Hobbing on:

[Wikipedia]

[Google]

[Amazon]

Hobbing is a

Hobbing is a

Hobbing uses a hobbing machine with two skew spindles. One spindle is mounted with a blank workpiece and the other holds the hob. The angle between the hob's spindle (axis) and the workpiece's spindle varies depending on the type part being manufactured. For example, if a spur gear is being produced, the spindle is held at the

Hobbing uses a hobbing machine with two skew spindles. One spindle is mounted with a blank workpiece and the other holds the hob. The angle between the hob's spindle (axis) and the workpiece's spindle varies depending on the type part being manufactured. For example, if a spur gear is being produced, the spindle is held at the

Hobbing machines, also known as ''hobbers'', come in many sizes to produce different sizes of gears. Tiny instrument gears are produced on small table-top machines, while large-diameter marine gears are produced on large industrial machines. A hobbing machine typically consists of a

Hobbing machines, also known as ''hobbers'', come in many sizes to produce different sizes of gears. Tiny instrument gears are produced on small table-top machines, while large-diameter marine gears are produced on large industrial machines. A hobbing machine typically consists of a

The ''hob'' is a cutting tool used to cut the teeth into the workpiece. It is cylindrical in shape with

The ''hob'' is a cutting tool used to cut the teeth into the workpiece. It is cylindrical in shape with

British Library remarks

; se

Google Books reprint

which is missing sheets 1 and 2. *. At p. 105, "But it had been recognized that the worm was a form of continuous rack and all that was necessary to cut gears with it was to provide cutting edges on it — to make a hob (Fig. 45). Teeth had been cut by this method probably for the first time by Ramsden in 1768." * *Dudley, Darle W. (1969), "The Evolution of the Gear Art", Published by, American Gear Manufacturers Association, Washington D.C., Library of Congress Catalog Card Number: 72-78509 *Radzevich, Stephen P. (2017), "Gear cutting tools: science and engineering", CRC Press, Second Edition, . Chapter 1 provides a very comprehensive and contemporary history of Gear Cutting Tools in Chapter 1.

Hobbing is a

Hobbing is a machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

process for gear cutting, cutting splines, and cutting sprocket

A sprocket, sprocket-wheel or chainwheel is a profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain pas ...

s on a hobbing machine, which is a special type of milling machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

. The teeth or splines of the gear are progressively cut into the material (a flat, cylindrical piece of metal) by a series of cuts made by a cutting tool

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The major ...

called a hob.

Hobbing is relatively fast and inexpensive compared to most other gear-forming processes and is used for a broad range of parts and quantities. Hobbing is especially common for machining spur and helical gears.

A type of skiving

Skive or skiving may refer to:

* Skive, Denmark, a place in Denmark

** Skive Municipality

** Skive Airport

** Skive station

** Skive fH, a handball club

** Skive IK, a football club

** Skive RC, a rugby club

* Skiving (leathercraft), the thi ...

that is analogous to the hobbing of external gears can be applied to the cutting of internal gears, which are skived with a rotary cutter (rather than shaped or broached).

Process

Hobbing uses a hobbing machine with two skew spindles. One spindle is mounted with a blank workpiece and the other holds the hob. The angle between the hob's spindle (axis) and the workpiece's spindle varies depending on the type part being manufactured. For example, if a spur gear is being produced, the spindle is held at the

Hobbing uses a hobbing machine with two skew spindles. One spindle is mounted with a blank workpiece and the other holds the hob. The angle between the hob's spindle (axis) and the workpiece's spindle varies depending on the type part being manufactured. For example, if a spur gear is being produced, the spindle is held at the lead angle

Lead is the axial advance of a helix or screw during one complete turn (360°) The lead for a screw thread is the axial travel for a single revolution.

''Pitch'' is defined as the axial distance between adjacent threads on a helix or screw. In ...

of the hob, whereas if a helical gear is being produced, the held at the lead angle of the hob plus the helix angle of the helical gear. The hobbing features for gears are straight, helical, straight bevel, face, crowned, worm, cylkro and chamfering. . The speeds of the two spindles are held at a constant proportion determined by the number of teeth being cut into the blank; for example, for a single-threaded hob with a gear ratio of 40:1 the hob rotates 40 times to each turn of the blank, producing 40 teeth in the blank. If the hob has multiple threads, the speed ratio is be multiplied by the number of threads on the hob.. The hob is then fed up into the workpiece until the correct tooth depth is obtained. To finish the operation, the hob is fed through the workpiece parallel to the blank's axis of rotation.

Often during mass production, multiple blanks are stacked using a suitable fixture and cut in one operation.

For very large gears, the blank may be preliminarily gashed to a rough shape to make hobbing more efficient.

Equipment

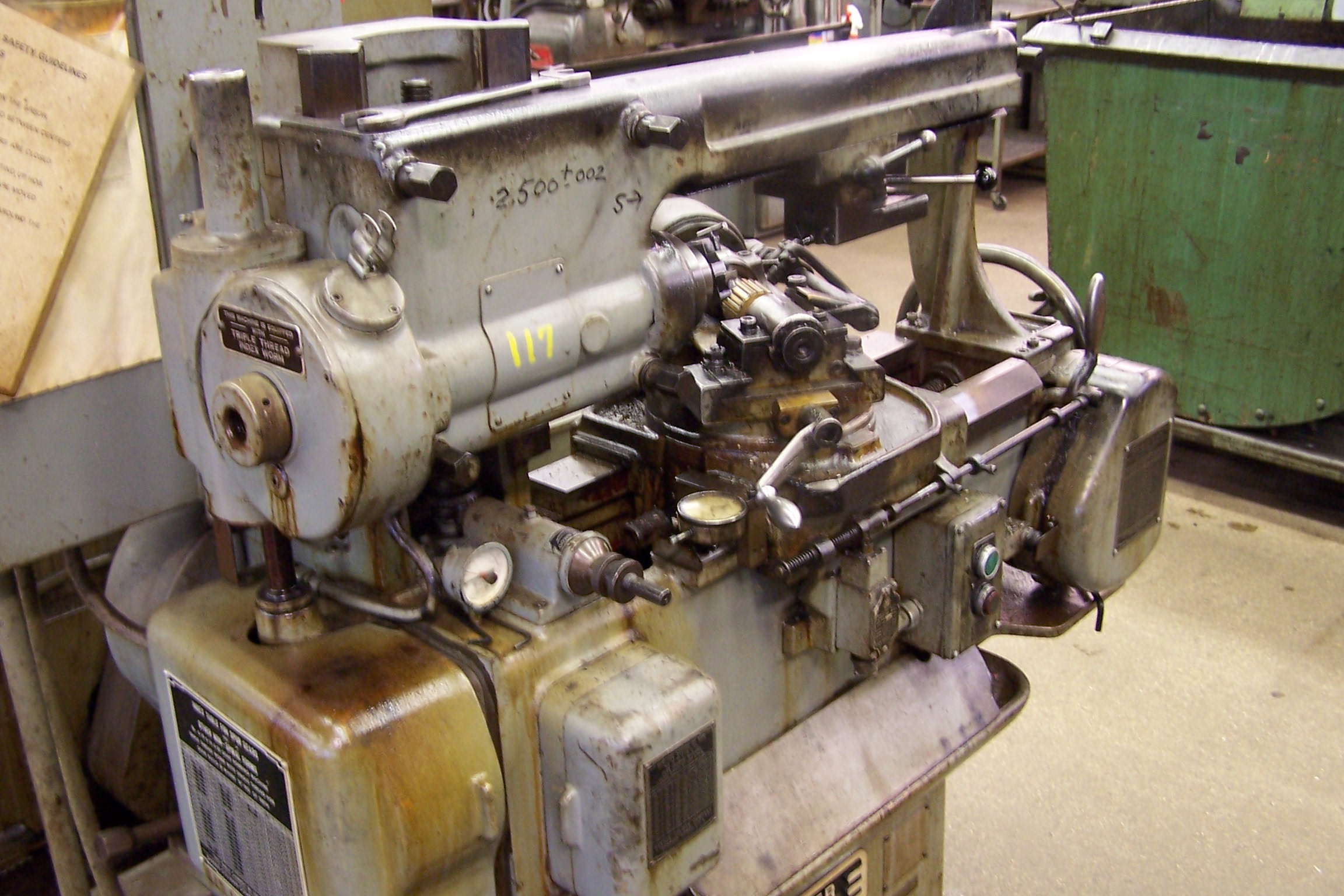

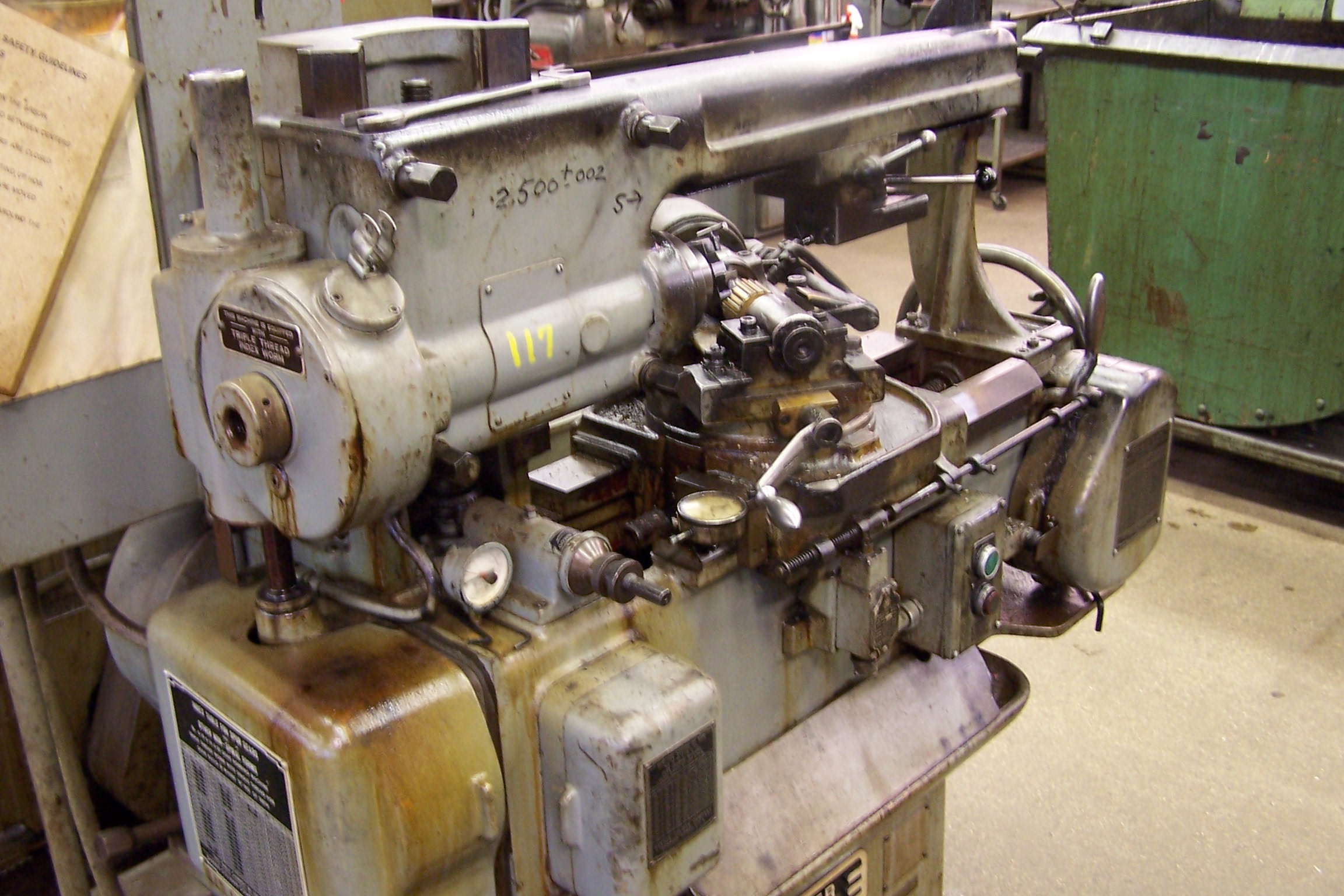

Hobbing machines, also known as ''hobbers'', come in many sizes to produce different sizes of gears. Tiny instrument gears are produced on small table-top machines, while large-diameter marine gears are produced on large industrial machines. A hobbing machine typically consists of a

Hobbing machines, also known as ''hobbers'', come in many sizes to produce different sizes of gears. Tiny instrument gears are produced on small table-top machines, while large-diameter marine gears are produced on large industrial machines. A hobbing machine typically consists of a chuck

Chuck is a masculine given name or a nickname for Charles or Charlie. It may refer to:

People

Arts and entertainment

* Chuck Alaimo, American saxophonist, leader of the Chuck Alaimo Quartet

* Chuck Barris (1929–2017), American TV producer

* C ...

and tailstock

Tailstock used for drilling

A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine.

It is usually used to apply support ...

to hold the workpiece, a spindle to mount the hob, and a drive motor..

For a tooth profile which is theoretically involute

In mathematics, an involute (also known as an evolvent) is a particular type of curve that is dependent on another shape or curve. An involute of a curve is the locus of a point on a piece of taut string as the string is either unwrapped from o ...

, the fundamental rack is straight-sided, with sides inclined at the pressure angle of the tooth form, with flat top and bottom. The necessary addendum correction

An addendum or appendix, in general, is an addition required to be made to a document by its author subsequent to its printing or publication. It comes from the gerundive , plural , "that which is to be added," from (, compare with memorandum, ...

to allow the use of small-numbered pinions can either be obtained by suitable modification of this rack to a cycloidal

In geometry, a cycloid is the curve traced by a point on a circle as it rolls along a straight line without slipping. A cycloid is a specific form of trochoid and is an example of a roulette, a curve generated by a curve rolling on another curv ...

form at the tips, or by hobbing at a diameter other than the theoretical pitch. Since the gear ratio

A gear train is a mechanical system formed by mounting gears on a frame so the teeth of the gears engage.

Gear teeth are designed to ensure the Pitch circle diameter (gears), pitch circles of engaging gears roll on each other without slipping, pr ...

between hob and blank is fixed, the resulting gear will have the correct pitch on the pitch circle but the tooth thickness will not be equal to the space width.

Hobbing machines are characterized by the largest module

Module, modular and modularity may refer to the concept of modularity. They may also refer to:

Computing and engineering

* Modular design, the engineering discipline of designing complex devices using separately designed sub-components

* Modul ...

or pitch diameter it can generate. For example, a capacity machine can generate gears with a 10 in pitch diameter and usually a maximum of a 10 in face width. Most hobbing machines are vertical hobbers, meaning the blank is mounted vertically. Horizontal hobbing machines are usually used for cutting longer workpieces; i.e. cutting splines on the end of a shaft.

Hob

The ''hob'' is a cutting tool used to cut the teeth into the workpiece. It is cylindrical in shape with

The ''hob'' is a cutting tool used to cut the teeth into the workpiece. It is cylindrical in shape with helical

Helical may refer to:

* Helix, the mathematical concept for the shape

* Helical engine, a proposed spacecraft propulsion drive

* Helical spring, a coilspring

* Helical plc, a British property company, once a maker of steel bar stock

* Helicoil

A t ...

cutting teeth. These teeth have grooves that run the length of the hob, which aid in cutting and chip Chromatin immunoprecipitation (ChIP) is a type of immunoprecipitation experimental technique used to investigate the interaction between proteins and DNA in the cell. It aims to determine whether specific proteins are associated with specific genom ...

removal. There are also special hobs designed for special gears such as the spline and sprocket gears.

The cross-sectional shape of the hob teeth are almost the same shape as teeth of a rack gear

A rack and pinion is a type of linear actuator that comprises a circular gear (the ''pinion'') engaging a linear gear (the ''rack''). Together, they convert rotational motion into linear motion. Rotating the pinion causes the rack to be driven i ...

that would be used with the finished product. There are slight changes to the shape for generating purposes, such as extending the hob's tooth length to create a clearance in the gear's roots. Each hob tooth is relieved on its back side to reduce friction.

Most hobs are single-thread hobs, but double-, and triple-thread hobs are used for high production volume shops. Multiple-thread hobs are more efficient but less accurate than single-thread hobs..

Depending on type of gear teeth to be cut, there are custom made hobs and general purpose hobs. Custom made hobs are different from other hobs as they are suited to make gears with modified tooth profiles. Modified tooth profiles are usually used to add strength and reduce size and gear noise.

Common types of hobs include:

* Roller chain

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, pri ...

sprocket hobs

* Worm wheel hobs

* Spline hobs

* Chamfer hobs

* Spur and helical gear hobs

* Straight side spline hobs

* Involute spline hobs

* Serration hobs

* Semitopping gear hobs

Uses

Hobbing is used to make the following types of finished gears: *Cycloid gears (see below) *Helical gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic p ...

s

*Involute gear

The involute gear profile is the most commonly used system for gearing today, with cycloid gearing still used for some specialties such as clocks. In an involute gear, the profiles of the teeth are ''involutes of a circle.'' The involute of a cir ...

s

* Ratchets

* Splines

*Sprockets

A sprocket, sprocket-wheel or chainwheel is a profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. The name 'sprocket' applies generally to any wheel upon which radial projections engage a chain passi ...

*Spur gear

Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with teeth projecting radially. Viewing the gear at 90 degrees from the shaft length (side on) the tooth faces are straight and aligned parallel to ...

s

*Worm gear

A worm drive is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear). The two elements are also called the worm screw and worm gear. The terminol ...

s

Hobbing is used to produce most throated worm wheels, but certain tooth profiles cannot be hobbed. If any portion of the hob profile is perpendicular to the axis, the hob will not have the cutting clearance generated by the usual backing off process and will not cut well.

Cycloidal forms

Forcycloidal gear

The cycloidal gear profile is a form of toothed gear used in mechanical clocks, rather than the involute gear form used for most other gears. The gear tooth profile is based on the epicycloid and hypocycloid curves, which are the curves generate ...

s (as used in BS978-2 Specification for fine pitch gears) and cycloidal-type gears, each module

Module, modular and modularity may refer to the concept of modularity. They may also refer to:

Computing and engineering

* Modular design, the engineering discipline of designing complex devices using separately designed sub-components

* Modul ...

, ratio, and number of teeth in the pinion

A pinion is a round gear—usually the smaller of two meshed gears—used in several applications, including drivetrain and rack and pinion systems.

Applications

Drivetrain

Drivetrains usually feature a gear known as the pinion, which may ...

requires a different hobbing cutter, so the hobbing is ineffective for small-volume production.

To circumvent this problem, a special war-time emergency circular arc

Circular may refer to:

* The shape of a circle

* ''Circular'' (album), a 2006 album by Spanish singer Vega

* Circular letter (disambiguation)

** Flyer (pamphlet), a form of advertisement

* Circular reasoning, a type of logical fallacy

* Circular ...

gear standard was produced giving a series of close-to-cycloidal forms which could be cut with a single hob for each module for eight teeth and upwards to economize on cutter manufacturing resources. A variant on this is still included in BS978-2a (Gears for instruments and clockwork mechanisms. Cycloidal type gears. Double circular arc type gears).

Tolerances of concentricity of the hob limit the lower modules which can be cut practically by hobbing to about 0.5 module.

History

Christian Schiele of Lancaster England patented the hobbing machine in 1856. It was a simple design, but the rudimentary components are all present in the customary patent drawings. The hob cutting tool and the gear train to provide the appropriate spindle speed ratio are clearly visible. Knowledge of hobbing likely precedes his patent within the watchmaking trade. Many manufacturing museums include examples of manual gear hobs that helped to produce gears prior to the 19th century. Along with these completely manual gear hobs will be samples of some of the first semi-automated gear hobs, and finally examples of more recent technology that demonstrates the fully automated process that modern gear hobs use to produce gears today. A few producers of gear hobs also have interesting literature on the history of gear hobs, including details about how modern gear hobs can produce thousands of gears in a single hour.See also

*List of gear nomenclature

This page lists the standard US nomenclature used in the description of mechanical gear construction and function, together with definitions of the terms. The terminology was established by the American Gear Manufacturers Association (AGMA), unde ...

References

Bibliography

*. *. *. *. *. *.Further reading

*. At p. 303, "The hobbing process conceived in 1856 by Christian Schiele became a practical one for production work as soon as involute-shaped gear teeth superseded the cycloidal type in the 1880s, since the involute hob, like the involute rack, has straight sides (for the worm is a form of continuous rack) so that to make a hob from a worm all one has to do is to gash some teeth in the worm so that it will cut the blank as it is rotated." *; pre-1890 patent not found at eSpaceNet (seBritish Library remarks

; se

Google Books reprint

which is missing sheets 1 and 2. *. At p. 105, "But it had been recognized that the worm was a form of continuous rack and all that was necessary to cut gears with it was to provide cutting edges on it — to make a hob (Fig. 45). Teeth had been cut by this method probably for the first time by Ramsden in 1768." * *Dudley, Darle W. (1969), "The Evolution of the Gear Art", Published by, American Gear Manufacturers Association, Washington D.C., Library of Congress Catalog Card Number: 72-78509 *Radzevich, Stephen P. (2017), "Gear cutting tools: science and engineering", CRC Press, Second Edition, . Chapter 1 provides a very comprehensive and contemporary history of Gear Cutting Tools in Chapter 1.

External links

*. Has schematics of hobbing machines in figures 8–10. {{Authority control Machine tools Gears