Half shaft on:

[Wikipedia]

[Google]

[Amazon]

An axle or axletree is a central shaft for a rotating

An axle or axletree is a central shaft for a rotating

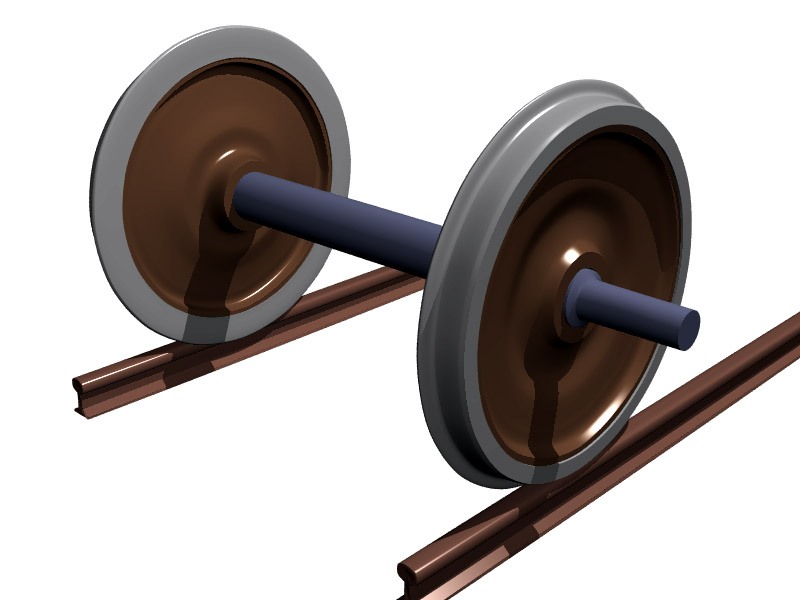

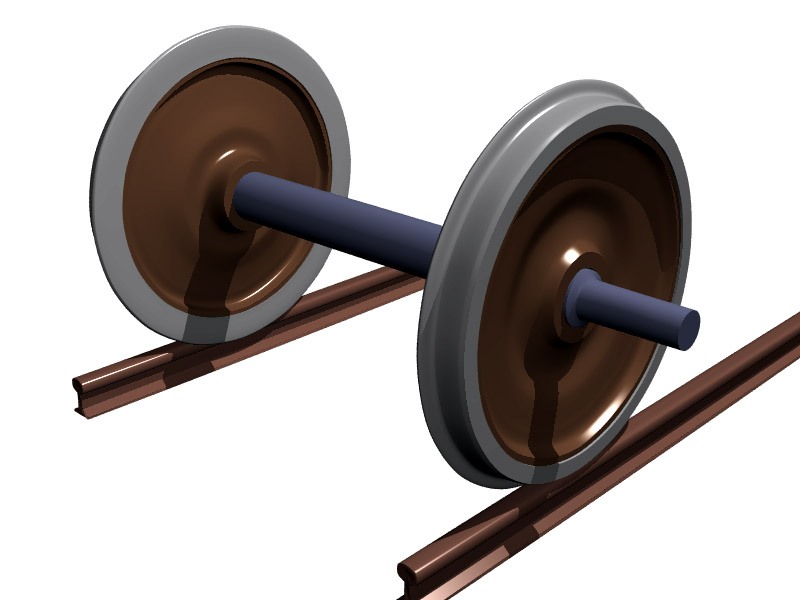

A straight axle is a single rigid shaft connecting a wheel on the left side of the vehicle to a wheel on the right side. The axis of rotation fixed by the axle is common to both wheels. Such a design can keep the wheel positions steady under heavy stress, and can therefore support heavy loads. Straight axles are used on trains (that is, locomotives and railway wagons), for the rear axles of commercial trucks, and on heavy duty off-road vehicles. The axle can optionally be protected and further reinforced by enclosing the length of the axle in a housing.

In split-axle designs, the wheel on each side is attached to a separate shaft. Modern passenger cars have split drive axles. In some designs, this allows independent suspension of the left and right wheels, and therefore a smoother ride. Even when the suspension is not independent, split axles permit the use of a differential, allowing the left and right drive wheels to be driven at different speeds as the automobile turns, improving traction and extending tire life.

A tandem axle is a group of two or more axles situated close together. Truck designs use such a configuration to provide a greater weight capacity than a single axle. Semi trailers usually have a tandem axle at the rear.

Axles are typically made from SAE grade

A straight axle is a single rigid shaft connecting a wheel on the left side of the vehicle to a wheel on the right side. The axis of rotation fixed by the axle is common to both wheels. Such a design can keep the wheel positions steady under heavy stress, and can therefore support heavy loads. Straight axles are used on trains (that is, locomotives and railway wagons), for the rear axles of commercial trucks, and on heavy duty off-road vehicles. The axle can optionally be protected and further reinforced by enclosing the length of the axle in a housing.

In split-axle designs, the wheel on each side is attached to a separate shaft. Modern passenger cars have split drive axles. In some designs, this allows independent suspension of the left and right wheels, and therefore a smoother ride. Even when the suspension is not independent, split axles permit the use of a differential, allowing the left and right drive wheels to be driven at different speeds as the automobile turns, improving traction and extending tire life.

A tandem axle is a group of two or more axles situated close together. Truck designs use such a configuration to provide a greater weight capacity than a single axle. Semi trailers usually have a tandem axle at the rear.

Axles are typically made from SAE grade

An axle that is driven by the engine or prime mover is called a ''drive axle''.

Modern

An axle that is driven by the engine or prime mover is called a ''drive axle''.

Modern

Some dump trucks and trailers may be configured with a lift axle (also known as an ''airlift axle'' or ''drop axle''), which may be mechanically raised or lowered. The axle is lowered to increase the weight capacity, or to distribute the weight of the cargo over more wheels, for example to cross a weight restricted bridge. When not needed, the axle is lifted off the ground to save wear on the tires and axle, and to increase traction in the remaining wheels. Lifting an axle also alleviates lateral scrubbing of the additional axle in very tight turns, allowing the vehicle to turn more readily. In some situations removal of pressure from the additional axle is necessary for the vehicle to complete a turn at all.

Several manufacturers offer computer-controlled airlift, so that the dead axles are automatically lowered when the main axle reaches its weight limit. The dead axles can still be lifted by the press of a button if needed, for better maneuverability.

Lift axles were in use in the early 1940s. Initially, the axle was lifted by a mechanical device. Soon hydraulics replaced the mechanical lift system. One of the early manufacturers was Zetterbergs, located in Östervåla, Sweden. Their brand was Zeta-lyften.

The liftable tandem drive axle was invented in 1957 by the Finnish truck manufacturer Vanajan Autotehdas, a company sharing history with

Some dump trucks and trailers may be configured with a lift axle (also known as an ''airlift axle'' or ''drop axle''), which may be mechanically raised or lowered. The axle is lowered to increase the weight capacity, or to distribute the weight of the cargo over more wheels, for example to cross a weight restricted bridge. When not needed, the axle is lifted off the ground to save wear on the tires and axle, and to increase traction in the remaining wheels. Lifting an axle also alleviates lateral scrubbing of the additional axle in very tight turns, allowing the vehicle to turn more readily. In some situations removal of pressure from the additional axle is necessary for the vehicle to complete a turn at all.

Several manufacturers offer computer-controlled airlift, so that the dead axles are automatically lowered when the main axle reaches its weight limit. The dead axles can still be lifted by the press of a button if needed, for better maneuverability.

Lift axles were in use in the early 1940s. Initially, the axle was lifted by a mechanical device. Soon hydraulics replaced the mechanical lift system. One of the early manufacturers was Zetterbergs, located in Östervåla, Sweden. Their brand was Zeta-lyften.

The liftable tandem drive axle was invented in 1957 by the Finnish truck manufacturer Vanajan Autotehdas, a company sharing history with

Truck Axle Design

{{Chassis control systems Automotive suspension technologies Vehicle parts Rail technologies

An axle or axletree is a central shaft for a rotating

An axle or axletree is a central shaft for a rotating wheel

A wheel is a circular component that is intended to rotate on an axle bearing. The wheel is one of the key components of the wheel and axle which is one of the six simple machines. Wheels, in conjunction with axles, allow heavy objects to be ...

or gear

A gear is a rotating circular machine part having cut teeth or, in the case of a cogwheel or gearwheel, inserted teeth (called ''cogs''), which mesh with another (compatible) toothed part to transmit (convert) torque and speed. The basic ...

. On wheeled vehicles, the axle may be fixed to the wheels, rotating with them, or fixed to the vehicle, with the wheels rotating around the axle. In the former case, bearings or bushings are provided at the mounting points where the axle is supported. In the latter case, a bearing or bushing sits inside a central hole in the wheel to allow the wheel or gear to rotate around the axle. Sometimes, especially on bicycles, the latter type axle is referred to as a '' spindle''.

Terminology

On cars and trucks, several senses of the word ''axle'' occur in casual usage, referring to the shaft itself, its housing, or simply any transverse pair of wheels. Strictly speaking, a shaft which rotates with the wheel, being either bolted or splined in fixed relation to it, is called an ''axle'' or ''axle shaft''. However, in looser usage, an entire assembly including the surrounding axle housing (typically acasting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a ''casting'', which is ejecte ...

) is also called an ''axle''.

An even broader (somewhat figurative) sense of the word refers to every pair of parallel wheels on opposite sides of a vehicle, regardless of their mechanical connection to each other and to the vehicle frame or body. Thus, transverse pairs of wheels in an independent suspension

Independent suspension is any automobile suspension system that allows each wheel on the same axle to move vertically (i.e. reacting to a bump on the road) independently of the others. This is contrasted with a beam axle or deDion axle system ...

may be called an ''axle'' in some contexts. This very loose definition of "axle" is often used in assessing toll road

A toll road, also known as a turnpike or tollway, is a public or private road (almost always a controlled-access highway in the present day) for which a fee (or '' toll'') is assessed for passage. It is a form of road pricing typically implement ...

s or vehicle taxes, and is taken as a rough proxy for the overall weight-bearing capacity of a vehicle, and its potential for causing wear or damage to roadway surfaces.

Vehicle axles

Axles are an integral component of most practical wheeled vehicles. In a live-axle suspension system, the axles serve to transmit drivingtorque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

to the wheel, as well as to maintain the position of the wheels relative to each other and to the vehicle body. The axles in this system must also bear the weight of the vehicle plus any cargo. A non-driving axle, such as the front beam axle in heavy duty trucks and some two-wheel drive light trucks and vans, will have no shaft, and serves only as a suspension and steering component. Conversely, many front-wheel drive cars have a solid rear beam axle.

In other types of suspension systems, the axles serve only to transmit driving torque to the wheels; the position and angle of the wheel hubs is an independent function of the suspension system. This is typical of the independent suspensions found on most newer cars and SUVs, and on the front of many light trucks. These systems still have differentials, but will not have attached axle housing tubes. They may be attached to the vehicle frame or body, or integral in a transaxle

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

Engine and drive at the s ...

. The axle shafts (usually constant-velocity type) then transmit driving torque to the wheels. Like a full floating axle system, the drive shafts in a front-wheel drive independent suspension system do not support any vehicle weight

Structural features and design

A straight axle is a single rigid shaft connecting a wheel on the left side of the vehicle to a wheel on the right side. The axis of rotation fixed by the axle is common to both wheels. Such a design can keep the wheel positions steady under heavy stress, and can therefore support heavy loads. Straight axles are used on trains (that is, locomotives and railway wagons), for the rear axles of commercial trucks, and on heavy duty off-road vehicles. The axle can optionally be protected and further reinforced by enclosing the length of the axle in a housing.

In split-axle designs, the wheel on each side is attached to a separate shaft. Modern passenger cars have split drive axles. In some designs, this allows independent suspension of the left and right wheels, and therefore a smoother ride. Even when the suspension is not independent, split axles permit the use of a differential, allowing the left and right drive wheels to be driven at different speeds as the automobile turns, improving traction and extending tire life.

A tandem axle is a group of two or more axles situated close together. Truck designs use such a configuration to provide a greater weight capacity than a single axle. Semi trailers usually have a tandem axle at the rear.

Axles are typically made from SAE grade

A straight axle is a single rigid shaft connecting a wheel on the left side of the vehicle to a wheel on the right side. The axis of rotation fixed by the axle is common to both wheels. Such a design can keep the wheel positions steady under heavy stress, and can therefore support heavy loads. Straight axles are used on trains (that is, locomotives and railway wagons), for the rear axles of commercial trucks, and on heavy duty off-road vehicles. The axle can optionally be protected and further reinforced by enclosing the length of the axle in a housing.

In split-axle designs, the wheel on each side is attached to a separate shaft. Modern passenger cars have split drive axles. In some designs, this allows independent suspension of the left and right wheels, and therefore a smoother ride. Even when the suspension is not independent, split axles permit the use of a differential, allowing the left and right drive wheels to be driven at different speeds as the automobile turns, improving traction and extending tire life.

A tandem axle is a group of two or more axles situated close together. Truck designs use such a configuration to provide a greater weight capacity than a single axle. Semi trailers usually have a tandem axle at the rear.

Axles are typically made from SAE grade 41xx steel

41xx steel is a family of SAE steel grades, as specified by the Society of Automotive Engineers (SAE). Alloying elements include chromium and molybdenum, and as a result these materials are often informally referred to as chromoly steel (common v ...

or SAE grade 10xx steel. SAE grade 41xx steel is commonly known as "chrome-molybdenum steel

41xx steel is a family of SAE steel grades, as specified by the Society of Automotive Engineers (SAE). Alloying elements include chromium and molybdenum, and as a result these materials are often informally referred to as chromoly steel (common ...

" (or "chrome-moly") while SAE grade 10xx steel is known as "carbon steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, coba ...

". The primary differences between the two are that chrome-moly steel is significantly more resistant to bending or breaking, and is very difficult to weld with tools normally found outside a professional welding shop.

Drive axle

An axle that is driven by the engine or prime mover is called a ''drive axle''.

Modern

An axle that is driven by the engine or prime mover is called a ''drive axle''.

Modern front-wheel drive

Front-wheel drive (FWD) is a form of engine and transmission layout used in motor vehicles, where the engine drives the front wheels only. Most modern front-wheel drive vehicles feature a transverse engine, rather than the conventional longitu ...

cars typically combine the transmission

Transmission may refer to:

Medicine, science and technology

* Power transmission

** Electric power transmission

** Propulsion transmission, technology allowing controlled application of power

*** Automatic transmission

*** Manual transmission

** ...

(gearbox and differential) and front axle into a single unit called a ''transaxle

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

Engine and drive at the s ...

''. The drive axle is a split axle with a differential and universal joint

A universal joint (also called a universal coupling or U-joint) is a joint or coupling connecting rigid shafts whose axes are inclined to each other. It is commonly used in shafts that transmit rotary motion. It consists of a pair of hinges ...

s between the two half axles. Each half axle connects to the wheel by use of a constant velocity (CV) joint which allows the wheel assembly to move freely vertically as well as to pivot when making turns.

In rear-wheel drive

Rear-wheel drive (RWD) is a form of engine and transmission layout used in motor vehicles, in which the engine drives the rear wheels only. Until the late 20th century, rear-wheel drive was the most common configuration for cars.

Most rear-wheel ...

cars and trucks, the engine turns a driveshaft

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power and torque and rotation, usually used to connec ...

(also called a ''propellor shaft'' or ''tailshaft'') which transmits rotational force to a drive axle at the rear of the vehicle. The drive axle may be a live axle

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have als ...

, but modern rear wheel drive automobiles generally use a split axle with a differential. In this case, one half-axle or half-shaft connects the differential with the left rear wheel, a second half-shaft does the same with the right rear wheel; thus the two half-axles and the differential constitute the rear axle. The front drive axle is providing the force to drive the truck. In fact, only one wheel of that axle is actually moving the truck and trailer down the road.

Some simple vehicle designs, such as leisure go-karts, may have a single driven wheel where the drive axle is a split axle with only one of the two shafts driven by the engine, or else have both wheels connected to one shaft without a differential (kart racing). However, other go-karts have two rear drive wheels too.

Lift axle

Some dump trucks and trailers may be configured with a lift axle (also known as an ''airlift axle'' or ''drop axle''), which may be mechanically raised or lowered. The axle is lowered to increase the weight capacity, or to distribute the weight of the cargo over more wheels, for example to cross a weight restricted bridge. When not needed, the axle is lifted off the ground to save wear on the tires and axle, and to increase traction in the remaining wheels. Lifting an axle also alleviates lateral scrubbing of the additional axle in very tight turns, allowing the vehicle to turn more readily. In some situations removal of pressure from the additional axle is necessary for the vehicle to complete a turn at all.

Several manufacturers offer computer-controlled airlift, so that the dead axles are automatically lowered when the main axle reaches its weight limit. The dead axles can still be lifted by the press of a button if needed, for better maneuverability.

Lift axles were in use in the early 1940s. Initially, the axle was lifted by a mechanical device. Soon hydraulics replaced the mechanical lift system. One of the early manufacturers was Zetterbergs, located in Östervåla, Sweden. Their brand was Zeta-lyften.

The liftable tandem drive axle was invented in 1957 by the Finnish truck manufacturer Vanajan Autotehdas, a company sharing history with

Some dump trucks and trailers may be configured with a lift axle (also known as an ''airlift axle'' or ''drop axle''), which may be mechanically raised or lowered. The axle is lowered to increase the weight capacity, or to distribute the weight of the cargo over more wheels, for example to cross a weight restricted bridge. When not needed, the axle is lifted off the ground to save wear on the tires and axle, and to increase traction in the remaining wheels. Lifting an axle also alleviates lateral scrubbing of the additional axle in very tight turns, allowing the vehicle to turn more readily. In some situations removal of pressure from the additional axle is necessary for the vehicle to complete a turn at all.

Several manufacturers offer computer-controlled airlift, so that the dead axles are automatically lowered when the main axle reaches its weight limit. The dead axles can still be lifted by the press of a button if needed, for better maneuverability.

Lift axles were in use in the early 1940s. Initially, the axle was lifted by a mechanical device. Soon hydraulics replaced the mechanical lift system. One of the early manufacturers was Zetterbergs, located in Östervåla, Sweden. Their brand was Zeta-lyften.

The liftable tandem drive axle was invented in 1957 by the Finnish truck manufacturer Vanajan Autotehdas, a company sharing history with Sisu Auto

Sisu Auto is a truck manufacturer based in Raseborg, Finland. Its name comes from the Finnish word '' sisu'' meaning guts, grit and determination.

Sisu Auto has a subsidiary company, "Sisu Defence", producing high mobility tactical vehicles f ...

.

Full-floating vs semi-floating

A full-floating axle carries the vehicle's weight on the axle casing, not the halfshafts; they serve only to transmit torque from the differential to the wheels. They "float" inside an assembly that carries the vehicle's weight. Thus the only stress it must endure is torque (not lateral bending force). Full-floating axle shafts are retained by a flange bolted to the hub, while the hub and bearings are retained on the spindle by a large nut. In contrast, a semi-floating design carries the weight of the vehicle on the axle shaft itself; there is a single bearing at the end of the axle housing that carries the load from the axle and that the axle rotates through. To be "semi-floating" the axle shafts must be able to "float" in the housing, bearings and seals and not subject to axial "thrust" and/or bearing preload. Needle bearings and separate lip seals are used in semi-floating axles with axle retained in the housing at their inner ends typically with "c-clips" which are 3/4-round hardened washers that slide into grooves machined at the inner end of the shafts and retained in/by recesses in the differential carrier side gears which are themselves retained by the differential pinion gear or "spider gear" shaft. A true semi-floating axle assembly places no side loads on the axle housing tubes or axle shafts. Axles which are pressed into ball or tapered roller bearings which are in turn retained in/on the axle housings with flanges, bolts and nuts do not "float" and place axial loads on the bearings, housings and only a short section of the shaft itself that also carries all radial loads. The full-floating design is typically used in most 3/4- and 1-ton light trucks, medium duty trucks and heavy-duty trucks. There are a few exceptions, such as many Land-Rover vehicles and in American stock car racing since the early 1960s. The overall assembly can carry more weight than a semi-floating or non-floating axle assembly, because the hubs have two bearings riding on a fixed spindle. A full-floating axle can be identified by a protruding hub to which the axle shaft flange is bolted. The semi-floating axle setup is commonly used on half-ton and lighter 4x4 trucks in the rear. This setup allows the axle shaft to be the means of propulsion, and also support the weight of the vehicle. The main difference between the full- and semi-floating axle setups is the number of bearings. The semi-floating axle features only one bearing, while the full-floating assembly has bearings in both the inside and outside of the wheel hub. The other difference is about the axle removal. To remove the semi-floating axle, one has to remove a wheel first; if such axle breaks, the wheel is most likely to come off the vehicle. The semi-floating design is found under most 1/2-ton and lighter trucks and SUVs and rear-wheel-drive passenger cars, usually being smaller or less expensive models. A benefit of a full-floating axle is that even if an axle shaft (used to transmit torque or power) breaks, the wheel will not come off, preventing serious accidents.See also

* * *Beam axle

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have als ...

* Gölsdorf axle

* Klien-Lindner axle

* Luttermöller axle

* Portal axle

Portal axles (or portal gear lifts) are an off-road vehicle suspension and drive technology where the axle tube or the half-shaft is off-set from – usually above – the center of the wheel hub and where driving power is transferred to each ...

* Powertrain

A drivetrain (also frequently spelled as drive train or sometimes drive-train) is the group of components that deliver mechanical power from the prime mover to the driven components. In automotive engineering, the drivetrain is the components o ...

* Transaxle

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

Engine and drive at the s ...

* Wagon wheel (transportation)

* Wheel and axle

The wheel and axle is a simple machine consisting of a wheel attached to a smaller axle so that these two parts rotate together in which a force is transferred from one to the other. The wheel and axle can be viewed as a version of the lever, wi ...

* Wheelset (rail transport)

References

External links

Truck Axle Design

{{Chassis control systems Automotive suspension technologies Vehicle parts Rail technologies