so can be worked in to such a chassis. Other torsion-based systems, such as twist-beam rear suspension

The twist-beam rear suspension (also torsion-beam axle, deformable torsion beam or compound crank) is a type of automobile suspension based on a large H or C-shaped member. The front of the H attaches to the body via rubber bushings, and the ...

, may be used as well for front-wheel drive cars with light rears.

Volkswagen Beetle chassis

The Volkswagen Type 1 ''Beetle'' used a platform chassis, with independenttorsion bar suspension

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end term ...

at each end. The 'Volkswagen', 'Peoples' Car' or 'KdF-Wagen' project began in 1933 and by 1934 Porsche had sketched out a design for a rear-engined, platform chassis car with four seats and torsion bar suspension. A central stiffening tube provided much of the strength of the chassis.

This basic design proceeded through the pre-war Porsche Type 60, and several wartime military vehicles, before finally the first post-war mass-production Volkswagen Beetles of 1945.

WWII military vehicles

In 1936, Porsche adapted the developing KdF-Wagen 'domestic' car as a sporting car suitable for the auto trials organised by the NSKK. These were slow-speed competitions across off-road terrain and obstacles, which developed both driving skill and vehicle agility, in ways which were expected to be useful for military motoring. This Porsche Type 62 was an open-topped, open-sided four seater, still with rounded bodywork. Although it performed well in military trials atMünsingen

Münsingen ( Highest Alemannic: ''Münsige'') is a municipality in the Bern-Mittelland administrative district in the canton of Bern in Switzerland. On 1 January 2013 the former municipality of Trimstein merged into Münsingen, and on 1 Jan ...

, its appearance was considered to be 'too civilian'.

Porsche continued to develop the Type 62 with such features as a rear portal axle to give increased ground clearance and the ability to move with infantry at a walking pace. The rounded bodywork was also replaced with ribbed flat panels, with doors, and by the end of 1939 this had been accepted as the military Type 82 Kübelwagen. The Kübelwagen was highly effective, in large part due to the light weight achieved by use of its platform chassis. It weighed only 1,510 lb, the same design weight as the road car, and was 200-300 lb lighter than its rival vehicles from Opel, DKW and Adler.

A four-wheel drive

Four-wheel drive, also called 4×4 ("four by four") or 4WD, refers to a two-axled vehicle drivetrain capable of providing torque to all of its wheels simultaneously. It may be full-time or on-demand, and is typically linked via a transfer cas ...

version was also developed, again using the same platform chassis and basic layout, but under the civilian enclosed bodywork. This became the Type 87 Kommandeurswagen (Porsche Type 287) and was intended for use by senior field commanders. The central tube of the chassis pan was enlarged to give space for a propeller shaft and a powered front axle provided, with similar driveshafts as the rear axle.

VW Beetle

The Beetlepowertrain

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components o ...

comprised a rear-mounted flat-four engine with a longitudinal transaxle

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

Engine and drive at the s ...

ahead of it. The rear suspension was by swing axle

A swing axle is a simple type of independent (rear wheel) suspension designed and patented by Edmund Rumpler in 1903. This was a revolutionary invention in automotive suspension, allowing driven (powered) wheels to follow uneven road surfaces ...

s. The first 1945 civilian Beetle used a platform chassis which stopped short of the rear wheels and which had a central stiffening tube. This tube extended rearwards as a Y-shaped fork, which passed each side of the transaxle and to the engine mounts. The rear swing axles were also held at their outboard ends by flat plate trailing arms, which were pivoted on the ends of a crosswise tube, containing the torsion bar

A torsion bar suspension, also known as a torsion spring suspension, is any vehicle suspension that uses a torsion bar as its main weight-bearing spring. One end of a long metal bar is attached firmly to the vehicle chassis; the opposite end termi ...

s. At this time the rear shock absorbers were only single-acting, lever-type.

The front suspension was provided by pairs of short trailing arm

A (semi) trailing-arm suspension, sometimes referred to as (semi) trailing-link is a vehicle axle or wheel suspension design in which one or more horizontal arms (or "links"), perpendicular to and forward of the axle, are connecting the axle or ...

s, again with transverse torsion bars mounted in two separate tubes, mounted ahead of the flat platform. These torsion bars were stacks of flat strips, and the number of leaves was changed to vary the suspension stiffness, over the production of the Beetle.

An advantage for the production of the vehicle was that controls such as the driver's pedals and brake piping, the gear stick

A gear stick (rarely spelled ''gearstick''), gear lever (both UK English), gearshift or shifter (both U.S. English), more formally known as a transmission lever, is a metal lever attached to the transmission of an automobile. The term ''gear st ...

and the handbrake which required connections to the engine or drive train could be installed onto the platform before the body was added. Even, until 1952, the engine choke control and its Bowden cable

A Bowden cable ( )

is a type of flexible cable used to transmit mechanical force or energy by the movement of an inner cable relative to a hollow outer cable housing. The housing is generally of composite construction, consisting of an inne ...

were mounted on the central tunnel. Unlike most contemporary chassis-on-frame designs though, the steering column

The automotive steering column is a device intended primarily for connecting the steering wheel to the steering mechanism.

Secondary functions

A steering column may also perform the following secondary functions:

*energy dissipation management ...

was mounted on the bodyshell and was not connected to the steering box

Steering is a system of components, linkages, and other parts that allows a driver to control the direction of the vehicle.

Introduction

The most conventional steering arrangement allows a driver to turn the front wheels of a vehicle using ...

on the chassis platform until the two were joined.

In the 35 year production history of the Beetle, the basic platform chassis remained largely unchanged, except for one change to the front suspension of the 'Super Beetle'.

Developments

From 1970, the new 1302 'Super Beetle' adoptedMacPherson strut

The MacPherson strut is a type of automotive suspension system that uses the top of a telescopic damper as the upper steering pivot. It is widely used in the front suspension of modern vehicles, and is named for American automotive engineer Ear ...

front suspension. This increased front luggage capacity by nearly 50%, also due to a slightly lengthened front bonnet, but the upper mounts of the struts now coupled suspension forces into the inner wing panels of bodyshell rather than the platform: the chassis was now no longer a pure platform. The 1303 'Super Beetle' continued in production until 1975, although the Economy Beetle continued in parallel with it, still using the trailing arms and platform chassis.

Beetle conversions

The platform chassis, and the large number of available VW Beetles, encouraged the use of the Beetle platform as a donor car for building

The platform chassis, and the large number of available VW Beetles, encouraged the use of the Beetle platform as a donor car for building kit car

A kit car is an automobile available as a set of parts that a manufacturer sells and the buyer then assembles into a functioning car. Usually, many of the major mechanical systems such as the engine and transmission are sourced from donor ve ...

s. The most iconic of these was the dune buggy: a stripped-down Beetle chassis, with the simplest fibreglass

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass clo ...

'bathtub' body on top of this.

The first production dune buggy, the Meyers Manx, used a shortened VW platform as a basis. The front of the chassis was cut off and replaced by a taller structure of welded square steel tube. This made the front end vertically stiffer and the suspension was replaced by one based on Chevrolet parts, although still with double trailing arms. The Meyers Manx was widely copied and most of these copies retained the full VW platform and VW front suspension.

Safety

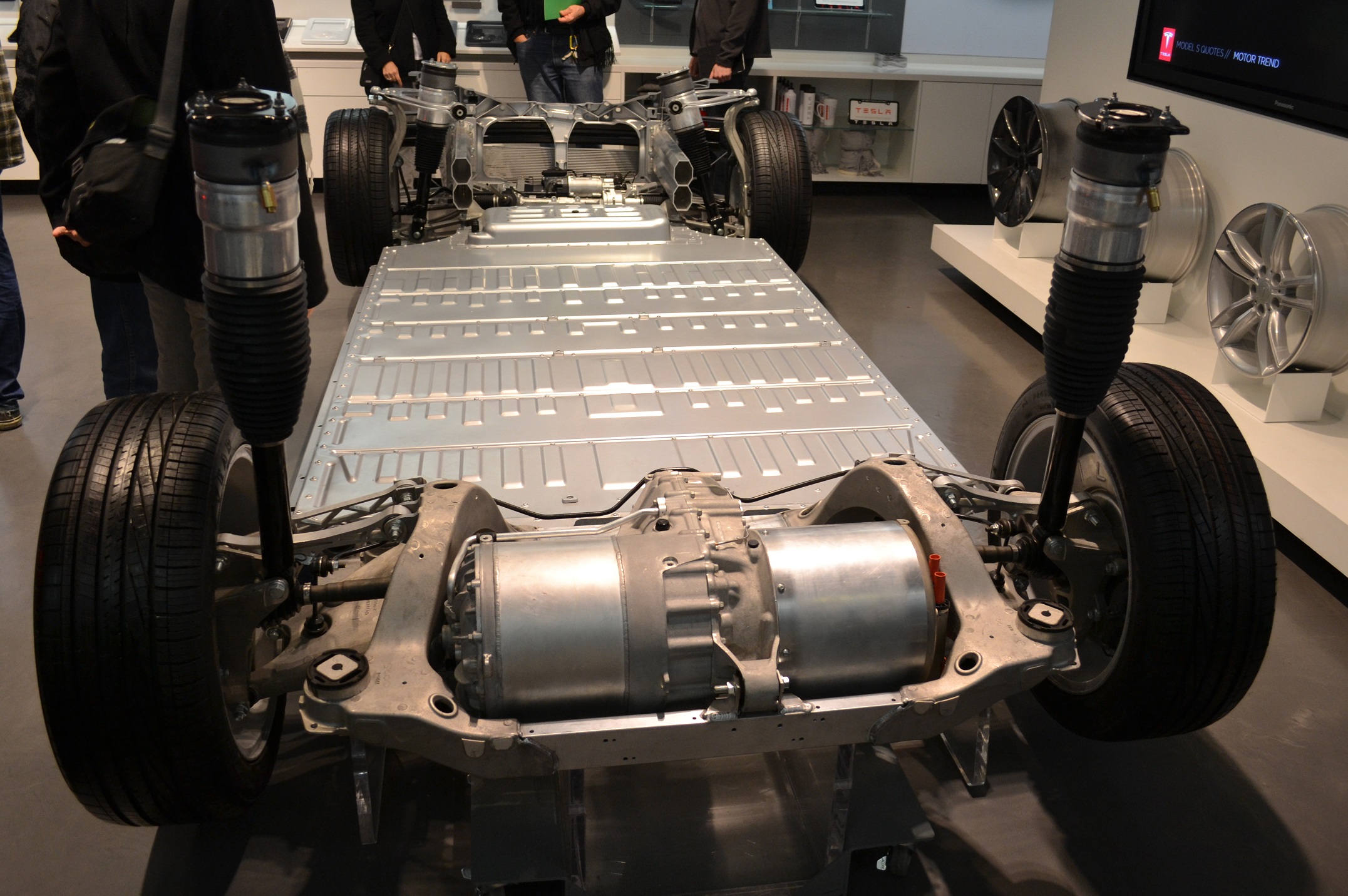

Platform chassis were not significantly more or less safe than contemporary ladder chassis, although much less safe in an impact than a modern design with a monocoque integrated into a passenger safety cell. They had a tendency in serious accidents for the complete bodyshell to separate from the chassis, as did the ladder chassis. However with the platform chassis, this formed the floor of the passenger area, rather than the body tub, and had the seats mounted to it. The passengers could thus stay with their seats on the chassis, while the bodyshell tried to pass through them.Modern platform chassis

drivetrain

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components o ...

have given the platform chassis a resurgence. They are now in use for some electric

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described by ...

and hybrid car

A hybrid vehicle is one that uses two or more distinct types of power, such as submarines that use diesel when surfaced and batteries when submerged. Other means to store energy include pressurized fluid in hydraulic hybrids.

The basic princip ...

s, such as the Tesla S.

An electric drivetrain (either hybrid or pure battery) does not require mechanical stiffness between an engine and final drive

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components o ...

. The entire drivetrain can be mounted in a subframe at one, or increasingly both, ends.

Battery storage is required, and as the battery pack is heavy it is an advantage for stability to mount it in the largest flat layer, as low down as possible. The pack weight for a Tesla S is As these are composed of 7,104 cells, packaged into 16 modules, their overall shape is flexible and can be adjusted to best fit the vehicle. This makes the platform chassis a good way to carry it, with the batteries themselves either above or below the chassis platform, making them easier to access for exchange.

Punt chassis

A punt chassis is similar to the platform chassis, but in addition to the lower platform there are also deep raised sides. These give vertical stiffness, without requiring added stiffeners.

Punt chassis have often been used with armoured vehicles. The armoured outer bodyshell forms a robust

A punt chassis is similar to the platform chassis, but in addition to the lower platform there are also deep raised sides. These give vertical stiffness, without requiring added stiffeners.

Punt chassis have often been used with armoured vehicles. The armoured outer bodyshell forms a robust monocoque

Monocoque ( ), also called structural skin, is a structural system in which loads are supported by an object's external skin, in a manner similar to an egg shell. The word ''monocoque'' is a French term for "single shell".

First used for boats, ...

which can serve double duty as the vehicle's chassis. Such armoured vehicles require all-wheel drive for off-road capacity with their weight, which many involve six or eight wheels, and so have often used a H-drive

An H-drive drivetrain is a system used for heavy off-road vehicles with 6×6 or 8×8 drive to supply power to each wheel station.

H-drives do not use axles but rather individual wheel stations, usually carried on a punt chassis. A single differ ...

layout for the drivetrain. Rather than axles connected by a central propeller shaft, the two sides are linked fore-and-aft by driveshafts in the lower corners of the punt. This also allows greater useful space inside for crew or equipment.

References

* * * * * {{Cite book , title=In National Service , last=Ware , first=Pat , publisher=Warehouse Publications , year=1994 , isbn=0-9525563-0-8 Automotive chassis types Ferdinand Porsche