Rail transport (also known as train transport) is a means of

transport

Transport (in British English), or transportation (in American English), is the intentional movement of humans, animals, and goods from one location to another. Modes of transport include air, land (rail and road), water, cable, pipeline, an ...

that transfers passengers and goods on wheeled

vehicle

A vehicle (from la, vehiculum) is a machine that transports people or cargo. Vehicles include wagons, bicycles, motor vehicles (motorcycles, cars, trucks, buses, mobility scooters for disabled people), railed vehicles (trains, trams), wa ...

s running on rails, which are incorporated in

tracks. In contrast to

road transport

Road transport or road transportation is a type of transport using roads. Transport on roads can be roughly grouped into the transportation of goods and transportation of people. In many countries licensing requirements and safety regulations e ...

, where the vehicles run on a prepared flat surface, rail vehicles (

rolling stock

The term rolling stock in the rail transport industry refers to railway vehicles, including both powered and unpowered vehicles: for example, locomotives, freight and passenger cars (or coaches), and non-revenue cars. Passenger vehicles can b ...

) are directionally guided by the tracks on which they run. Tracks usually consist of

steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

rails, installed on

sleepers

''Sleepers'' is a 1996 American legal crime drama film written, produced, and directed by Barry Levinson, and based on Lorenzo Carcaterra's 1995 book of the same name. The film stars Kevin Bacon, Jason Patric, Brad Pitt, Robert De Niro, Dustin H ...

(ties) set in

ballast

Ballast is material that is used to provide stability to a vehicle or structure. Ballast, other than cargo, may be placed in a vehicle, often a ship or the gondola of a balloon or airship, to provide stability. A compartment within a boat, ship, ...

, on which the rolling stock, usually fitted with metal wheels, moves. Other variations are also possible, such as "slab track", in which the rails are fastened to a concrete foundation resting on a prepared subsurface.

Rolling stock in a rail transport system generally encounters lower

frictional resistance than rubber-tyred road vehicles, so passenger and freight cars (carriages and wagons) can be coupled into longer

train

In rail transport, a train (from Old French , from Latin , "to pull, to draw") is a series of connected vehicles that run along a railway track and Passenger train, transport people or Rail freight transport, freight. Trains are typically pul ...

s. The

operation

Operation or Operations may refer to:

Arts, entertainment and media

* ''Operation'' (game), a battery-operated board game that challenges dexterity

* Operation (music), a term used in musical set theory

* ''Operations'' (magazine), Multi-Ma ...

is carried out by a

railway company

A railway company is a company within the rail industry. It can be a manufacturing firm or an rail transport operations, operator. Some railway companies operate both the trains and the track, while, particularly in the European Union, operation ...

, providing transport between

train station

A train station, railway station, railroad station or depot is a railway facility where trains stop to load or unload passengers, freight or both. It generally consists of at least one platform, one track and a station building providing suc ...

s or freight customer facilities. Power is provided by

locomotive

A locomotive or engine is a rail transport vehicle that provides the Power (physics), motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, Motor coach (rail), motor ...

s which either draw

electric power

Electric power is the rate at which electrical energy is transferred by an electric circuit. The SI unit of power is the watt, one joule per second. Standard prefixes apply to watts as with other SI units: thousands, millions and billions o ...

from a

railway electrification system

A railway electrification system supplies electric power to railway trains and trams without an on-board prime mover or local fuel supply.

Electric railways use either electric locomotives (hauling passengers or freight in separate cars), ele ...

or produce their own power, usually by

diesel engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-call ...

s or, historically,

steam

Steam is a substance containing water in the gas phase, and sometimes also an aerosol of liquid water droplets, or air. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization ...

engines. Most tracks are accompanied by a

signalling system

In signal processing, a signal is a function that conveys information about a phenomenon. Any quantity that can vary over space or time can be used as a signal to share messages between observers. The ''IEEE Transactions on Signal Processing'' ...

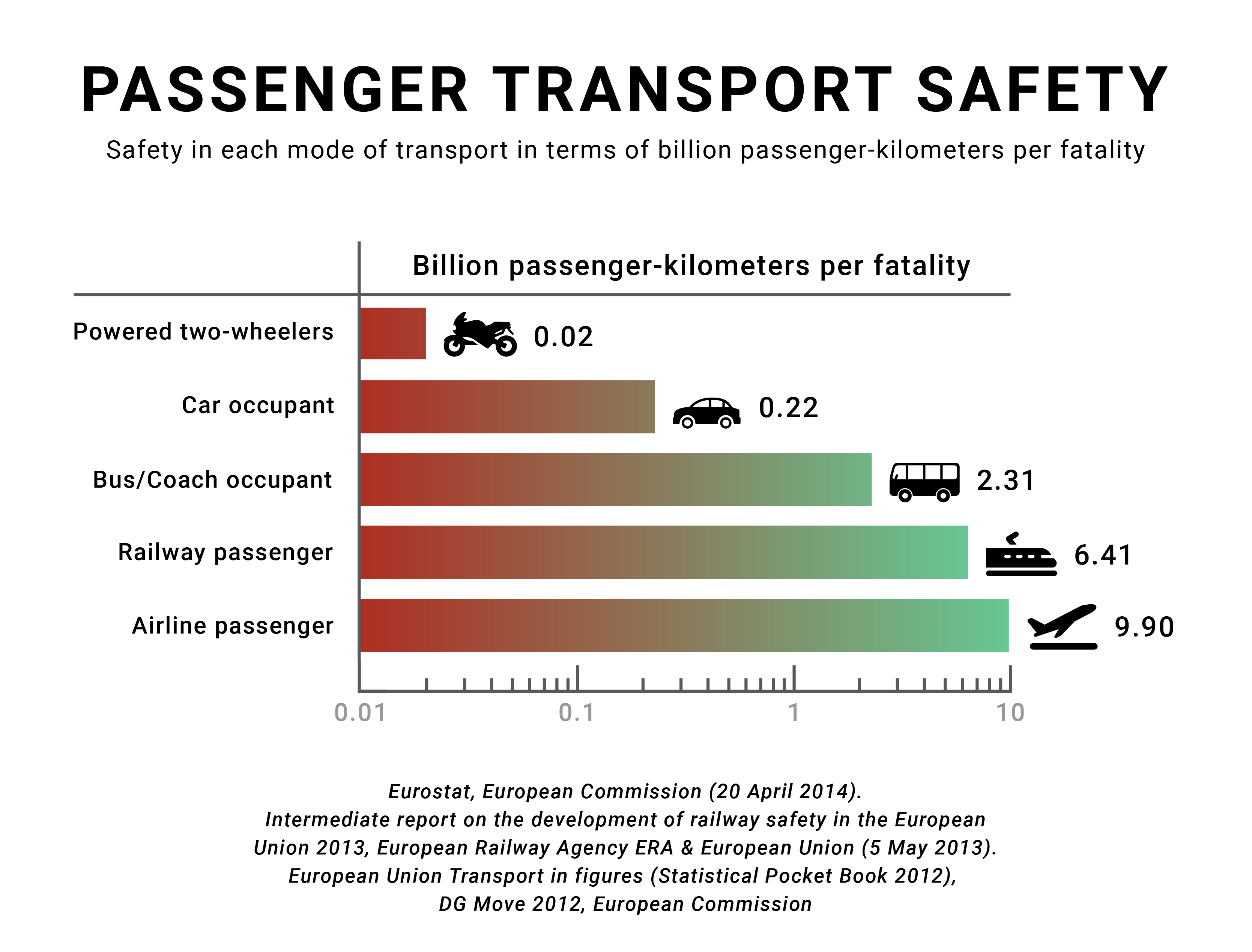

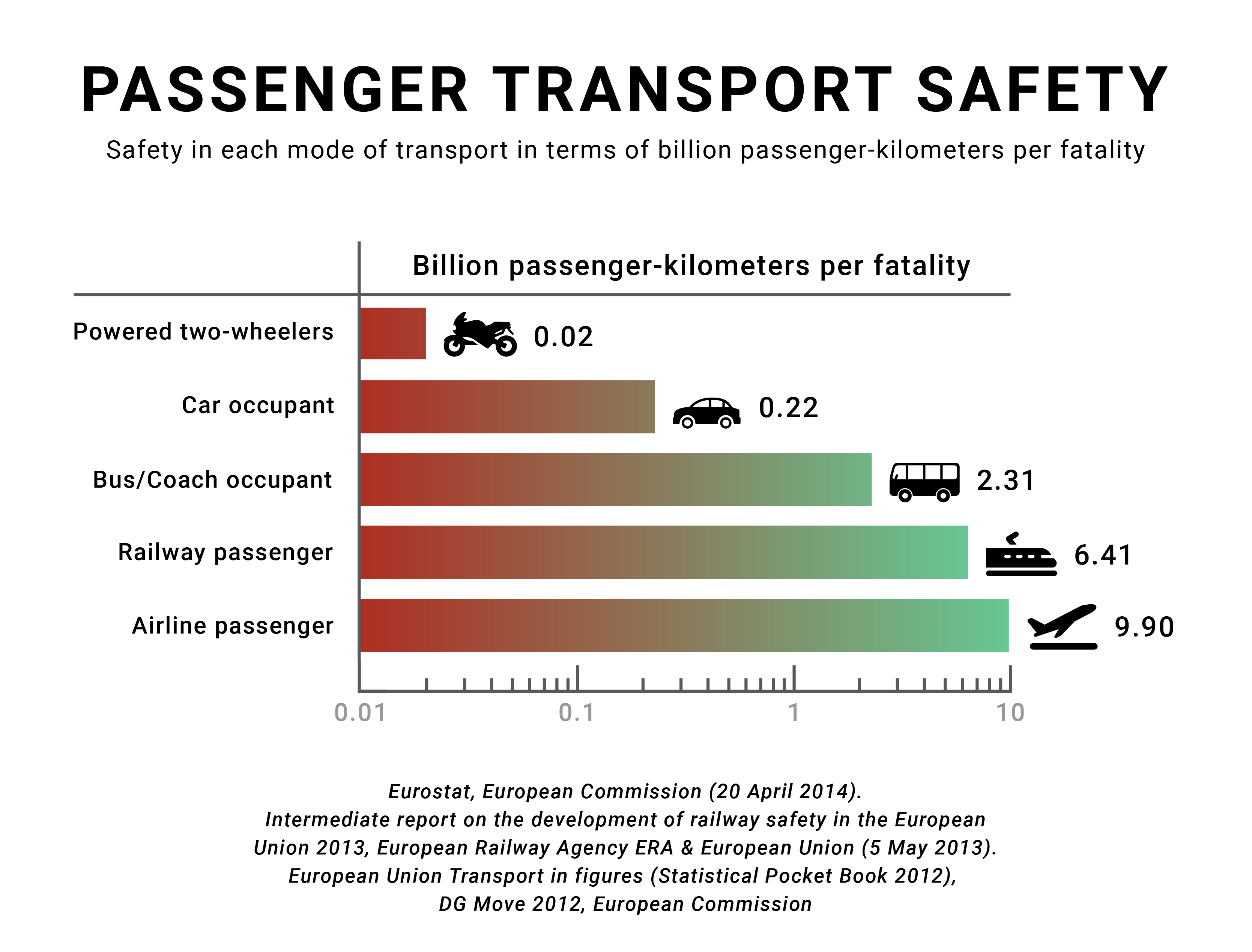

. Railways are a safe land transport system when compared to other forms of transport. Railway transport is capable of high levels of passenger and cargo utilisation and energy efficiency, but is often less flexible and more

capital

Capital may refer to:

Common uses

* Capital city, a municipality of primary status

** List of national capital cities

* Capital letter, an upper-case letter Economics and social sciences

* Capital (economics), the durable produced goods used f ...

-intensive than road transport, when lower traffic levels are considered.

The oldest known, man/animal-hauled railways date back to the 6th century BC in

Corinth

Corinth ( ; el, Κόρινθος, Kórinthos, ) is the successor to an ancient city, and is a former municipality in Corinthia, Peloponnese, which is located in south-central Greece. Since the 2011 local government reform, it has been part o ...

,

Greece

Greece,, or , romanized: ', officially the Hellenic Republic, is a country in Southeast Europe. It is situated on the southern tip of the Balkans, and is located at the crossroads of Europe, Asia, and Africa. Greece shares land borders with ...

. Rail transport then commenced in mid 16th century in

Germany

Germany,, officially the Federal Republic of Germany, is a country in Central Europe. It is the second most populous country in Europe after Russia, and the most populous member state of the European Union. Germany is situated betwe ...

in the form of horse-powered

funicular

A funicular (, , ) is a type of cable railway system that connects points along a railway track laid on a steep slope. The system is characterized by two counterbalanced carriages (also called cars or trains) permanently attached to opposite en ...

s and

wagonway

Wagonways (also spelt Waggonways), also known as horse-drawn railways and horse-drawn railroad consisted of the horses, equipment and tracks used for hauling wagons, which preceded Steam locomotive, steam-powered rail transport, railways. The t ...

s. Modern rail transport commenced with the British development of the

steam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomot ...

in Merthyr Tydfil when

Richard Trevithick

Richard Trevithick (13 April 1771 – 22 April 1833) was a British inventor and mining engineer. The son of a mining captain, and born in the mining heartland of Cornwall, Trevithick was immersed in mining and engineering from an early age. He w ...

ran a steam locomotive and loaded wagons between Penydarren Ironworks and Abercynon in 1802. Thus the

railway system in Great Britain is the oldest in the world. Built by

George Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was a British civil engineer and mechanical engineer. Renowned as the "Father of Railways", Stephenson was considered by the Victorians a great example of diligent application and thirst for ...

and his son

Robert

The name Robert is an ancient Germanic given name, from Proto-Germanic "fame" and "bright" (''Hrōþiberhtaz''). Compare Old Dutch ''Robrecht'' and Old High German ''Hrodebert'' (a compound of '' Hruod'' ( non, Hróðr) "fame, glory, honou ...

's company

Robert Stephenson and Company

Robert Stephenson and Company was a locomotive manufacturing company founded in 1823 in Forth Street, Newcastle upon Tyne in England. It was the first company in the world created specifically to build railway engines.

Famous early locomotiv ...

, the

''Locomotion'' No. 1 is the first steam locomotive to carry passengers on a public rail line, the

Stockton and Darlington Railway

The Stockton and Darlington Railway (S&DR) was a railway company that operated in north-east England from 1825 to 1863. The world's first public railway to use steam locomotives, its first line connected collieries near Shildon with Darl ...

in 1825. George Stephenson also built the first public inter-city railway line in the world to use only the steam locomotives, the

Liverpool and Manchester Railway

The Liverpool and Manchester Railway (L&MR) was the first inter-city railway in the world. It opened on 15 September 1830 between the Lancashire towns of Liverpool and Manchester in England. It was also the first railway to rely exclusively ...

which

opened in 1830. With steam engines, one could construct mainline railways, which were a key component of the

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

. Also, railways reduced the costs of

shipping

Freight transport, also referred as ''Freight Forwarding'', is the physical process of transporting Commodity, commodities and merchandise goods and cargo. The term shipping originally referred to transport by sea but in American English, it h ...

, and allowed for fewer lost goods, compared with water transport, which faced occasional sinking of ships. The change from

canals

Canals or artificial waterways are waterways or river engineering, engineered channel (geography), channels built for drainage management (e.g. flood control and irrigation) or for conveyancing water transport watercraft, vehicles (e.g. ...

to railways allowed for "national markets" in which prices varied very little from city to city. The spread of the railway network and the use of railway timetables, led to the standardisation of time (railway time) in Britain based on Greenwich Mean Time. Prior to this, major towns and cities varied their local time relative to GMT. The invention and development of the railway in the United Kingdom was one of the most important technological inventions of the 19th century. The world's first underground railway, the

Metropolitan Railway

The Metropolitan Railway (also known as the Met) was a passenger and goods railway that served London from 1863 to 1933, its main line heading north-west from the capital's financial heart in the City to what were to become the Middlesex su ...

(part of the

London Underground

The London Underground (also known simply as the Underground or by its nickname the Tube) is a rapid transit system serving Greater London and some parts of the adjacent ceremonial counties of England, counties of Buckinghamshire, Essex and He ...

), opened in 1863.

In the 1880s,

electrified

Electrification is the process of powering by electricity and, in many contexts, the introduction of such power by changing over from an earlier power source.

The broad meaning of the term, such as in the history of technology, economic history ...

trains were introduced, leading to electrification of tramways and rapid transit systems. Starting during the 1940s, the non-electrified railways in most countries had their steam locomotives replaced by

diesel

Diesel may refer to:

* Diesel engine, an internal combustion engine where ignition is caused by compression

* Diesel fuel, a liquid fuel used in diesel engines

* Diesel locomotive, a railway locomotive in which the prime mover is a diesel engin ...

-electric locomotives, with the process being almost complete by the 2000s. During the 1960s, electrified

high-speed railway systems were introduced in

Japan

Japan ( ja, 日本, or , and formally , ''Nihonkoku'') is an island country in East Asia. It is situated in the northwest Pacific Ocean, and is bordered on the west by the Sea of Japan, while extending from the Sea of Okhotsk in the north ...

and later in some other countries. Many countries are in the process of replacing diesel locomotives with electric locomotives, mainly due to environmental concerns, a notable example being

Switzerland

). Swiss law does not designate a ''capital'' as such, but the federal parliament and government are installed in Bern, while other federal institutions, such as the federal courts, are in other cities (Bellinzona, Lausanne, Luzern, Neuchâtel ...

, which has completely electrified its network. Other forms of guided ground transport outside the traditional railway definitions, such as

monorail

A monorail (from "mono", meaning "one", and "rail") is a railway in which the track consists of a single rail or a beam.

Colloquially, the term "monorail" is often used to describe any form of elevated rail or people mover. More accurately, ...

or

maglev

Maglev (derived from '' magnetic levitation''), is a system of train transportation that uses two sets of electromagnets: one set to repel and push the train up off the track, and another set to move the elevated train ahead, taking advantage ...

, have been tried but have seen limited use.

Following a decline after

World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposin ...

due to competition from cars and aeroplanes, rail transport has had a revival in recent decades due to road congestion and rising fuel prices, as well as governments

investing in rail as a means of reducing

CO2 emissions in the context of concerns about

global warming

In common usage, climate change describes global warming—the ongoing increase in global average temperature—and its effects on Earth's climate system. Climate change in a broader sense also includes previous long-term changes to E ...

.

History

The history of rail transport began in prehistoric times.

Ancient systems

Evidence indicates that there was 6 to 8.5 km long ''

Diolkos'' paved trackway, which transported boats across the

Isthmus of Corinth

The Isthmus of Corinth (Greek: Ισθμός της Κορίνθου) is the narrow land bridge which connects the Peloponnese peninsula with the rest of the mainland of Greece, near the city of Corinth. The word "isthmus" comes from the Ancien ...

in

Greece

Greece,, or , romanized: ', officially the Hellenic Republic, is a country in Southeast Europe. It is situated on the southern tip of the Balkans, and is located at the crossroads of Europe, Asia, and Africa. Greece shares land borders with ...

from around 600 BC. Wheeled vehicles pulled by men and animals ran in grooves in

limestone

Limestone ( calcium carbonate ) is a type of carbonate sedimentary rock which is the main source of the material lime. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of . Limestone forms whe ...

, which provided the track element, preventing the wagons from leaving the intended route. The Diolkos was in use for over 650 years, until at least the 1st century AD.

Paved trackways were also later built in

Roman Egypt

, conventional_long_name = Roman Egypt

, common_name = Egypt

, subdivision = Province

, nation = the Roman Empire

, era = Late antiquity

, capital = Alexandria

, title_leader = Praefectus Augustalis

, image_map = Roman E ...

.

In China, a railway has been discovered in southwest Henan province near

Nanyang

Nanyang is the romanization of two common Chinese place names. It may refer to:

Written as 南洋 (Southern Ocean)

* Nanyang (region), a Chinese term denoting the Southeast Asian lands surrounding the South China Sea

;China

* Nanyang Fleet, Qing ...

. It was carbon-dated to be about 2200 years old, from the Qin dynasty. The rails were made from hard wood and treated against corrosion, while the railway ties were made from wood that was not treated and has since rotted. The Qin railway was designed to allow horses to gallop through to the next rail station, where they would be swapped with a fresh horse. The railway is theorized to have been used for transportation of goods to the front-line troops and to fix the Great Wall.

Pre-steam modern systems

Wooden rails introduced

In 1515,

Cardinal Matthäus Lang wrote a description of the

Reisszug

The Reisszug (also spelt Reißzug or Reiszug) is a private cable railway providing goods access to the Hohensalzburg Castle at Salzburg in Austria. It is notable for its extreme age, as it is believed to date back to either 1495 or 1504.

The Reis ...

, a

funicular

A funicular (, , ) is a type of cable railway system that connects points along a railway track laid on a steep slope. The system is characterized by two counterbalanced carriages (also called cars or trains) permanently attached to opposite en ...

railway at the

Hohensalzburg Fortress

Hohensalzburg Fortress (german: Festung Hohensalzburg, lit=High Salzburg Fortress) is a large medieval fortress in the city of Salzburg, Austria. It sits atop the Festungsberg at an altitude of 506 m. It was erected at the behest of the Prince-Arc ...

in Austria. The line originally used wooden rails and a

hemp

Hemp, or industrial hemp, is a botanical class of ''Cannabis sativa'' cultivars grown specifically for industrial or medicinal use. It can be used to make a wide range of products. Along with bamboo, hemp is among the fastest growing plants o ...

haulage rope and was operated by human or animal power, through a

treadwheel

A treadwheel, or treadmill, is a form of engine typically powered by humans. It may resemble a water wheel in appearance, and can be worked either by a human treading paddles set into its circumference (treadmill), or by a human or animal standing ...

.

The line still exists and is operational, although in updated form and is possibly the oldest operational railway.

Wagonway

Wagonways (also spelt Waggonways), also known as horse-drawn railways and horse-drawn railroad consisted of the horses, equipment and tracks used for hauling wagons, which preceded Steam locomotive, steam-powered rail transport, railways. The t ...

s (or

tramways) using wooden rails, hauled by horses, started appearing in the 1550s to facilitate the transport of ore tubs to and from mines, and soon became popular in Europe. Such an operation was illustrated in Germany in 1556 by

Georgius Agricola

Georgius Agricola (; born Georg Pawer or Georg Bauer; 24 March 1494 – 21 November 1555) was a German Humanist scholar, mineralogist and metallurgist. Born in the small town of Glauchau, in the Electorate of Saxony of the Holy Roman Empir ...

in his work

De re metallica. This line used "Hund" carts with unflanged wheels running on wooden planks and a vertical pin on the truck fitting into the gap between the planks to keep it going the right way. The miners called the wagons ''Hunde'' ("dogs") from the noise they made on the tracks.

There are many references to their use in central Europe in the 16th century. Such a transport system was later used by German miners at

Caldbeck

Caldbeck is a village in Cumbria, England, historically within Cumberland, it is situated within the Lake District National Park. The village had 714 inhabitants according to the census of 2001.

Caldbeck is closely associated with neighbouring ...

,

Cumbria

Cumbria ( ) is a ceremonial and non-metropolitan county in North West England, bordering Scotland. The county and Cumbria County Council, its local government, came into existence in 1974 after the passage of the Local Government Act 1972. Cumb ...

, England, perhaps from the 1560s. A wagonway was built at

Prescot

Prescot is a town and civil parish within the Metropolitan Borough of Knowsley in Merseyside, England. Within the boundaries of the historic county of Lancashire, it lies about to the east of Liverpool city centre. At the 2001 Census, the civ ...

, near

Liverpool

Liverpool is a city and metropolitan borough in Merseyside, England. With a population of in 2019, it is the 10th largest English district by population and its metropolitan area is the fifth largest in the United Kingdom, with a popul ...

, sometime around 1600, possibly as early as 1594. Owned by Philip Layton, the line carried coal from a pit near Prescot Hall to a terminus about half a mile (800 m) away. A funicular railway was also made at

Broseley

Broseley is a market town in Shropshire, England, with a population of 4,929 at the 2011 Census and an estimate of 5,022 in 2019. The River Severn flows to its north and east. The first The Iron Bridge, iron bridge in the world was built in 17 ...

in

Shropshire

Shropshire (; alternatively Salop; abbreviated in print only as Shrops; demonym Salopian ) is a landlocked historic county in the West Midlands region of England. It is bordered by Wales to the west and the English counties of Cheshire to th ...

some time before 1604. This carried coal for James Clifford from his mines down to the

river Severn

, name_etymology =

, image = SevernFromCastleCB.JPG

, image_size = 288

, image_caption = The river seen from Shrewsbury Castle

, map = RiverSevernMap.jpg

, map_size = 288

, map_c ...

to be loaded onto barges and carried to riverside towns. The

Wollaton Wagonway

The Wollaton Wagonway (or Waggonway), built between October 1603 and 1604 in the East Midlands of England by Huntingdon Beaumont in partnership with Sir Percival Willoughby, has sometimes been credited as the world's first ''overground'' wagonwa ...

, completed in 1604 by

Huntingdon Beaumont

Huntingdon Beaumont (c.1560–1624) was an English coal mining entrepreneur who built two of the earliest wagonways in England for trans-shipment of coal. He was less successful as a businessman and died having been imprisoned for debt.

Beaum ...

, has sometimes erroneously been cited as the earliest British railway. It ran from

Strelley

Strelley is a village and civil parish in the Borough of Broxtowe and City of Nottingham in Nottinghamshire, England. It is to the west of Nottingham. The population of the civil parish taken at the 2011 census was 653. It is also the name of t ...

to

Wollaton

Wollaton is a suburb and former parish in the western part of Nottingham, England. Wollaton has two Wards in the City of Nottingham (''Wollaton East and Lenton Abbey'' and ''Wollaton West'') with a total population as at the 2011 census of 24,69 ...

near

Nottingham

Nottingham ( , East Midlands English, locally ) is a city status in the United Kingdom, city and Unitary authorities of England, unitary authority area in Nottinghamshire, East Midlands, England. It is located north-west of London, south-east ...

.

The

Middleton Railway

The Middleton Railway is the world's oldest continuously working railway, situated in the English city of Leeds. It was founded in 1758 and is now a heritage railway, run by volunteers from The Middleton Railway Trust Ltd. since 1960.

The rail ...

in

Leeds

Leeds () is a city and the administrative centre of the City of Leeds district in West Yorkshire, England. It is built around the River Aire and is in the eastern foothills of the Pennines. It is also the third-largest settlement (by populati ...

, which was built in 1758, later became the world's oldest operational railway (other than funiculars), albeit now in an upgraded form. In 1764, the first railway in the Americas was built in

Lewiston, New York

Lewiston is a town in Niagara County, New York, United States. The population was 15,944 at the 2020 census. The town and its contained village are named after Morgan Lewis, a governor of New York.

The Town of Lewiston is on the western bord ...

.

Metal rails introduced

In the late 1760s, the

Coalbrookdale

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

This is where iron ore was first s ...

Company began to fix plates of

cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

to the upper surface of the wooden rails. This allowed a variation of

gauge

Gauge ( or ) may refer to:

Measurement

* Gauge (instrument), any of a variety of measuring instruments

* Gauge (firearms)

* Wire gauge, a measure of the size of a wire

** American wire gauge, a common measure of nonferrous wire diameter, es ...

to be used. At first only

balloon loop

A balloon loop, turning loop, or reversing loop ( North American Terminology) allows a rail vehicle or train to reverse direction without having to shunt or stop. Balloon loops can be useful for passenger trains and unit freight trains.

Bal ...

s could be used for turning, but later, movable points were taken into use that allowed for switching.

A system was introduced in which unflanged wheels ran on L-shaped metal plates these became known as

plateway

A plateway is an early kind of railway, tramway or wagonway, where the rails are made from cast iron. They were mainly used for about 50 years up to 1830, though some continued later.

Plateways consisted of "L"-shaped rails, where the flange o ...

s.

John Curr

John Curr (c. 1756 – 27 January 1823) was the manager or viewer of the Duke of Norfolk's collieries in Sheffield, England from 1781 to 1801. During this time he made a number of innovations that contributed significantly to the development of t ...

, a Sheffield colliery manager, invented this flanged rail in 1787, though the exact date of this is disputed. The plate rail was taken up by

Benjamin Outram

Benjamin Outram (1 April 1764 – 22 May 1805) was an English civil engineer, surveyor and industrialist. He was a pioneer in the building of canals and tramways.

Life

Born at Alfreton in Derbyshire, he began his career assisting his father ...

for wagonways serving his canals, manufacturing them at his

Butterley ironworks. In 1803,

William Jessop

William Jessop (23 January 1745 – 18 November 1814) was an English civil engineer, best known for his work on canals, harbours and early railways in the late 18th and early 19th centuries.

Early life

Jessop was born in Devonport, Devon, the ...

opened the

Surrey Iron Railway

The Surrey Iron Railway (SIR) was a horse-drawn plateway that linked Wandsworth and Croydon via Mitcham, all then in Surrey but now suburbs of south London, in England. It was established by Act of Parliament in 1801, and opened partly in 1802 a ...

, a double track plateway, erroneously sometimes cited as world's first public railway, in south London.

Meanwhile,

William Jessop

William Jessop (23 January 1745 – 18 November 1814) was an English civil engineer, best known for his work on canals, harbours and early railways in the late 18th and early 19th centuries.

Early life

Jessop was born in Devonport, Devon, the ...

had earlier used a form of all-iron

edge rail

Wagonways (also spelt Waggonways), also known as horse-drawn railways and horse-drawn railroad consisted of the horses, equipment and tracks used for hauling wagons, which preceded steam-powered railways. The terms plateway, tramway, dramway ...

and flanged wheels successfully for an extension to the

Charnwood Forest Canal

The Charnwood Forest Canal, sometimes known as the "Forest Line of the Leicester Navigation", was opened between Thringstone and Nanpantan, with a further connection to Barrow Hill, near Worthington, in 1794

It marks the beginning of a period ...

at

Nanpantan

Nanpantan is a suburb in the Charnwood borough of Leicestershire, England. It is located in the south-west of the town of Loughborough, but the village is slightly separated from the main built-up area of Loughborough. It is also the site of ...

,

Loughborough

Loughborough ( ) is a market town in the Charnwood borough of Leicestershire, England, the seat of Charnwood Borough Council and Loughborough University. At the 2011 census the town's built-up area had a population of 59,932 , the second larg ...

,

Leicestershire

Leicestershire ( ; postal abbreviation Leics.) is a ceremonial and non-metropolitan county in the East Midlands, England. The county borders Nottinghamshire to the north, Lincolnshire to the north-east, Rutland to the east, Northamptonshire t ...

in 1789. In 1790, Jessop and his partner Outram began to manufacture edge-rails. Jessop became a partner in the Butterley Company in 1790. The first public edgeway (thus also first public railway) built was

Lake Lock Rail Road

The Lake Lock Rail Road was an early, approximately long, horse drawn narrow gauge railway built near Wakefield, West Yorkshire, England. The railway is recognised as the world's first public railway, though other railway schemes around the same ...

in 1796. Although the primary purpose of the line was to carry coal, it also carried passengers.

These two systems of constructing iron railways, the "L" plate-rail and the smooth edge-rail, continued to exist side by side until well into the early 19th century. The flanged wheel and edge-rail eventually proved its superiority and became the standard for railways.

Cast iron used in rails proved unsatisfactory because it was brittle and broke under heavy loads. The

wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

invented by

John Birkinshaw

John Birkinshaw (1777-1842) was a 19th-century railway engineer from Bedlington, Northumberland noted for his invention of wrought iron rails in 1820 (patented on October 23, 1820).

Up to this point, rail systems had used either wooden rails, w ...

in 1820 replaced cast iron.

Wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

(usually simply referred to as "iron") was a ductile material that could undergo considerable deformation before breaking, making it more suitable for iron rails. But iron was expensive to produce until

Henry Cort

Henry Cort (c. 1740 – 23 May 1800) was an English ironware producer although formerly a Navy pay agent. During the Industrial Revolution in England, Cort began refining iron from pig iron to wrought iron (or bar iron) using innovative producti ...

patented the

puddling process in 1784. In 1783 Cort also patented the

rolling process, which was 15 times faster at consolidating and shaping iron than hammering. These processes greatly lowered the cost of producing iron and rails. The next important development in iron production was

hot blast

Hot blast refers to the preheating of air blown into a blast furnace or other metallurgical process. As this considerably reduced the fuel consumed, hot blast was one of the most important technologies developed during the Industrial Revolution. ...

developed by

James Beaumont Neilson

James Beaumont Neilson (22 June 1792 – 18 January 1865) was a Scottish inventor whose hot-blast process greatly increased the efficiency of smelting iron.

Life

He was the son of the engineer Walter Neilson, a millwright and later engin ...

(patented 1828), which considerably reduced the amount of

coke (fuel)

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iro ...

or charcoal needed to produce pig iron. Wrought iron was a soft material that contained slag or ''dross''. The softness and dross tended to make iron rails distort and delaminate and they lasted less than 10 years. Sometimes they lasted as little as one year under high traffic. All these developments in the production of iron eventually led to replacement of composite wood/iron rails with superior all-iron rails.

The introduction of the

Bessemer process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is steelmaking, removal of impurities from the iron by ox ...

, enabling steel to be made inexpensively, led to the era of great expansion of railways that began in the late 1860s. Steel rails lasted several times longer than iron.

Steel rails made heavier locomotives possible, allowing for longer trains and improving the productivity of railroads. The Bessemer process introduced nitrogen into the steel, which caused the steel to become brittle with age. The

open hearth furnace

An open-hearth furnace or open hearth furnace is any of several kinds of industrial Industrial furnace, furnace in which excess carbon and other impurities are burnt out of pig iron to Steelmaking, produce steel. Because steel is difficult to ma ...

began to replace the Bessemer process near the end of the 19th century, improving the quality of steel and further reducing costs. Thus steel completely replaced the use of iron in rails, becoming standard for all railways.

The first passenger

horsecar

A horsecar, horse-drawn tram, horse-drawn streetcar (U.S.), or horse-drawn railway (historical), is an animal-powered (usually horse) tram or streetcar.

Summary

The horse-drawn tram (horsecar) was an early form of public rail transport, wh ...

or

tram

A tram (called a streetcar or trolley in North America) is a rail vehicle that travels on tramway tracks on public urban streets; some include segments on segregated right-of-way. The tramlines or networks operated as public transport are ...

,

Swansea and Mumbles Railway

The Swansea and Mumbles Railway was the venue for the world's first passenger horsecar railway service, located in Swansea, Wales, United Kingdom.

Originally built under an Act of Parliament of 1804 to move limestone from the quarries of Mum ...

was opened between

Swansea

Swansea (; cy, Abertawe ) is a coastal city and the second-largest city of Wales. It forms a principal area, officially known as the City and County of Swansea ( cy, links=no, Dinas a Sir Abertawe).

The city is the twenty-fifth largest in ...

and

Mumbles

Mumbles ( cy, Mwmbwls) is a headland sited on the western edge of Swansea Bay on the southern coast of Wales.

Toponym

Mumbles has been noted for its unusual place name. The headland is thought by some to have been named by French sailors, ...

in

Wales

Wales ( cy, Cymru ) is a Countries of the United Kingdom, country that is part of the United Kingdom. It is bordered by England to the Wales–England border, east, the Irish Sea to the north and west, the Celtic Sea to the south west and the ...

in 1807. Horses remained the preferable mode for tram transport even after the arrival of steam engines until the end of the 19th century, because they were cleaner compared to steam-driven trams which caused smoke in city streets.

Steam power introduced

In 1784

James Watt

James Watt (; 30 January 1736 (19 January 1736 OS) – 25 August 1819) was a Scottish inventor, mechanical engineer, and chemist who improved on Thomas Newcomen's 1712 Newcomen steam engine with his Watt steam engine in 1776, which was fun ...

, a Scottish inventor and mechanical engineer, patented a design for a

steam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomot ...

. Watt had improved the

steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be trans ...

of

Thomas Newcomen

Thomas Newcomen (; February 1664 – 5 August 1729) was an English inventor who created the atmospheric engine, the first practical fuel-burning engine in 1712. He was an ironmonger by trade and a Baptist lay preacher by calling.

He ...

, hitherto used to pump water out of mines, and developed a

reciprocating engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common featu ...

in 1769 capable of powering a wheel. This was a large

stationary engine

A stationary engine is an engine whose framework does not move. They are used to drive immobile equipment, such as pumps, generators, mills or factory machinery, or cable cars. The term usually refers to large immobile reciprocating engines, pr ...

, powering cotton mills and a variety of machinery; the state of boiler technology necessitated the use of low-pressure steam acting upon a vacuum in the cylinder, which required a separate

condenser and an

air pump

An air pump is a pump for pushing air. Examples include a bicycle pump, pumps that are used to aerate an aquarium or a pond via an airstone; a gas compressor used to power a pneumatic tool, air horn or pipe organ; a bellows used to encourage ...

. Nevertheless, as the construction of boilers improved, Watt investigated the use of high-pressure steam acting directly upon a piston, raising the possibility of a smaller engine that might be used to power a vehicle. Following his patent, Watt's employee

William Murdoch

William Murdoch (sometimes spelled Murdock) (21 August 1754 – 15 November 1839) was a Scottish engineer and inventor.

Murdoch was employed by the firm of Boulton & Watt and worked for them in Cornwall, as a steam engine erector for ten yea ...

produced a working model of a self-propelled steam carriage in that year.

The first full-scale working railway

steam locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomot ...

was built in the United Kingdom in 1804 by

Richard Trevithick

Richard Trevithick (13 April 1771 – 22 April 1833) was a British inventor and mining engineer. The son of a mining captain, and born in the mining heartland of Cornwall, Trevithick was immersed in mining and engineering from an early age. He w ...

, a British engineer born in

Cornwall

Cornwall (; kw, Kernow ) is a historic county and ceremonial county in South West England. It is recognised as one of the Celtic nations, and is the homeland of the Cornish people. Cornwall is bordered to the north and west by the Atlantic ...

. This used high-pressure steam to drive the engine by one power stroke. The transmission system employed a large

flywheel

A flywheel is a mechanical device which uses the conservation of angular momentum to store rotational energy; a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, ass ...

to even out the action of the piston rod. On 21 February 1804, the world's first steam-powered railway journey took place when Trevithick's unnamed steam locomotive hauled a train along the tramway of the

Penydarren

: ''For Trevithick's Pen-y-darren locomotive, see Richard Trevithick.''

Penydarren is a community and electoral ward in Merthyr Tydfil County Borough in Wales.

Description

The area is most notable for being the site of a 1st-century Roman fort, ...

ironworks, near

Merthyr Tydfil

Merthyr Tydfil (; cy, Merthyr Tudful ) is the main town in Merthyr Tydfil County Borough, Wales, administered by Merthyr Tydfil County Borough Council. It is about north of Cardiff. Often called just Merthyr, it is said to be named after Tydf ...

in

South Wales

South Wales ( cy, De Cymru) is a loosely defined region of Wales bordered by England to the east and mid Wales to the north. Generally considered to include the historic counties of Glamorgan and Monmouthshire, south Wales extends westwards ...

. Trevithick later demonstrated a locomotive operating upon a piece of circular rail track in

Bloomsbury

Bloomsbury is a district in the West End of London. It is considered a fashionable residential area, and is the location of numerous cultural, intellectual, and educational institutions.

Bloomsbury is home of the British Museum, the largest mus ...

, London, the ''

Catch Me Who Can

''Catch Me Who Can'' was the fourth and last steam locomotive, steam railway locomotive created by the inventor and mining engineer Richard Trevithick. It was an evolution of three earlier locomotives which had been built for Coalbrookdale, Pe ...

'', but never got beyond the experimental stage with railway locomotives, not least because his engines were too heavy for the cast-iron plateway track then in use.

The first commercially successful steam locomotive was

Matthew Murray

Matthew Murray (1765 – 20 February 1826) was an English steam engine and machine tool manufacturer, who designed and built the first commercially viable steam locomotive, the twin cylinder ''Salamanca'' in 1812. He was an innovative design ...

's

rack

Rack or racks may refer to:

Storage and installation

* Amp rack, short for amplifier rack, a piece of furniture in which amplifiers are mounted

* Bicycle rack, a frame for storing bicycles when not in use

* Bustle rack, a type of storage bi ...

locomotive ''

Salamanca

Salamanca () is a city in western Spain and is the capital of the Province of Salamanca in the autonomous community of Castile and León. The city lies on several rolling hills by the Tormes River. Its Old City was declared a UNESCO World Heritag ...

'' built for the

Middleton Railway

The Middleton Railway is the world's oldest continuously working railway, situated in the English city of Leeds. It was founded in 1758 and is now a heritage railway, run by volunteers from The Middleton Railway Trust Ltd. since 1960.

The rail ...

in

Leeds

Leeds () is a city and the administrative centre of the City of Leeds district in West Yorkshire, England. It is built around the River Aire and is in the eastern foothills of the Pennines. It is also the third-largest settlement (by populati ...

in 1812. This twin-cylinder locomotive was light enough to not break the

edge-rails track and solved the problem of

adhesion

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another ( cohesion refers to the tendency of similar or identical particles/surfaces to cling to one another).

The forces that cause adhesion and cohesion can be ...

by a

cog-wheel

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic pr ...

using teeth cast on the side of one of the rails. Thus it was also the first

rack railway

A rack railway (also rack-and-pinion railway, cog railway, or cogwheel railway) is a steep grade railway with a toothed rack rail, usually between the running rails. The trains are fitted with one or more cog wheels or pinions that mesh with th ...

.

This was followed in 1813 by the locomotive ''

Puffing Billy'' built by

Christopher Blackett

Christopher Blackett (1751 – 25 January 1829) owned the Northumberland colliery at Wylam that built ''Puffing Billy'', the first commercial adhesion steam locomotive. He was also the founding owner of ''The Globe'' newspaper in 1803.

Lif ...

and

William Hedley

William Hedley (13 July 1779 – 9 January 1843) was born in Newburn, near Newcastle upon Tyne. He was one of the leading industrial engineers of the early 19th century, and was instrumental in several major innovations in early rail transpor ...

for the

Wylam

Wylam is a village and civil parish in the county of Northumberland. It is located about west of Newcastle upon Tyne.

It is famous for the being the birthplace of George Stephenson, one of the early railway pioneers. George Stephenson's Birth ...

Colliery Railway, the first successful locomotive running by

adhesion

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another ( cohesion refers to the tendency of similar or identical particles/surfaces to cling to one another).

The forces that cause adhesion and cohesion can be ...

only. This was accomplished by the distribution of weight between a number of wheels. ''Puffing Billy'' is now on display in the

Science Museum

A science museum is a museum devoted primarily to science. Older science museums tended to concentrate on static displays of objects related to natural history, paleontology, geology, industry and industrial machinery, etc. Modern trends in mu ...

in London, and is the oldest locomotive in existence.

In 1814

George Stephenson

George Stephenson (9 June 1781 – 12 August 1848) was a British civil engineer and mechanical engineer. Renowned as the "Father of Railways", Stephenson was considered by the Victorians a great example of diligent application and thirst for ...

, inspired by the early locomotives of Trevithick, Murray and Hedley, persuaded the manager of the

Killingworth

Killingworth, formerly Killingworth Township, is a town in North Tyneside, England.

Killingworth was built as a planned town in the 1960s, next to Killingworth Village, which existed for centuries before the Township. Other nearby towns and ...

colliery

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from ...

where he worked to allow him to build a

steam-powered

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be tr ...

machine. Stephenson played a pivotal role in the development and widespread adoption of the steam locomotive. His designs considerably improved on the work of the earlier pioneers. He built the locomotive ''

Blücher'', also a successful

flange

A flange is a protruded ridge, lip or rim (wheel), rim, either external or internal, that serves to increase shear strength, strength (as the flange of an iron beam (structure), beam such as an I-beam or a T-beam); for easy attachment/transfer of ...

d-wheel adhesion locomotive. In 1825 he built the locomotive ''

Locomotion

Locomotion means the act or ability of something to transport or move itself from place to place.

Locomotion may refer to:

Motion

* Motion (physics)

* Robot locomotion, of man-made devices

By environment

* Aquatic locomotion

* Flight

* Locomo ...

'' for the

Stockton and Darlington Railway

The Stockton and Darlington Railway (S&DR) was a railway company that operated in north-east England from 1825 to 1863. The world's first public railway to use steam locomotives, its first line connected collieries near Shildon with Darl ...

in the north east of England, which became the first public steam railway in the world in 1825, although it used both horse power and steam power on different runs. In 1829, he built the locomotive ''

Rocket

A rocket (from it, rocchetto, , bobbin/spool) is a vehicle that uses jet propulsion to accelerate without using the surrounding air. A rocket engine produces thrust by reaction to exhaust expelled at high speed. Rocket engines work entirely fr ...

'', which entered in and won the

Rainhill Trials. This success led to Stephenson establishing his company as the pre-eminent builder of steam locomotives for railways in Great Britain and Ireland, the United States, and much of Europe.

The first public railway which used only steam locomotives, all the time, was

Liverpool and Manchester Railway

The Liverpool and Manchester Railway (L&MR) was the first inter-city railway in the world. It opened on 15 September 1830 between the Lancashire towns of Liverpool and Manchester in England. It was also the first railway to rely exclusively ...

, built in 1830.

Steam power continued to be the dominant power system in railways around the world for more than a century.

Electric power introduced

The first known electric locomotive was built in 1837 by chemist

Robert Davidson of

Aberdeen

Aberdeen (; sco, Aiberdeen ; gd, Obar Dheathain ; la, Aberdonia) is a city in North East Scotland, and is the third most populous city in the country. Aberdeen is one of Scotland's 32 local government council areas (as Aberdeen City), and ...

in Scotland, and it was powered by

galvanic cell

A galvanic cell or voltaic cell, named after the scientists Luigi Galvani and Alessandro Volta, respectively, is an electrochemical cell in which an electric current is generated from spontaneous Oxidation-Reduction reactions. A common apparatus ...

s (batteries). Thus it was also the earliest battery electric locomotive. Davidson later built a larger locomotive named ''Galvani'', exhibited at the

Royal Scottish Society of Arts

The Royal Scottish Society of Arts is a learned society in Scotland, dedicated to the study of science and technology. It was founded as The Society for the Encouragement of the Useful Arts in Scotland by David Brewster, Sir David Brewster in 182 ...

Exhibition in 1841. The seven-ton vehicle had two

direct-drive

A direct-drive mechanism is a mechanism design where the force or torque from a prime mover is transmitted directly to the effector device (such as the drive wheels of a vehicle) without involving any intermediate couplings such as a gear train o ...

reluctance motor

A reluctance motor is a type of electric motor that induces non-permanent magnetic poles on the ferromagnetic rotor. The rotor does not have any windings. It generates torque through magnetic reluctance.

Reluctance motor subtypes include synchro ...

s, with fixed electromagnets acting on iron bars attached to a wooden cylinder on each axle, and simple

commutators. It hauled a load of six tons at four miles per hour (6 kilometers per hour) for a distance of . It was tested on the

Edinburgh and Glasgow Railway

The Edinburgh and Glasgow Railway was authorised by Act of Parliament on 4 July 1838. It was opened to passenger traffic on 21 February 1842, between its Glasgow Queen Street railway station (sometimes referred to at first as Dundas Street) and ...

in September of the following year, but the limited power from batteries prevented its general use. It was destroyed by railway workers, who saw it as a threat to their job security.

[Renzo Pocaterra, ''Treni'', De Agostini, 2003]

Werner von Siemens

Ernst Werner Siemens (von Siemens from 1888; ; ; 13 December 1816 – 6 December 1892) was a German electrical engineer, inventor and industrialist. Siemens's name has been adopted as the SI unit of electrical conductance, the siemens. He foun ...

demonstrated an electric railway in 1879 in Berlin. The world's first electric tram line,

Gross-Lichterfelde Tramway

The Gross Lichterfelde Tramway was one of the world's first electric tramways ( Miller's line was electrified in 1875). It was built by the Siemens & Halske company in Lichterfelde, a suburb of Berlin, and went in service on 16 May 1881.

Ove ...

, opened in

Lichterfelde Lichterfelde may refer to:

* Lichterfelde (Berlin), a locality in the borough of Steglitz-Zehlendorf in Berlin, Germany

* Lichterfelde West, an elegant residential area in Berlin

* Lichterfelde, Saxony-Anhalt, a municipality in the Stendhal Distric ...

near

Berlin

Berlin ( , ) is the capital and largest city of Germany by both area and population. Its 3.7 million inhabitants make it the European Union's most populous city, according to population within city limits. One of Germany's sixteen constitue ...

, Germany, in 1881. It was built by Siemens. The tram ran on 180 volts DC, which was supplied by running rails. In 1891 the track was equipped with an

overhead wire

An overhead line or overhead wire is an electrical cable that is used to transmit electrical energy to electric locomotives, trolleybuses or trams. It is known variously as:

* Overhead catenary

* Overhead contact system (OCS)

* Overhead equipmen ...

and the line was extended to

Berlin-Lichterfelde West station

Berlin-Lichterfelde West (in German Bahnhof Berlin-Lichterfelde West) is a railway station in Lichterfelde West, within the district of Lichterfelde ( Steglitz-Zehlendorf) in Berlin, Germany. It is served by the Berlin S-Bahn and several local bus ...

. The

Volk's Electric Railway

Volk's Electric Railway (VER) is a narrow gauge railway, narrow gauge heritage railway that runs along a length of the seafront of the English seaside resort of Brighton. It was built by Magnus Volk, the first section being completed in August ...

opened in 1883 in

Brighton

Brighton () is a seaside resort and one of the two main areas of the City of Brighton and Hove in the county of East Sussex, England. It is located south of London.

Archaeological evidence of settlement in the area dates back to the Bronze A ...

, England. The railway is still operational, thus making it the oldest operational electric railway in the world. Also in 1883,

Mödling and Hinterbrühl Tram

Mödling and Hinterbrühl Tram or ''Mödling and Hinterbrühl Local Railway'' (German: ''Lokalbahn Mödling–Hinterbrühl'') was an electric tramway in Austria, running 4.5 km (2.8 mi) from Mödling to Hinterbrühl, in the southwest ...

opened near Vienna in Austria. It was the first tram line in the world in regular service powered from an overhead line. Five years later, in the U.S. electric

trolleys were pioneered in 1888 on the

Richmond Union Passenger Railway

The Richmond Union Passenger Railway, in Richmond, Virginia, was the first practical electric Tram, trolley (tram) system, and set the pattern for most subsequent electric trolley systems around the world. It is an Institute of Electrical and E ...

, using equipment designed by

Frank J. Sprague

Frank Julian Sprague (July 25, 1857 in Milford, Connecticut – October 25, 1934) was an American inventor who contributed to the development of the electric motor, electric railways, and electric elevators. His contributions were especially ...

.

The first use of electrification on a main line was on a four-mile section of the

Baltimore Belt Line

The Baltimore Belt Line was constructed by the Baltimore and Ohio Railroad (B&O) in the early 1890s to connect the railroad's newly constructed line to Philadelphia and Central Railroad of New Jersey Terminal, New York City/Jersey City with the re ...

of the

Baltimore and Ohio Railroad

The Baltimore and Ohio Railroad was the first common carrier railroad and the oldest railroad in the United States, with its first section opening in 1830. Merchants from Baltimore, which had benefited to some extent from the construction of ...

(B&O) in 1895 connecting the main portion of the B&O to the new line to

New York

New York most commonly refers to:

* New York City, the most populous city in the United States, located in the state of New York

* New York (state), a state in the northeastern United States

New York may also refer to:

Film and television

* '' ...

through a series of tunnels around the edges of Baltimore's downtown. Electricity quickly became the power supply of choice for subways, abetted by the Sprague's invention of multiple-unit train control in 1897. By the early 1900s most street railways were electrified.

The

London Underground

The London Underground (also known simply as the Underground or by its nickname the Tube) is a rapid transit system serving Greater London and some parts of the adjacent ceremonial counties of England, counties of Buckinghamshire, Essex and He ...

, the world's oldest underground railway, opened in 1863, and it began operating electric services using a

fourth rail

A railway electrification system supplies electric power to railway trains and trams without an on-board prime mover or local fuel supply.

Electric railways use either electric locomotives (hauling passengers or freight in separate cars), ele ...

system in 1890 on the

City and South London Railway

The City and South London Railway (C&SLR) was the first successful deep-level underground "tube" railway in the world, and the first major railway to use electric traction. The railway was originally intended for cable-hauled trains, but owing ...

, now part of the

London Underground

The London Underground (also known simply as the Underground or by its nickname the Tube) is a rapid transit system serving Greater London and some parts of the adjacent ceremonial counties of England, counties of Buckinghamshire, Essex and He ...

Northern line

The Northern line is a London Underground line that runs from North London to South London. It is printed in black on the Tube map. The Northern line is unique on the Underground network in having two different routes through central London, two ...

. This was the first major railway to use

electric traction

A railway electrification system supplies electric power to railway trains and trams without an on-board prime mover or local fuel supply.

Electric railways use either electric locomotives (hauling passengers or freight in separate cars), ele ...

. The world's first deep-level electric railway, it runs from the

City of London

The City of London is a city, ceremonial county and local government district that contains the historic centre and constitutes, alongside Canary Wharf, the primary central business district (CBD) of London. It constituted most of London fr ...

, under the

River Thames

The River Thames ( ), known alternatively in parts as the The Isis, River Isis, is a river that flows through southern England including London. At , it is the longest river entirely in England and the Longest rivers of the United Kingdom, se ...

, to

Stockwell

Stockwell is a district in south west London, part of the London Borough of Lambeth, England. It is situated south of Charing Cross. Battersea, Brixton, Clapham, South Lambeth, Oval and Kennington all border Stockwell.

History

The na ...

in south London.

The first practical

AC electric locomotive was designed by

Charles Brown, then working for

Oerlikon, Zürich. In 1891, Brown had demonstrated long-distance power transmission, using

three-phase AC, between a

hydro-electric plant

Hydroelectricity, or hydroelectric power, is electricity generated from hydropower (water power). Hydropower supplies one sixth of the world's electricity, almost 4500 TWh in 2020, which is more than all other renewable sources combined and ...

at

Lauffen am Neckar

Lauffen am Neckar () or simply Lauffen is a town in the district of Heilbronn, Baden-Württemberg, Germany. It is on the river Neckar, southwest of Heilbronn. The town is famous as the birthplace of the poet Friedrich Hölderlin and for its qu ...

and

Frankfurt am Main

Frankfurt, officially Frankfurt am Main (; Hessian: , "Frank ford on the Main"), is the most populous city in the German state of Hesse. Its 791,000 inhabitants as of 2022 make it the fifth-most populous city in Germany. Located on its na ...

West, a distance of 280 km. Using experience he had gained while working for

Jean Heilmann on steam-electric locomotive designs, Brown observed that

three-phase motors had a higher power-to-weight ratio than

DC motors and, because of the absence of a

commutator

In mathematics, the commutator gives an indication of the extent to which a certain binary operation fails to be commutative. There are different definitions used in group theory and ring theory.

Group theory

The commutator of two elements, a ...

, were simpler to manufacture and maintain. However, they were much larger than the DC motors of the time and could not be mounted in underfloor

bogie

A bogie ( ) (in some senses called a truck in North American English) is a chassis or framework that carries a wheelset, attached to a vehicle—a modular subassembly of wheels and axles. Bogies take various forms in various modes of transp ...

s: they could only be carried within locomotive bodies.

In 1894, Hungarian engineer

Kálmán Kandó

Kálmán Kandó de Egerfarmos et Sztregova (''egerfarmosi és sztregovai Kandó Kálmán''; 10 July 1869 – 13 January 1931) was a Hungarian engineer, the inventor of phase converter and a pioneer in the development of AC electric railway tract ...

developed a new type 3-phase asynchronous electric drive motors and generators for electric locomotives. Kandó's early 1894 designs were first applied in a short three-phase AC tramway in

Évian-les-Bains

Évian-les-Bains (), or simply Évian ( frp, Èvian, , or ), is a Communes of France, commune in the northern part of the Haute-Savoie Departments of France, department in the Auvergne-Rhône-Alpes Regions of France, region, Southeastern France. ...

(France), which was constructed between 1896 and 1898.

In 1896, Oerlikon installed the first commercial example of the system on the

Lugano Tramway. Each 30-tonne locomotive had two motors run by three-phase 750 V 40 Hz fed from double overhead lines. Three-phase motors run at constant speed and provide

regenerative braking

Regenerative braking is an energy recovery mechanism that slows down a moving vehicle or object by converting its kinetic energy into a form that can be either used immediately or stored until needed. In this mechanism, the electric traction mo ...

, and are well suited to steeply graded routes, and the first main-line three-phase locomotives were supplied by Brown (by then in partnership with

Walter Boveri

Walter Boveri (born 21 February 1865 in Bamberg, Bavaria, died 28 October 1924 in Baden, Switzerland) was a Swiss-German industrialist and co-founder of the global electrical engineering group Brown, Boveri & Cie. (BBC).

Biography

Boveri's anc ...

) in 1899 on the 40 km

Burgdorf–Thun line, Switzerland.

Italian railways were the first in the world to introduce electric traction for the entire length of a main line rather than a short section. The 106 km

Valtellina

Valtellina or the Valtelline (occasionally spelled as two words in English: Val Telline; rm, Vuclina (); lmo, Valtelina or ; german: Veltlin; it, Valtellina) is a valley in the Lombardy region of northern Italy, bordering Switzerland. Toda ...

line was opened on 4 September 1902, designed by Kandó and a team from the Ganz works.

The electrical system was three-phase at 3 kV 15 Hz. In 1918, Kandó invented and developed the

rotary phase converter

A rotary phase converter, abbreviated RPC, is an electrical machine that converts power from one polyphase system to another, converting through rotary motion. Typically, single-phase electric power is used to produce three-phase electric power ...

, enabling electric locomotives to use three-phase motors whilst supplied via a single overhead wire, carrying the simple industrial frequency (50 Hz) single phase AC of the high voltage national networks.

An important contribution to the wider adoption of AC traction came from SNCF of France after World War II. The company conducted trials at AC 50 Hz, and established it as a standard. Following SNCF's successful trials, 50 Hz, now also called industrial frequency was adopted as standard for main-lines across the world.

Diesel power introduced

Earliest recorded examples of an internal combustion engine for railway use included a prototype designed by

William Dent Priestman

William Dent Priestman (23 August 1847 7 September 1936), born near Kingston upon Hull was a Quaker and engineering pioneer, inventor of the Priestman Oil Engine, and co-founder with his brother Samuel of the Priestman Brothers engineering com ...

, which was examined by

Sir William Thomson

William Thomson, 1st Baron Kelvin, (26 June 182417 December 1907) was a British mathematician, mathematical physicist and engineer born in Belfast. Professor of Natural Philosophy at the University of Glasgow for 53 years, he did important ...

in 1888 who described it as a ''"

riestman oil enginemounted upon a truck which is worked on a temporary line of rails to show the adaptation of a petroleum engine for locomotive purposes."''. In 1894, a two axle machine built by

Priestman Brothers

Priestman Brothers was an engineering company based in Kingston upon Hull, England that manufactured diggers, dredgers, cranes and other industrial machinery. In the later 1800s the company also produced the Priestman Oil Engine, an early desi ...

was used on the

Hull Docks

The Port of Hull is a port at the confluence of the River Hull and the Humber Estuary in Kingston upon Hull, in the East Riding of Yorkshire, England.

Seaborne trade at the port can be traced to at least the 13th century, originally cond ...

.

In 1906,

Rudolf Diesel

Rudolf Christian Karl Diesel (, ; 18 March 1858 – 29 September 1913) was a German inventor and Mechanical engineering, mechanical engineer who is famous for having invented the diesel engine, which burns diesel fuel; both are named after him.

...

,

Adolf Klose

Adolf Klose (21 May 1844 – 2 September 1923) was the chief engineer of the Royal Württemberg State Railways in southern Germany from June 1885 to 1896.

Klose was born in Bernstadt auf dem Eigen, in Saxony. Before his taking up his post in Stu ...

and the steam and diesel engine manufacturer

Gebrüder Sulzer founded Diesel-Sulzer-Klose GmbH to manufacture diesel-powered locomotives. Sulzer had been manufacturing diesel engines since 1898. The Prussian State Railways ordered a diesel locomotive from the company in 1909. The world's first diesel-powered locomotive was operated in the summer of 1912 on the

Winterthur–Romanshorn railway

The Winterthur–Romanshorn railway, also known in German as the ''Thurtallinie'' ("Thur valley line"), is a Swiss railway line and was built as part of the railway between Zürich and Lake Constance (Bodensee). It connects Winterthur with Romans ...

in Switzerland, but was not a commercial success. The locomotive weight was 95 tonnes and the power was 883 kW with a maximum speed of 100 km/h. Small numbers of prototype diesel locomotives were produced in a number of countries through the mid-1920s. The

Soviet Union

The Soviet Union,. officially the Union of Soviet Socialist Republics. (USSR),. was a transcontinental country that spanned much of Eurasia from 1922 to 1991. A flagship communist state, it was nominally a federal union of fifteen national ...

operated three experimental units of different designs since late 1925, though only one of them (the

E el-2) proved technically viable.

A significant breakthrough occurred in 1914, when

Hermann Lemp, a

General Electric

General Electric Company (GE) is an American multinational conglomerate founded in 1892, and incorporated in New York state and headquartered in Boston. The company operated in sectors including healthcare, aviation, power, renewable energ ...

electrical engineer, developed and patented a reliable

direct current

Direct current (DC) is one-directional flow of electric charge. An electrochemical cell is a prime example of DC power. Direct current may flow through a conductor such as a wire, but can also flow through semiconductors, insulators, or even ...

electrical control system (subsequent improvements were also patented by Lemp). Lemp's design used a single lever to control both engine and generator in a coordinated fashion, and was the

prototype

A prototype is an early sample, model, or release of a product built to test a concept or process. It is a term used in a variety of contexts, including semantics, design, electronics, and Software prototyping, software programming. A prototyp ...

for all

diesel–electric locomotive

A diesel locomotive is a type of railway locomotive in which the prime mover is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels ...

control systems. In 1914, world's first functional diesel–electric railcars were produced for the ''Königlich-Sächsische Staatseisenbahnen'' (

Royal Saxon State Railways

The Royal Saxon State Railways (german: Königlich Sächsische Staatseisenbahnen) were the state-owned railways operating in the Kingdom of Saxony from 1869 to 1918. From 1918 until their merger into the Deutsche Reichsbahn the title 'Royal' was ...

) by

Waggonfabrik Rastatt

( en, Rastatt Coach Factory) is a German public-limited company based in Rastatt in the state of Baden-Württemberg in southwestern Germany. Its chief products are tramway vehicles and railway coaches and wagons. The firm was founded in and b ...

with electric equipment from

Brown, Boveri & Cie

Brown, Boveri & Cie. (Brown, Boveri & Company; BBC) was a Swiss group of electrical engineering companies.

It was founded in Zürich, in 1891 by Charles Eugene Lancelot Brown and Walter Boveri who worked at the Maschinenfabrik Oerlikon. In 1 ...

and diesel engines from

Swiss

Swiss may refer to:

* the adjectival form of Switzerland

* Swiss people

Places

* Swiss, Missouri

* Swiss, North Carolina

*Swiss, West Virginia

* Swiss, Wisconsin

Other uses

*Swiss-system tournament, in various games and sports

*Swiss Internation ...

Sulzer AG

Sulzer Ltd. is a Swiss industrial engineering and manufacturing firm, founded by Salomon Sulzer-Bernet in 1775 and established as Sulzer Brothers Ltd. (Gebrüder Sulzer) in 1834 in Winterthur, Switzerland. Today it is a publicly traded company w ...

. They were classified as

DET 1 and DET 2 (

de.wiki). The first regular use of diesel-electric locomotives was in

switching (shunter) applications. General Electric produced several small switching locomotives in the 1930s (the famous "

44-tonner" switcher was introduced in 1940) Westinghouse Electric and Baldwin collaborated to build switching locomotives starting in 1929.

In 1929, the

Canadian National Railways

The Canadian National Railway Company (french: Compagnie des chemins de fer nationaux du Canada) is a Canadian Class I railroad, Class I freight railway headquartered in Montreal, Quebec, which serves Canada and the Midwestern United States, M ...

became the first North American railway to use diesels in mainline service with two units, 9000 and 9001, from Westinghouse.

High-speed rail

Although steam and diesel services reaching speeds up to 200 km/h were started before the 1960s in Europe, they were not very successful.

The first electrified

high-speed rail

High-speed rail (HSR) is a type of rail system that runs significantly faster than traditional rail, using an integrated system of specialised rolling stock and dedicated tracks. While there is no single standard that applies worldwide, lines ...

Tōkaidō Shinkansen

The is a Japanese high-speed rail line that is part of the nationwide Shinkansen network. Along with the Sanyo Shinkansen, it forms a continuous high-speed railway through the Taiheiyō Belt, also known as the Tokaido corridor. Opened in 1964, ...

was introduced in 1964 between

Tokyo

Tokyo (; ja, 東京, , ), officially the Tokyo Metropolis ( ja, 東京都, label=none, ), is the capital and largest city of Japan. Formerly known as Edo, its metropolitan area () is the most populous in the world, with an estimated 37.468 ...

and

Osaka

is a designated city in the Kansai region of Honshu in Japan. It is the capital of and most populous city in Osaka Prefecture, and the third most populous city in Japan, following Special wards of Tokyo and Yokohama. With a population of 2. ...

in Japan. Since then

high-speed rail

High-speed rail (HSR) is a type of rail system that runs significantly faster than traditional rail, using an integrated system of specialised rolling stock and dedicated tracks. While there is no single standard that applies worldwide, lines ...

transport, functioning at speeds up to and above 300 km/h, has been built in Japan, Spain, France, Germany, Italy, the People's Republic of China, Taiwan (Republic of China), the

United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Europe, off the north-western coast of the continental mainland. It comprises England, Scotland, Wales and North ...

,

South Korea

South Korea, officially the Republic of Korea (ROK), is a country in East Asia, constituting the southern part of the Korea, Korean Peninsula and sharing a Korean Demilitarized Zone, land border with North Korea. Its western border is formed ...

,

Scandinavia

Scandinavia; Sámi languages: /. ( ) is a subregion#Europe, subregion in Northern Europe, with strong historical, cultural, and linguistic ties between its constituent peoples. In English usage, ''Scandinavia'' most commonly refers to Denmark, ...

,

Belgium

Belgium, ; french: Belgique ; german: Belgien officially the Kingdom of Belgium, is a country in Northwestern Europe. The country is bordered by the Netherlands to the north, Germany to the east, Luxembourg to the southeast, France to th ...

and the

Netherlands

)

, anthem = ( en, "William of Nassau")

, image_map =

, map_caption =

, subdivision_type = Sovereign state

, subdivision_name = Kingdom of the Netherlands

, established_title = Before independence

, established_date = Spanish Netherl ...

. The construction of many of these lines has resulted in the dramatic decline of short-haul flights and automotive traffic between connected cities, such as the London–Paris–Brussels corridor, Madrid–Barcelona, Milan–Rome–Naples, as well as many other major lines.

High-speed trains normally operate on

standard gauge